Supercritical boiler combusting ZhunDong coal of Xinjiang for realizing 660MW opposed combustion

A 660MW, supercritical boiler technology, applied in the boiler field, can solve the problems of boiler tube burst and shutdown, and achieve the effects of stable flame, low furnace heat load, and increased burnout height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

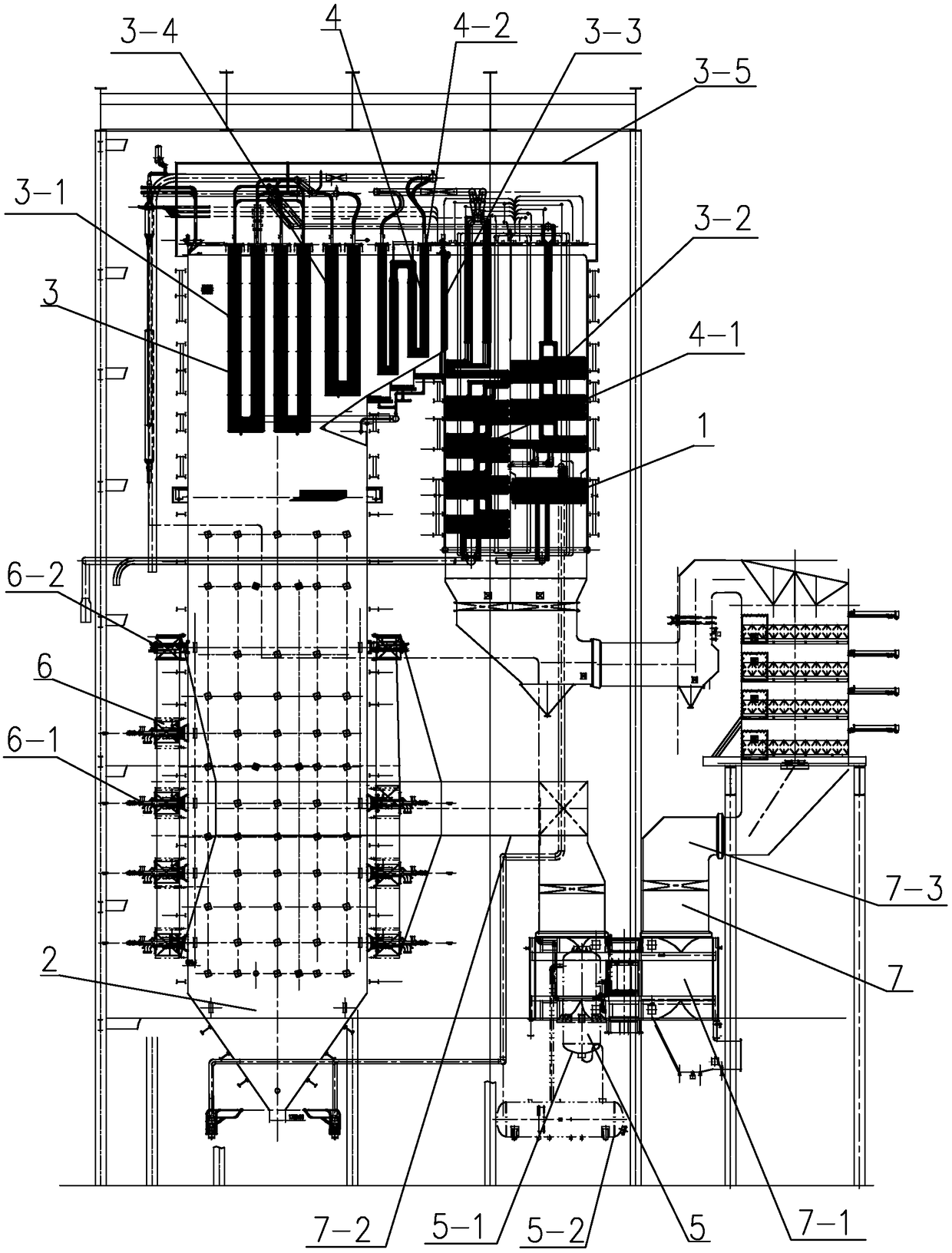

[0020] Specific implementation mode 1: Combination figure 1 with figure 2 To illustrate this embodiment, this embodiment includes an economizer system 1, a water wall system 2, a superheater system 3, a reheater system 4, a starting system 5, a combustion system 6 and a flue gas system 7;

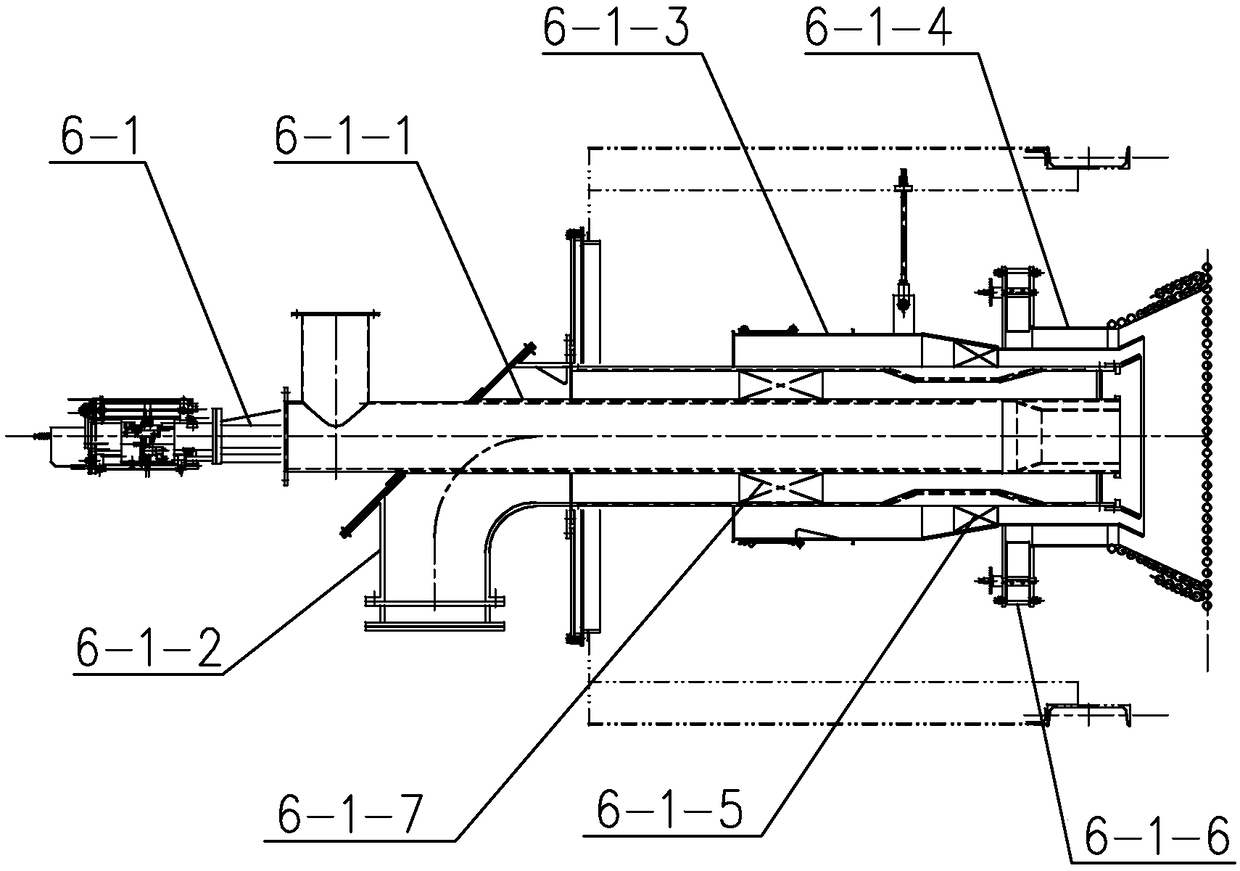

[0021] The combustion system 6 includes a plurality of main burners 6-1 and a plurality of SOFA burners 6-2;

[0022] A plurality of main burners 6-1 and a plurality of SOFA burners 6-2 are respectively arranged on both sides of the furnace and fixed on the water wall system 2, and the burners burn in the furnace to form an opposing flame;

[0023] Each main burner 6-1 includes central air pipe 6-1-1, coal feed pipe 6-1-2, secondary air pipe 6-1-3, tertiary air pipe 6-1-4, and secondary air cyclone Flow device 6-1-5, tertiary wind cyclone 6-1-6 and box body;

[0024] The central air pipe 6-1-1, the coal feed pipe 6-1-2, the secondary air pipe 6-1-3 and the tertiary air pipe 6-1-4 are set together...

specific Embodiment approach 2

[0028] Specific implementation manner two: combination figure 1 To describe this embodiment, the pipes of the economizer system 1 in this embodiment are smooth tubes or scale tubes arranged in series.

[0029] The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the reheater system 4 of this embodiment includes a low temperature reheater 4-1 and a final stage reheater 4-2;

[0031] The low-temperature reheater 4-1 and the low-temperature superheater 3-2 are arranged side by side at the end of the furnace, and the final reheater 4-2 is arranged near the outlet of the furnace.

[0032] The other composition and connection relationship are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com