Medium-pressure boiler is suitable for burning xinjiang quasi-east coal

A boiler and economizer technology, applied in the field of boiler combustion, can solve problems such as coking of boiler parts, boiler tube burst, and shutdown of the boiler, and achieve the effects of reduced coking tendency, low furnace heat load, and increased burnout height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

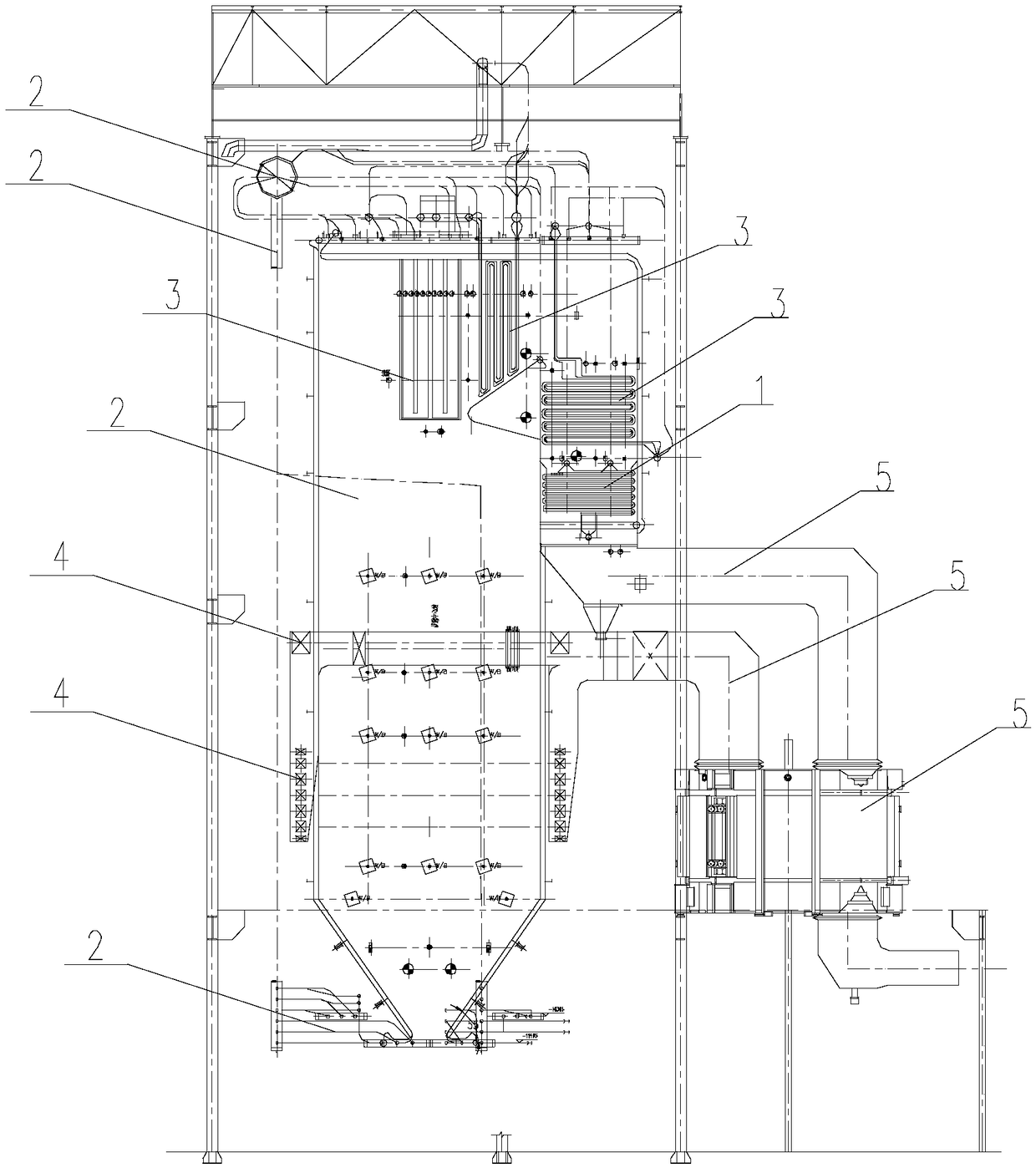

[0019] Specific implementation mode one: as figure 1 As shown, the medium-pressure boiler suitable for burning Xinjiang Zhundong coal in this embodiment includes an economizer system 1, a water wall system 2, a superheater system 3, a combustion system 4 and a flue gas system 5. The economizer The heating surfaces in the furnace of system 1 are arranged in series. The water wall system 2 includes a vertical tube ring water wall and headers, steam drums and downcomers connected to the vertical tube ring water wall. The combustion system 4 is located in the furnace In the corner surrounded by the water-cooled wall system 2, the flame forms four corners tangentially burned in the furnace. The wall superheater encloses the tail flue and the boiler roof, the low-temperature superheater and economizer system 1 are arranged in the rear shaft of the tail flue, the partition superheater is arranged on the top of the furnace, and the final superheater is arranged at the outlet of the fu...

specific Embodiment approach 2

[0020] Specific implementation mode two: as figure 1 As shown, the heating surface of the economizer system 1 in this embodiment is in the form of a plain tube or a finned tube. Such a design can increase the heating area. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: as figure 1 As shown, the combustion system 4 in this embodiment includes a main burner, a SOFA burner, a transmission device and an actuator, and the SOFA burner is arranged above the main burner. Such a design enables the pulverized coal to form a staged combustion in the boiler, which can reduce pollutant emissions. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com