Complete device for industrial production of paste and application of device

A complete set of equipment and ointment technology, applied in the direction of application, making medicines into special physical or ingestible devices, household components, etc., can solve the requirements of low production efficiency and energy utilization, low processing capacity, and environmental purification High-level problems, to achieve rapid dissolution and diffusion, reduce heavy metal content, and controllable concentration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

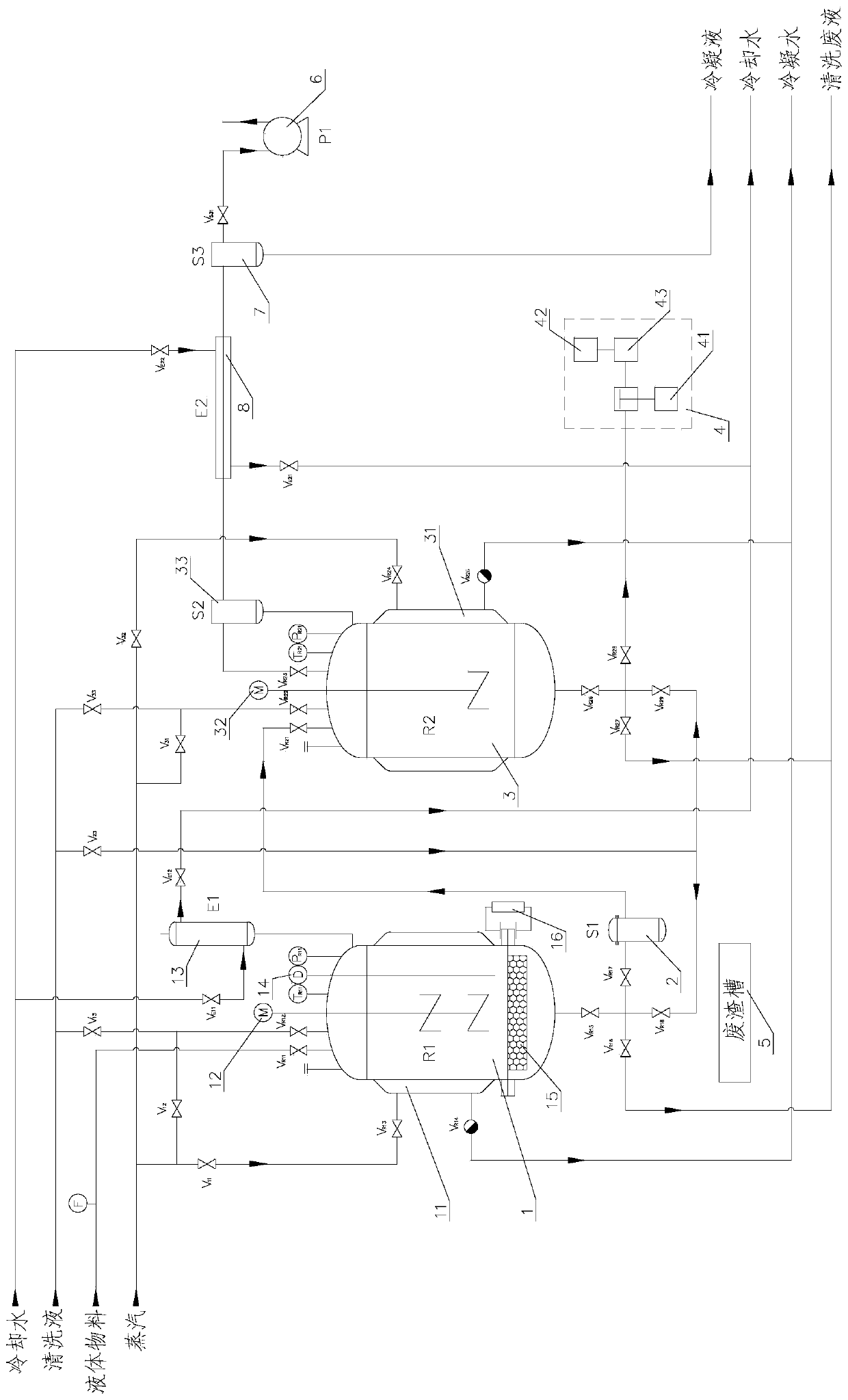

[0032] Such as figure 1 As shown, a complete set of equipment for industrial production of ointment (concentrated decoction), including three main devices and accessories of extraction tank 1, precision filter 2 and concentration tank 3, as well as the matching automatic packaging machine 4, waste residue Tank 5, vacuum pump 6, condensate recovery tank 7, condenser 8, also includes online cleaning CIP and high temperature steam sterilization system, the liquid material enters the extraction tank 1 after extraction, and the liquid is filtered by the precision filter 2 and then input into the concentration tank 3 for concentration The final gas is discharged through the condenser 8, the condensate recovery tank 7 and the vacuum pump 6 in sequence, and the concentrated liquid is a paste product, which enters the automatic packaging machine 4 for packaging.

[0033] Described extracting tank 1 is provided with jacket temperature control 11 outside, is provided with stirring device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com