Synthetic high temperature chain oil and preparation method thereof

A high-temperature chain and high-temperature antioxidant technology, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of insufficient high-temperature oxidation resistance and coking performance, and achieve the effect of improving high-temperature oxidation resistance and reducing the tendency of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of Organic Rare Earth A

[0032] In a 1.5L flask equipped with a stirrer, add 200ml of water, 335.5g (3.05mol) of thiophenol and 171g (3.05mol) of potassium hydroxide, stir and heat up to 90-95°C for 0.5 hours of constant temperature reaction, then Add 354.4 g (1 mole) of rare earth chloride and react at a constant temperature of 90-95°C for 1.5 hours. Cool to room temperature, filter, wash the solid with water until neutral, and then dry it in a constant temperature oven at 80-90°C to obtain an organic rare earth A compound.

Embodiment 2

[0033] Example 2 Preparation of Organic Rare Earth B

[0034] In a 1.5L flask equipped with a stirrer, add 200ml of water, 379.4g (3.05mol) of p-cresol and 171g (3.05mol) of potassium hydroxide, stir and heat up to 90-95°C for constant temperature reaction 1 Hours, then add 354.4 g (1 mole) of rare earth chloride and react at a constant temperature of 90-95°C for 2 hours. Cool to room temperature, filter, wash the solid with water until neutral, and then dry it in a constant temperature oven at 80-90°C to obtain the organic rare earth B compound.

Embodiment 3-5

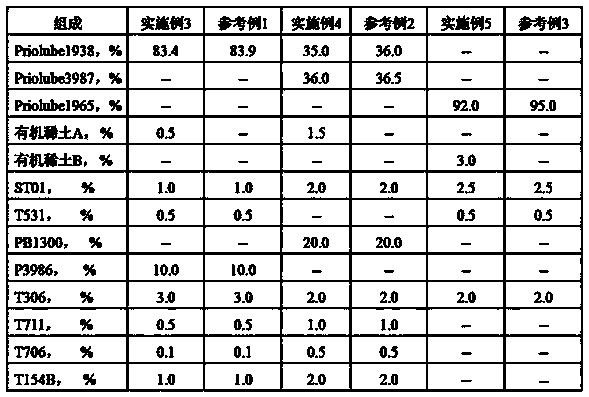

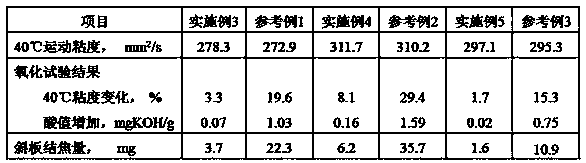

[0036] Prepared for synthetic ultra-high temperature chain oils. Examples 3-5 are prepared in the same way except that the composition of raw materials is different. The preparation method is: add base oil, organic rare earth, high-temperature antioxidant, extreme pressure anti-wear additive, rust inhibitor, metal deactivator and detergent dispersant into the mixing container, stir and heat up to 120-130°C, constant temperature stirring and dehydration After 1-1.5 hours, stop heating, stir and cool to 70-80°C, and filter to obtain the product. The composition of each embodiment is shown in Table 1, and the performance analysis results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com