Coal tar hydrogenation pretreatment method and coal tar hydrogenation treatment method

A technology of hydrotreating pretreatment and hydrotreating, which is applied in hydrotreating process, treating hydrocarbon oil, refining tar by chemical method, etc., can solve the problem of short operation cycle of catalyst bed device, and achieve long continuous operation cycle. , the effect of low density and low sulfur and nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

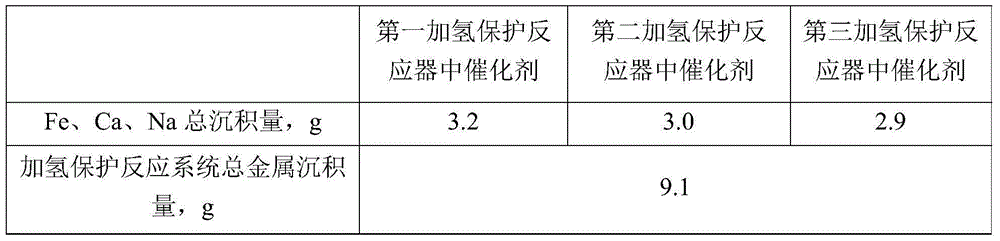

Embodiment 1

[0060] This embodiment is carried out in a coal tar hydrotreating device, and the hydrogenation protection system in this embodiment includes 3 hydrogenation protection reactors connected in series in sequence, and RGC-1 is all filled in these 3 hydrogenation protection reactors as Hydrogenation protection catalyst, the loading amount is 20mL; the hydrogenation main reactor is filled with 100mL of the main hydrogenation refining catalyst RTC-2; the temperature of the high-temperature hydrogenation tail oil is 350 ° C, and the low-temperature hydrogenation tail The temperature of the oil was 60°C.

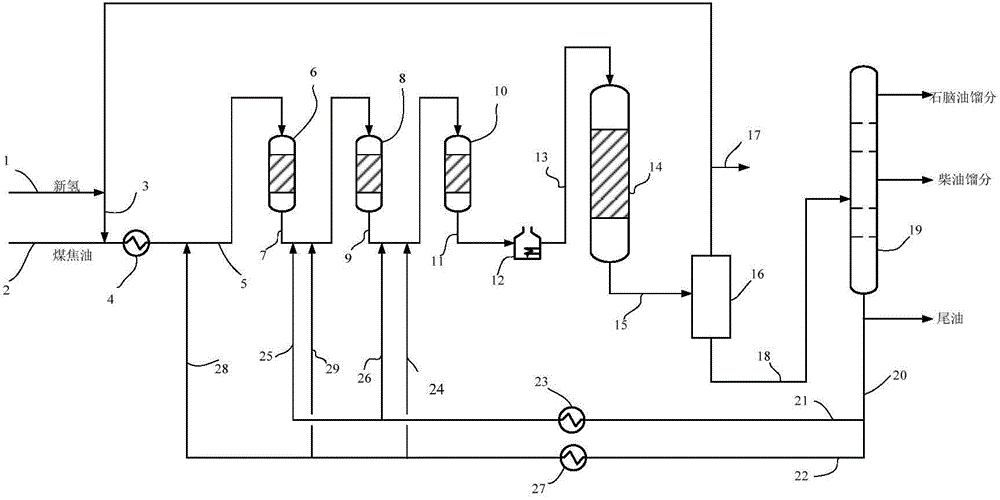

[0061] This embodiment adopts as figure 1 The process method shown is carried out, specifically:

[0062]The circulating hydrogen in the device is mixed with the new hydrogen from pipeline 1, then mixed with the coal tar raw material from pipeline 2 through pipeline 3, and mixed with the high-temperature hydrogenated tail oil from pipeline 28 after heat exchange in heat exchanger 4...

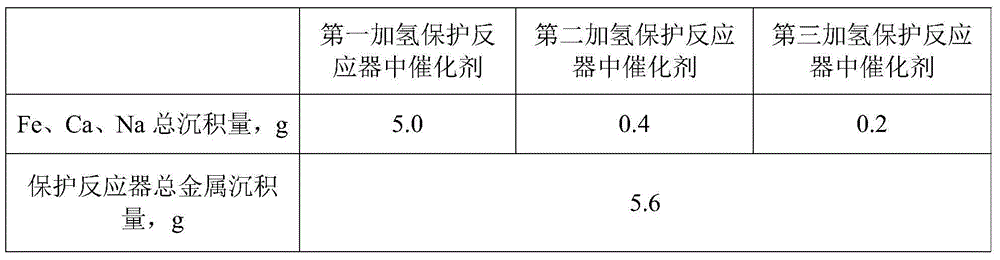

Embodiment 2

[0090] Present embodiment adopts the method similar to embodiment 1 to carry out, and difference is:

[0091] Each hydrogenation protection reactor adopts the following operating conditions when the device is running, specifically:

[0092] The first stage: the temperature of the first hydrogenation protection reactor is 300°C, the temperature of the second hydrogenation protection reactor is 160°C; the temperature of the third hydrogenation protection reactor is 160°C, and the hydrogenation main reaction The temperature of the reactor is 400°C; the pressure in the hydrogenation protection reaction system and the hydrogenation main reactor is 18MPa, and the liquid hourly volume space velocity is 1.2h -1 , the volume ratio of hydrogen to oil is 1200:1; the amount of the high-temperature hydrogenation tail oil introduced from the pipeline before the first hydrogenation protection reactor makes the high-temperature hydrogenation tail oil and the material in the hydrogenation prot...

Embodiment 3

[0101] Present embodiment adopts the method similar to embodiment 1 to carry out, and difference is:

[0102] Each hydrogenation protection reactor adopts the following operating conditions when the device is running, specifically:

[0103] The first stage: the temperature of the first hydrogenation protection reactor is 250°C, the temperature of the second hydrogenation protection reactor is 140°C; the temperature of the third hydrogenation protection reactor is 140°C, the hydrogenation main reaction The temperature of the reactor is 380°C; the pressure in the hydrogenation protection reaction system and the hydrogenation main reactor is 12MPa, and the liquid hourly volume space velocity is 0.9h -1 , the volume ratio of hydrogen to oil is 800:1; the amount of the high-temperature hydrogenation tail oil introduced from the pipeline before the first hydrogenation protection reactor makes the high-temperature hydrogenation tail oil and the material in the hydrogenation protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com