Full wax oil under-refluxing overheat-removing and circulation ratio quantitative controlling coking-retarding apparatus and method

A delayed coking method and delayed coking technology, applied in the field of delayed coking devices, can solve the problems of low separation precision of coking wax oil and circulating oil, high residual carbon and dry point of wax oil, fluctuation of circulation ratio, etc., and achieve reduction of residual carbon and Dry point, large reflux flow under wax oil, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

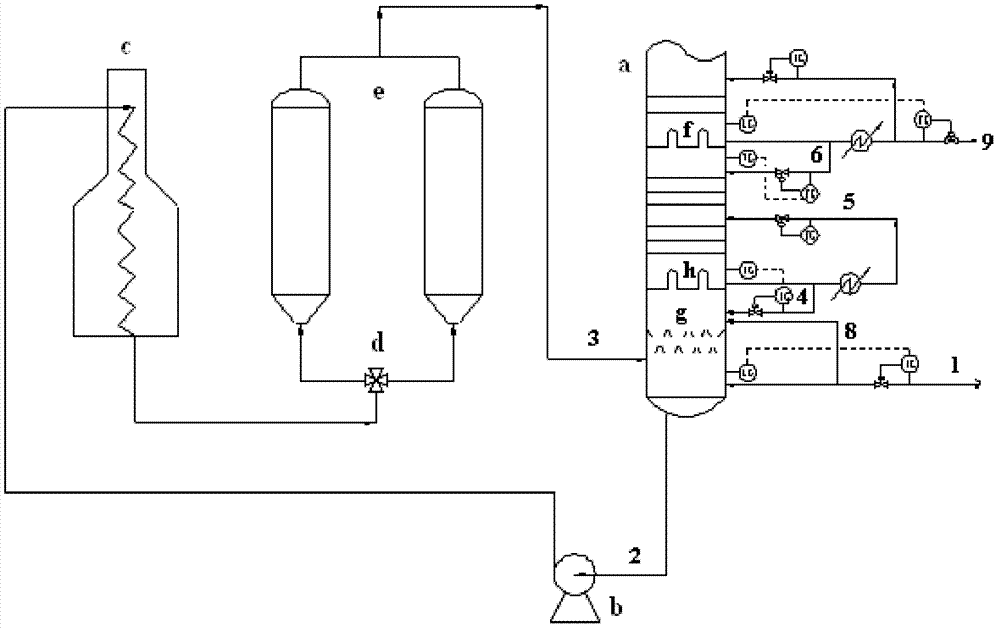

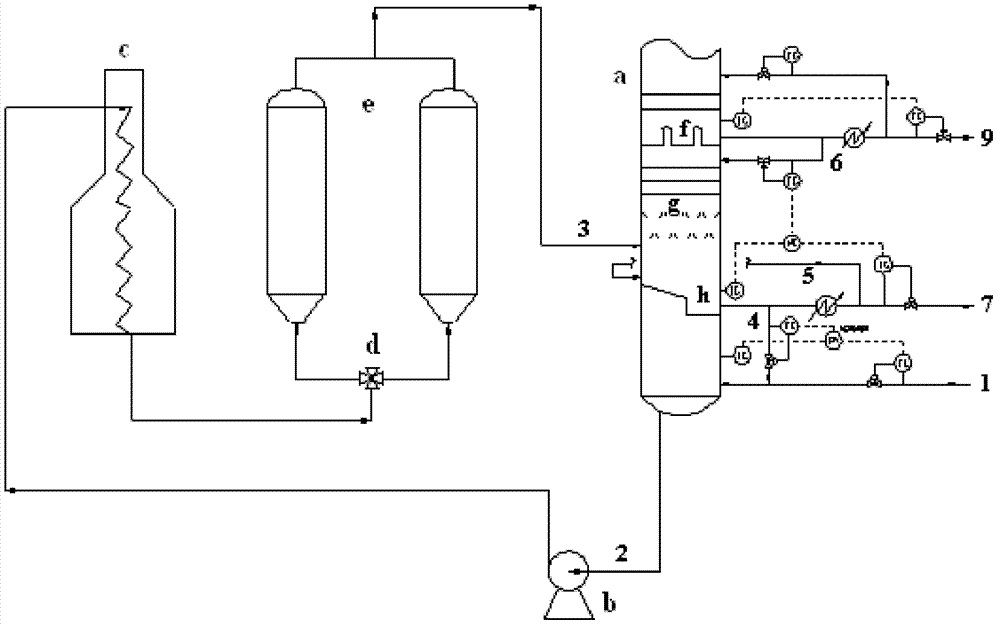

[0036] Such as figure 2As shown, a delayed coking device with full wax oil under reflux to desuperheat and quantitative control of circulation ratio, including heating furnace c, coke tower e and fractionating tower a connected in sequence, the outlet at the bottom of fractionating tower a is connected to heating furnace c The feed port is connected, the heat exchange baffle g in the fractionation tower a is set between the wax oil collection tank f and the heavy oil collection tank h, and the high-temperature oil and gas inlet is set under the heat exchange baffle g; a stirrer is set at the bottom of the fractionation tower a ; The bottom of the fractionation tower a is equipped with a bottom circulation system and a filter, and a filter is set before the circulating oil is mixed with the raw oil.

[0037] After heat exchange, coking raw oil 1 is mixed with circulating oil 4 and enters the bottom of fractionation tower a. Coking oil 2 is pumped out from the bottom of fractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com