Patents

Literature

71results about How to "Reduced coking tendency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

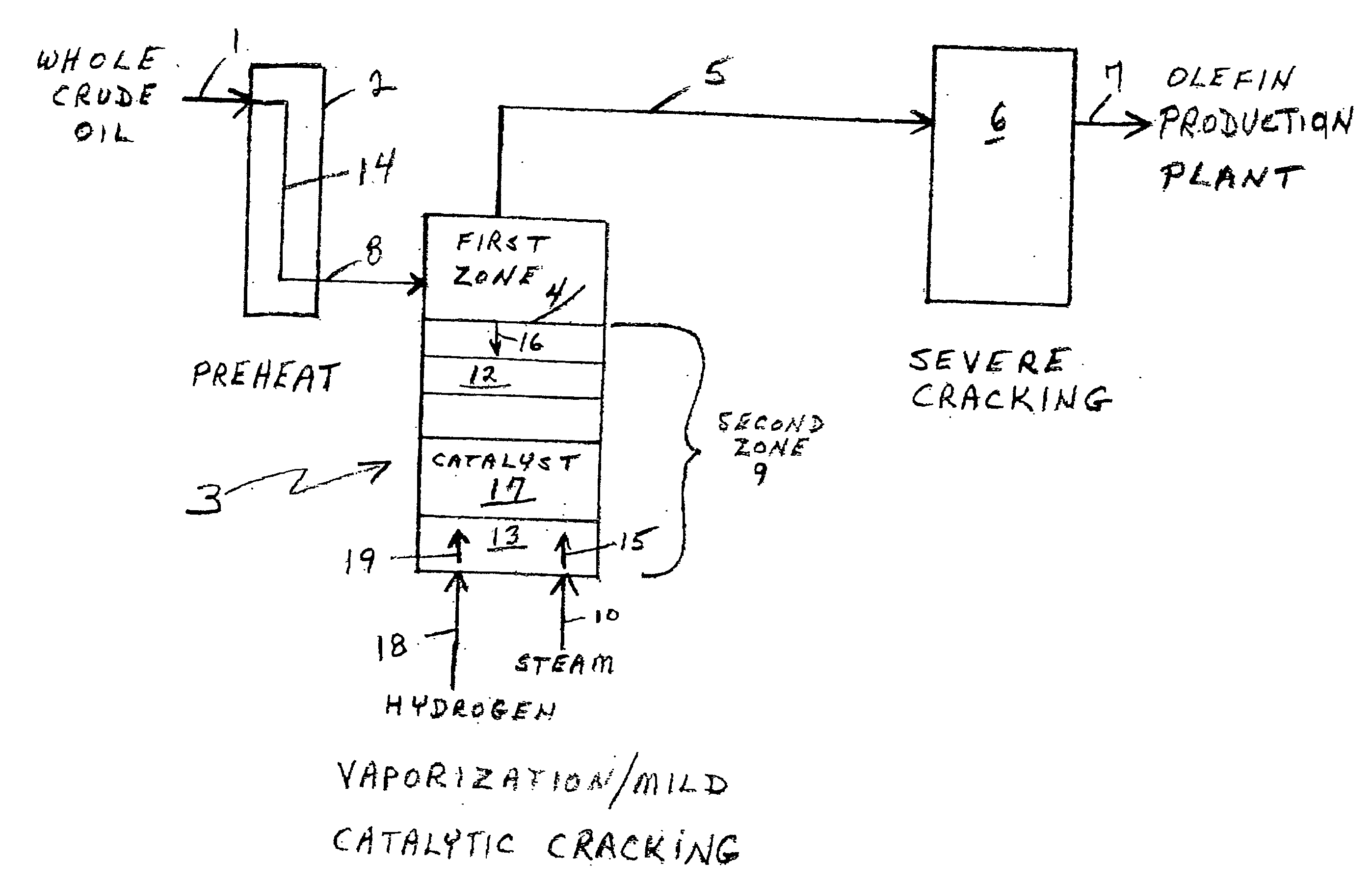

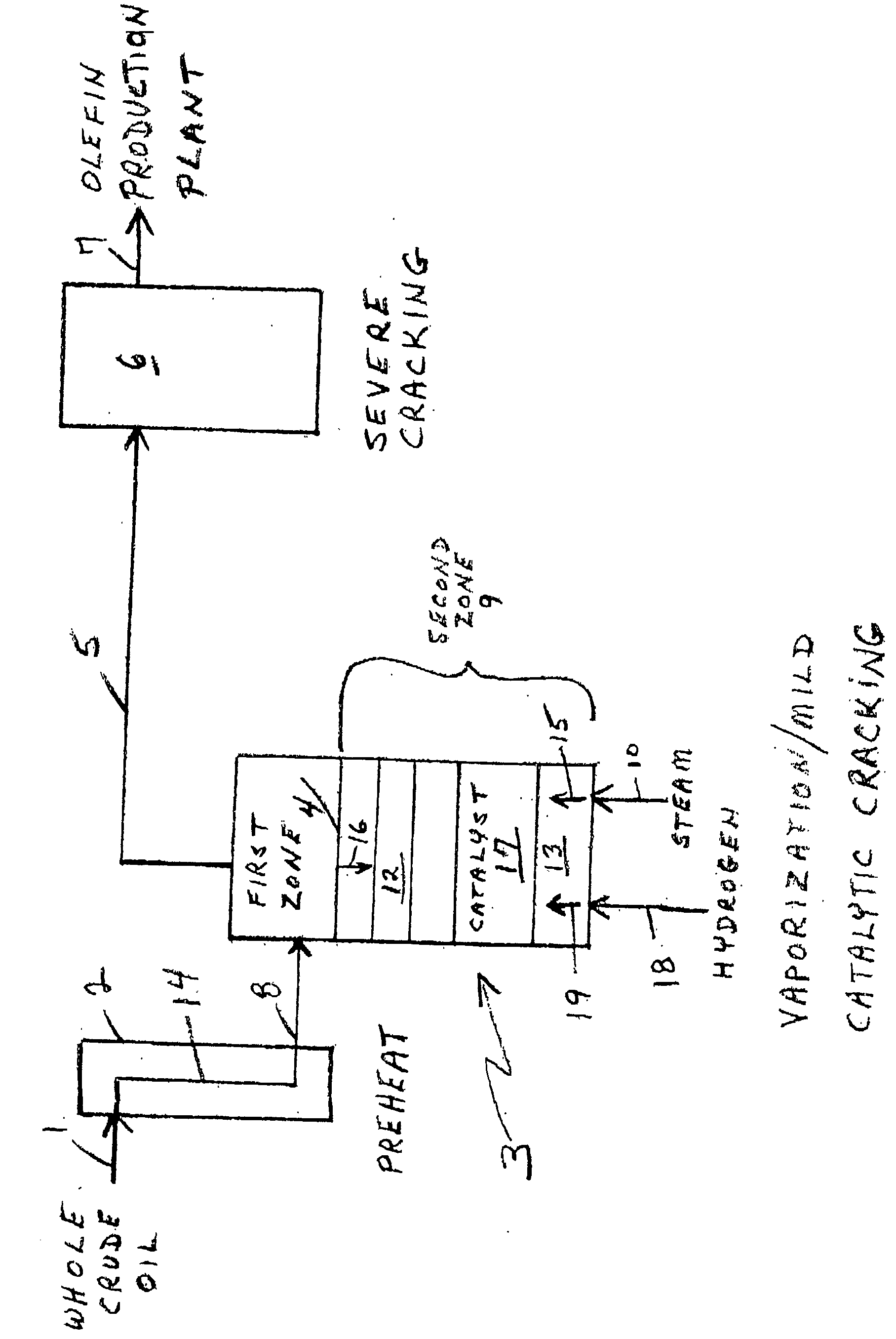

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

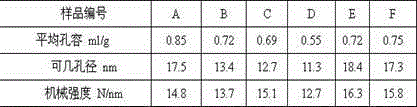

Method for recycling waste hydrogenation catalyst

ActiveCN105709853AReduce pollutionHarm reductionCatalyst carriersProcess efficiency improvementCarbon compositesUltrasound - action

The invention discloses a method for recycling a waste hydrogenation catalyst. The method comprises the following steps: (1) subjectintg the waste hydrogenation catalyst to deoiling and grinding successively so as to obtain powder; (2) washing the waste catalyst powder with hydrochloric acid and then successively carrying out filtering, washing and drying; (3) introducing chlorine and air into a container used in the step (2) under the action of supersonic waves and carrying out a reaction; (4) transferring a solid product obtained in the step (3) into a container filled with nitrogen, carrying out heating to allow metallic molybdenum and nickel or chloride or oxychloride of cobalt and vanadium to be volatilized, thereby separating a gas phase from a solid phase, carrying out condensation on the gas phase to recover metal, washing residual solids obtained after separation with water or an acidic solution and then carrying out drying; (5) subjecting a material obtained in the step (4) with an extrusion aid and a binder to kneading and compacting and then carrying out drying; and (6) roasting a molded carrier obtained in the step (5) in a nitrogen atmosphere so as to prepare an alumina-carbon composite carrier. The method not only can recover metallic active components and use waste alumina powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

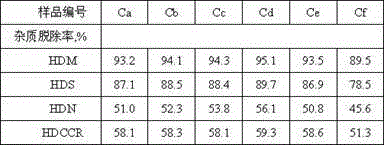

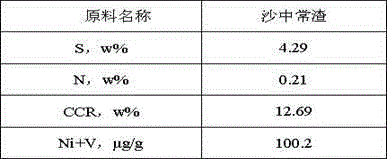

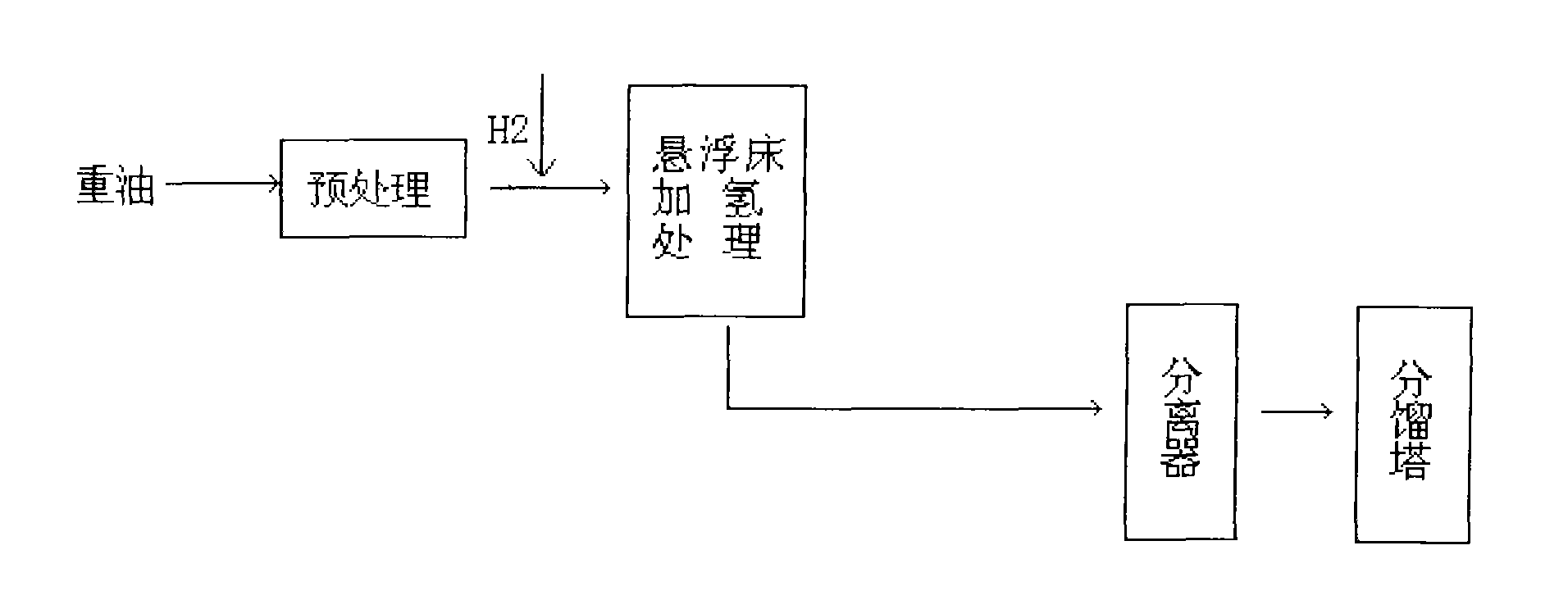

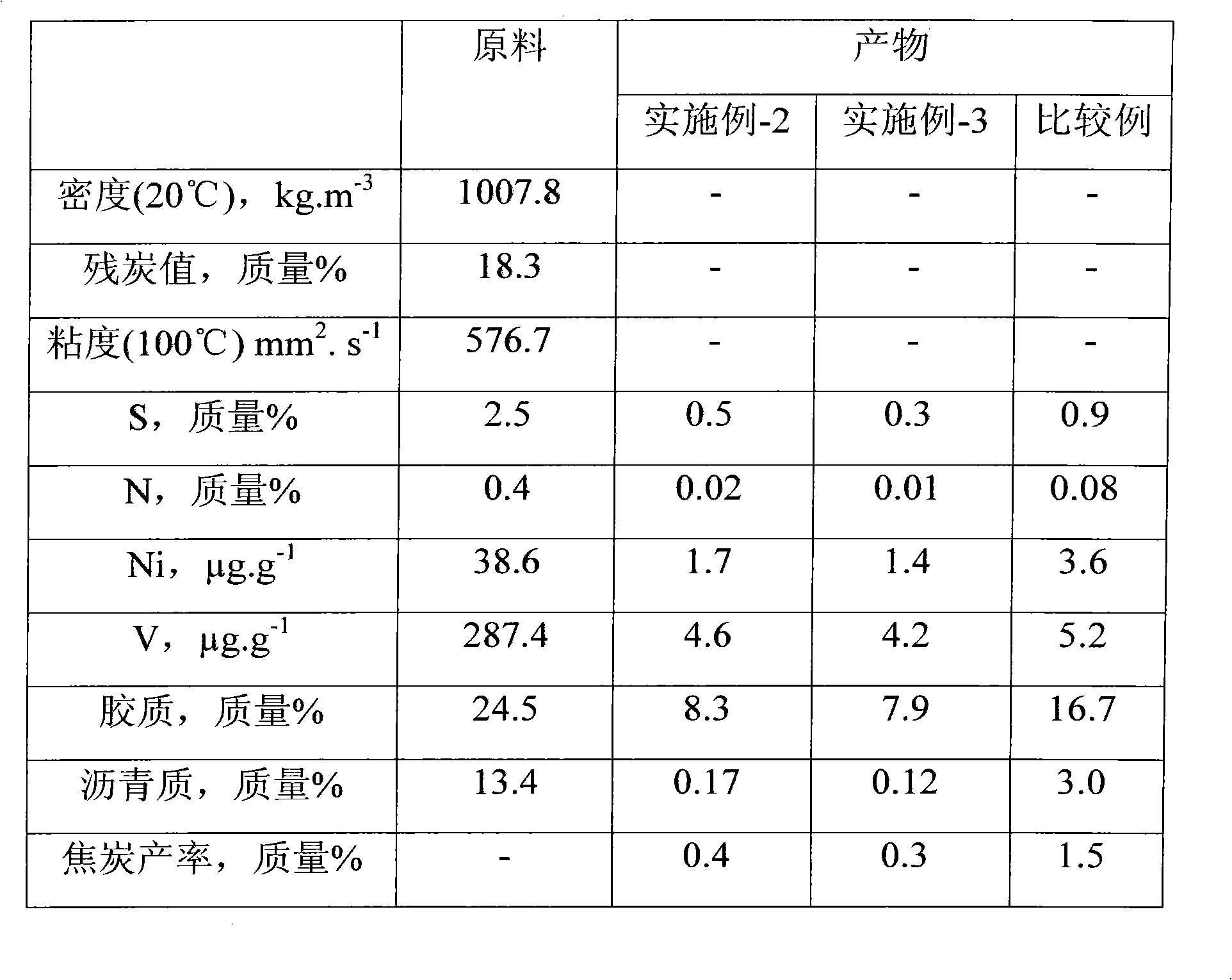

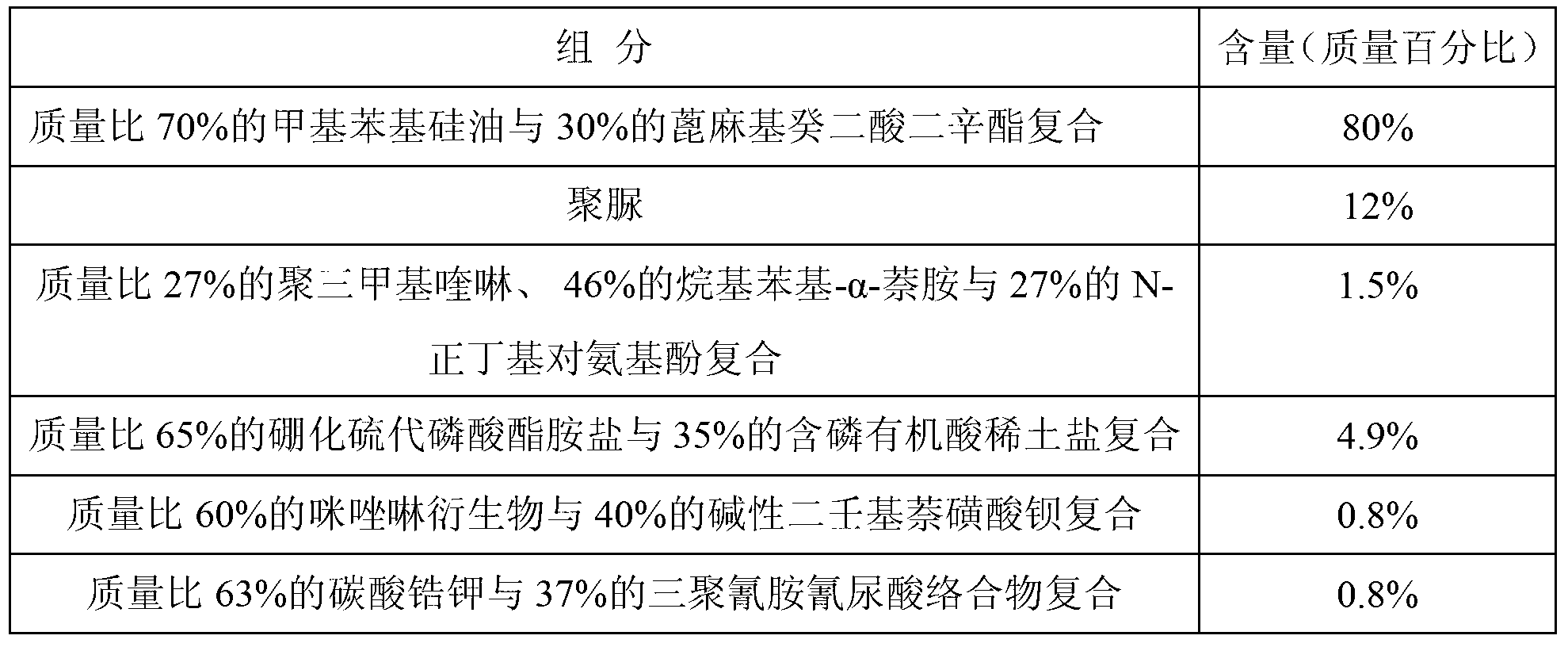

Heavy oil hydrogenation modifying method

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

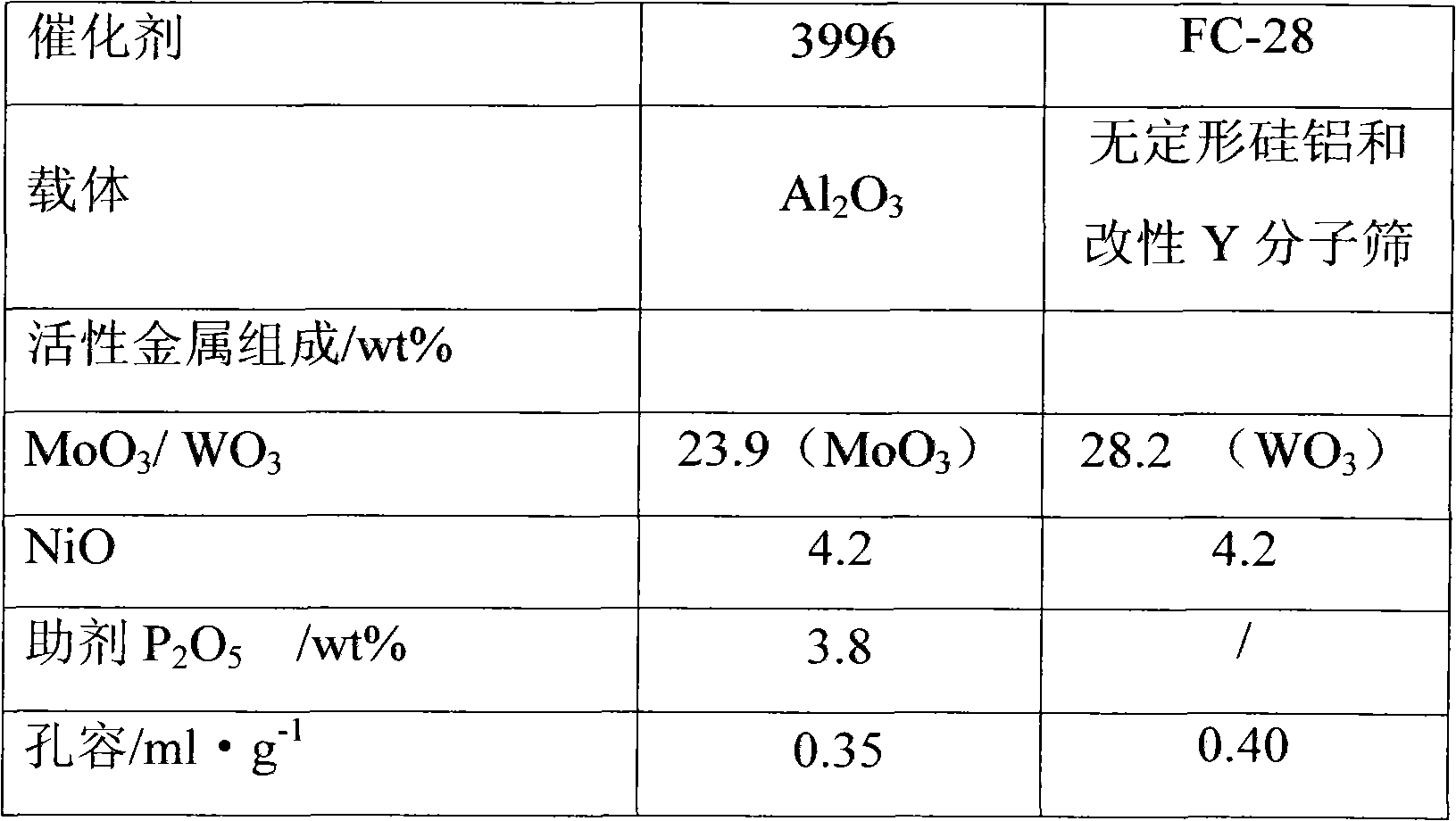

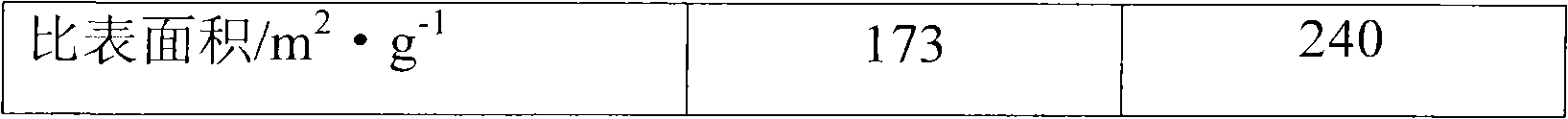

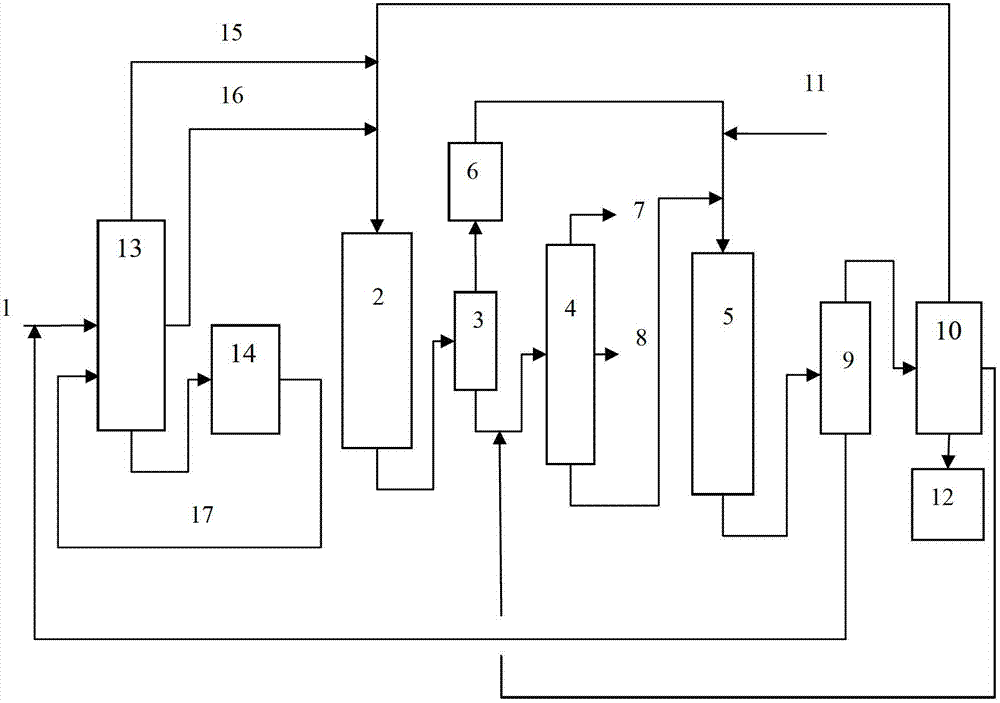

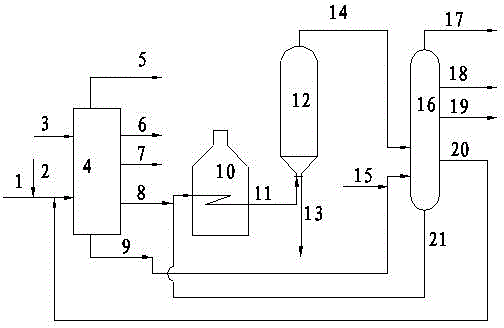

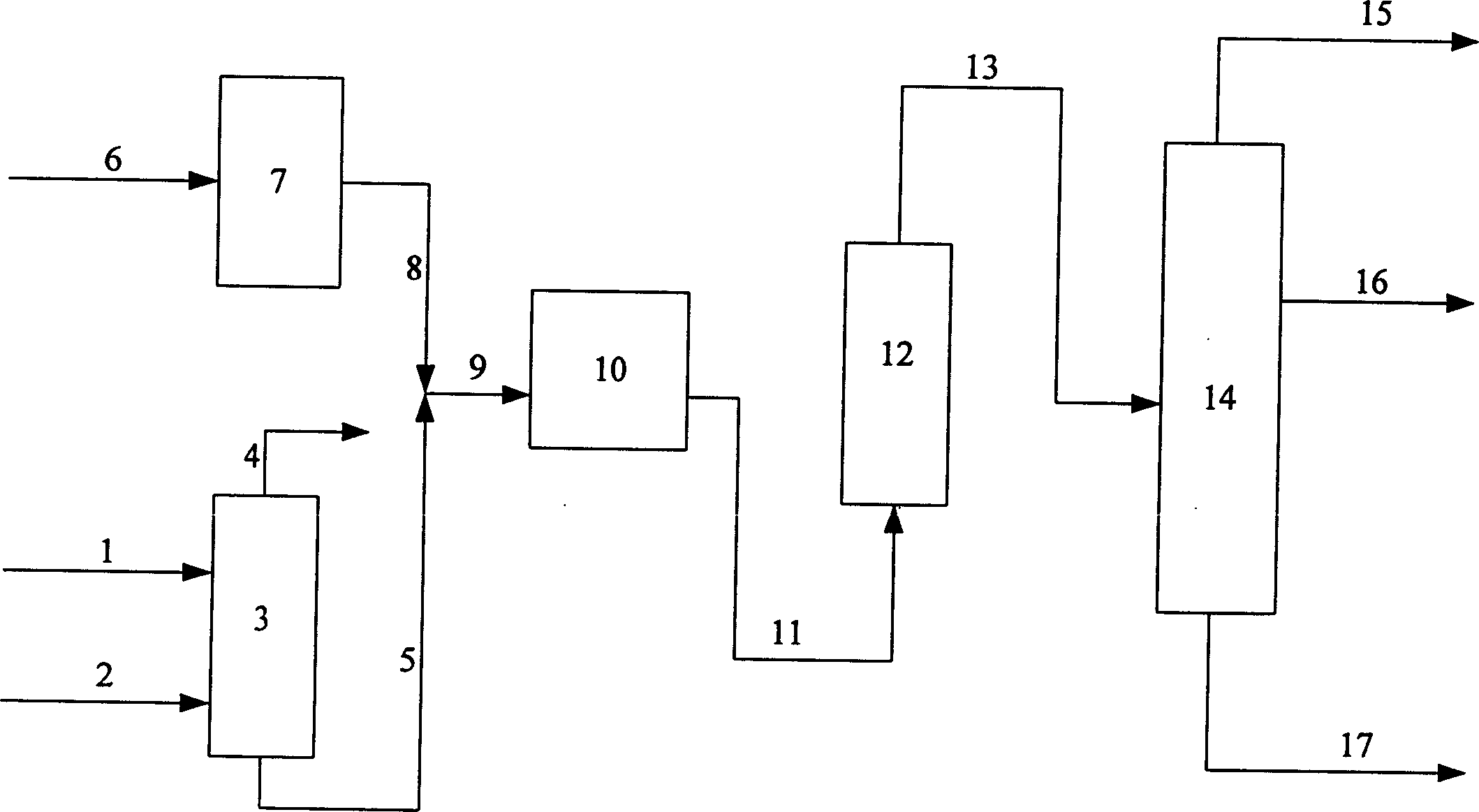

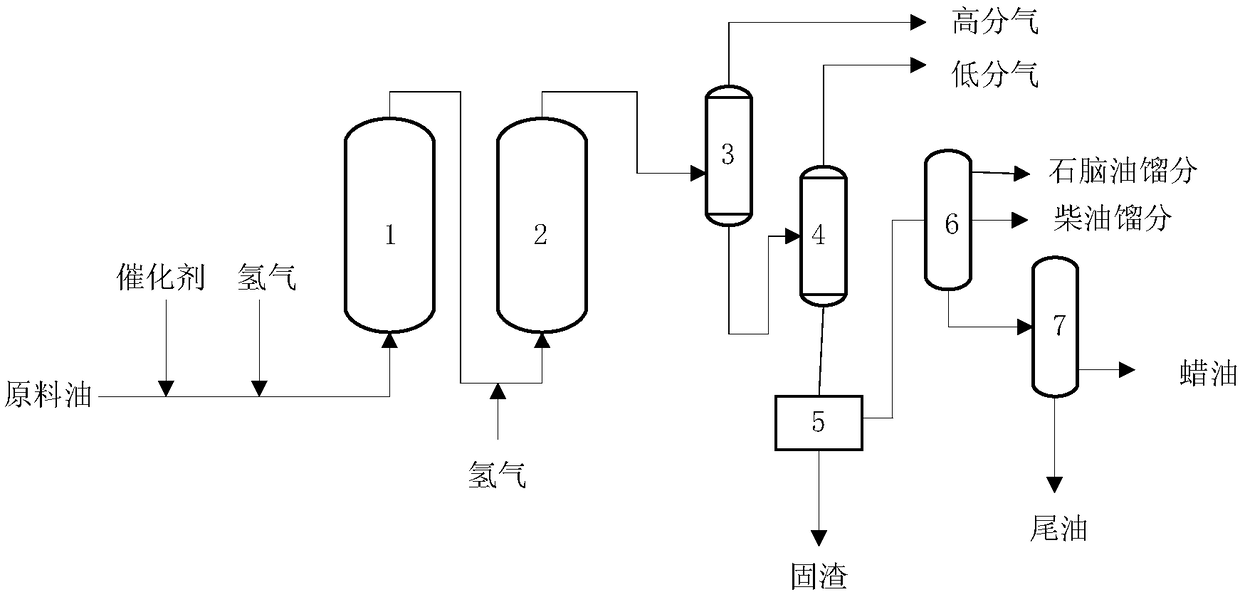

Two-stage hydrogenation process of coal tar

ActiveCN102851071AHigh yieldOvercome expensiveTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention discloses a two-stage hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrotreating reaction section, and carrying out a hydrotreating reaction on the coal tar by contacting with a hydrotreating catalyst in the presence of hydrogen and under hydrogenation conditions; (b) carrying out gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, in order to distillate out a light fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section, and carrying out a hydrocracking reaction on the heavy fraction by contacting with a hydrocracking catalyst in the presence of hydrogen and under hydrogenation cracking conditions; and (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a). Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

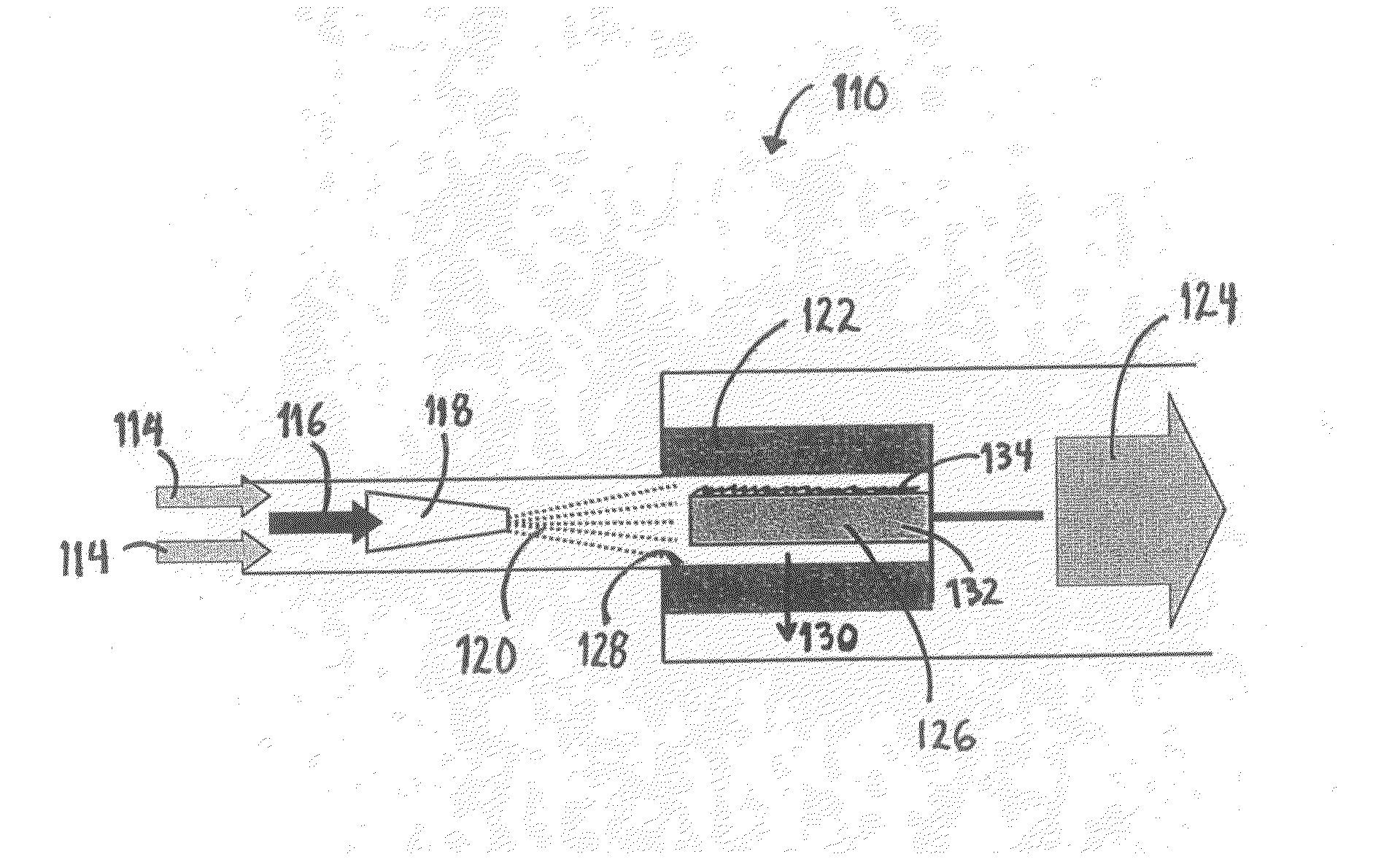

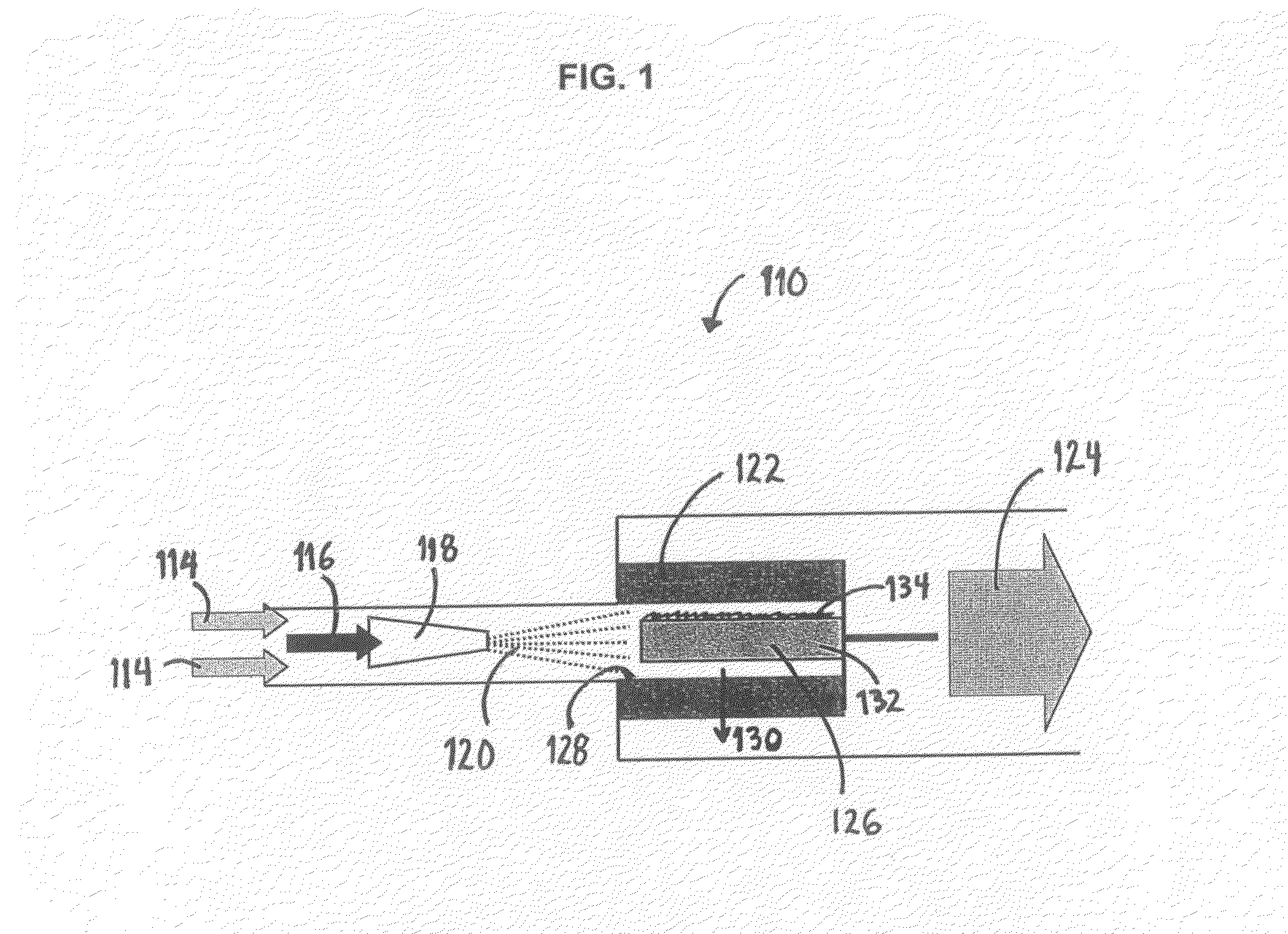

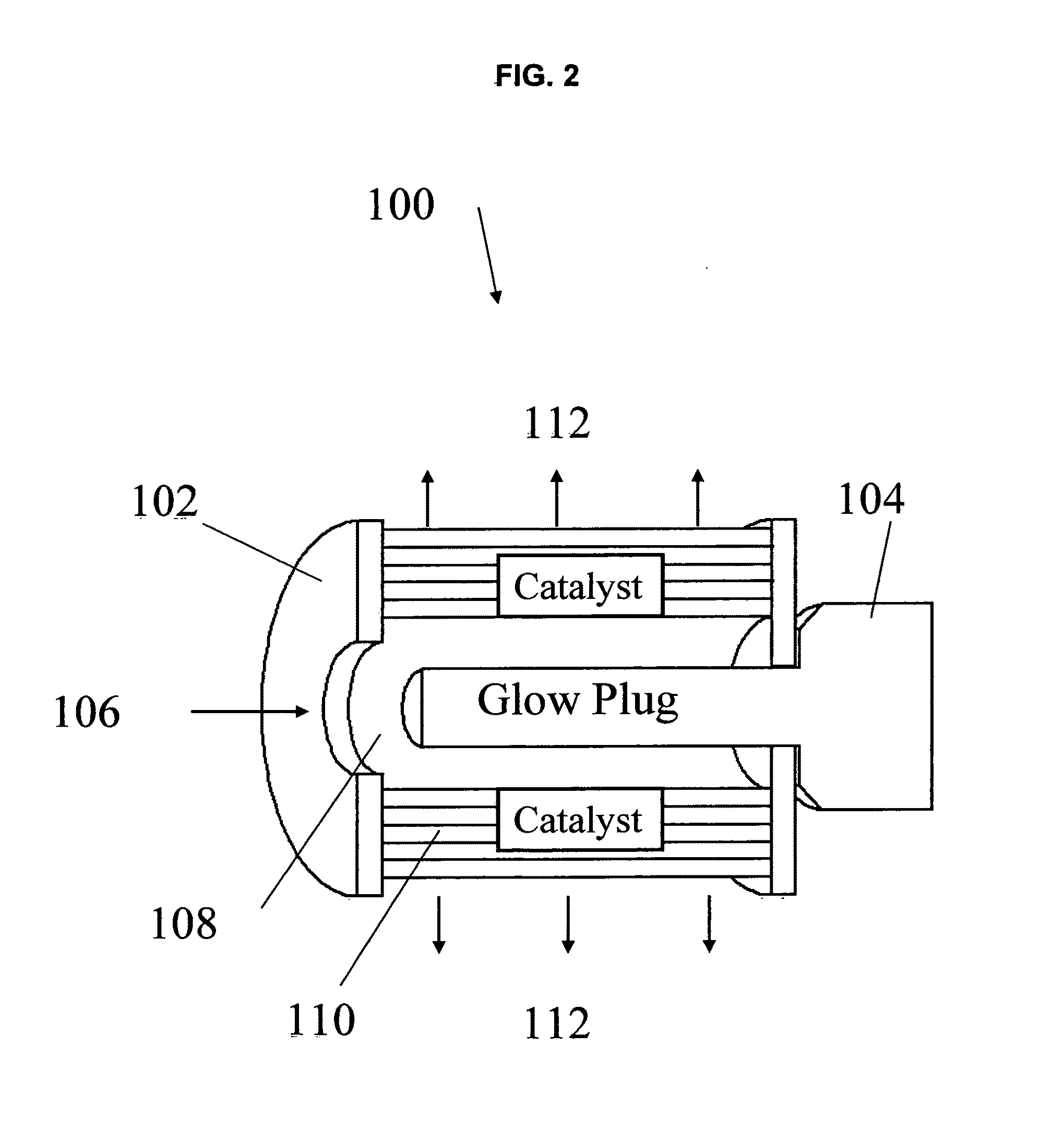

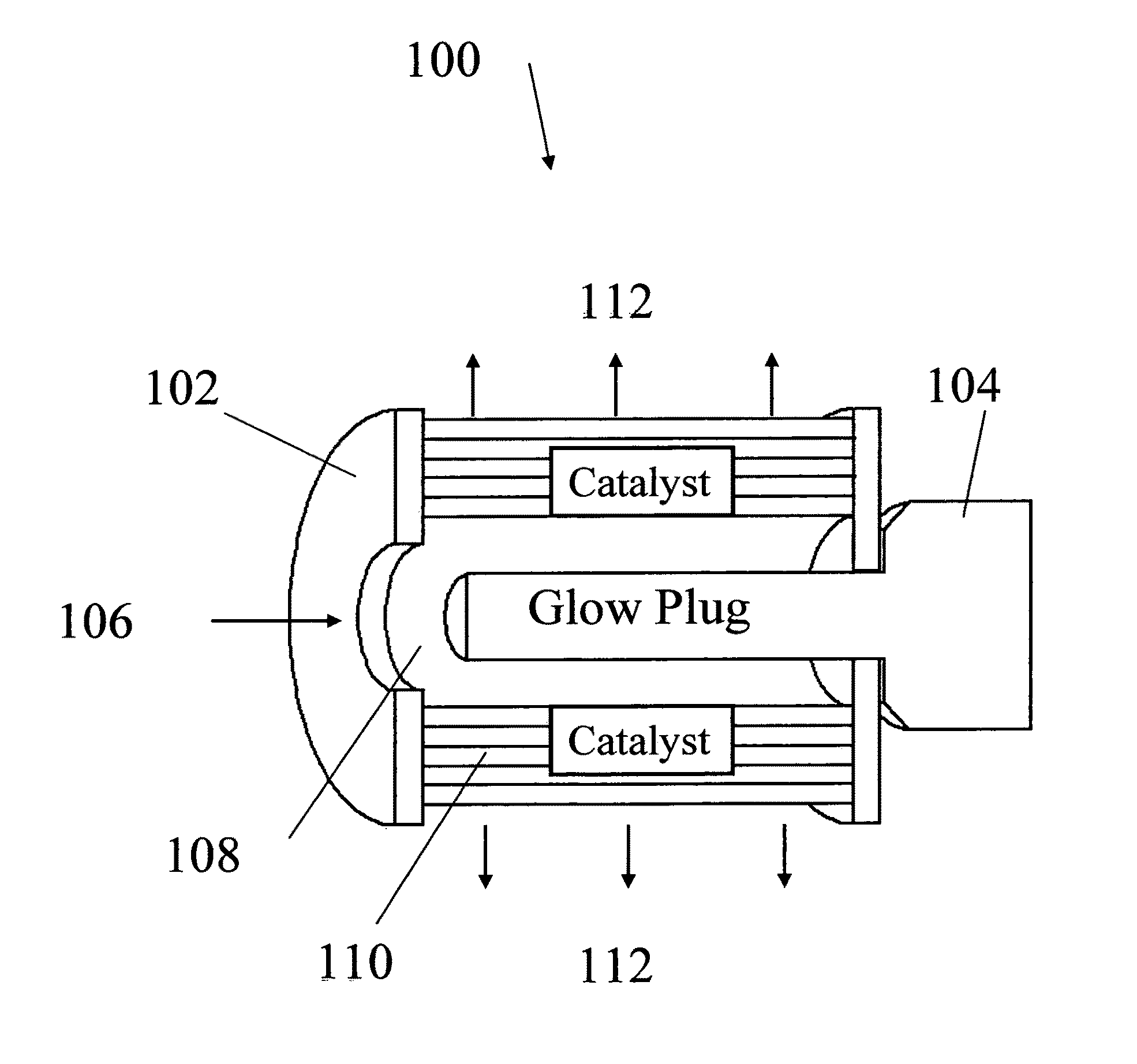

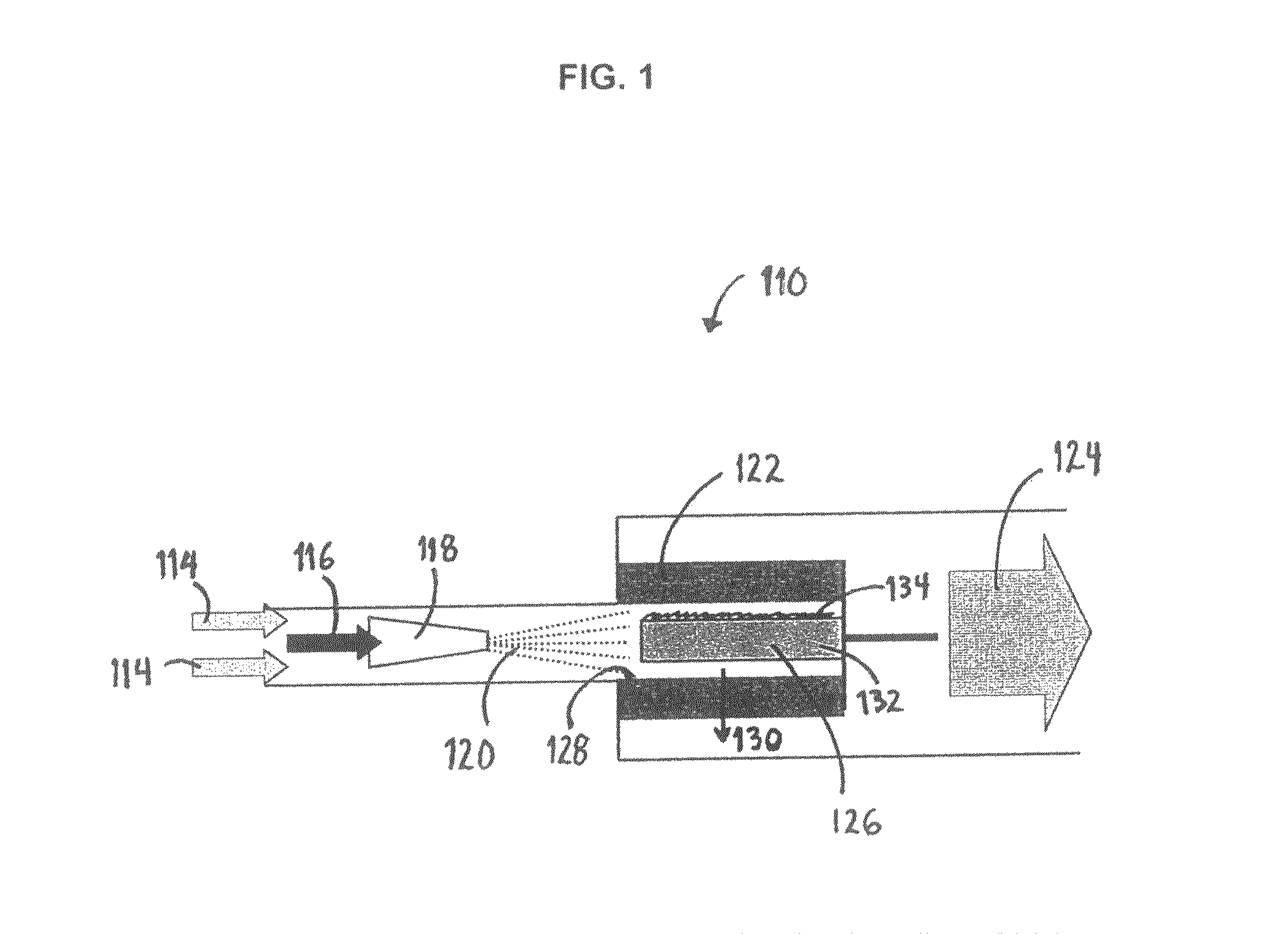

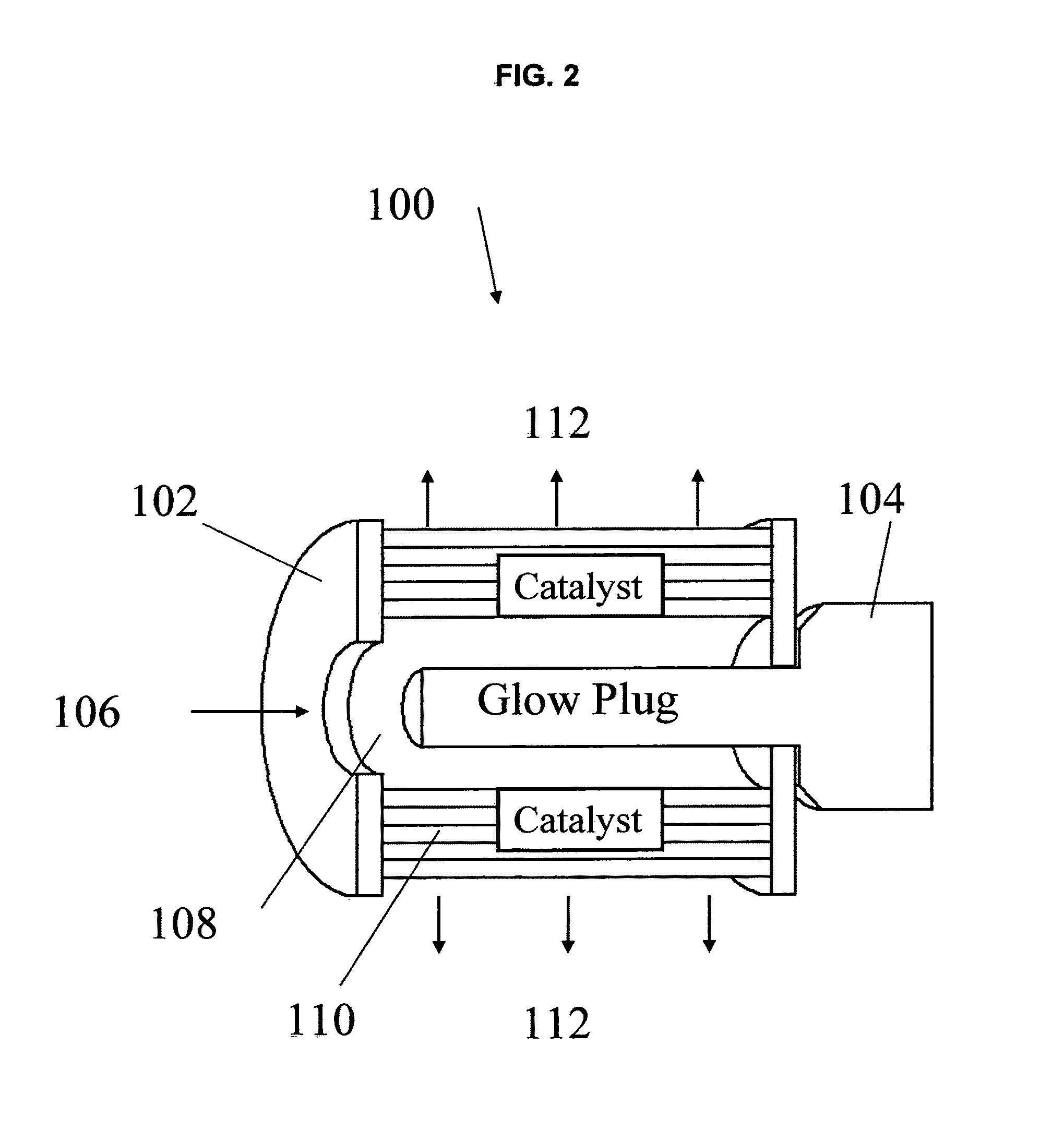

Apparatus for vaporizing and reforming liquid fuels

ActiveUS20110296759A1Simplified fuel injectionReduction tendencyHydrogenCatalytic crackingRandom orderEngineering

The present invention is an apparatus for the gasification of liquid fuels, involving: (a) a nozzle for atomizing and feeding a liquid fuel into a mixing region; (b) an inlet for feeding an oxidizer into the mixing region; (c) the mixing region for mixing the atomized fuel with the oxidizer; (d) a radiation hot box for vaporizing the liquid fuel, the radiation hot box comprising an ignition source positioned inside coiled catalytic reactor; (e) the coiled catalytic reactor comprising a coiled metal screen providing for a radial flow path from an inner diameter to an outer diameter of the coiled metal screen and providing for a plurality of void volumes in random order along the flow path from the inner diameter to the outer diameter; and (f) an outlet for exiting a gaseous reformate.

Owner:PRECISION COMBUSTION

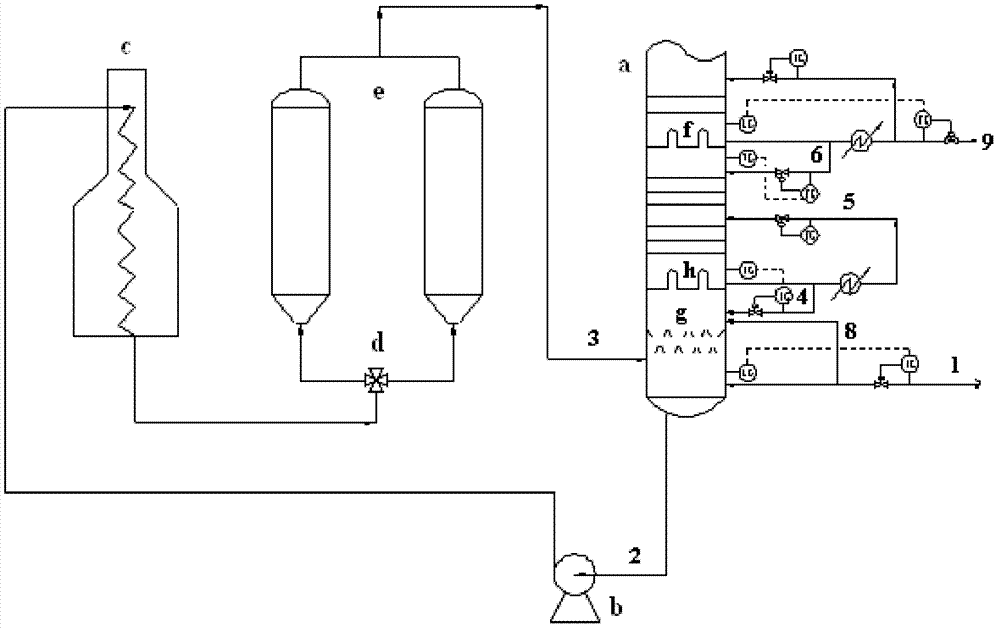

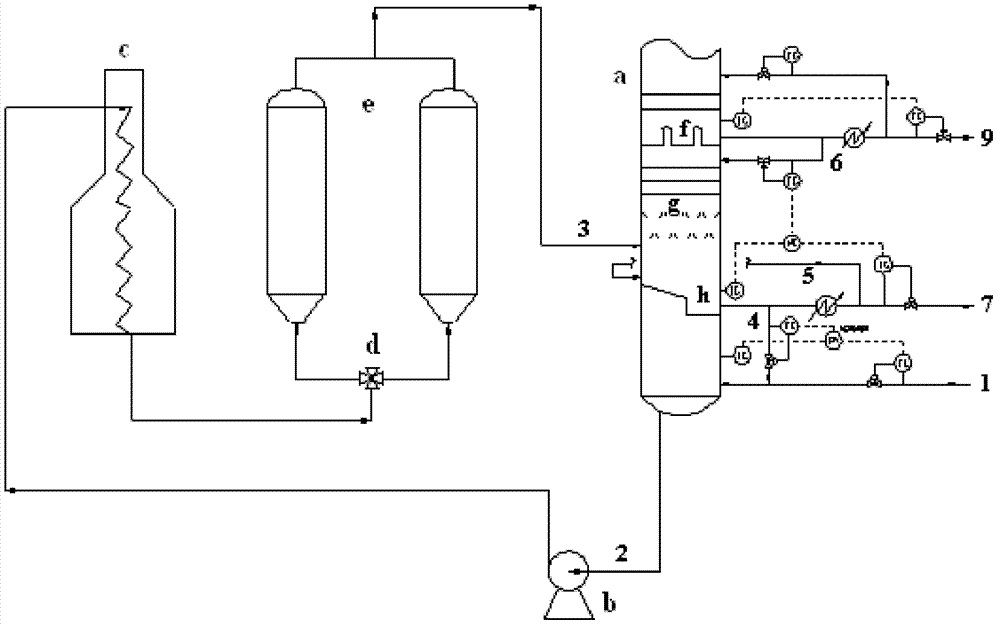

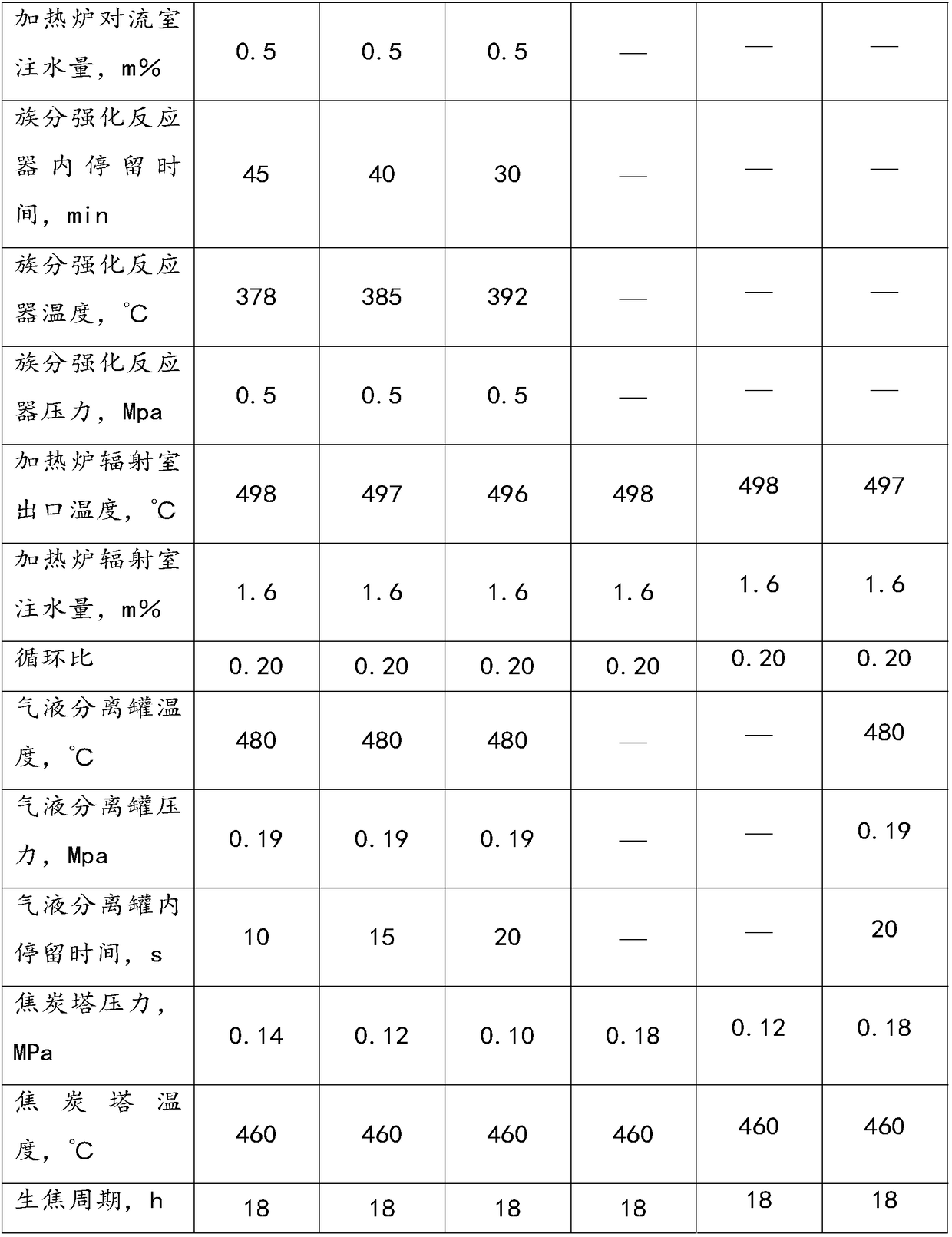

Full wax oil under-refluxing overheat-removing and circulation ratio quantitative controlling coking-retarding apparatus and method

ActiveCN102816587AStable in natureEasy to operateTreatment with plural serial stages onlyWaxFuel tank

The invention discloses full wax oil under-refluxing overheat-removing and circulation ratio quantitative controlling coking-retarding apparatus and method. The apparatus comprises a heating furnace, a coke tower and a fractionating tower. A heat exchange baffle is arranged in the fractionating tower and between a wax oil collecting tank and a heavy oil collecting tank. A high-temperature oil and gas inlet is arranged below the heat exchange baffle. The method comprises the steps that: the wax oil pumped from the wax oil collecting tank is subjected to under refluxing from top to bottom, such that the wax oil and high-temperature oil and gas are subjected to washing and heat exchange; heavy wax oil obtained by washing is delivered into a heavy wax oil collecting plate. Ratio controlling is adopted between circulation oil and raw material oil. When liquid level at the bottom of the fractionating tower is changed, flow rates of the raw material oil and the circulation oil can both be adjusted. After heat exchange, a part of heavy wax oil is delivered back to the heavy wax oil collecting plate for washing. Prior arts have problems, such as that the separation precision of coked wax oil and circulation wax oil is low, wax oil residual coke is high, wax oil dry point is high, circulation ratio fluctuation is high, and the fractionating tower is easy to get coked. With the apparatus and the method provided by the invention, the problems are solved. The operation is simple, flexible, and reliable.

Owner:CHINA PETROCHEMICAL CORP +1

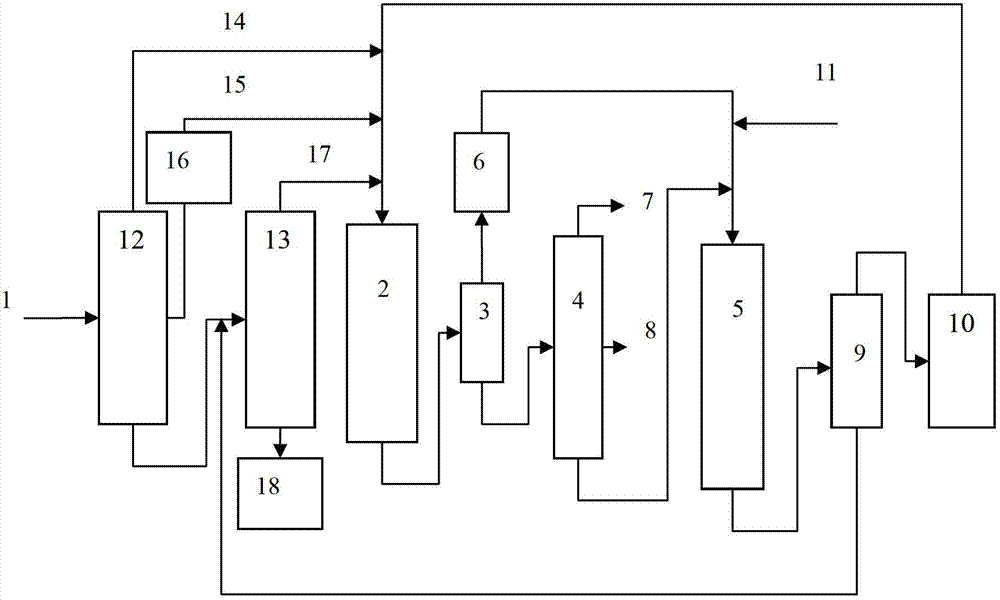

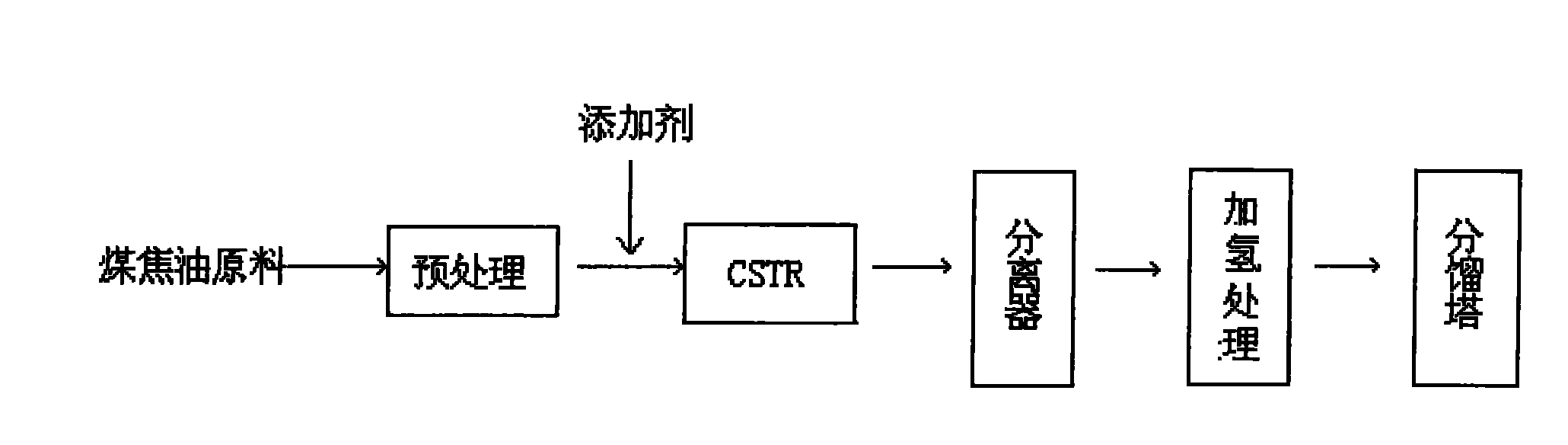

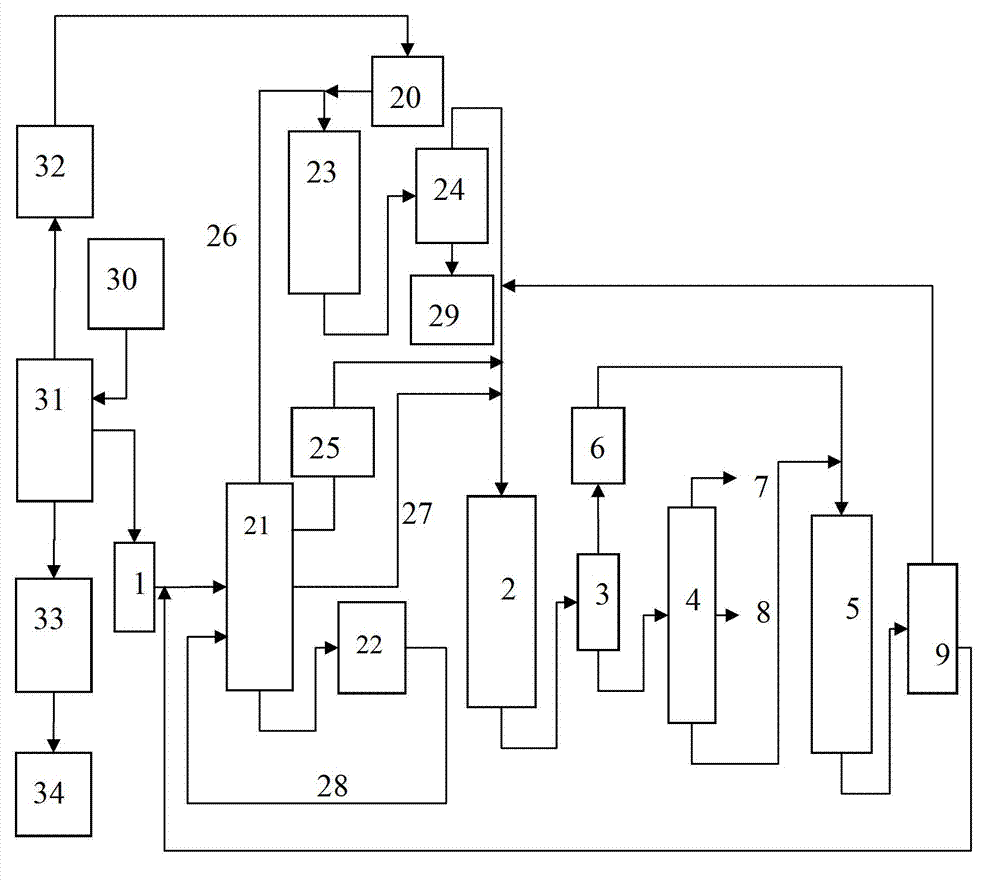

Medium and low temperature combination processing method of coal tar

ActiveCN102851073AHigh yieldLow yieldTreatment with hydrotreatment processesTar working-up by distillationLighter fuelHigh pressure

The invention comprises a combination processing method of coal tar. The method comprises the steps of: (a) subjecting a coal tar raw material to atmospheric distillation to obtain light distillate oil, phenol oil and bottom oil; dephenolizing the phenol oil to obtain the dephenolized oil; sending the bottom oil and a liquid phase from a hot high pressure separator in a step (d) into a vacuum distillation tower to obtain a heavy distillate with asphaltene removed; and conducting a hydrotreating reaction on the light distillate, dephenolized oil and the heavy distillate; (b) fractionating a liquid phase from the hydrotreating reaction into a light fraction and a heavy fraction; (c) subjecting the heavy fraction from the step (b) to a hydrocracking reaction; and (d) sending an effluent from the hydrocracking reaction into the hot high pressure separator, and sending the separated liquid phase to the vacuum distillation tower in the step (a). Compared with prior art, the method provided by the invention increases yield of light fuel production from coal tar, prolongs the service life of catalyst, and improves operation cycle of the device.

Owner:吉林省弘泰新能源有限公司

Apparatus for vaporizing and reforming liquid fuels

ActiveUS8795398B2Quickly starting and operatingStart fastHydrogenCatalytic crackingRandom orderEngineering

The present invention is an apparatus for the gasification of liquid fuels, involving: (a) a nozzle for atomizing and feeding a liquid fuel into a mixing region; (b) an inlet for feeding an oxidizer into the mixing region; (c) the mixing region for mixing the atomized fuel with the oxidizer; (d) a radiation hot box for vaporizing the liquid fuel, the radiation hot box comprising an ignition source positioned inside coiled catalytic reactor; (e) the coiled catalytic reactor comprising a coiled metal screen providing for a radial flow path from an inner diameter to an outer diameter of the coiled metal screen and providing for a plurality of void volumes in random order along the flow path from the inner diameter to the outer diameter; and (f) an outlet for exiting a gaseous reformate.

Owner:PRECISION COMBUSTION

Coal tar processing method

ActiveCN102041053AEfficient processingReduce dosageTreatment with hydrogen-generating compoundsHydrogenSolvent

The invention discloses a coal tar processing method which comprises the following steps: mixing coal tar and a hydrogen-donor solvent, wherein the hydrogen-donor solvent comprises tetrahydronaphthalene or decahydronaphthalene, and the weight ratio of the coal tar to the hydrogen-donor solvent is (1:0.5)-(1:10); processing the mixture of the coal tar and the hydrogen-donor solvent for 0.2-5 hoursat the pressure of 15-40 MPa and the temperature of 200-500 DEG C; separating solid impurities from the processed product; and then, hydrogenating. The coal tar processing method provided by the invention is implemented in the supercritical state or approximately-critical state of the hydrogen-donor solvent, thus the mixing effect and reaction effect of the hydrogen-donor solvent and the coking precursor in the coal tar are improved, the coking tendency is reduced, the comprehensive reaction effect is enhanced in combination with hydrogenation, the impurity removing capability and long-term operation stability of the device are improved, and the more inferior coal tar can be processed.

Owner:CHINA PETROLEUM & CHEM CORP +1

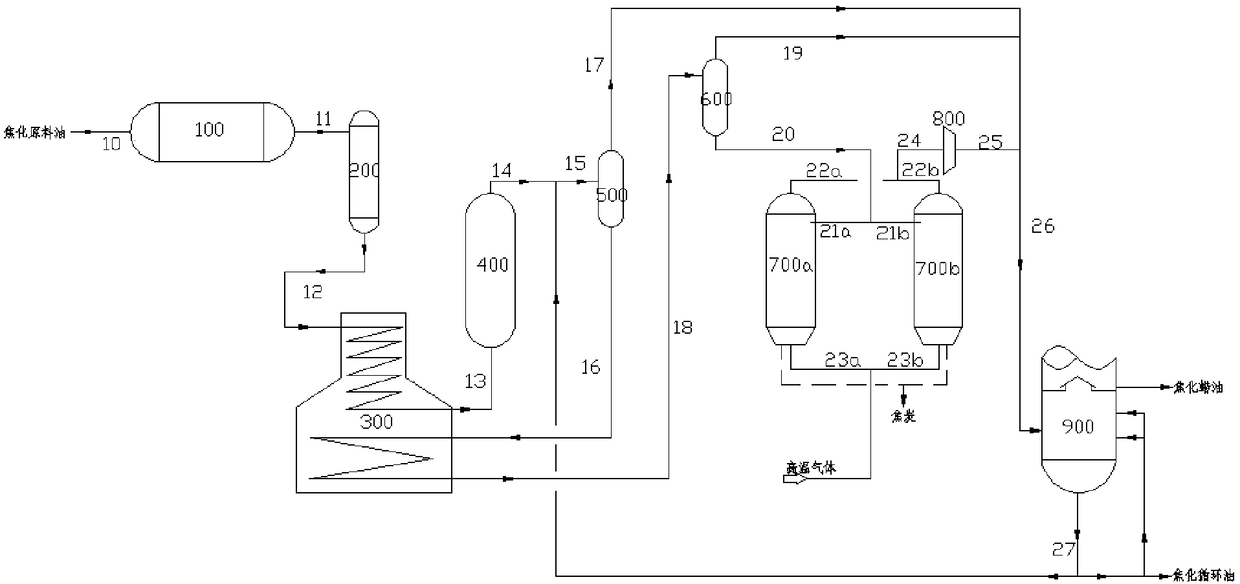

Combination processing method of coal tar

The invention comprises a combination processing method of coal tar. The method comprises the steps of: the coal tar raw material: (a) introducing a coal tar raw material, delayed coking gas oil and at least part of a liquid phase from a step (d) into a distillation tower, so as to distillate out a light distillate, wax oil and bottom oil; and subjecting the light distillate and the wax oil to a hydrotreating reaction; (b) carrying out gas-liquid separation on an effluent from the hydrotreating reaction, and sending a liquid phase into a fractionation device, so as to distillate out a light fraction and a heavy fraction; (c) carrying out a hydrocracking reaction on at least part of the heavy fraction obtained in the step (b); (d) sending an effluent from the hydrocracking reaction into a hot high pressure separator, so as to separate out a gas phase and a liquid phase; and sending at least part of the liquid phase to the distillation tower in the step (a); and (e) subjecting the bottom oil obtained from distillation in the step (a) to delayed coking, and sending the delayed coking oil gas to the distillation tower in the step (a). Compared with the prior art, the invention method improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

Deep processing method of non-caking coal or feebly caking coal

The invention discloses a deep processing method of non-caking coal or feebly caking coal, which comprises the following steps: performing medium-and-low-temperature carbonization reaction on non-caking coal or feebly caking coal to generate coal gas, semicoke and coal tar; treating the coal tar as follows: inputting the coal tar material, oil gas obtained through delayed coking reaction and a hydrocracking liquid-phase product into a distillation tower, and distilling out naphtha fractions, carbolic-oil-containing fractions, wax oil fractions and tower bottom oil; mixing the naphtha fractions with hydrogen, and inputting into a naphtha hydrofining reaction section; dephenolizing the carbolic-oil-containing fractions to obtain dephenolized oil, mixing with the wax oil fractions, and inputting into a hydrotreating reaction section; fractionating the hydrotreating reaction liquid phase into light fractions and heavy fractions, and performing hydrocracking on the heavy fractions; and inputting the tower bottom oil obtained through distillation into a delayed coker. Compared with the prior art, the method disclosed by the invention performs sufficient deep processing on coal, improves the yield of light fuel oil produced from coal tar, and simultaneously prolongs the service life of a catalyst in a hydrogenation device.

Owner:中铝能源有限公司

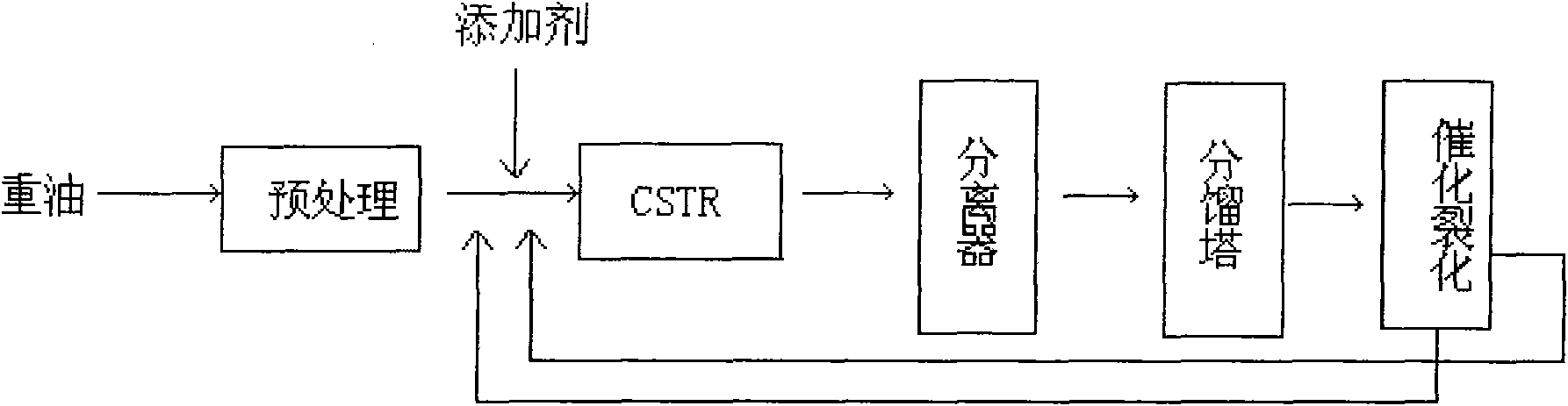

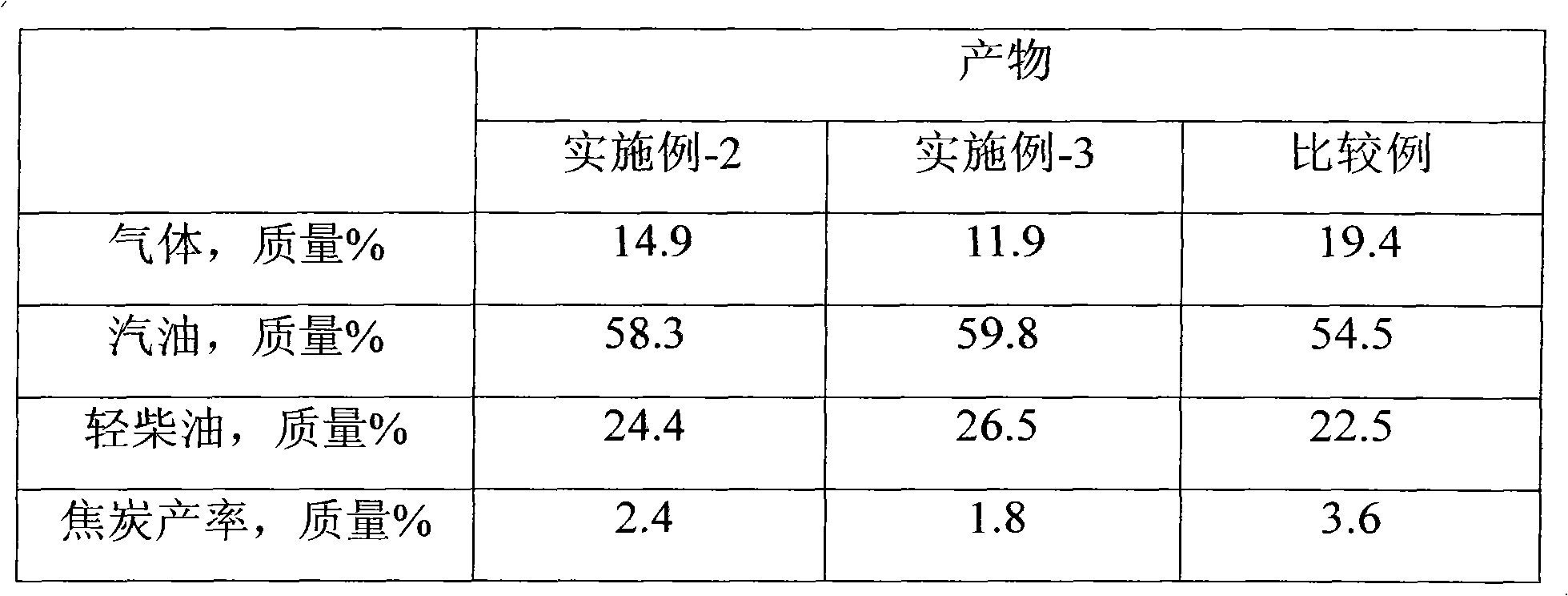

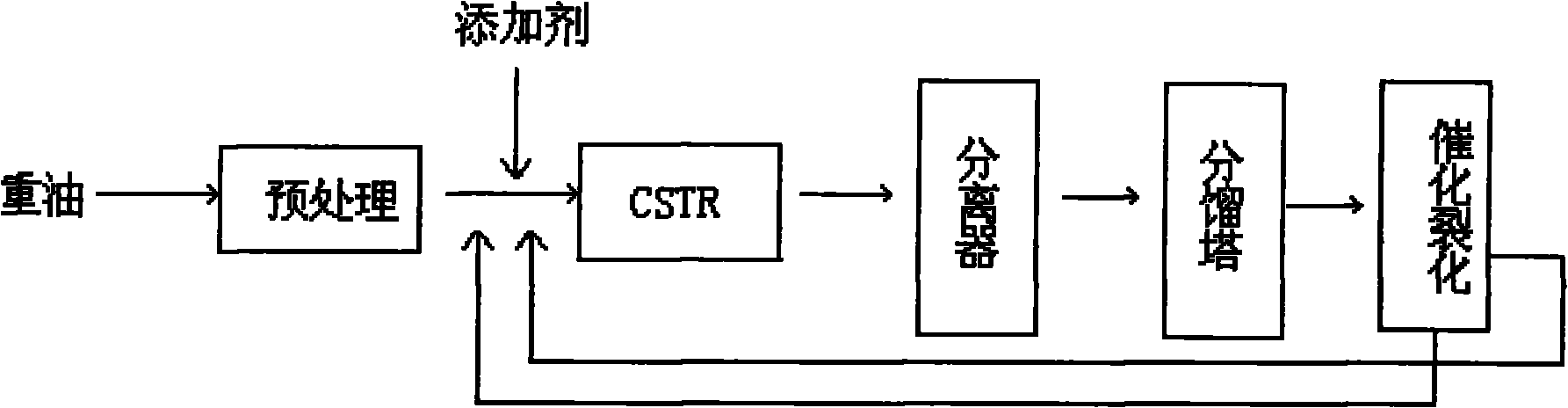

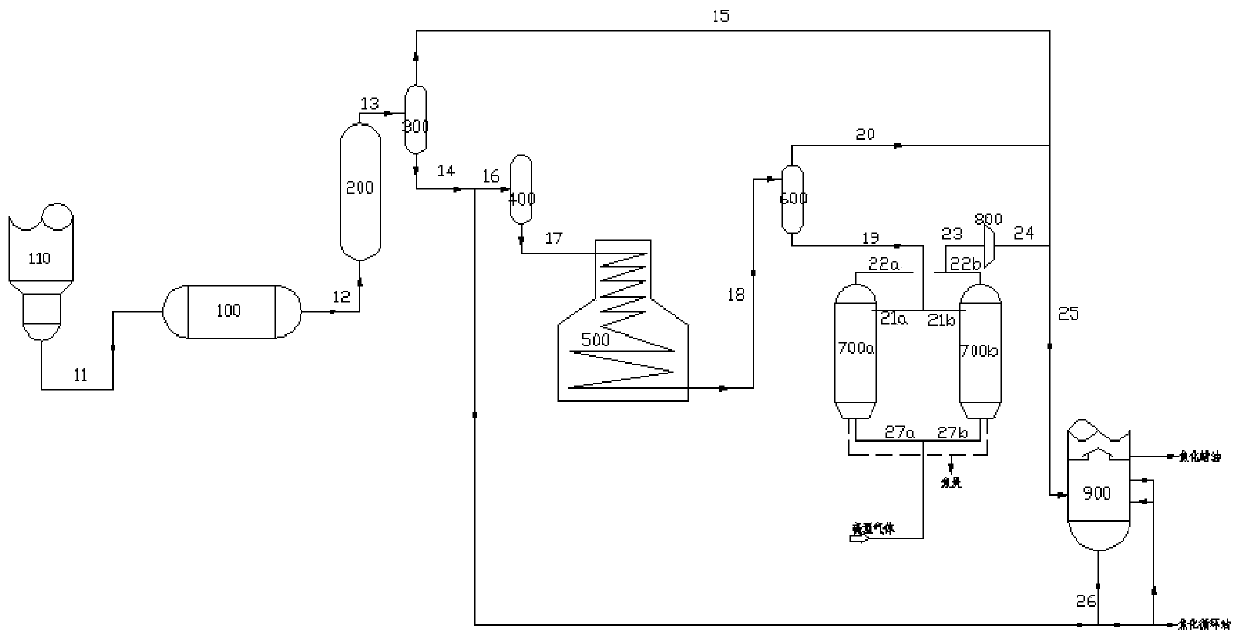

Combined process method for heavy oil modification

ActiveCN101942338AImprove fusion effectImprove responseTreatment with hydrotreatment processesFuel oilSlurry

The invention discloses a combined process method for heavy oil modification, which comprises the following steps of: mixing heavy oil raw materials and a hydrogen supply solvent for supercritical treatment, and making the heavy oil subjected to the supercritical treatment enter a catalytic cracking unit for treatment; and performing a cracking reaction in the presence of a cracking catalyst, and separating reaction products to obtain dry gas, liquefied gas, gasoline, diesel oil, heavy cycle oil and slurry oil, wherein the heavy cycle oil partially or totally cycles for the supercritical treatment, and the slurry oil partially or totally cycles for the supercritical treatment. The supercritical treatment method for the heavy oil raw materials comprises the step of mixing the heavy oil raw materials and the hydrogen supply solvent for the supercritical treatment, wherein the hydrogen supply solvent comprises tetrahydronaphthalene or decahydronaphthalene. The method has the advantages of capacity of effectively improving the utilization rate of poor-quality heavy oil, low coking rate, stable production process, and suitability for light treatment of various heavy and poor-quality raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

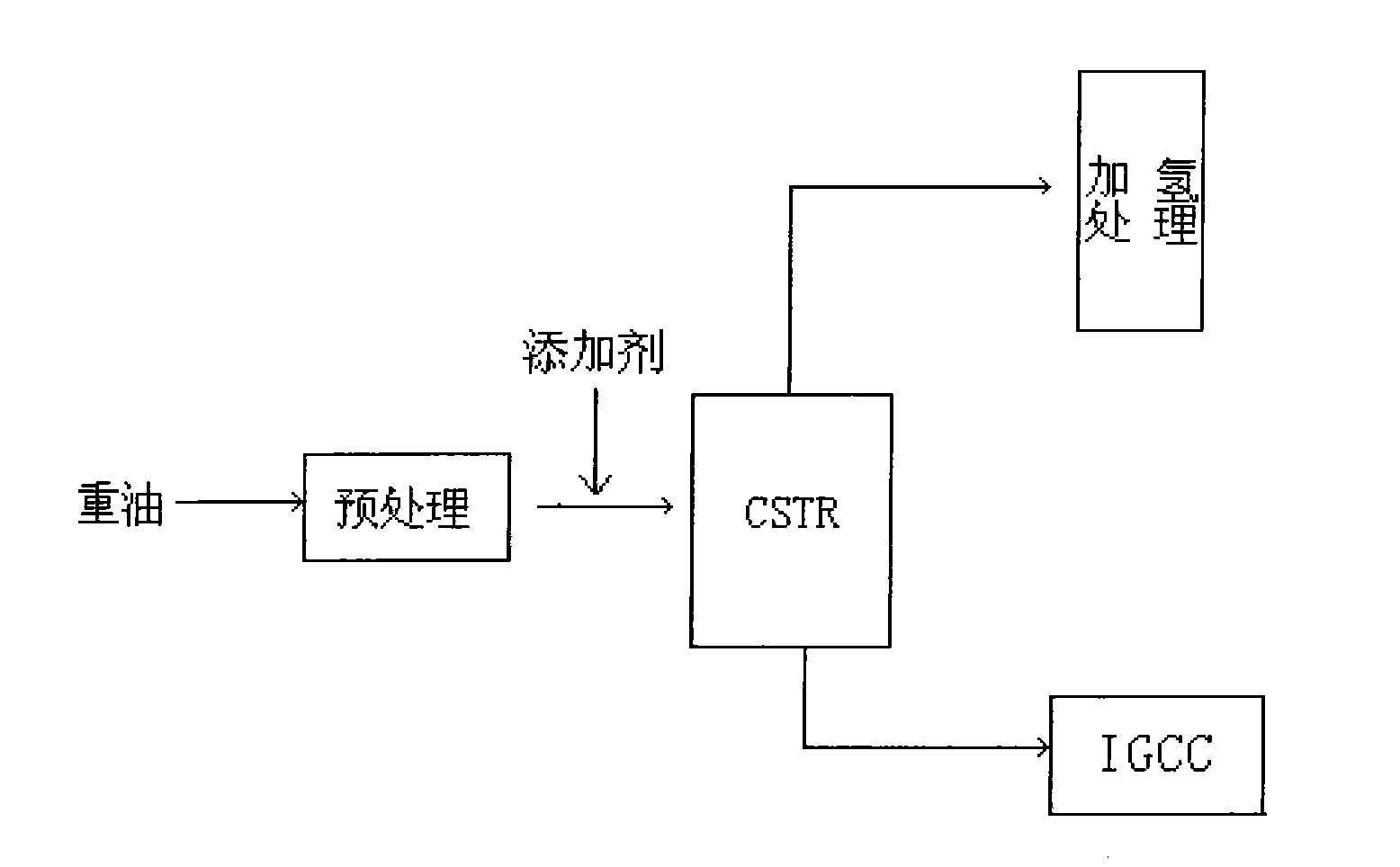

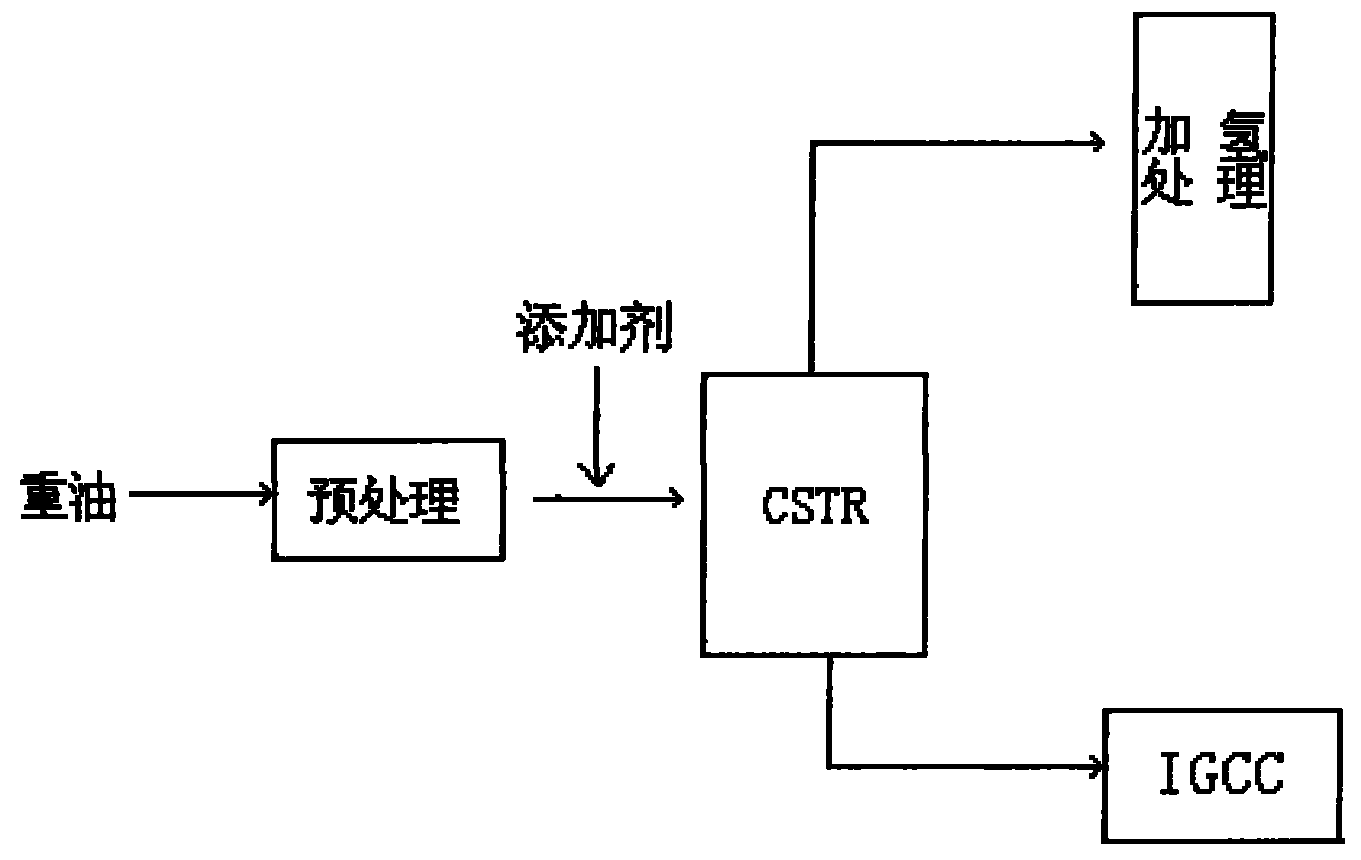

Combined process method for modifying heavy oil

InactiveCN102311797AImprove fusion effectImprove responseHydrocarbon oil crackingTreatment with hydrotreatment processesFuel oilSolvent

The invention discloses a combined process method for modifying heavy oil, which comprises the following contents: a heavy oil raw material is pretreated first to remove water and mechanical impurities; then supercritical treatment is performed in the presence of a hydrogendonating solvent and in a supercritical or subcritical state; and light oil obtained after supercritical treatment is subjected to hydrogenation treatment or catalytic cracking treatment, and a heavy component obtained after supercritical treatment is treated by an integrated gasification combined cycle (IGCC) technique. When the method is used, the impurities in low-quality heavy oil can be removed effectively, and the utilization rate of a heavy oil raw material can be improved effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

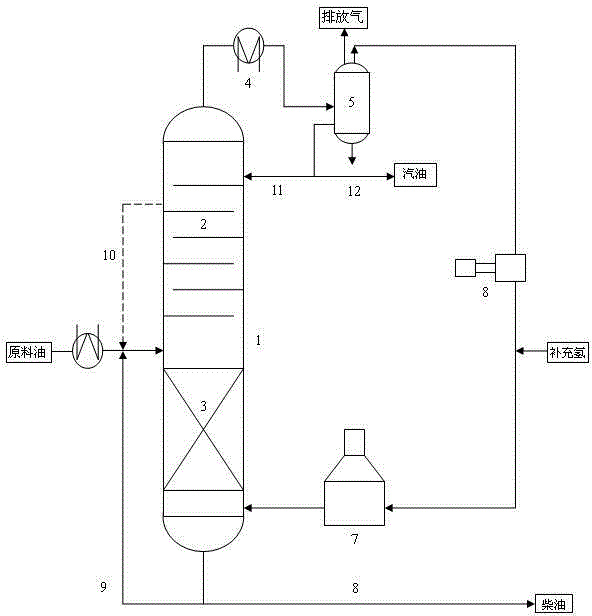

Catalytic diesel fuel reaction distillation method

ActiveCN104611049ABoost octaneIncrease cetane numberTreatment with hydrotreatment processesIsomerizationPoor quality

The present invention discloses a catalytic diesel fuel reaction distillation method. According to the method, equipment mainly comprises a reaction distillation tower and a hydrogen circulation system, the stripping section of the reaction distillation tower adopts a hydrocracking catalyst as a filler, the rectification section is provided with the rectification tower plate, the tower plate can be provided with an isomerization catalyst, one part of the tower bottom oil is circulated to the material inlet of the tower, the remaining part is discharged out from the equipment and is adopted as the product, a hydrogen circulation heating furnace is arranged, the heated hydrogen gas enters the bottom of the tower, and the gasoline distillate is obtained from the top of the tower. With the method, the characteristics of the hydrocracking and the reaction distillation process are completely utilized so as to reduce the secondary reaction of the light distillates and improve the hydrogenation reaction speed of the gasoline distillate. According to the present invention, the poor-quality cracking diesel fuel is adopted as the raw material to produce the high octane number naphtha and the high-quality diesel fuel, such that the obtained products can respectively be adopted as the blending component of the high octane number naphtha and the blending component of the high-quality diesel fuel; and compared with the conventional hydrogenation process, the method of the present invention has characteristics of simple process and energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

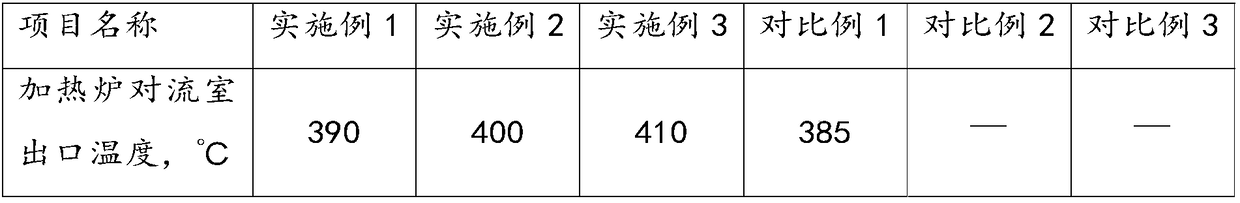

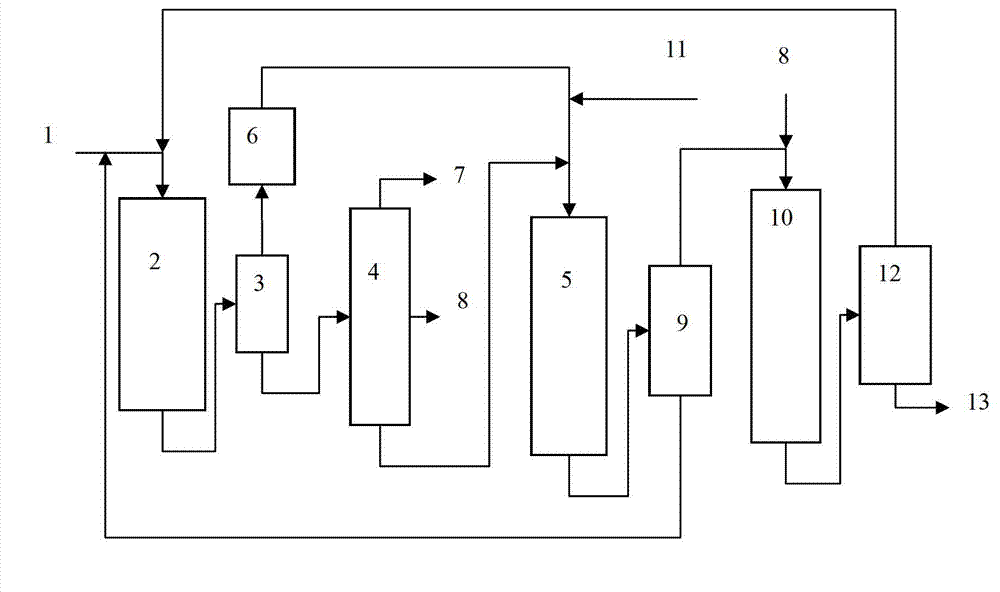

Delayed coking method and device

ActiveCN108546560AAlleviate reactivityRelief heightThermal non-catalytic crackingCoking carbonaceous materialsLiquid productBuffer tank

The invention belongs to the field of petrochemical industry and relates to a delayed coking method and device. The delayed coking method comprises the following steps: coking raw material oil entersan external field strengthening reactor for enhanced desulfurization, a material out of the external field strengthening reactor passes through a raw material oil buffer tank and a heating furnace convection chamber, and then enters a group component strengthening reactor for thermal cracking reaction, and a material out of the group component strengthening reactor or a mixture of the material outof the group component strengthening reactor and coking recycle oil from a coking fractionation column enters a gas-liquid separation unit for gas-liquid separation and the like. The delayed coking device comprises the external field strengthening reactor, the raw material oil buffer tank, a heating furnace, the group component strengthening reactor, a first gas-liquid separation unit, a second gas-liquid separation unit, a coke tower, a pumping device and the coking fractionation column. The delayed coking method and device can reduce the sulfur content in petroleum coke, increase the yieldof a liquid product, overcome the problems of environmental pollution caused by the existing high sulfur petroleum coke, poor petroleum coke product quality, and the low yield of the liquid product.

Owner:SINOPEC LUOYANG TECH CO LTD +1

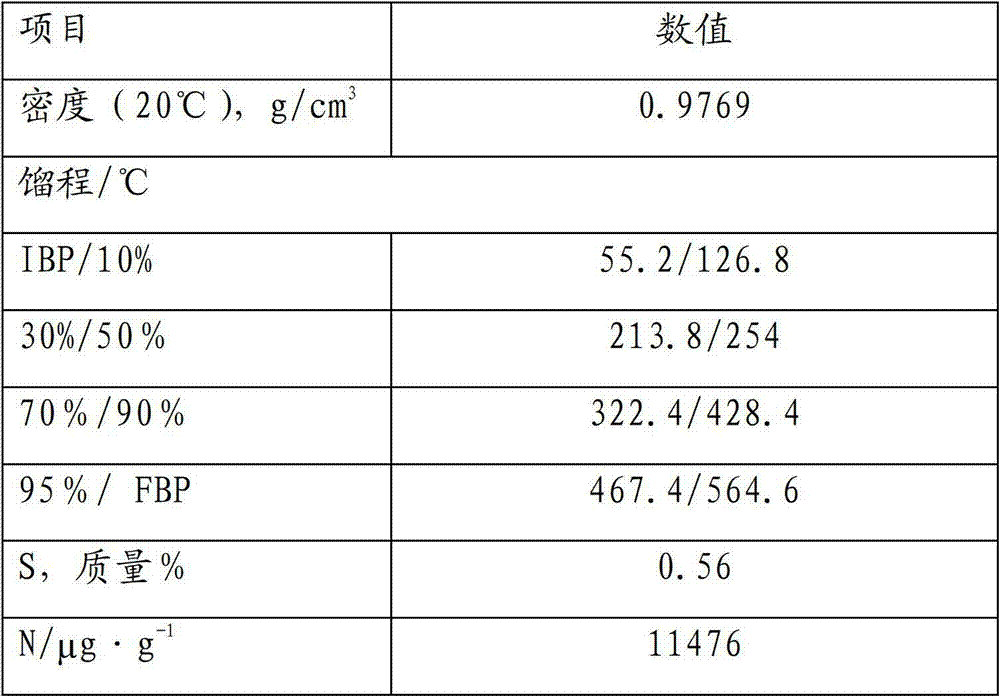

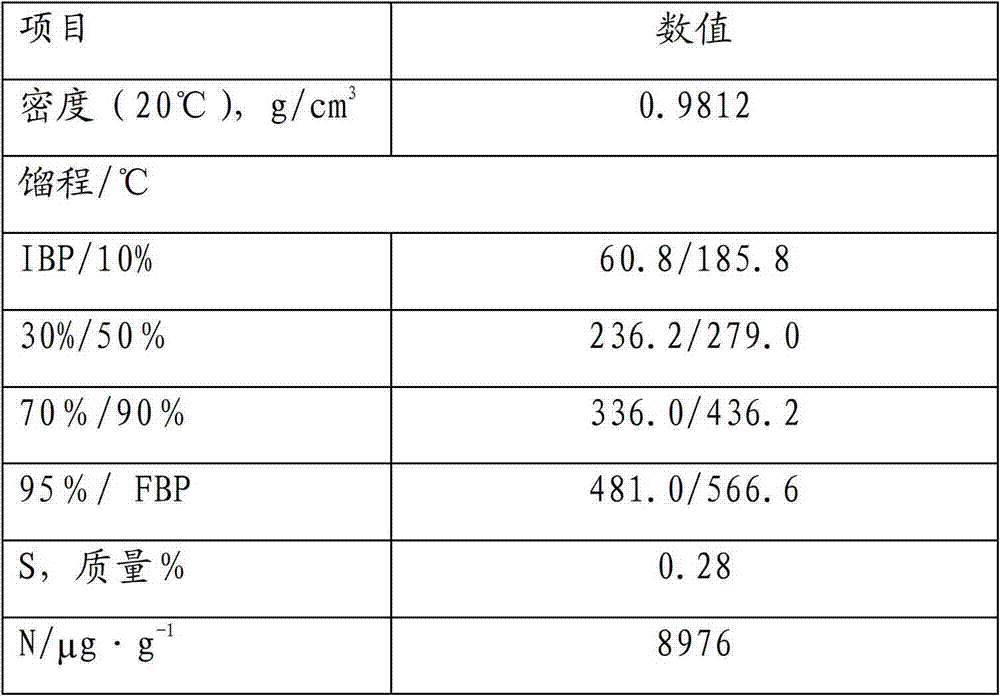

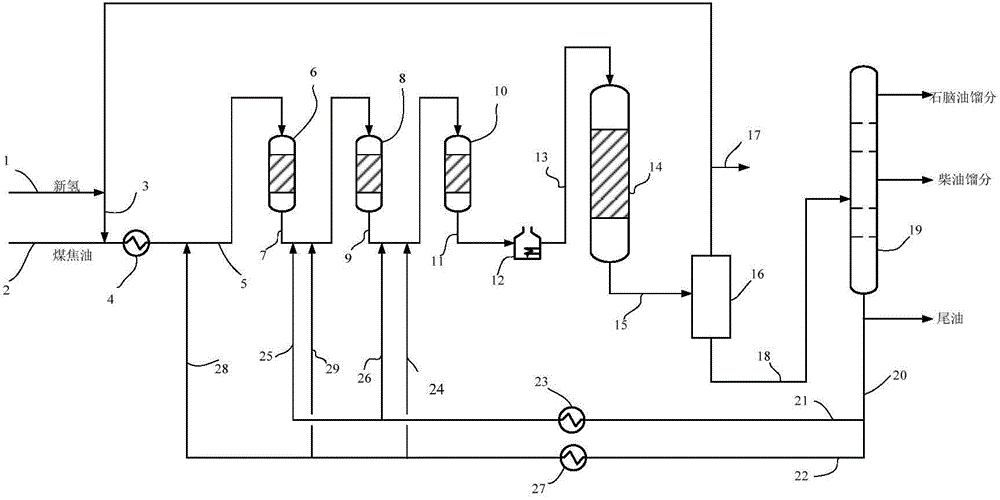

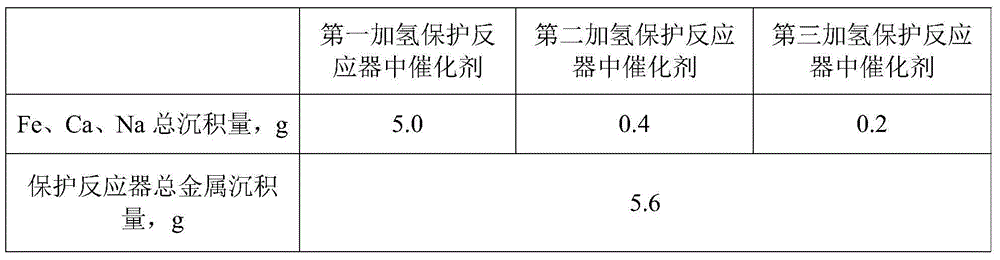

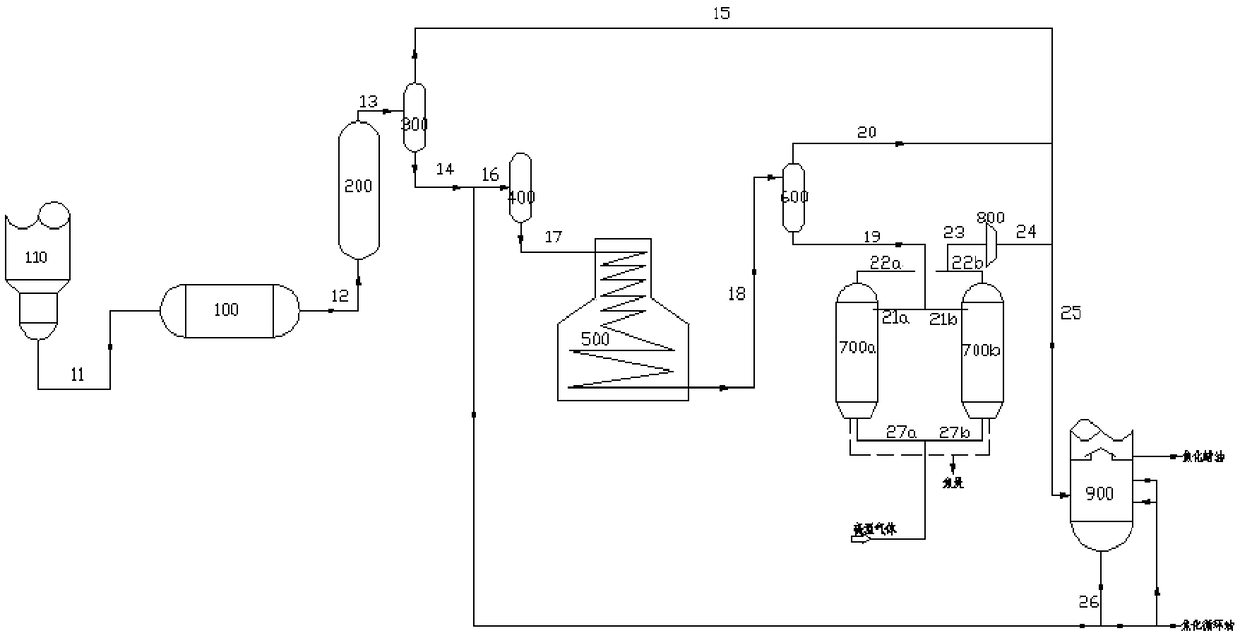

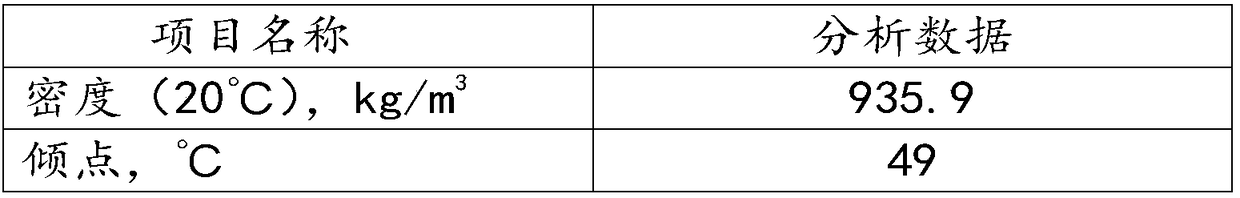

Coal tar hydrogenation pretreatment method and coal tar hydrogenation treatment method

ActiveCN105567273ALow densityLow sulfur and nitrogen contentTreatment with hydrotreatment processesTar working-up by chemical refiningHydrogenPretreatment method

The invention discloses a coal tar hydrogenation pretreatment method and a method for coal tar hydrogenation treatment by using the coal tar hydrogenation pretreatment method. The coal tar hydrogenation pretreatment method comprises the following steps: introducing materials containing coal tar and hydrogen to a hydrogenation protective reaction system to carry out hydrogenation pretreatment, so as to obtain a hydrogenation protective effluent; the hydrogenation pretreatment is implemented under the conditions of respectively introducing high temperature hydrogenation tail oil and low temperature hydrogenation tail oil to the hydrogenation protective reaction system. The method disclosed by the invention can improve the utilization efficiency of a hydrogenation protective catalyst, and prolong the running cycle of a coal tar hydrogenation device, and further can obtain product oil of which the metal content is remarkably reduced. Furthermore, a diesel product obtained by the hydrogenation treatment method disclosed by the invention has high cetane number, low density and low sulfur and nitrogen content, thereby being a high-quality diesel oil blending component suitable for vehicles.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage combined hydrogenation process of coal tar

The invention discloses a two-stage combined hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrogenation reaction section for a hydrotreating reaction; (b) carrying out a gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, so as to distillate out a gasoline fraction, a diesel fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section for a hydrocracking reaction; (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a); (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a); Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

Combined process of hydrotreatment and delayed coking for residual oil

ActiveCN103102986BReduce processing loadReduce generationTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention discloses a combined process of hydrotreatment and delayed coking for residual oil. According to the invention, residual oil, coker gas oil and hydrogen are mixed together, and an obtained mixture enters into a hydrotreatment unit in the presence of a catalyst; a reaction product of hydrotreatment is separated; residual oil having undergone hydrotreatment is mixed with separated pressure-reduced gas oil or with other conventional raw materials, and an obtained mixture enters into a delayed coking unit; a coking product is separated, and coked gas oil therein is totally recycled to a residual oil hydrogenation unit. With the combined process, a product structure is improved, a coked gas oil product is not generated, a light oil product can be maximumly produced, high-quality needle coke can be obtained, generation of foam in a coking tower can be effectively reduced, and the coking tendency of a coking furnace is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

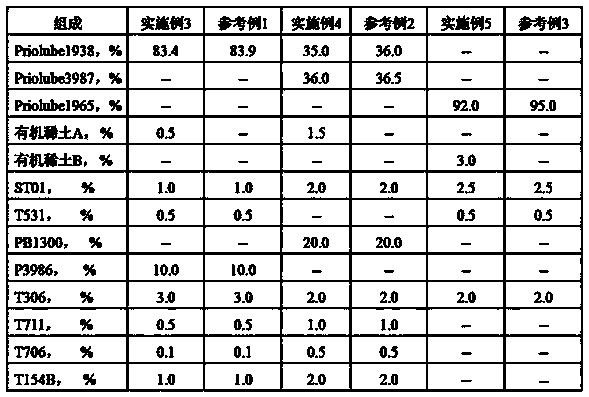

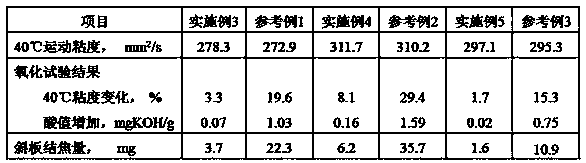

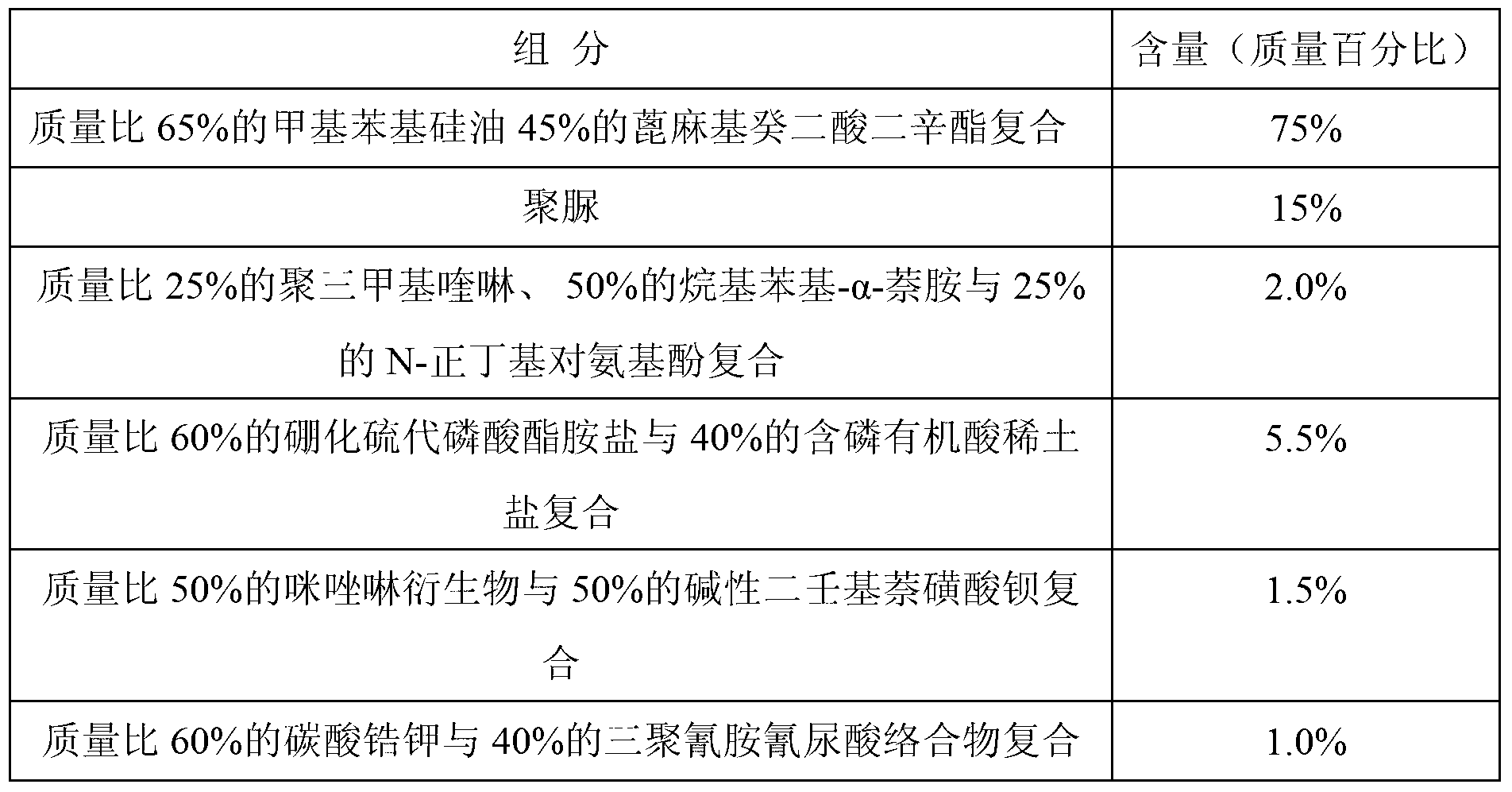

Synthetic high temperature chain oil and preparation method thereof

InactiveCN108949289AImprove high temperature oxidation resistanceReduced coking tendencyAdditivesRare earthViscosity index

The invention relates to a synthetic high temperature chain oil and a preparation method thereof. The weight ratio of raw materials of the chain oil is as follows: 70-95% of base oil; 0.5-3% of organic rare earth; 0.5-3% of a high temperature anti-oxidant; 0-20% of a viscosity index improver; 2-3% of an extreme pressure-antiwear additive, 0-1% of an antirust agent, 0-1% of a metal passivator; and0-3% of a detergent / dispersant additive. The introduction of the organic rare earth in a formula can significantly enhance the high temperature antioxidation performance and anti-coking performance ofthe chain oil.

Owner:芜湖市欧贝润滑剂有限责任公司

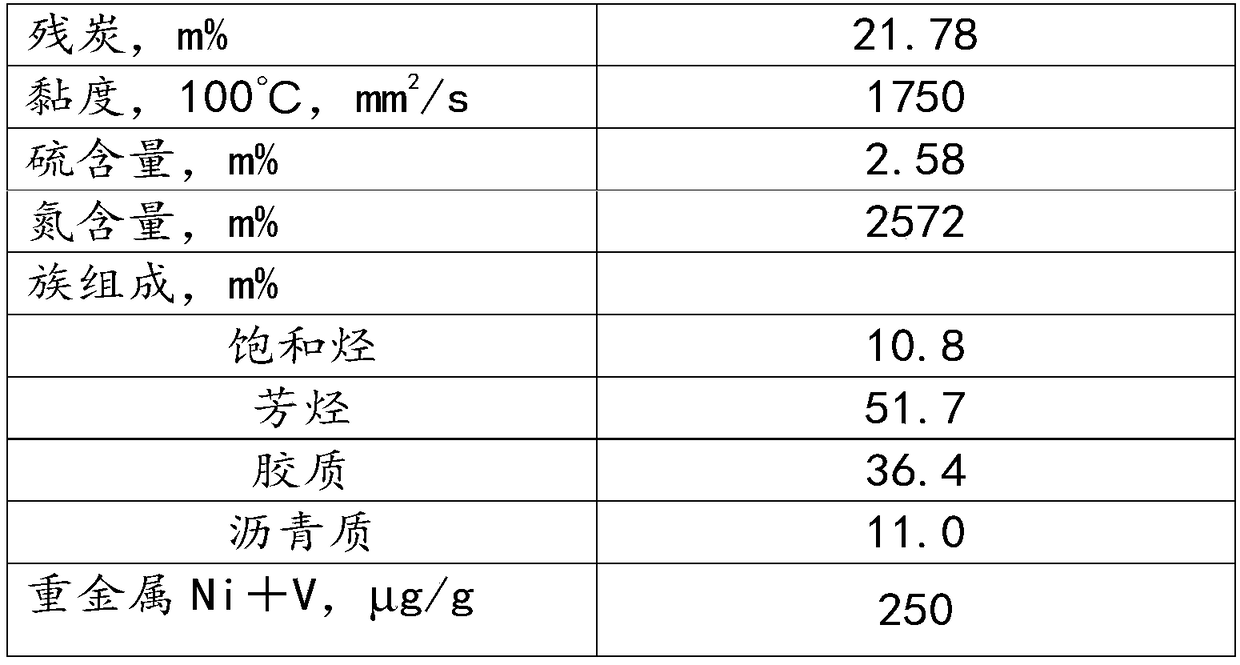

Process for viscosity breaking of deoiled asphalt

InactiveCN1195822CFulfil requirementsAvoid cokingThermal non-catalytic crackingCatalytic crackingEngineeringHeating furnace

A process for viscosity breaking of deoiled asphalt produced by the apparatus using solvent to remove oil from asphalt features that said deoiled asphalt and the catalytic cracking clean oil (1-50%) are fed in the flow-up viscosity breaking apparatus and a low-temp long-stay operation manner is used. It has high effect on reducing viscosity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for delayed coking and device

ActiveCN108587683AAlleviate reactivityRelief heightThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productGas phase

The invention belongs to the field of petrochemical industry and relates to a method for delayed coking and a device. The method for delayed coking, disclosed by the invention, comprises the steps: depressurized raw oil from a vacuum distillation tower enters an external-field strengthened reactor for strengthened desulfurization, a material from the external-field strengthened reactor enters a clustering strengthened reactor for a thermal cracking reaction, and a material from the clustering strengthened reactor enters a first gas-liquid separation unit for gas-liquid separation; and a gas-phase material separated by the first gas-liquid separation unit enters a coking fractionating tower, a liquid-phase material or a mixture of the liquid-phase material and coking circulating oil from the coking fractionating tower enters a buffer tank, a material from the buffer tank enters a heater for heating, and a material from the heater enters a second gas-liquid separation unit for gas-liquidseparation, and the like. According to the method and the device, the sulfur content of petroleum coke can be lowered, the yield of liquid product is increased, and technical problems, i.e., environmental pollution, poor petroleum coke product quality and low liquid product recovery rate caused by the existing high-sulfur petroleum coke can be overcome.

Owner:SINOPEC LUOYANG TECH CO LTD +1

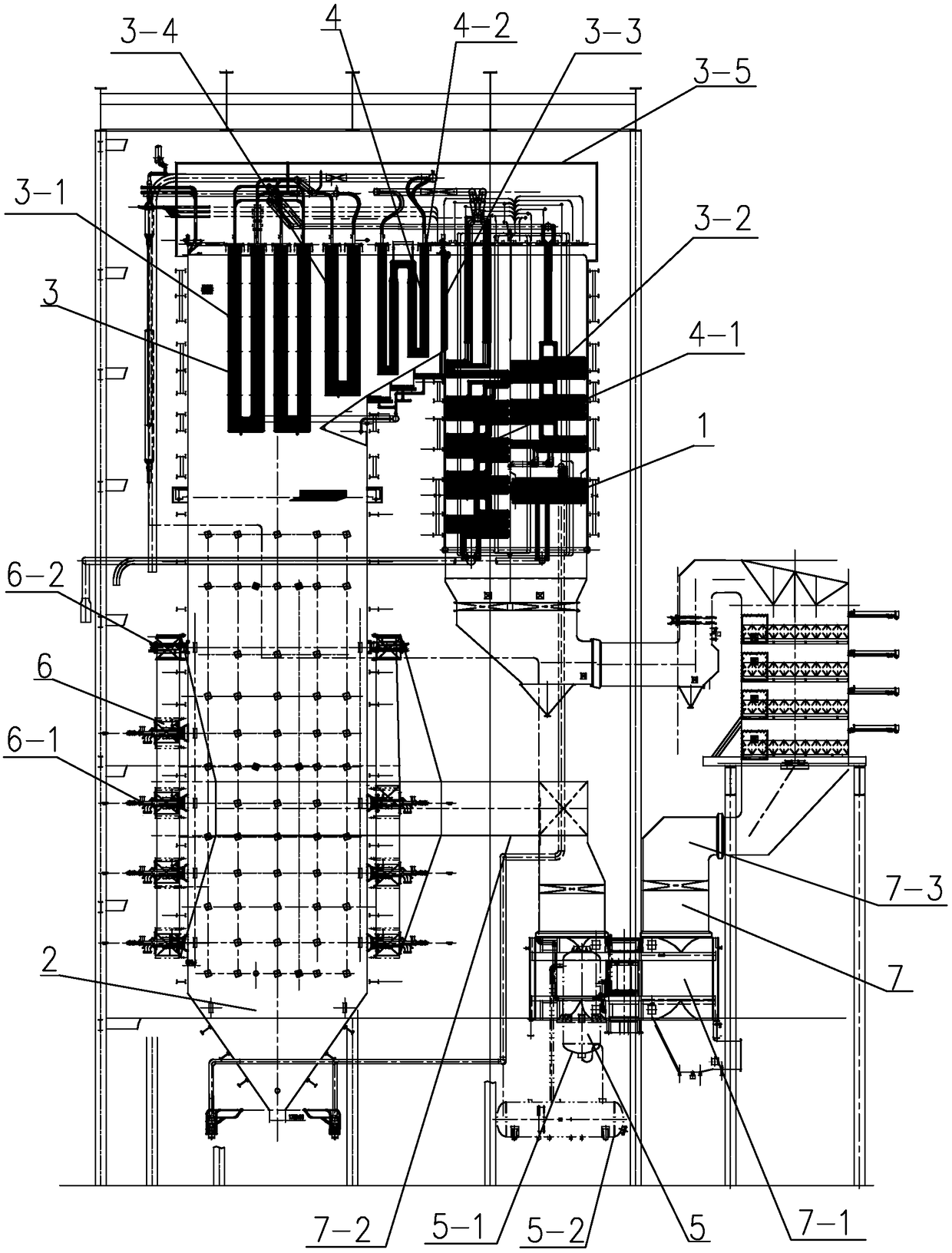

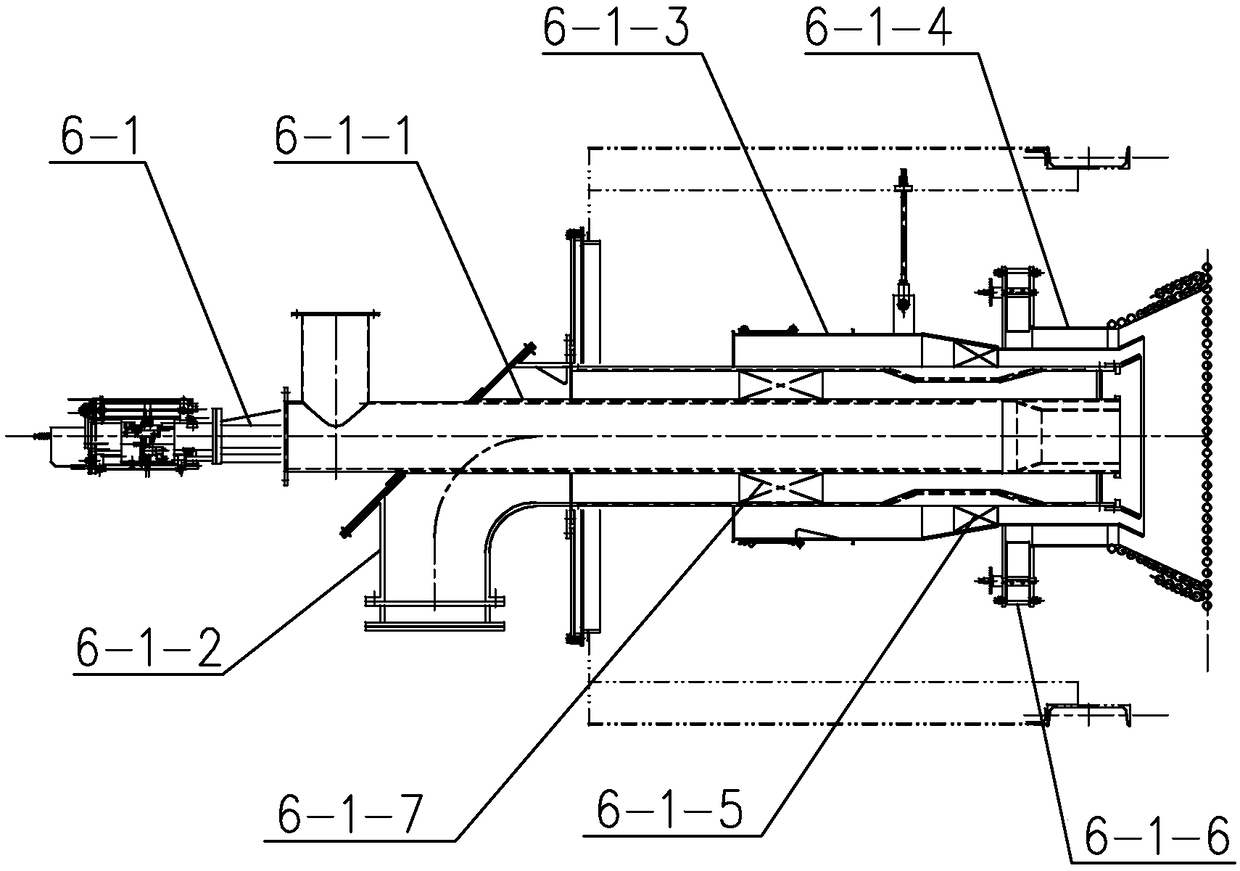

Supercritical boiler combusting ZhunDong coal of Xinjiang for realizing 660MW opposed combustion

PendingCN108758600AReduce heat loadReduce the temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSupercritical steam generatorCombustion system

The invention discloses a supercritical boiler combusting ZhunDong coal of Xinjiang for realizing 660MW opposed combustion, relates to a boiler, and aims at solving the problems that when ZhunDong coal of Xinjiang is combusted in an existing boiler, the boiler is shut down due to pipe explosion which is caused by coking 'bridging' in the boiler, so that the boiler faces great safety problem. The supercritical boiler disclosed by the invention comprises a coal economizer system, a water-cooling wall system, a superheater system, a reheater system, a start-up system, a combustion system, and a flue gas and air system, wherein the combustion system comprises a plurality of main combustors and a plurality of SOFA combustors; the plurality of main combustors and the plurality of SOFA combustorsare oppositely arranged at the two sides of a hearth separately and fixed to the water-cooling wall system, and the combustors are capable of forming opposed flame through combustion in the hearth; the superheater system comprises a ceiling enclosure wall superheater, a low-temperature superheater, a split-screen superheater, a finishing superheater and a header; and the start-up system is arranged on the flue gas and air system, the low-temperature superheater, the coal economizer system and the reheater system are arranged on the tail part of the hearth. The supercritical boiler disclosed by the invention is applicable to combustion for ZhunDong coal of Xinjiang.

Owner:HARBIN BOILER

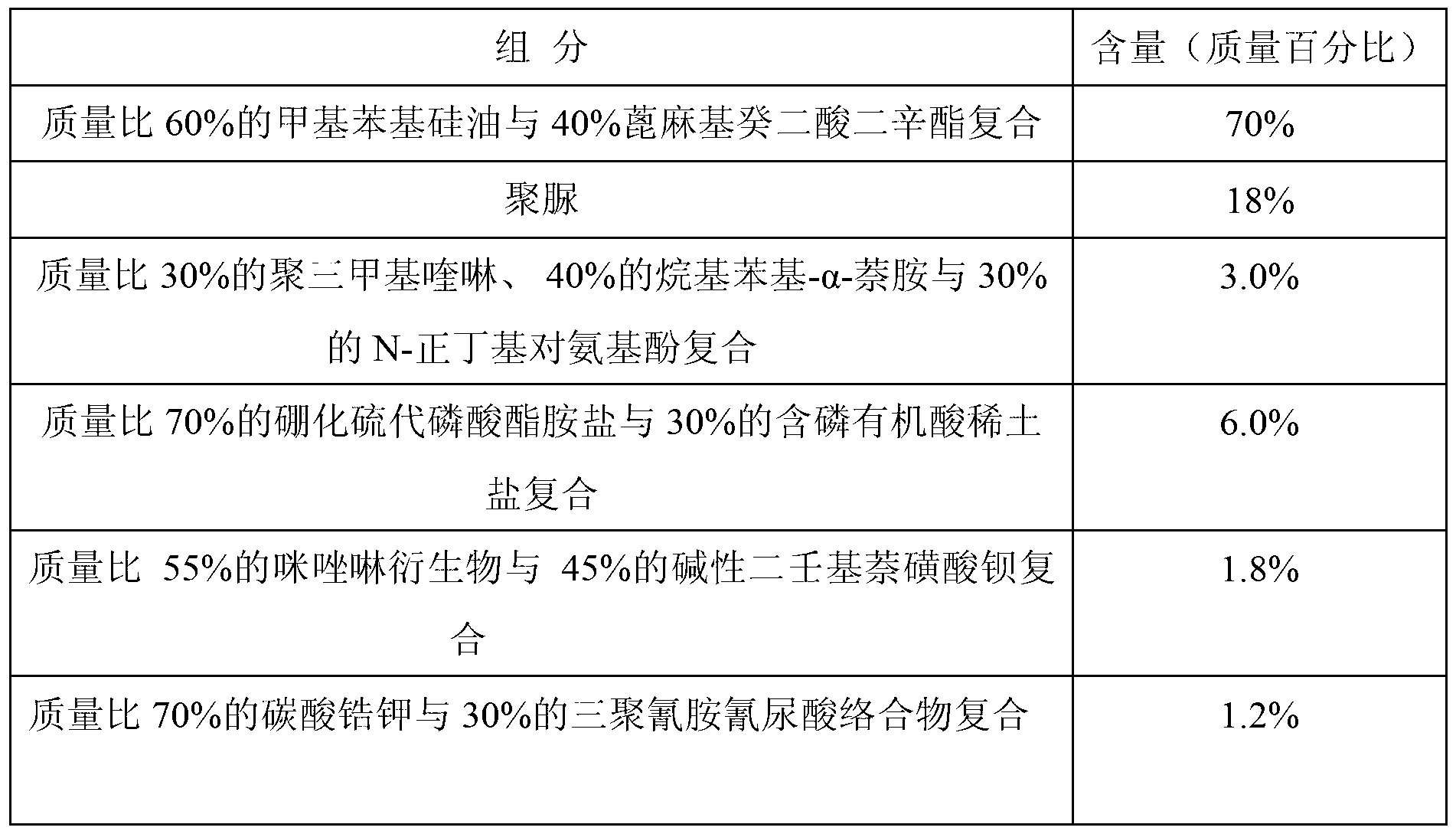

High-acid-resistance and high-corrosion-resistance grease special for sintering machine

ActiveCN103254988AImprove reliabilityReduce air leakage rateLubricant compositionBase oilSilicone oil

The invention discloses a high-acid-resistance and high-corrosion-resistance grease special for a sintering machine. The grease is composed of the following components by mass percent: 70-80% of base oil, 18-12% of thickening agent and 12-8% of other addition agents. Methyl phenyl silicone oil and castor-base dioctyl sebacate are compounded and taken as the base oil of the high-acid-resistance and high-corrosion-resistance grease special for the sintering machine; and polyurea is taken as the thickening agent. The obvious advantages of the high-acid-resistance and high-corrosion-resistance grease special for the sintering machine are as follows: each performance index meets use requirements, the grease special for the sintering machine has good high-temperature property, pumping property, sealing property, excellent lubricity and abrasion resistance, low coking tendency and outstanding corrosion resistance, the reliability of a bearing in the sintering machine is improved, the air leakage rate and energy consumption of the sintering machine are reduced, the service life and grease change period of the sintering machine are prolonged, and the grease is suitable for the lubrication and sealing of the sintering machine under high-temperature, high-load and corrosive environments.

Owner:GUANGXI UNIV

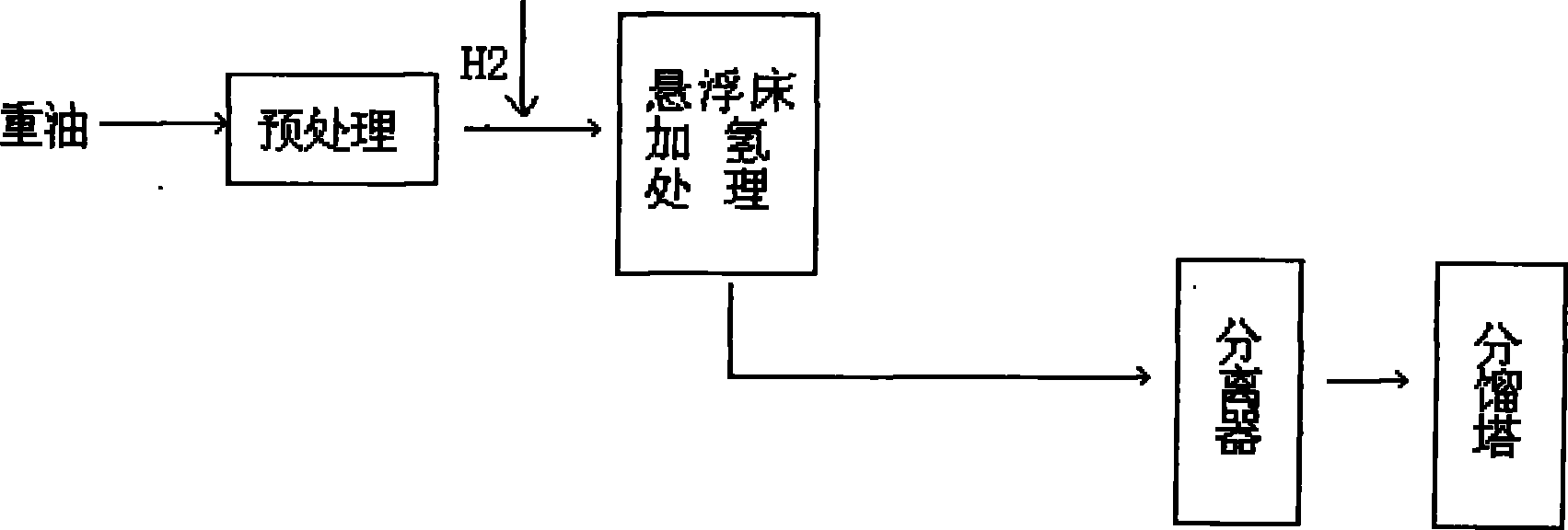

Heavy oil hydrogenation modifying method

ActiveCN102041047BReduce and ease harshnessEasy to operateHydrocarbon oil crackingFuel oilHydrogen supply

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

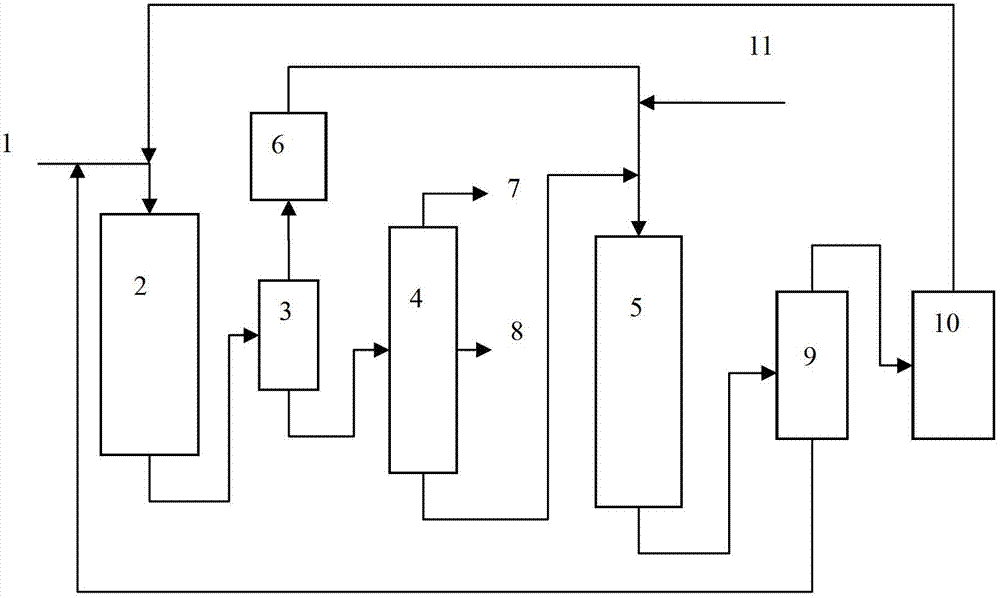

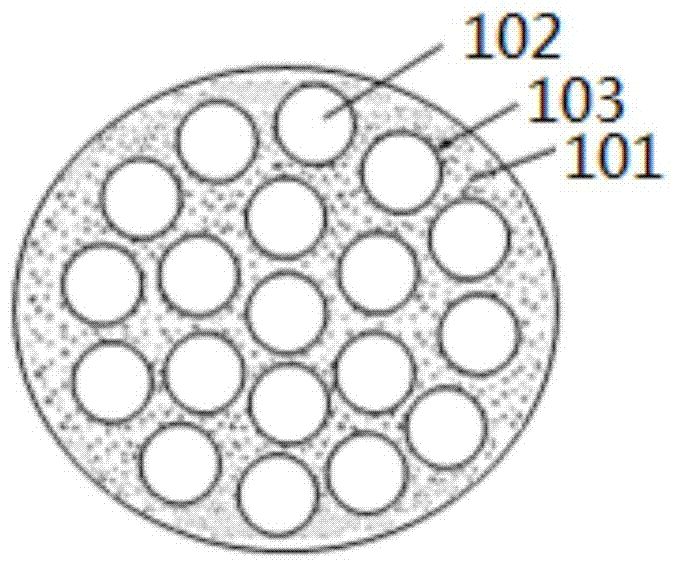

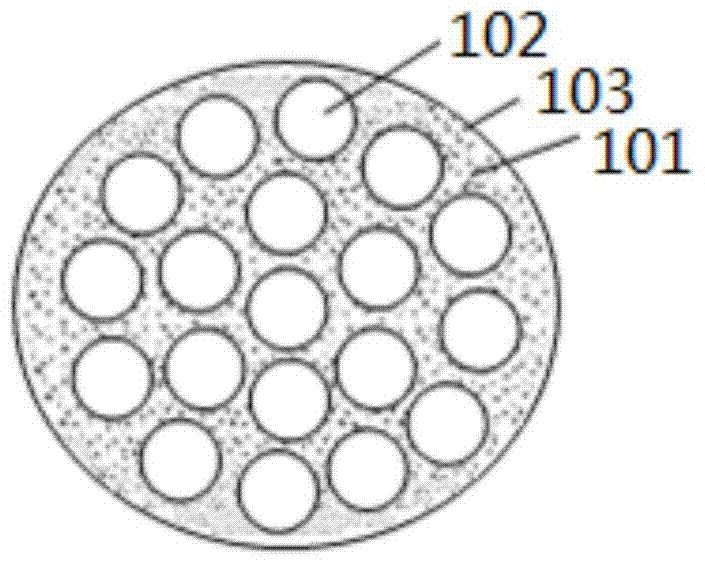

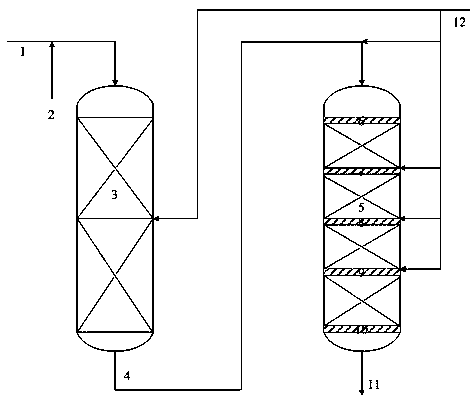

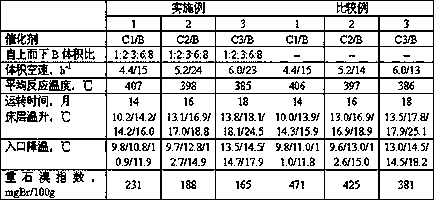

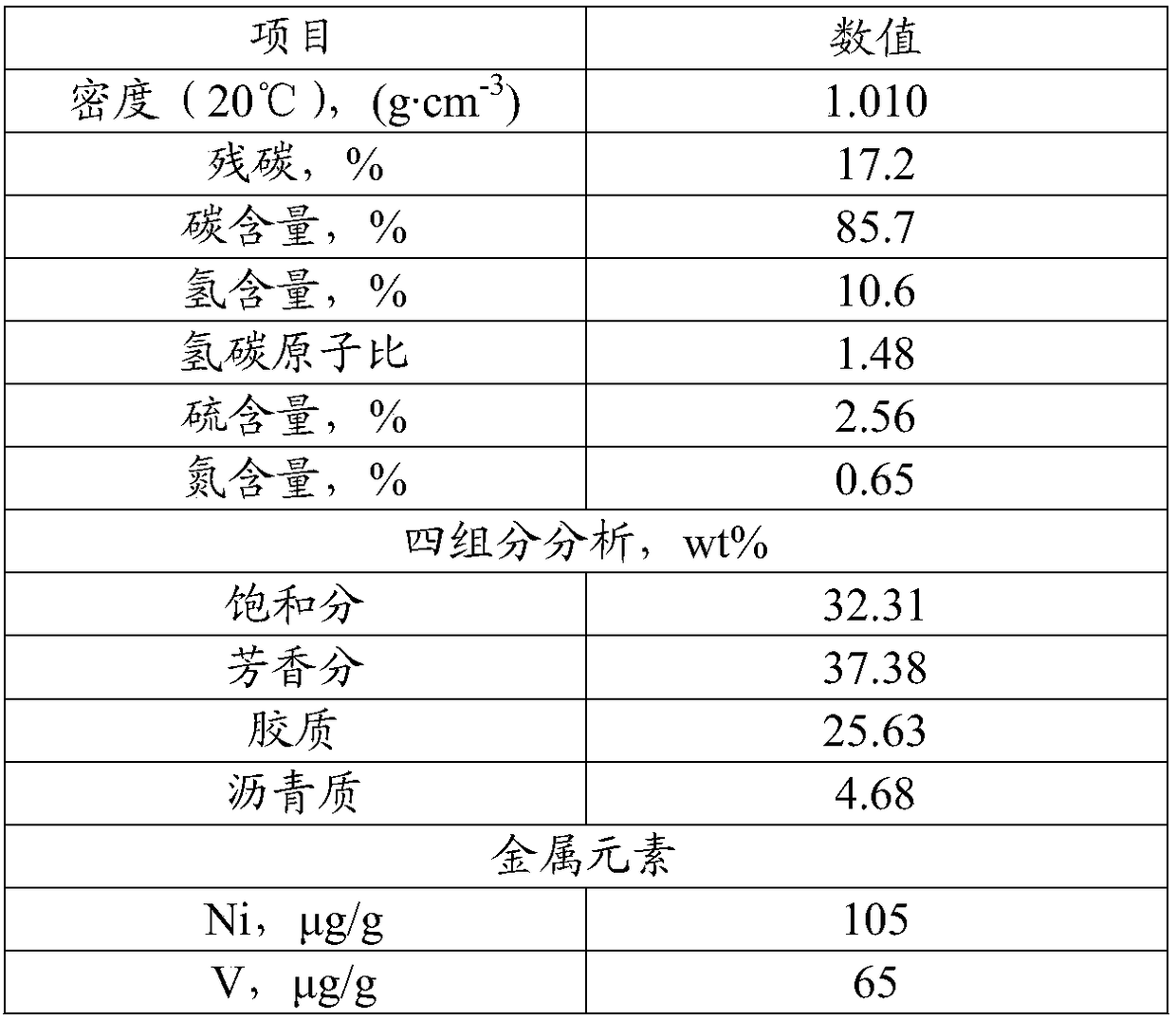

A kind of wax oil hydrogenation treatment method

ActiveCN104927902BIncrease the atomic ratio of hydrogen to carbonEfficient removalHydrocarbon oils treatmentWaxHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for prolonging quality stability of hydrocracking product

ActiveCN109777482ATendency to delay coking inactivationReduce acidityTreatment with hydrotreatment processesHydrogenPre treatment

The invention discloses a method for prolonging the quality stability of a hydrocracking product. The method comprises the following steps that hydrocracking raw materials and hydrogen gas are mixed to enter a hydrocracking pretreatment reactor for refining reaction; reaction effluents enter a hydrocracking reactor for hydrocracking reaction; four hydrocracking catalyst bed layers are arranged inthe hydrocracking reactor; when the conversion rate of fractions higher than 350 DEG C in hydrocracking raw materials is 90 to 99 percent, a hydrogenation posttreatment catalyst bed layer is arrangedat each of the top and the bottom of any one hydrocracking catalyst bed layer; the volume ratio of posttreatment catalysts filled along the material flow direction is (3 to 7):(5 to 15):(5 to 25):(20to 40):(30 to 50); the volume ratio of the hydrogenation posttreatment catalysts in the hydrocracking reactor to hydrocracking catalysts filled in the hydrocracking reactor is 1:(6 to 8); after hydrocracking products are separated, various products are obtained. By the method, the stability of the hydrocracking products can be obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving quality of hydrocracking products

ActiveCN109777485ATendency to delay coking inactivationReduce acidityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a method for improving the quality of hydrocracking products. The method comprises the following contents: a hydrocracking material and hydrogen are mixed and then enter a hydrocracking pretreatment reactor, so as to be subjected to refining reaction; a reaction effluent enters a hydrocracking reactor, so as to be subjected to hydrocracking reaction; a hydrogen aftertreatment catalyst is filled between the bottom of the hydrocracking reactor and beds of a hydrocracking catalyst; and a hydrocracking product is separated, so that various products are obtained. The methodcan solve the ubiquitous problems of high heavy naphtha bromine index, high mercaptan and excess aviation fuel product sulphur in middle and later stages of reaction in the process of hydrocracking reaction of aftertreatment catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

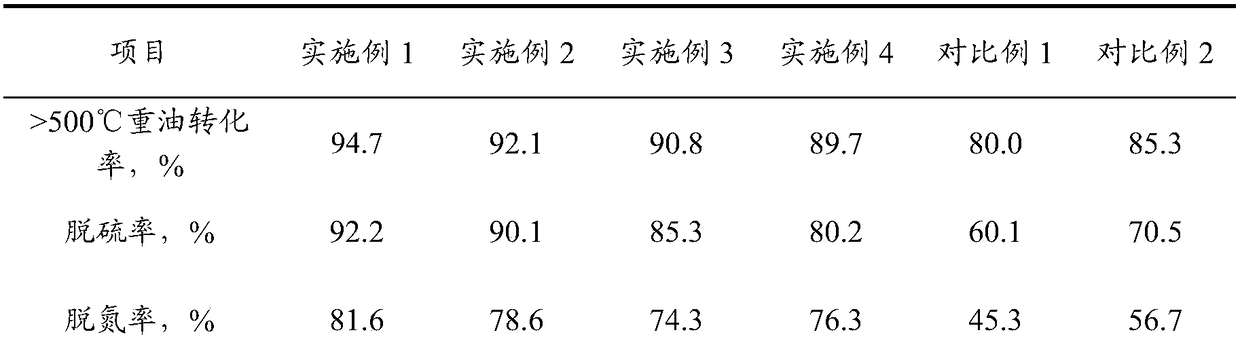

Heavy oil hydrocracking technology

ActiveCN108085057AImprove light conversion rateImprove qualityTreatment with hydrotreatment processesHydrogenHeteroatom

The invention belongs to the technical field of petrochemical industry, and relates to a hydrocracking technology. By a heavy oil hydrocracking technology provided by the invention, through addition of a hydrocracking catalyst and a hydrofinishing catalyst simultaneously in a hydrocracking reaction, in cooperation with supplementation of fresh hydrogen, the partial pressures of H2S and NH3 in a secondary hydrocracking reaction are reduced, and a hydrodesulfurization reaction and a hydrodenitrification reaction can be promoted to be reversely performed. The lightweight conversion rate of heavyoil is improved, and the desulfurization rate and the denitrification rate are greatly increased, so that an oil product with relatively high quality is directly and efficiently obtained. In allusionto the characteristics of components contained in the heavy oil, the time of inflating the secondary hydrogen and heating is further controlled, so that the reaction time is saved on the basis that amore easily cracked heavy oil component is hydrocracked as much as possible; through timely heating and supplementation of fresh hydrogen, hydrocracking and refinement of a heavy oil component which is more difficultly cracked for removing heteroatoms is promoted.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A kind of anti-coking type turbine oil and preparation method thereof

The invention relates to an anti-coking turbine oil, which is composed of hydrorefined base oil, synthetic base oil, extreme pressure antiwear agent, antioxidant, pour point depressant, demulsifier, and antifoam agent. The oil refers to API II and III base oils, the synthetic base oil is propylene oxide polyalkylene ether, the extreme pressure antiwear agent is a composition of ashless composite additive and acid sulfide, and the antioxidant is A mixture of sulfide-based liquid high molecular weight phenol, alkyl diphenylamine or derivatives thereof, the pour point depressant is polyalphaolefin, the demulsifier is a polyether demulsifier, and the antifoaming agent is a composite antifoam Foaming agent; by weight percentage, each component is composed of hydrorefined base oil 70‑95%, synthetic base oil 0‑30%, extreme pressure antiwear agent 0.3‑1.5%, antioxidant 0.5‑2%, pour point depressant 0.1‑1%, demulsifier 0.01‑0.05%, antifoam agent 0.01‑0.04%. The invention has excellent anti-coking tendency, is not easy to form black paint film at high temperature, and has excellent heat and oxidation stability.

Owner:辽宁海华科技股份有限公司

Delayed coking method and device

ActiveCN108587683BExtended operating cycleReduce coke sulfur contentThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productFractionating column

The invention belongs to the field of petrochemical industry and relates to a method for delayed coking and a device. The method for delayed coking, disclosed by the invention, comprises the steps: depressurized raw oil from a vacuum distillation tower enters an external-field strengthened reactor for strengthened desulfurization, a material from the external-field strengthened reactor enters a clustering strengthened reactor for a thermal cracking reaction, and a material from the clustering strengthened reactor enters a first gas-liquid separation unit for gas-liquid separation; and a gas-phase material separated by the first gas-liquid separation unit enters a coking fractionating tower, a liquid-phase material or a mixture of the liquid-phase material and coking circulating oil from the coking fractionating tower enters a buffer tank, a material from the buffer tank enters a heater for heating, and a material from the heater enters a second gas-liquid separation unit for gas-liquidseparation, and the like. According to the method and the device, the sulfur content of petroleum coke can be lowered, the yield of liquid product is increased, and technical problems, i.e., environmental pollution, poor petroleum coke product quality and low liquid product recovery rate caused by the existing high-sulfur petroleum coke can be overcome.

Owner:SINOPEC LUOYANG TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com