Process for viscosity breaking of deoiled asphalt

A technology of visbreaking and deoiling asphalt, which is applied in the direction of cracking, catalytic cracking, non-catalytic thermal cracking, etc., and can solve the problems of increasing costs and expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

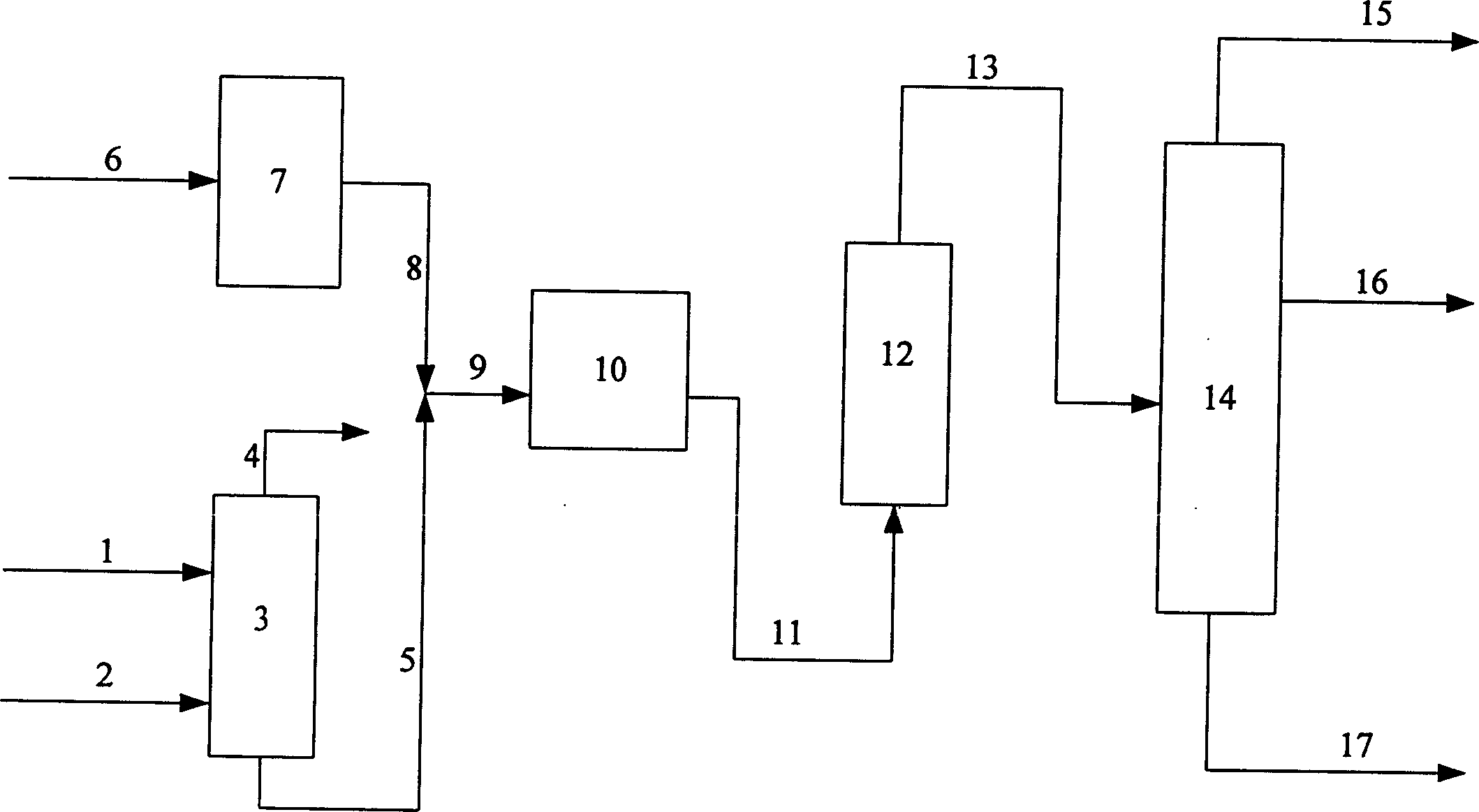

Method used

Image

Examples

Embodiment 1

[0026] The raw material for solvent deasphalting used in this example is vacuum residue A, and the vacuum residue A is deasphalted with propane to obtain deoiled asphalt, and the yield of deoiled asphalt is 50m%. The properties of vacuum residue A and deoiled bitumen are shown in Table 1 and Table 2, respectively. It can be seen from Table 2 that the kinematic viscosity of deoiled asphalt at 100°C is 5 times that of vacuum residue A, the crackable component saturated hydrocarbon is only 15.4m%, and the colloid is as high as nearly 50m%.

[0027] After the catalytic cracking oil slurry is settled in the settling tank at 150°C for 48 hours, the ash content is reduced by 75%, and the metal aluminum content is reduced by more than 80%. The catalytic cracking clarified oil and the above-mentioned deoiled asphalt were mixed according to the weight ratio of 0.042:1, and then visbreaking was carried out. The visbreaking test was carried out on a medium-sized visbreaking device with a ...

Embodiment 2

[0029] Visbreaking test was carried out after mixing the catalytic cracking decant oil and deoiled asphalt in Example 1 at a weight ratio of 0.087:1. The properties of the mixture of FCC clarified oil and deoiled asphalt are shown in Table 3, and Table 4 shows the visbreaking process conditions and material balance of the mixture. Table 5 shows the properties of the visbroken residue. It can be seen from Table 5 that the viscosity (100°C) of deoiled asphalt has dropped to 118.3mm 2 / s, the effect of reducing viscosity is obvious.

Embodiment 3

[0031] The visbreaking test was carried out after mixing the catalytic cracking decant oil and deoiled bitumen in the weight ratio of 0.111:1 in Example 1. The properties of the mixture of FCC clarified oil and deoiled asphalt are shown in Table 3, and Table 4 shows the visbreaking process conditions and material balance of the mixture. Table 5 shows the properties of the visbroken residue. It can be seen from Table 5 that the viscosity (100°C) of deoiled asphalt has dropped to 105.8mm 2 / s, the effect of reducing viscosity is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com