Patents

Literature

65results about "Treatment with hydrogen-generating compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

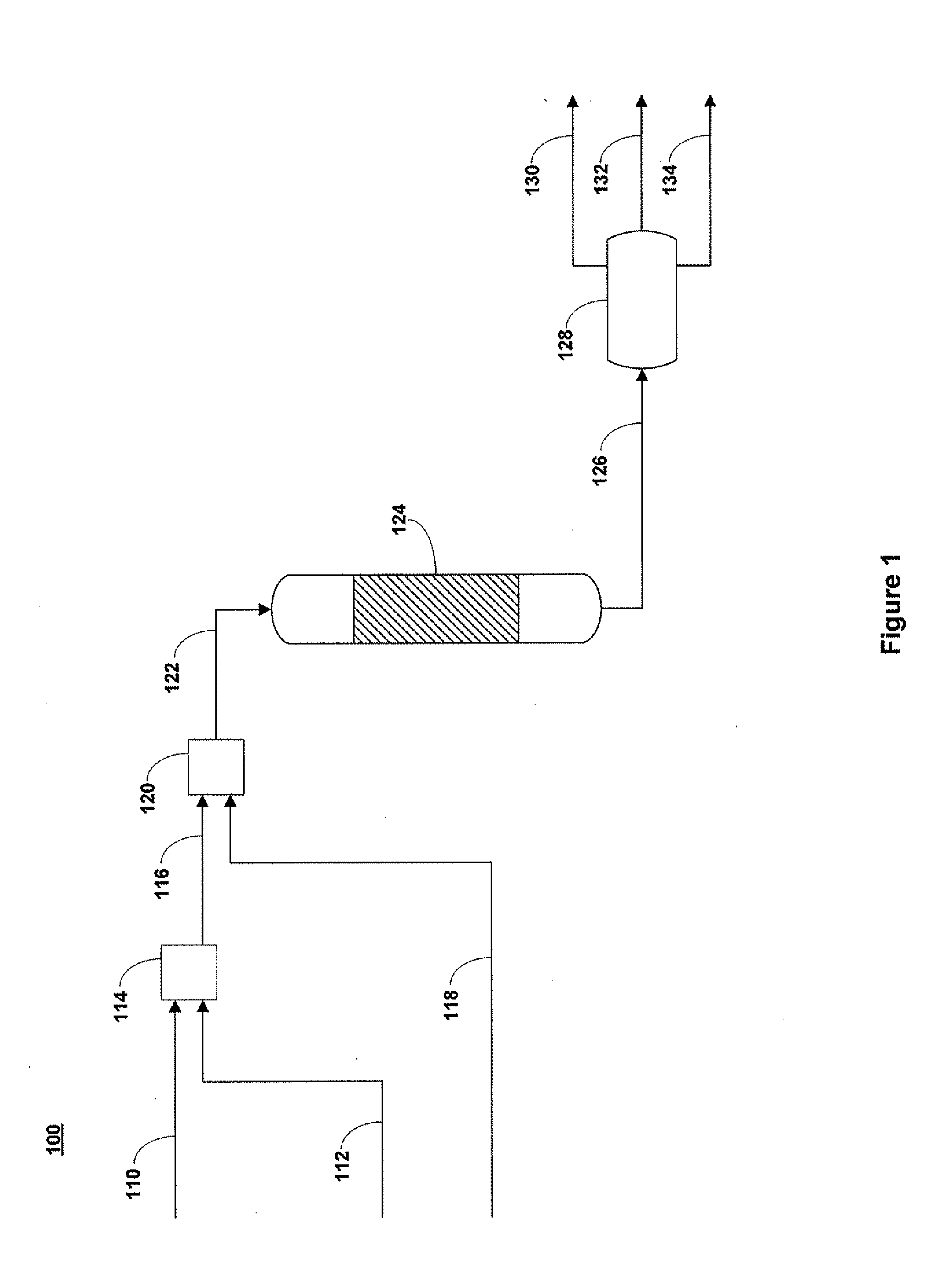

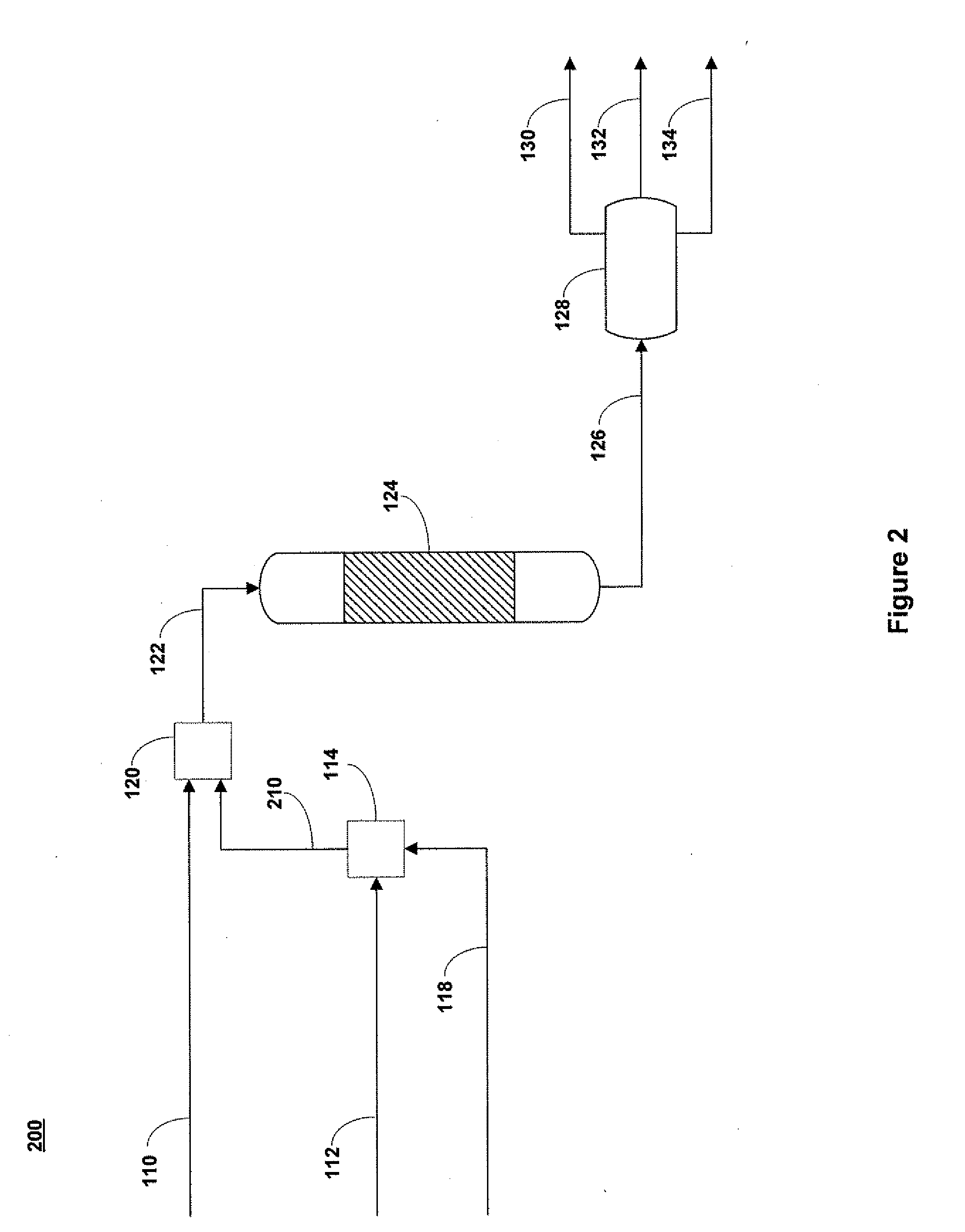

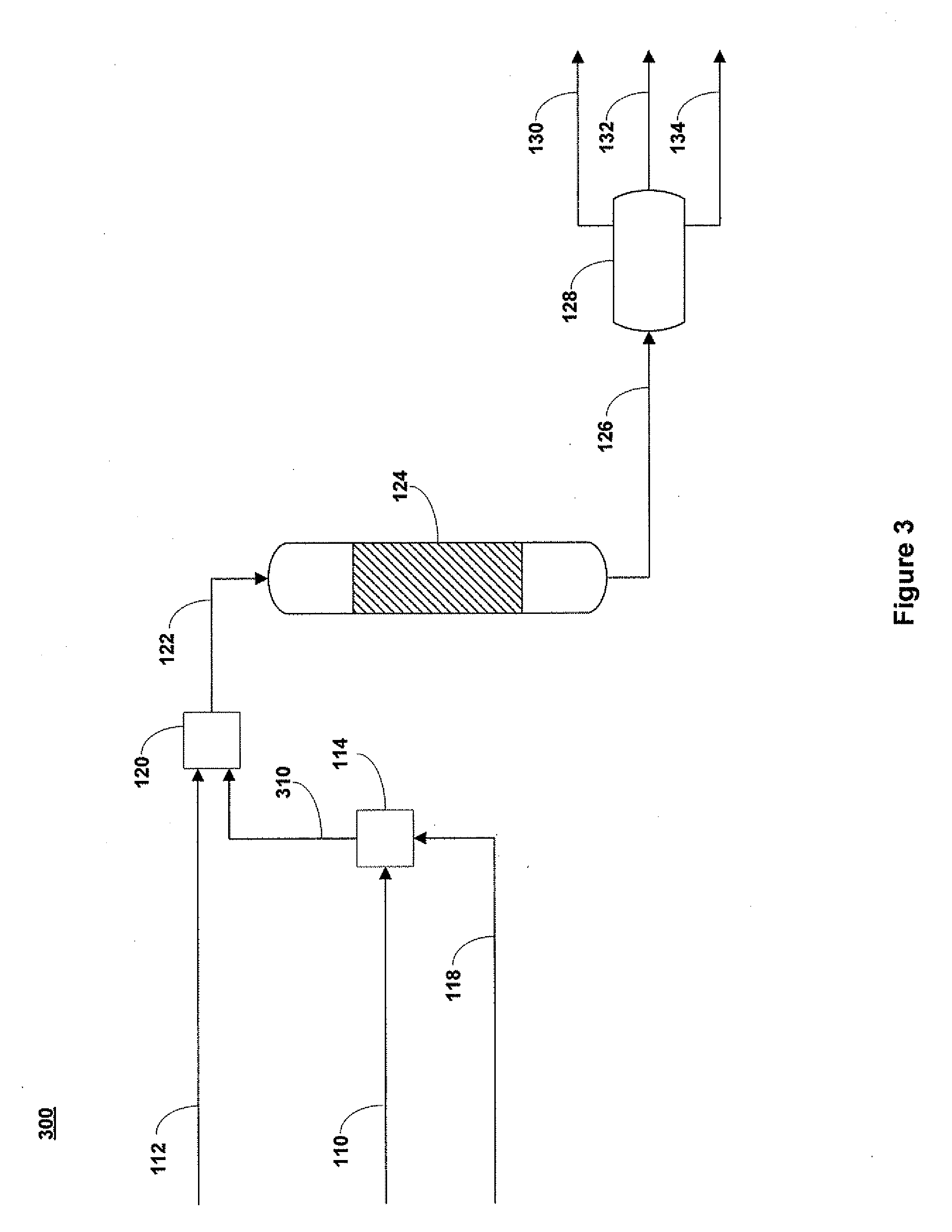

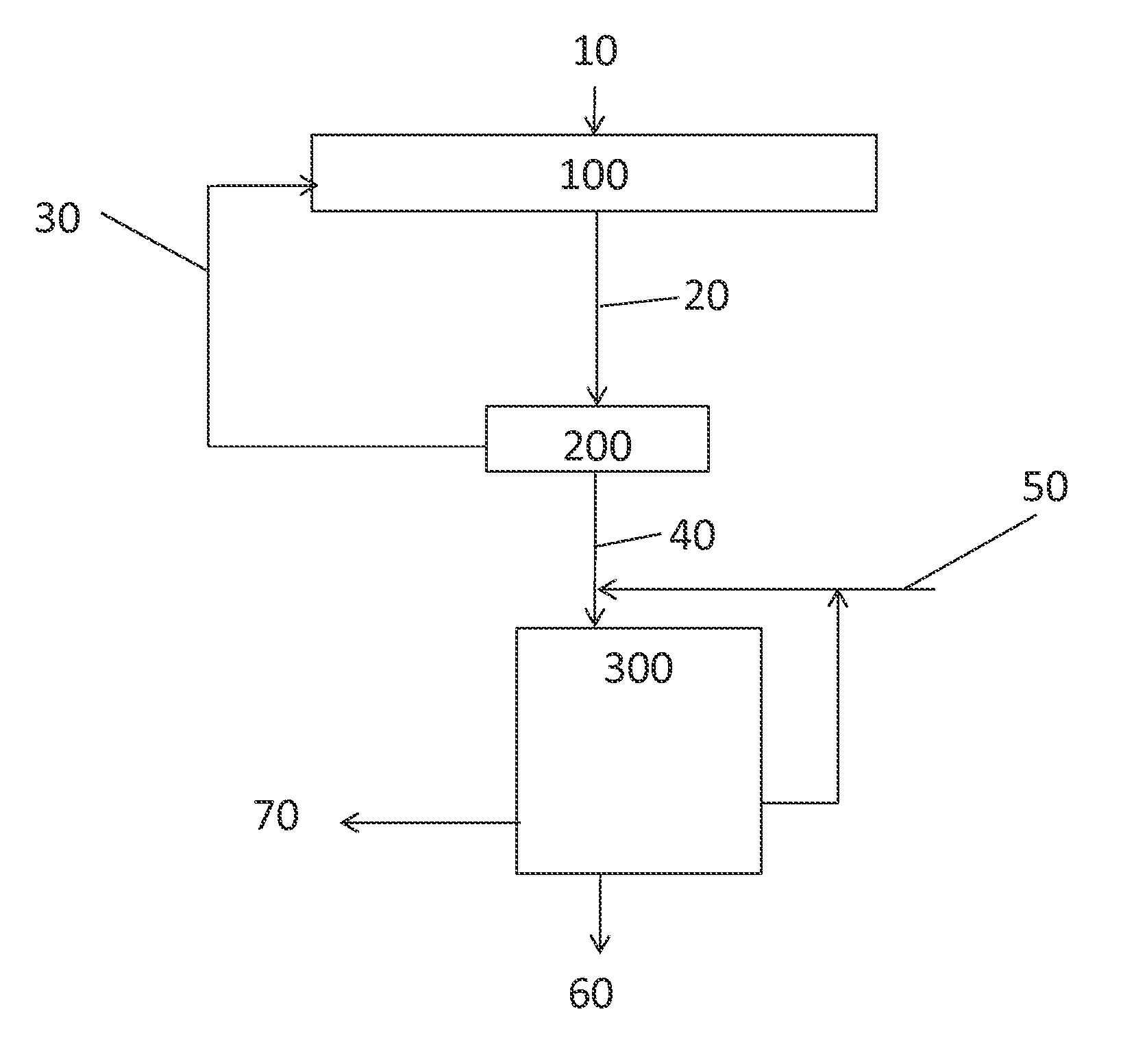

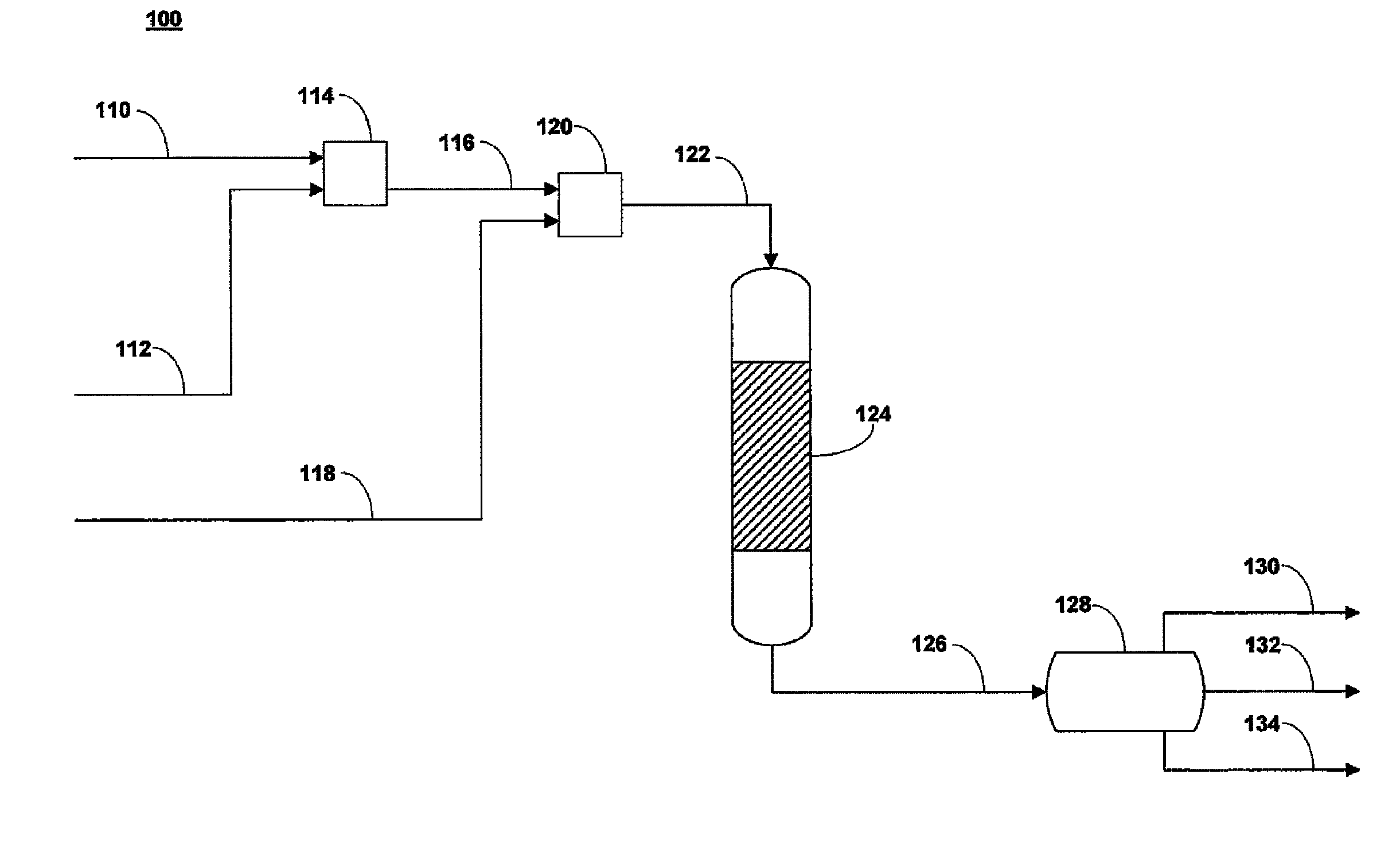

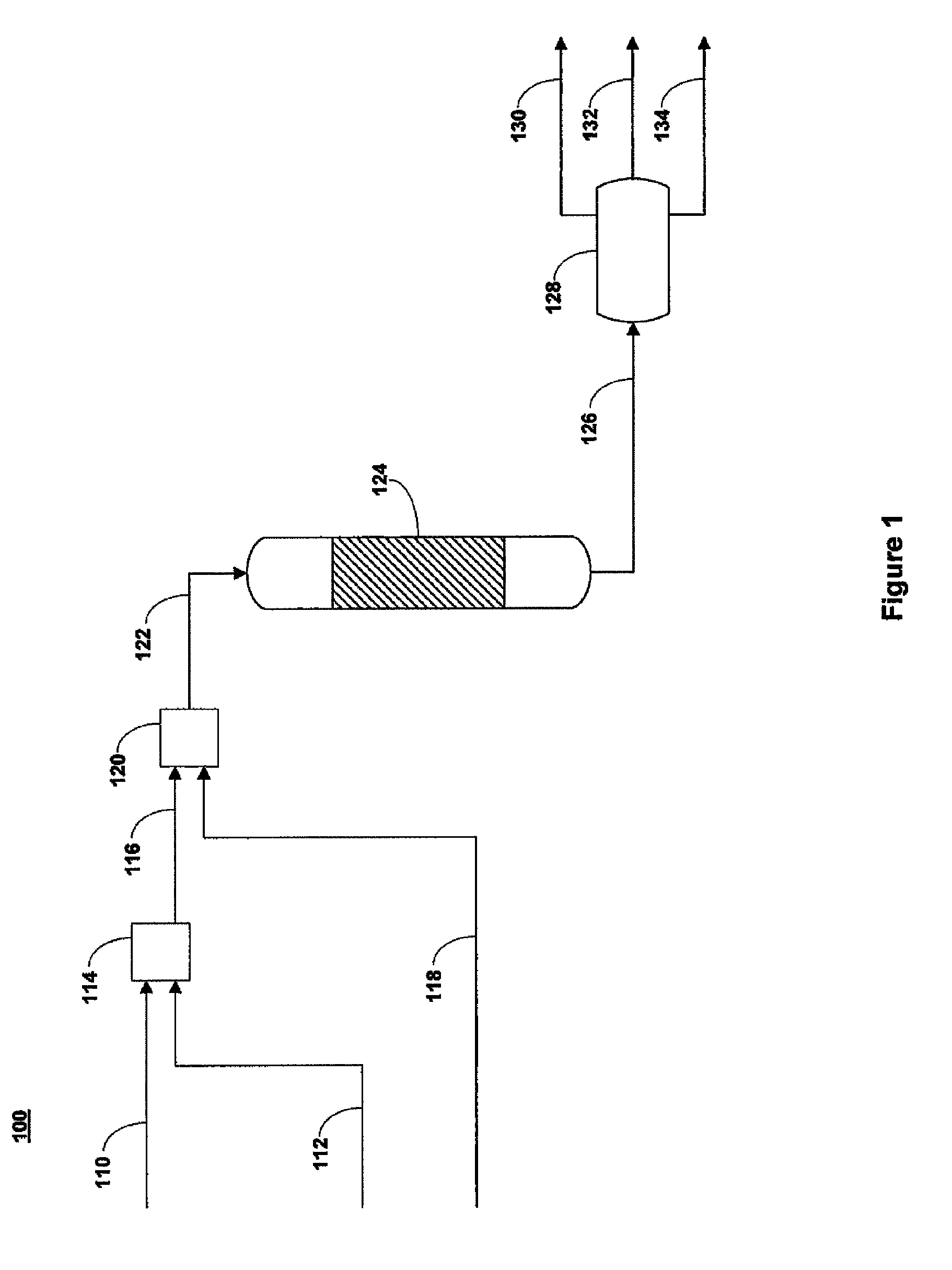

Upgrading of Hydrocarbons by Hydrothermal Process

ActiveUS20120061291A1Good physical propertiesLow costThermal non-catalytic crackingTreatment with plural serial cracking stages onlyHydrogenWater flow

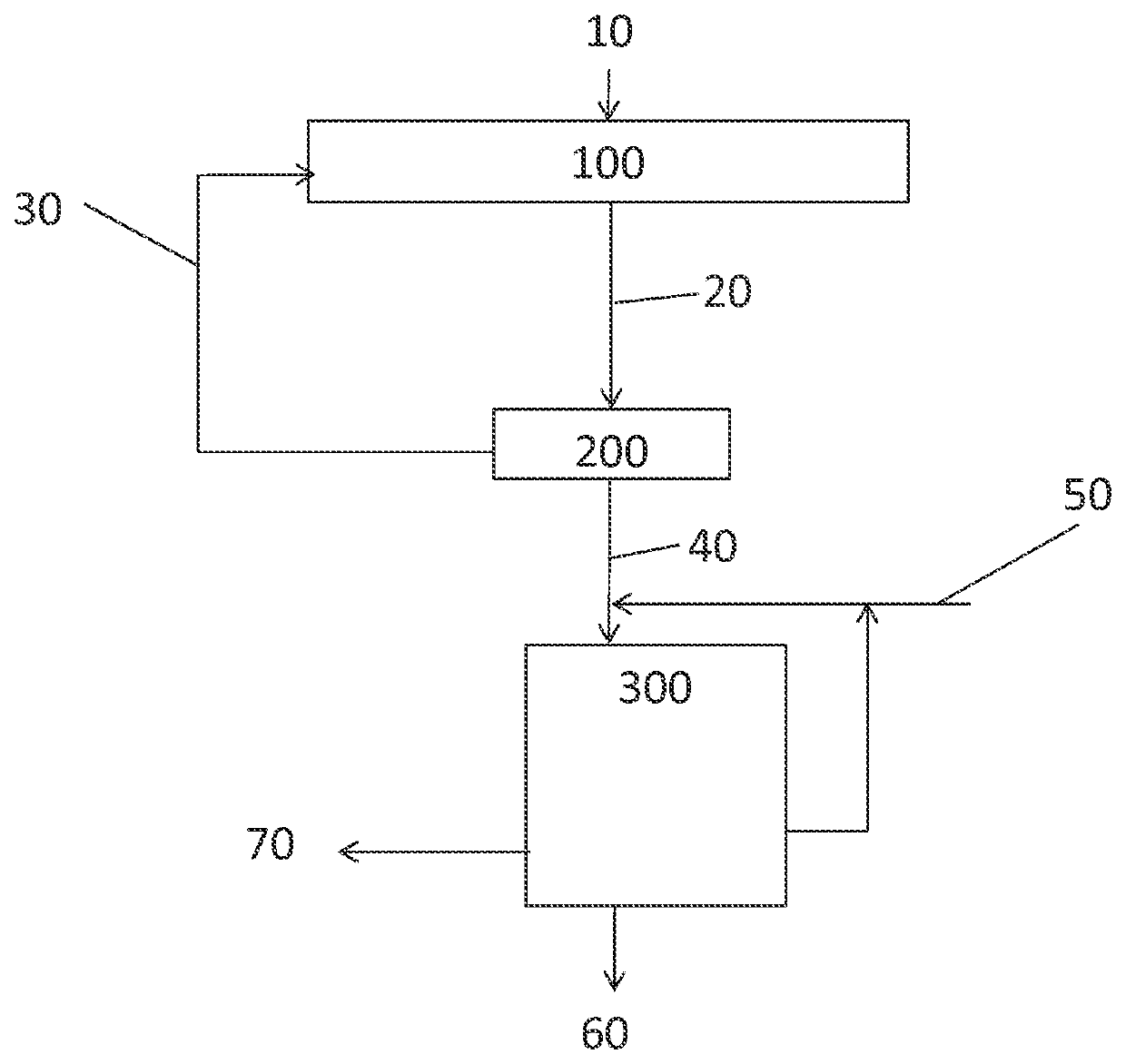

A hydrocarbon feedstock upgrading method is provided. The method includes supplying the hydrocarbon feedstock, water and a pre-heated hydrogen donating composition to a hydrothermal reactor where the mixed stream is maintained at a temperature and pressure greater than the critical temperatures and pressure of water in the absence of catalyst for a residence time sufficient to convert the mixed stream into a modified stream. The hydrogen donating composition is pre-heated and maintained at a temperature of greater than about 50° C. for a period of at least about 10 minutes. The modified stream includes upgraded hydrocarbons relative to the hydrocarbon feedstock. The modified stream is then separated into a gas stream and a liquid stream and the liquid stream is separated into a water stream and an upgraded hydrocarbon product stream.

Owner:SAUDI ARABIAN OIL CO

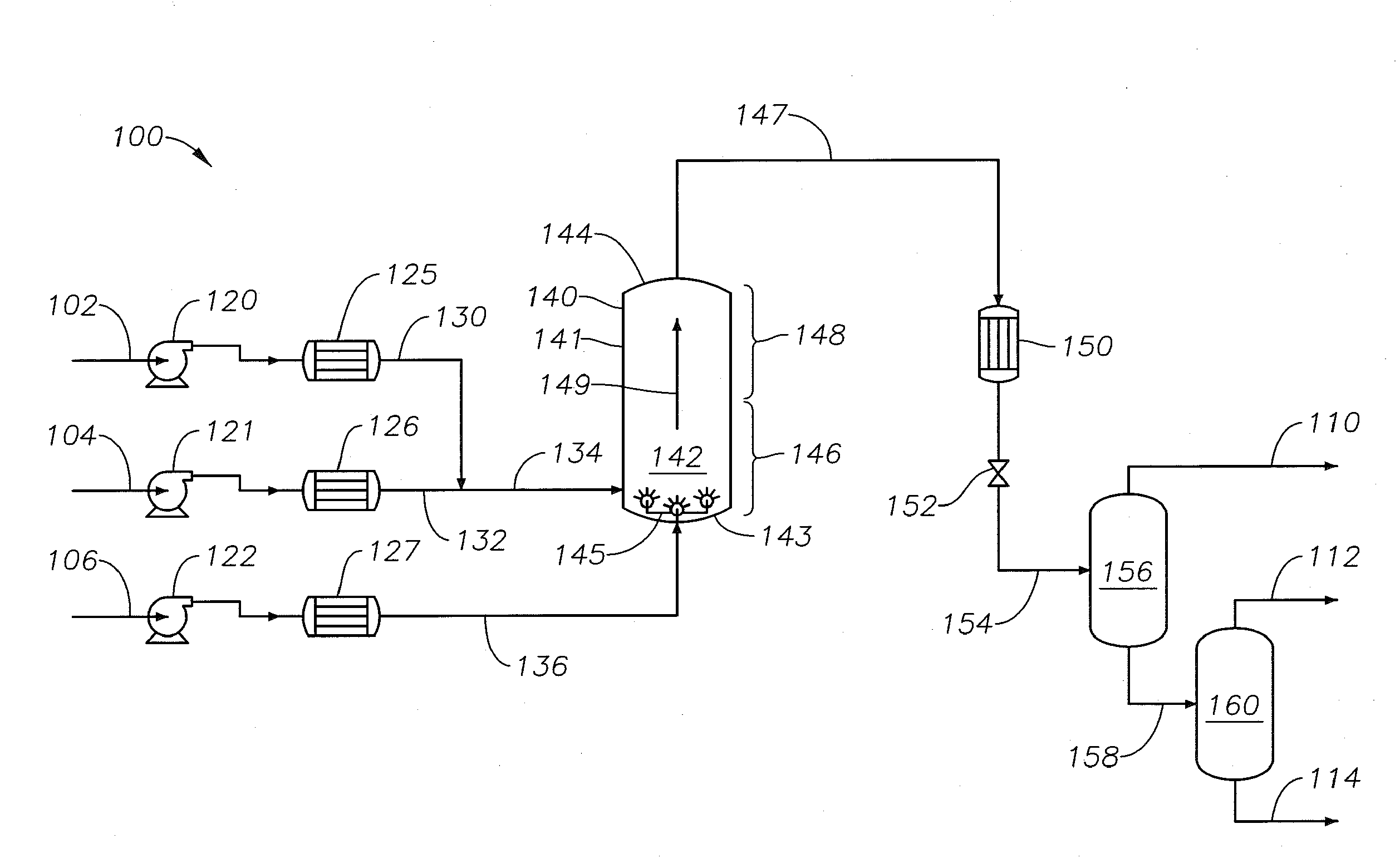

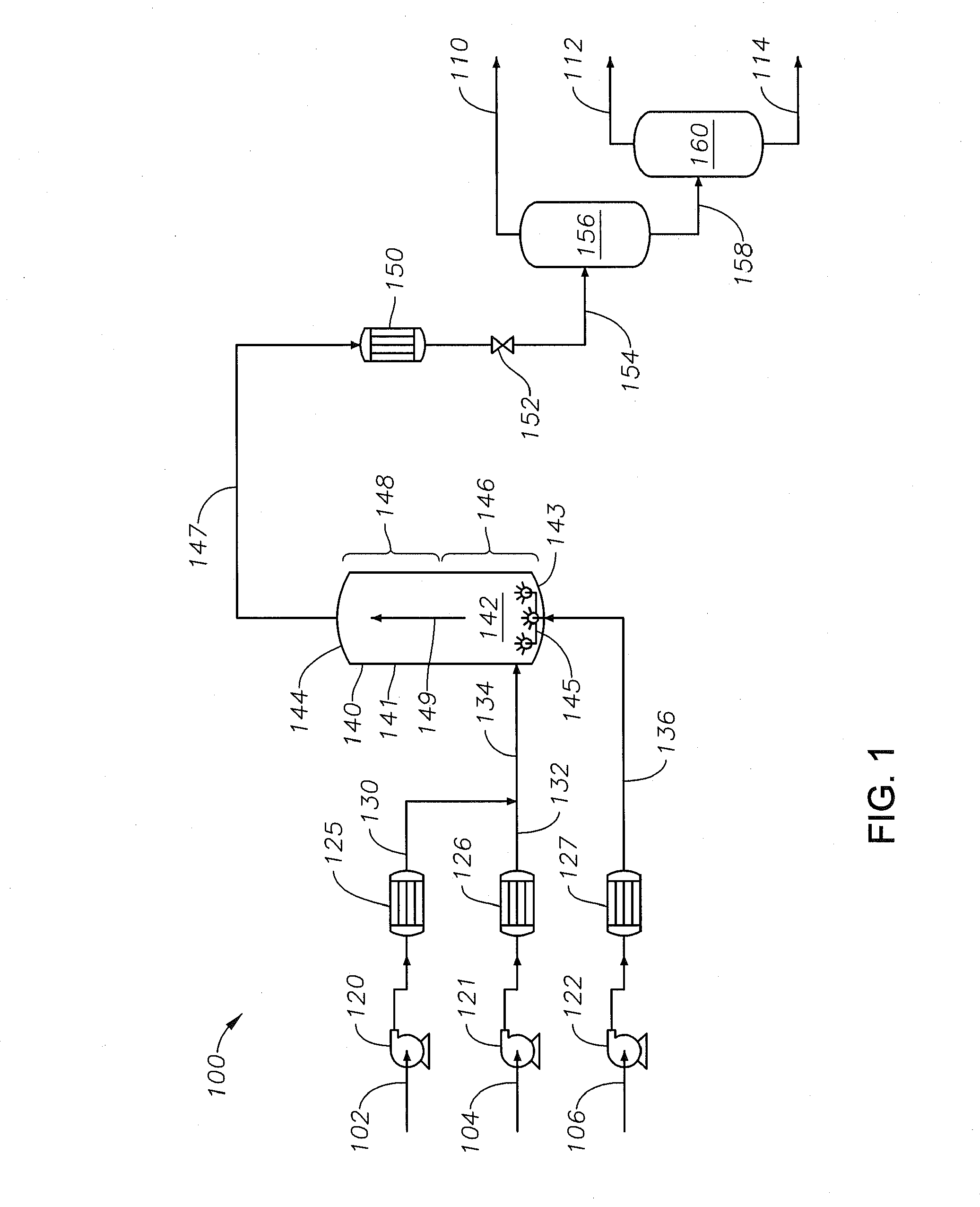

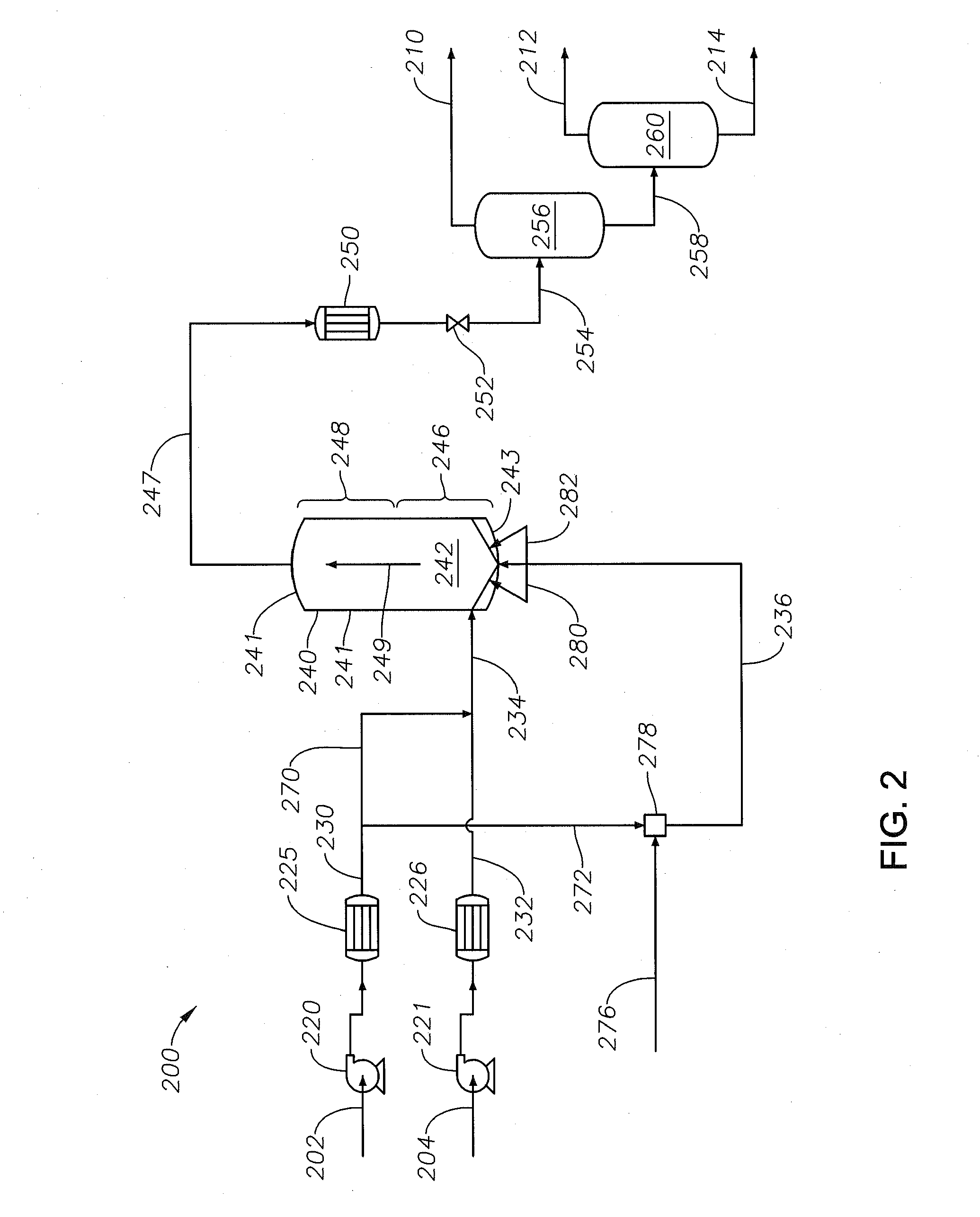

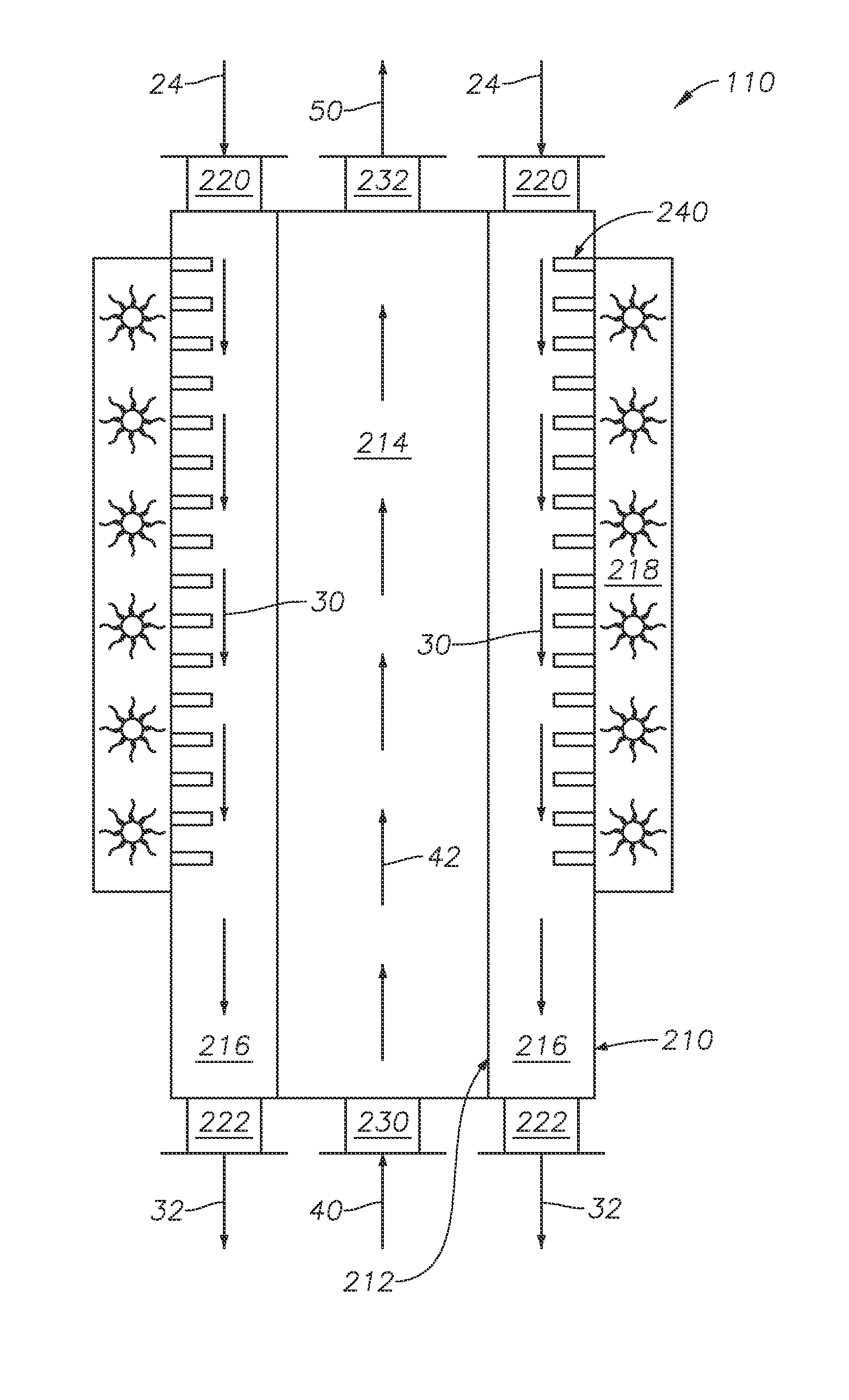

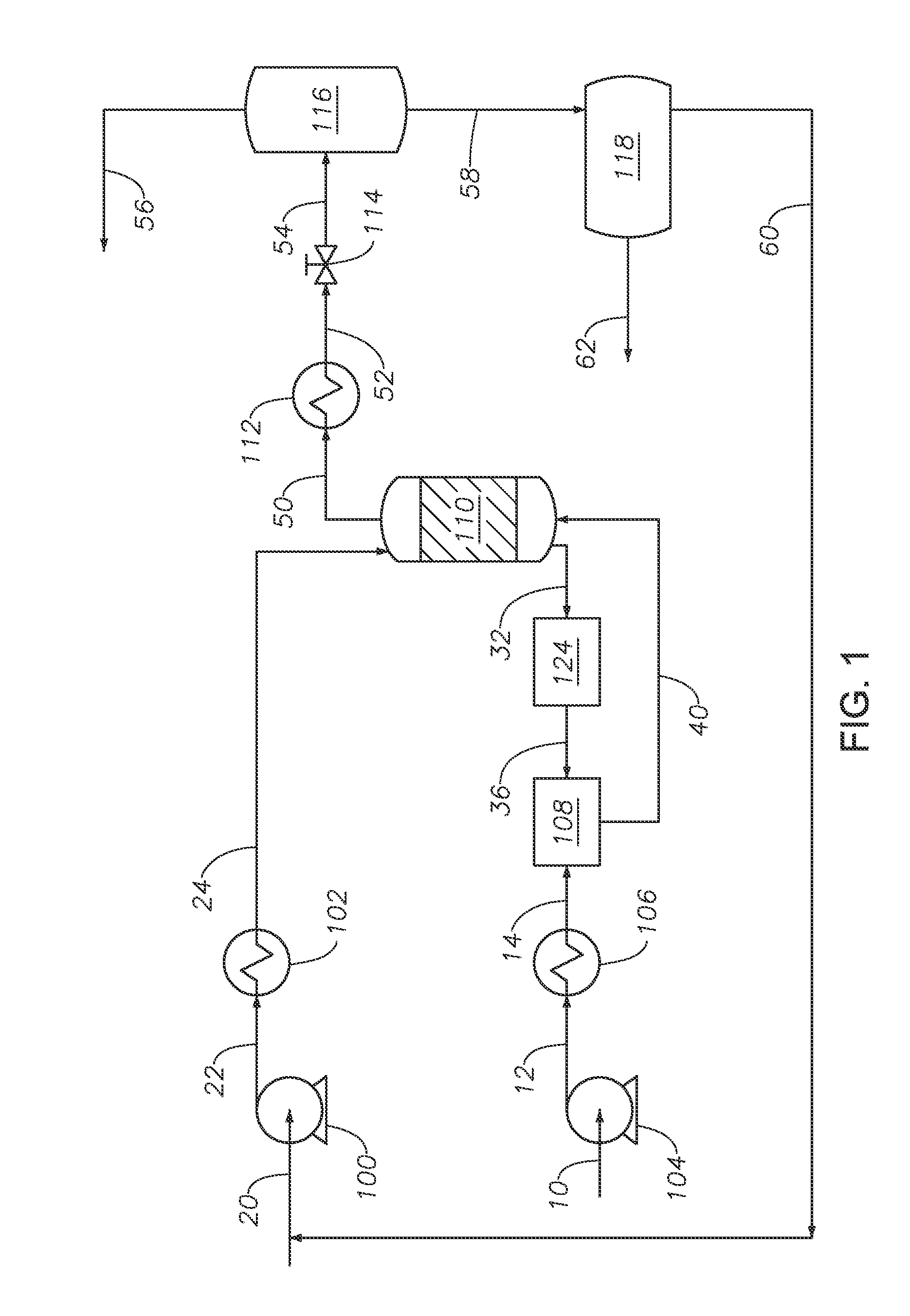

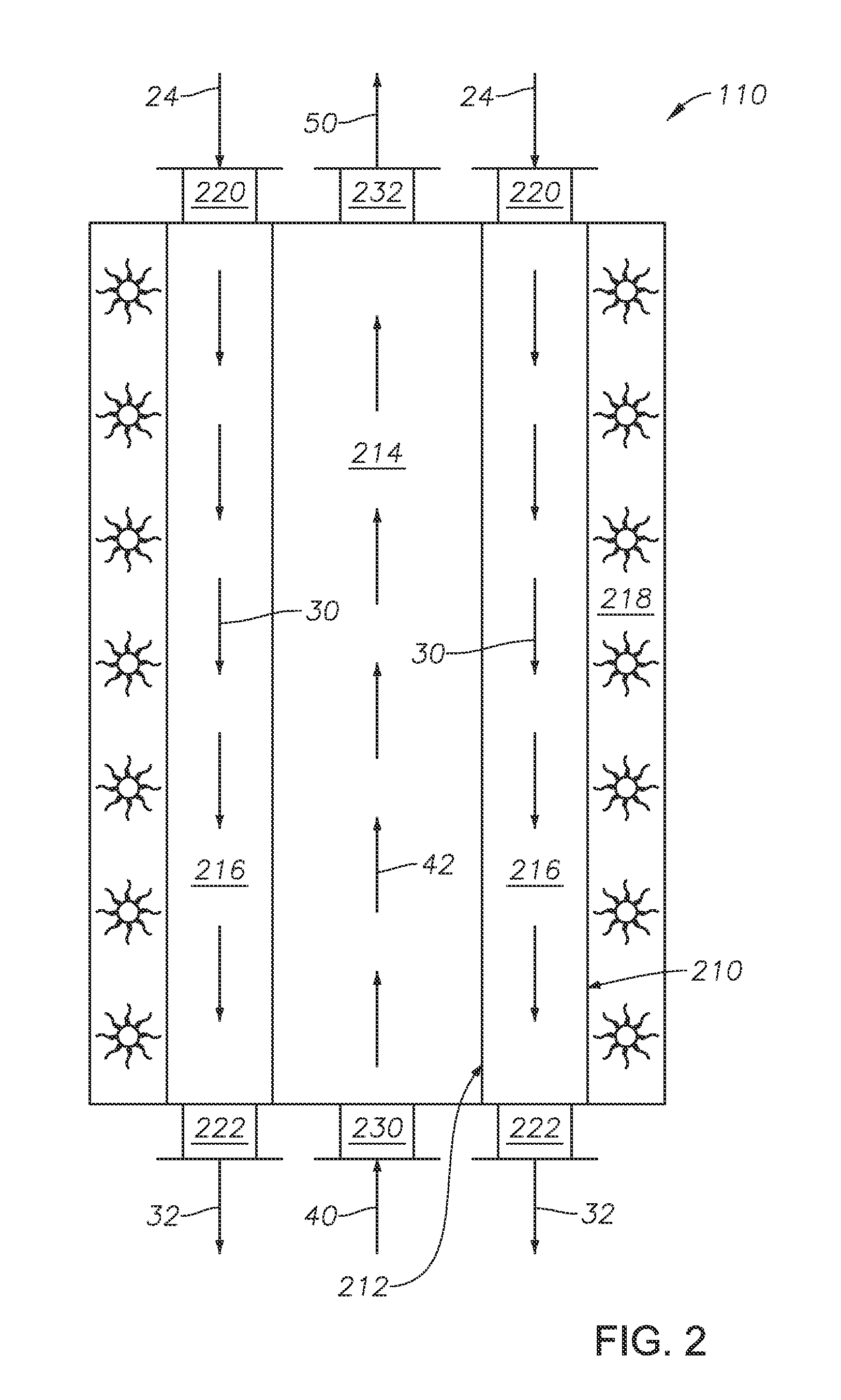

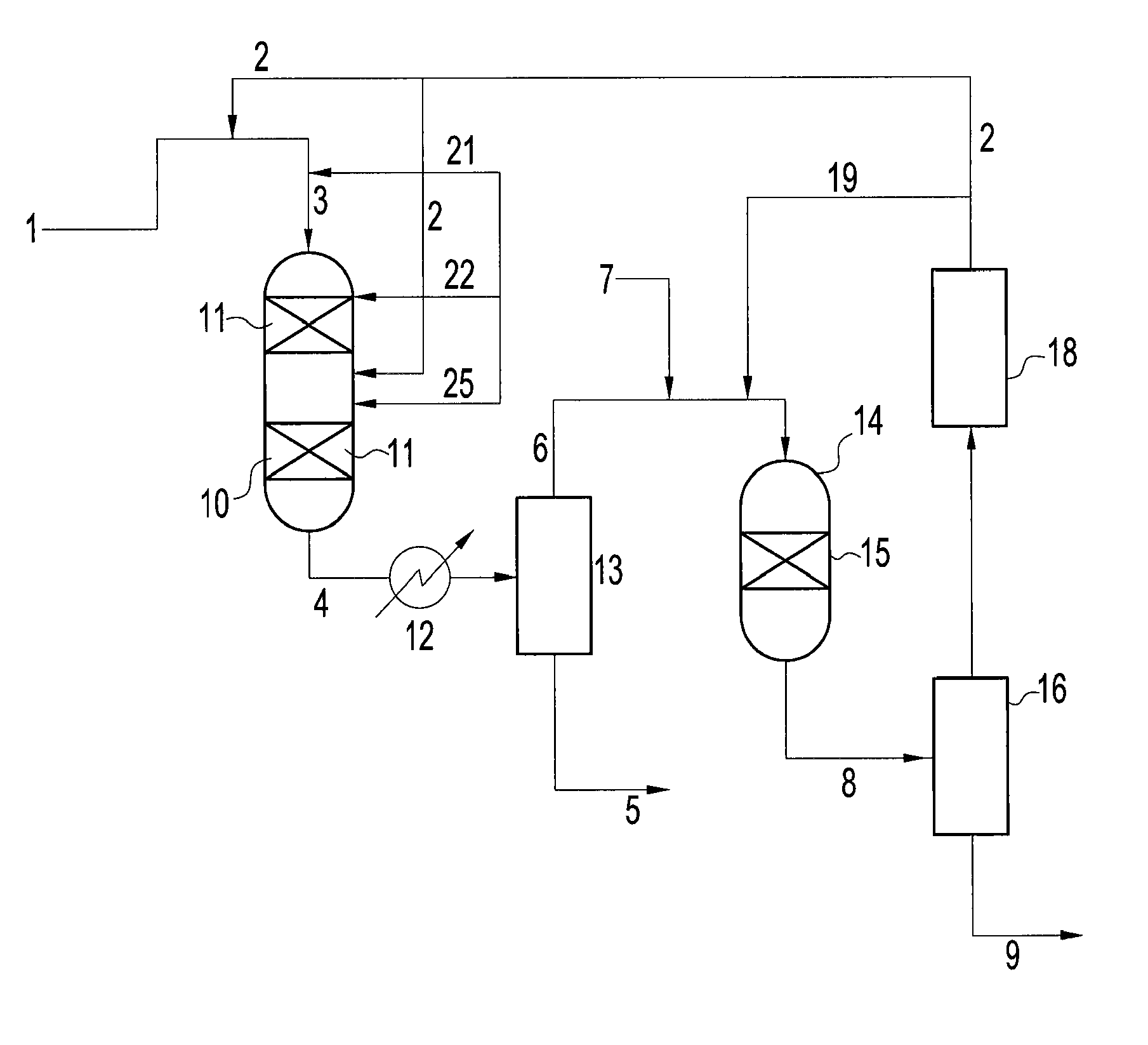

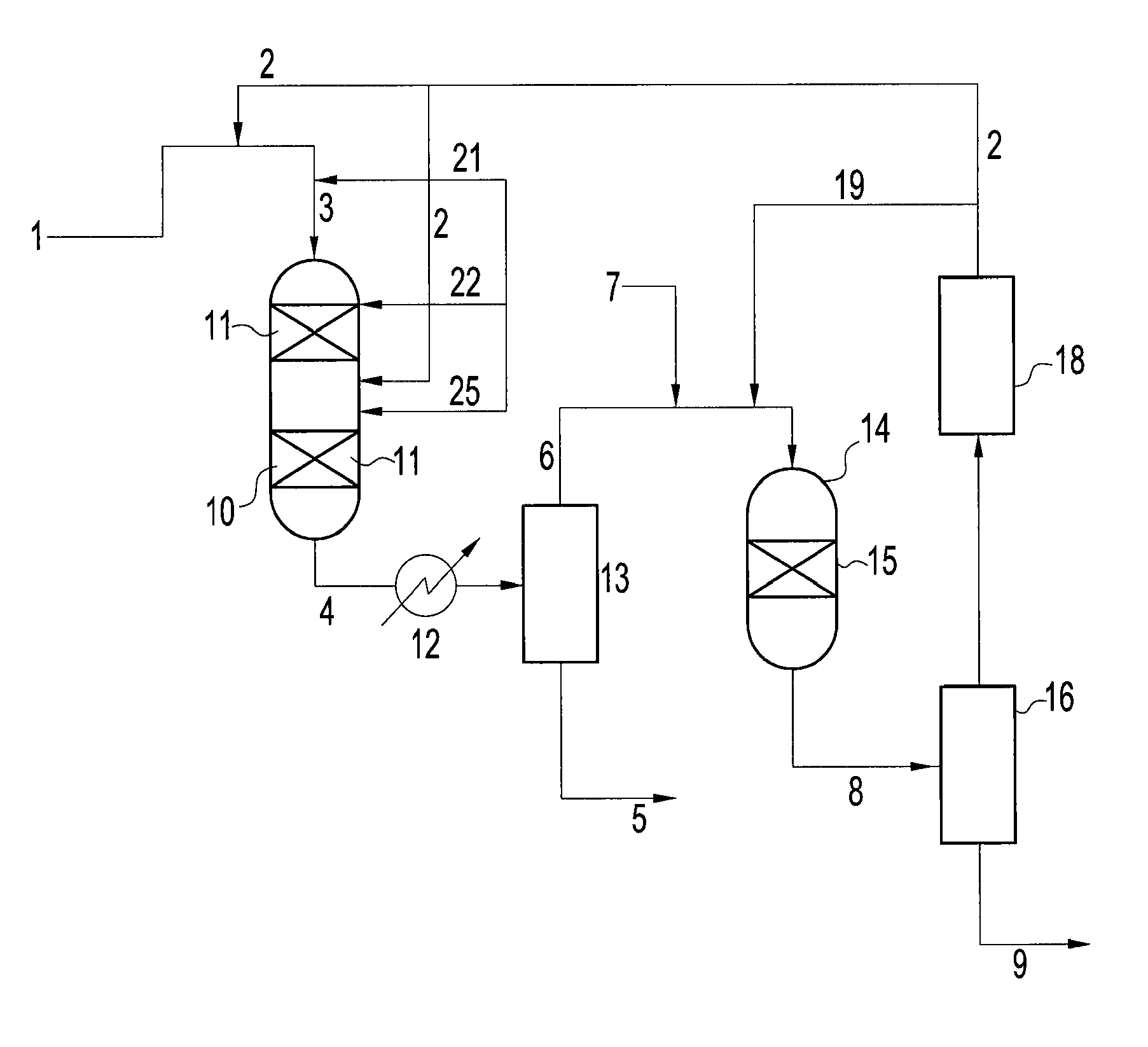

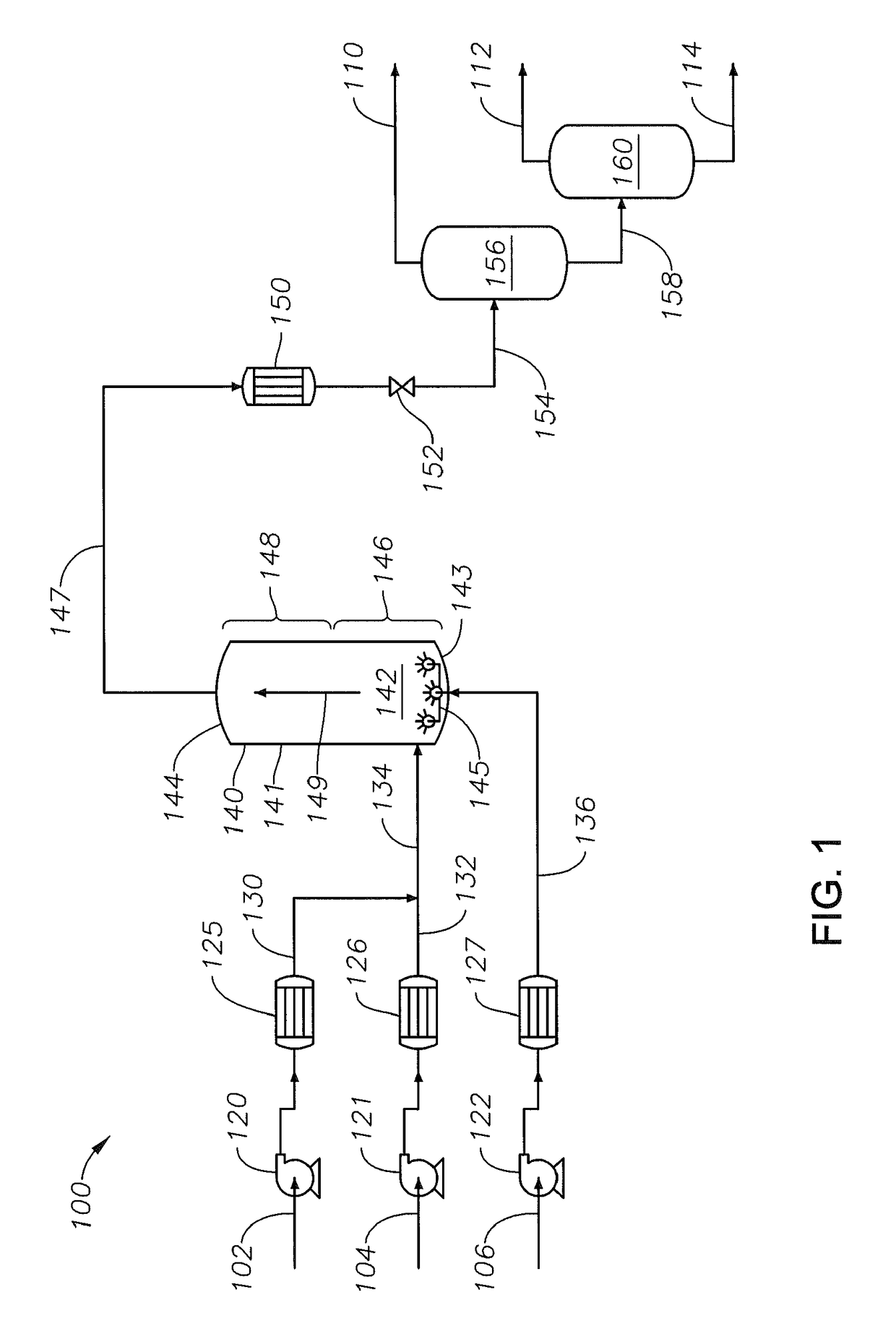

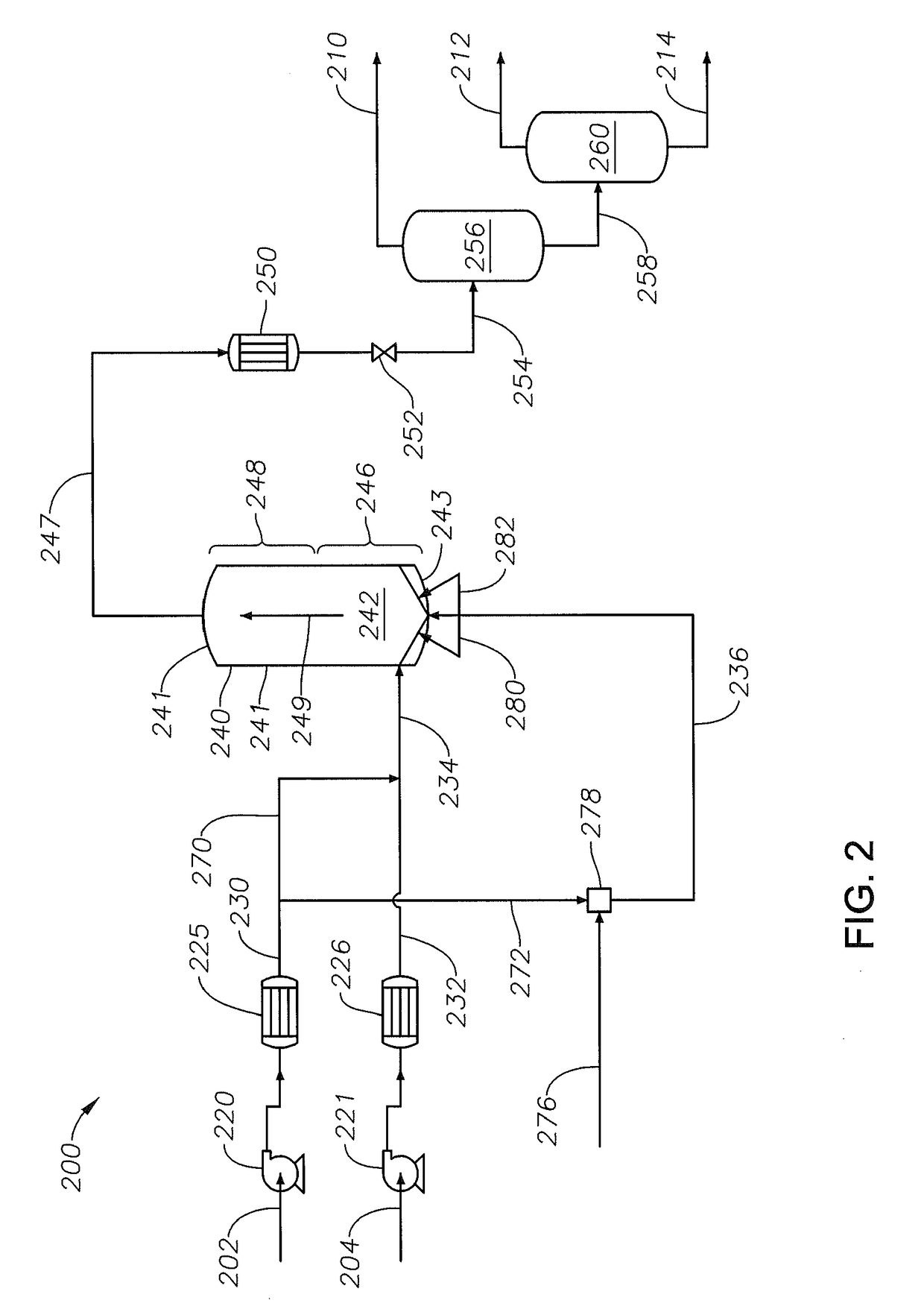

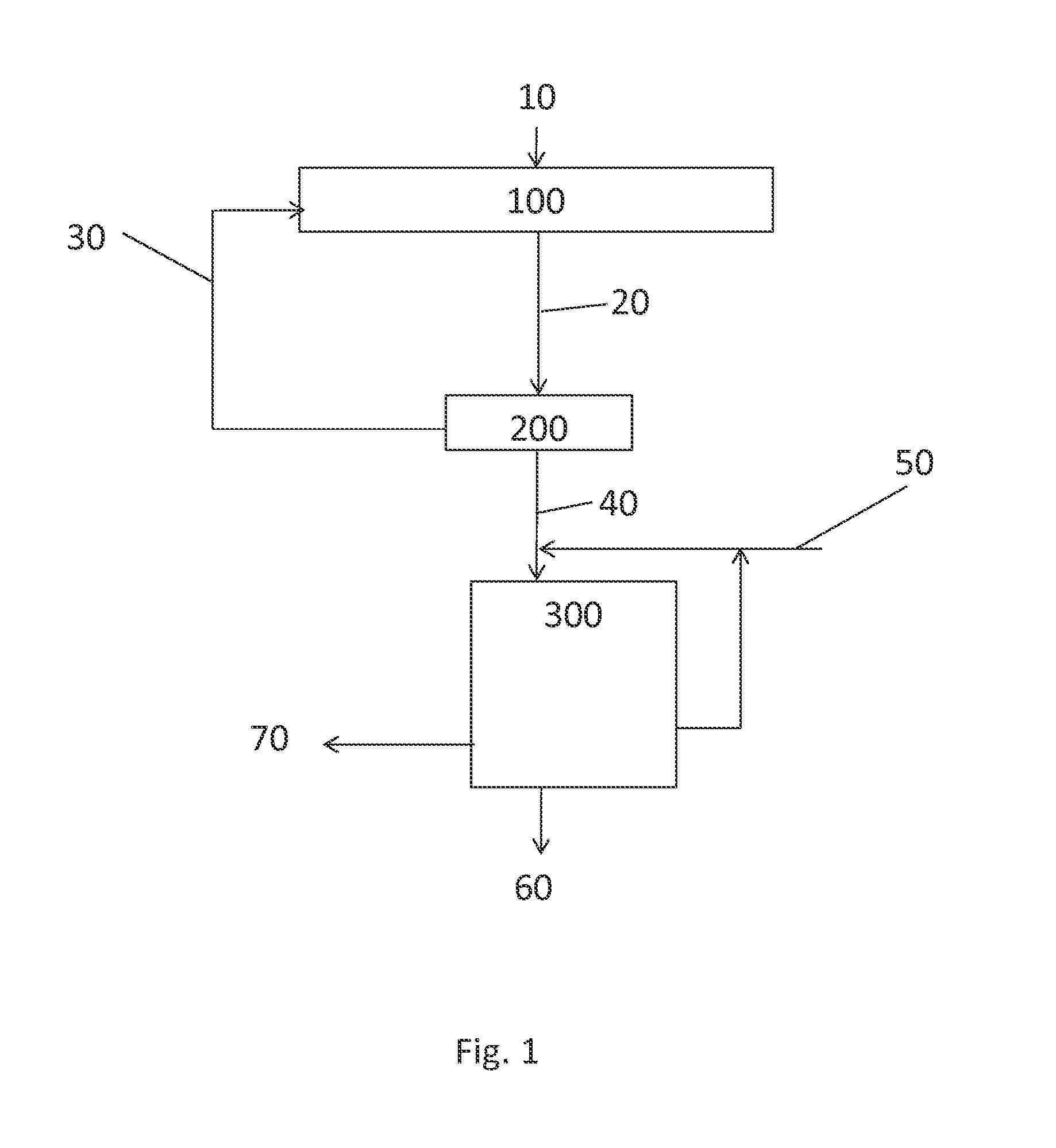

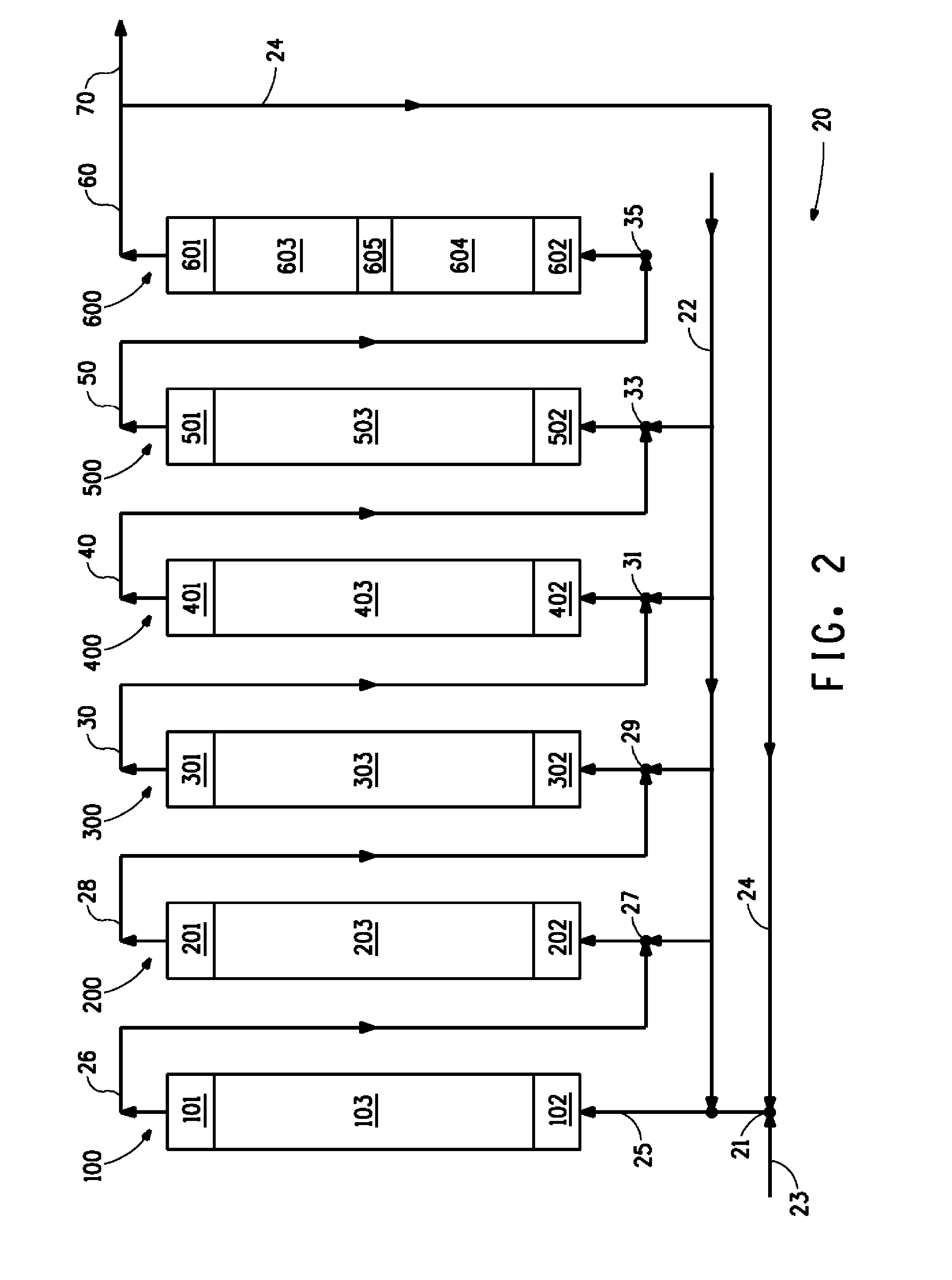

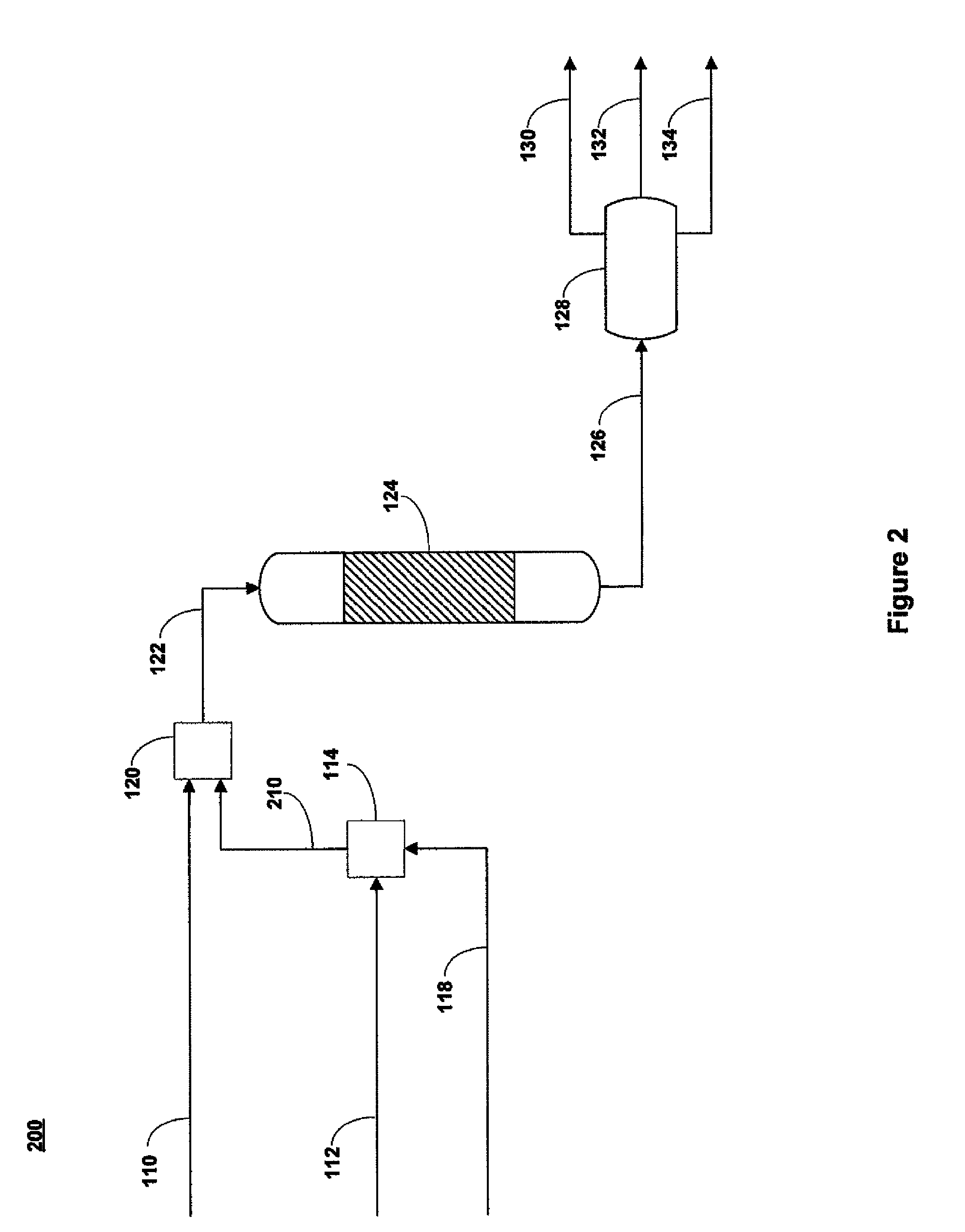

Production of upgraded petroleum by supercritical water

ActiveUS20160312129A1Long residence timeLong exposureSolvent extractionHydrocarbon oil crackingPetroleumPetroleum engineering

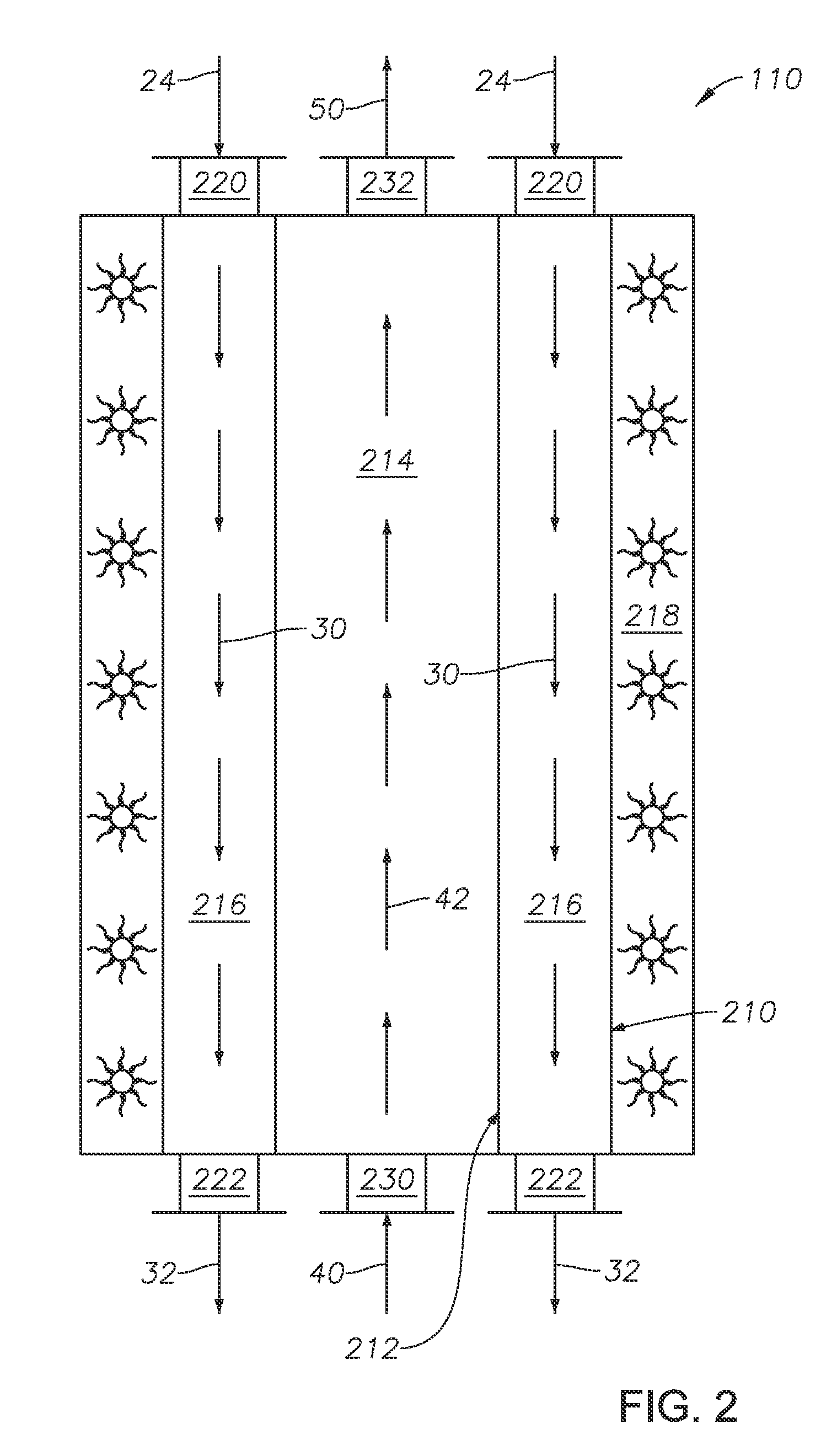

A method for upgrading a petroleum feedstock using a supercritical water petroleum upgrading system includes introducing the petroleum feedstock, water and an auxiliary feedstock. The method includes operating the system to combine the petroleum feedstock and the water to form a mixed petroleum feedstock and introducing separately and simultaneously into a lower portion of an upflowing supercritical water reactor. The auxiliary feedstock is introduced such that a portion of a fluid contained within the upflowing reactor located proximate to the bottom does not lack fluid momentum. An embodiment of the method includes operating the supercritical water petroleum upgrading system such that the upflowing reactor product fluid is introduced into an upper portion of a downflowing supercritical water reactor. The supercritical water petroleum upgrading system includes the upflowing supercritical water reactor and optionally a downflowing supercritical water reactor.

Owner:SAUDI ARABIAN OIL CO

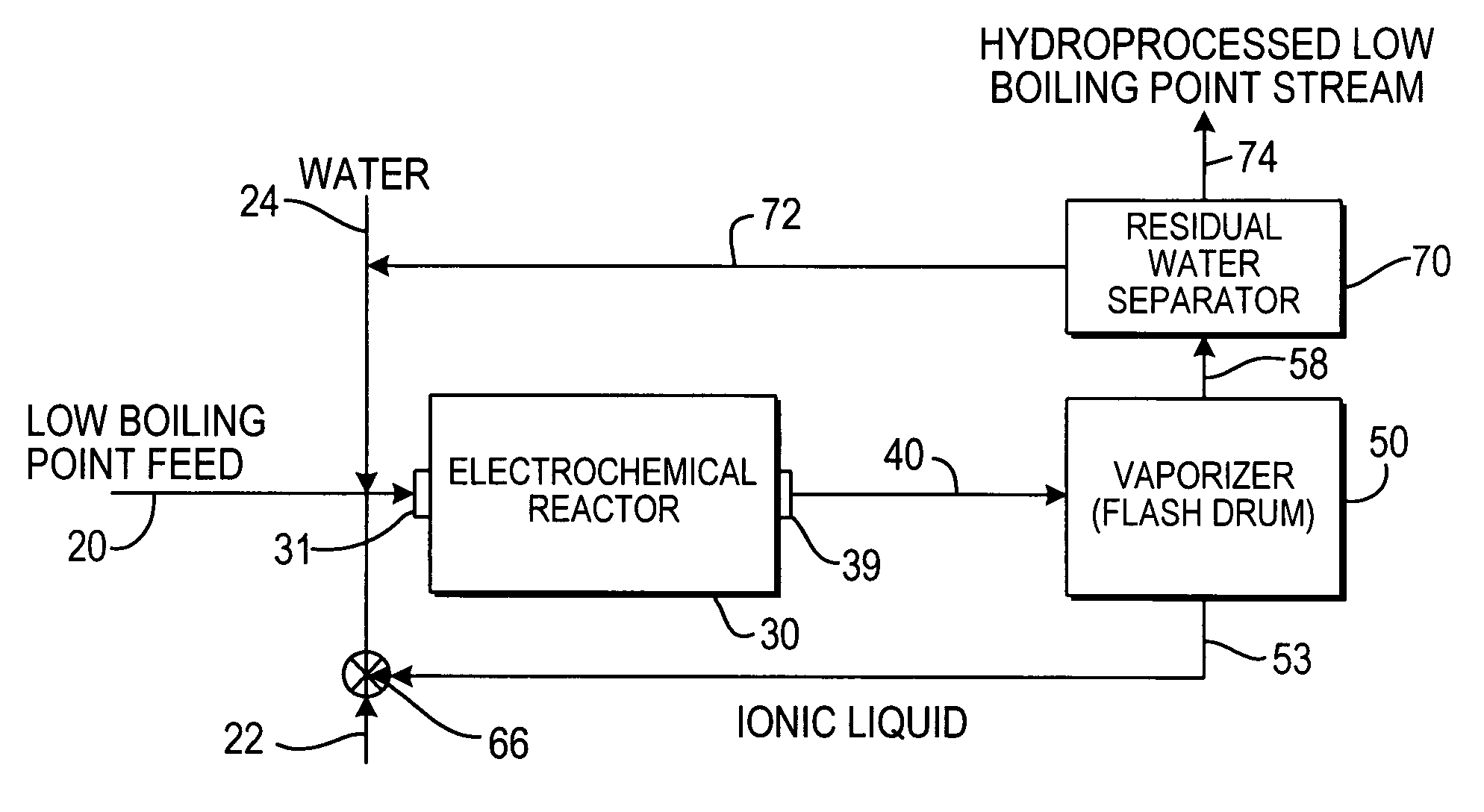

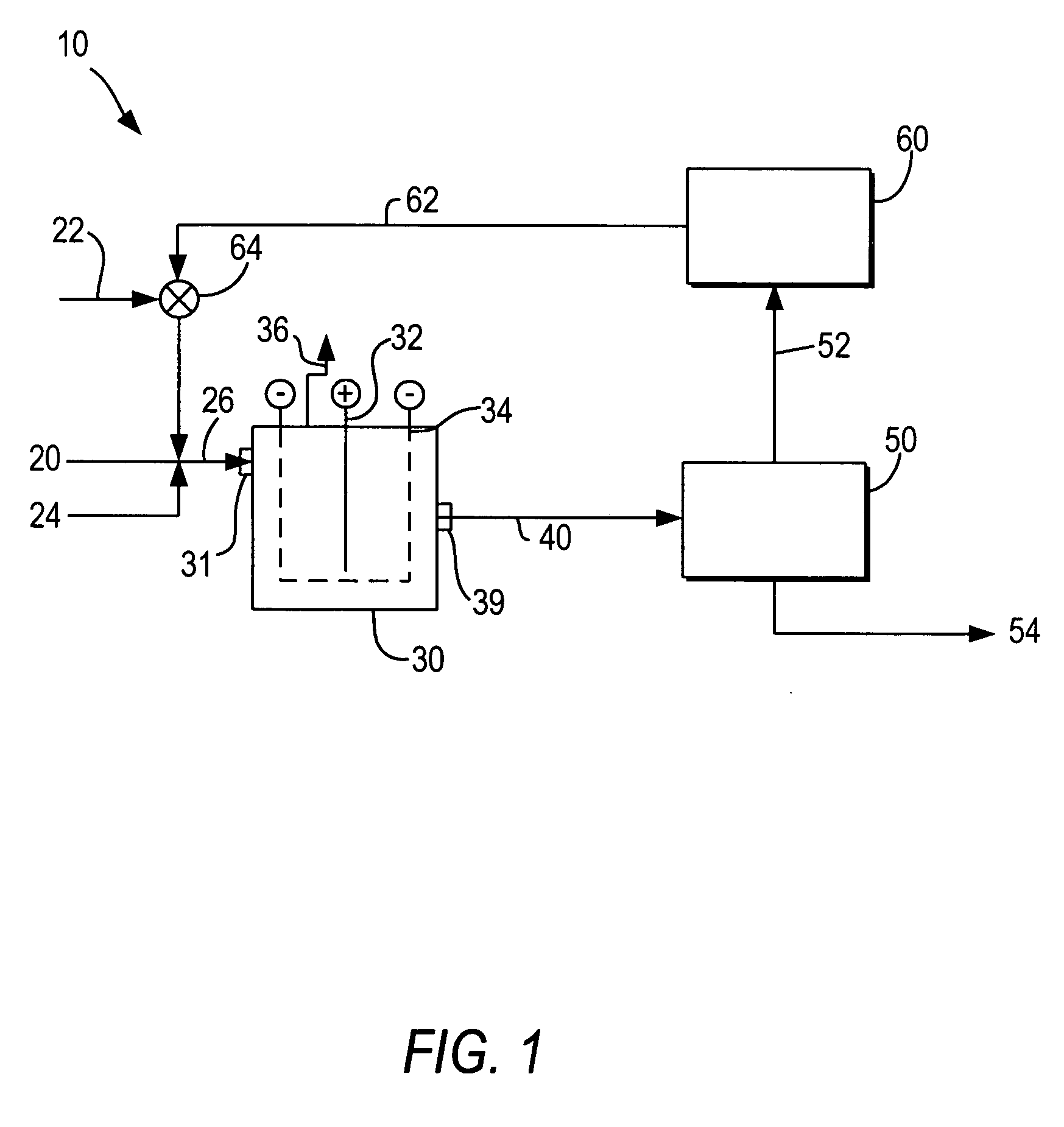

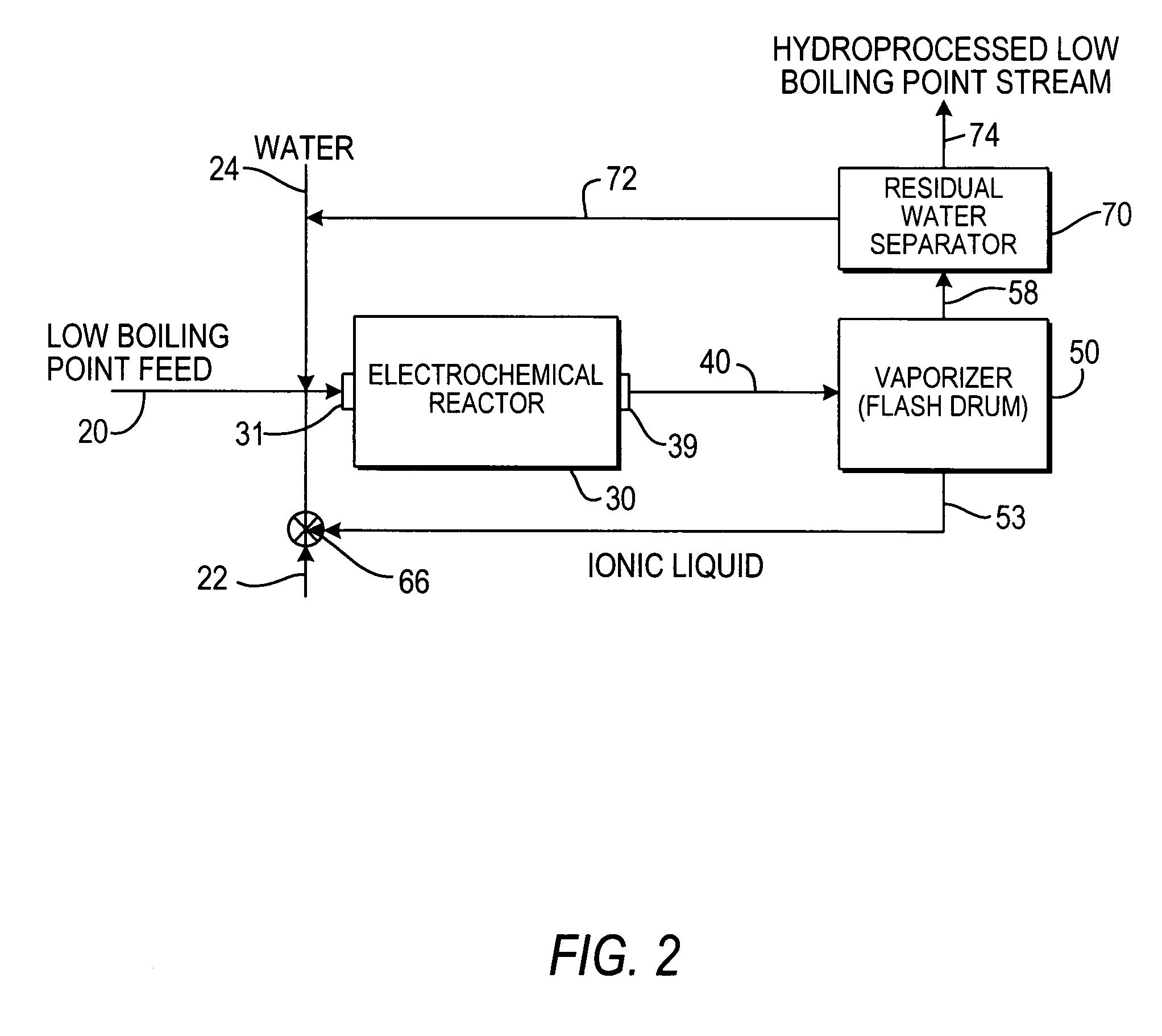

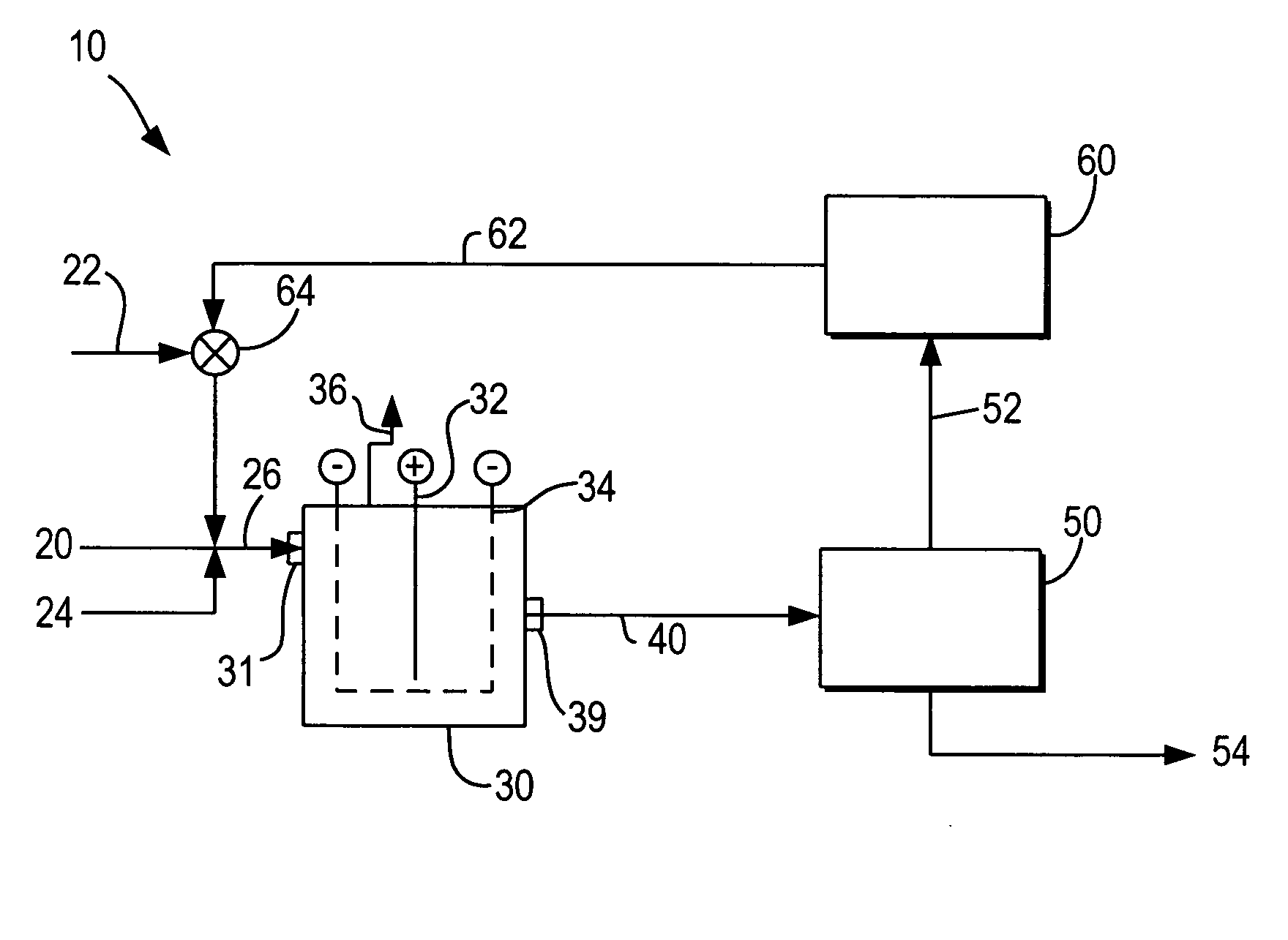

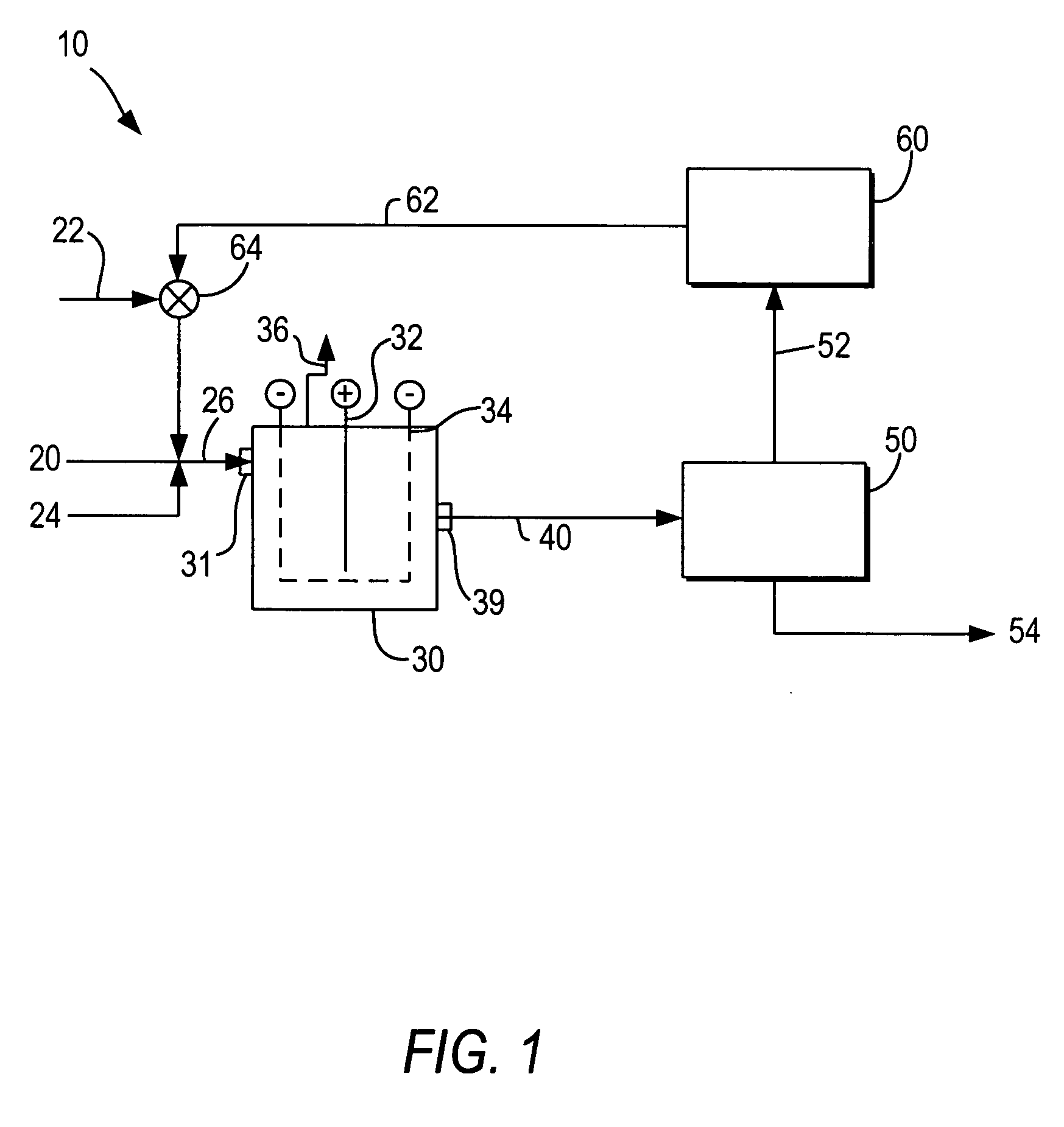

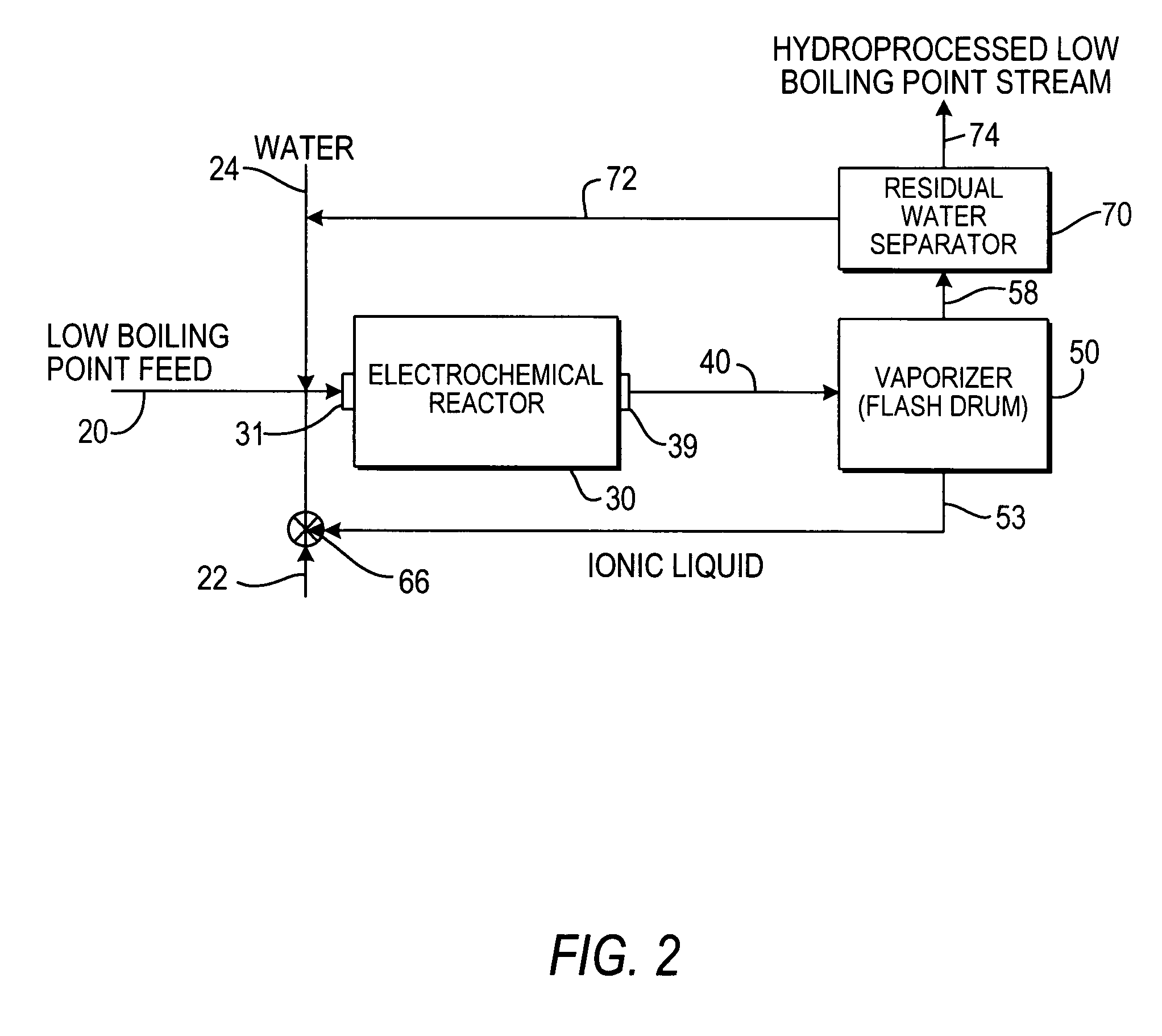

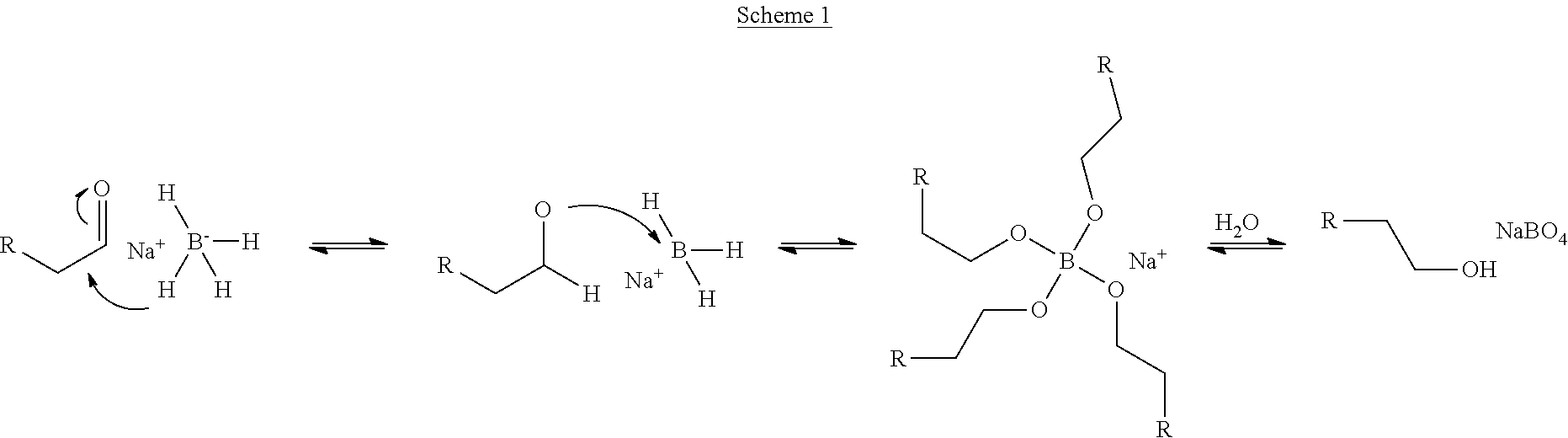

Upgrading crude oil using electrochemically-generated hydrogen

ActiveUS20090145806A1Lower cost of capitalReduce operating costsThermal non-catalytic crackingCellsHydrogen atomHydrogen

A method for upgrading a petroleum oil by a hydroprocessing reaction in which the oil is hydrogenated, includes the steps of:a. forming a liquid reaction mixture of the oil with water and an amphiphilic liquid in predetermined proportions to thereby render the oil and water miscible;b. introducing the liquid reaction mixture into an electrolytic reactor having one or more cathodic elements formed from a porous high surface area,conductive material;c. operating the reactor to form reactive hydrogen atoms whereby the oil is hydrogenated by the hydrogen atoms;d. removing the liquid mixture from the reactor; ande. separating the hydrogenated upgraded oil from the amphiphilic liquid and any remaining water, e.g., by distillation, recovering and recycling the amphiphilic liquid for use.

Owner:SAUDI ARABIAN OIL CO

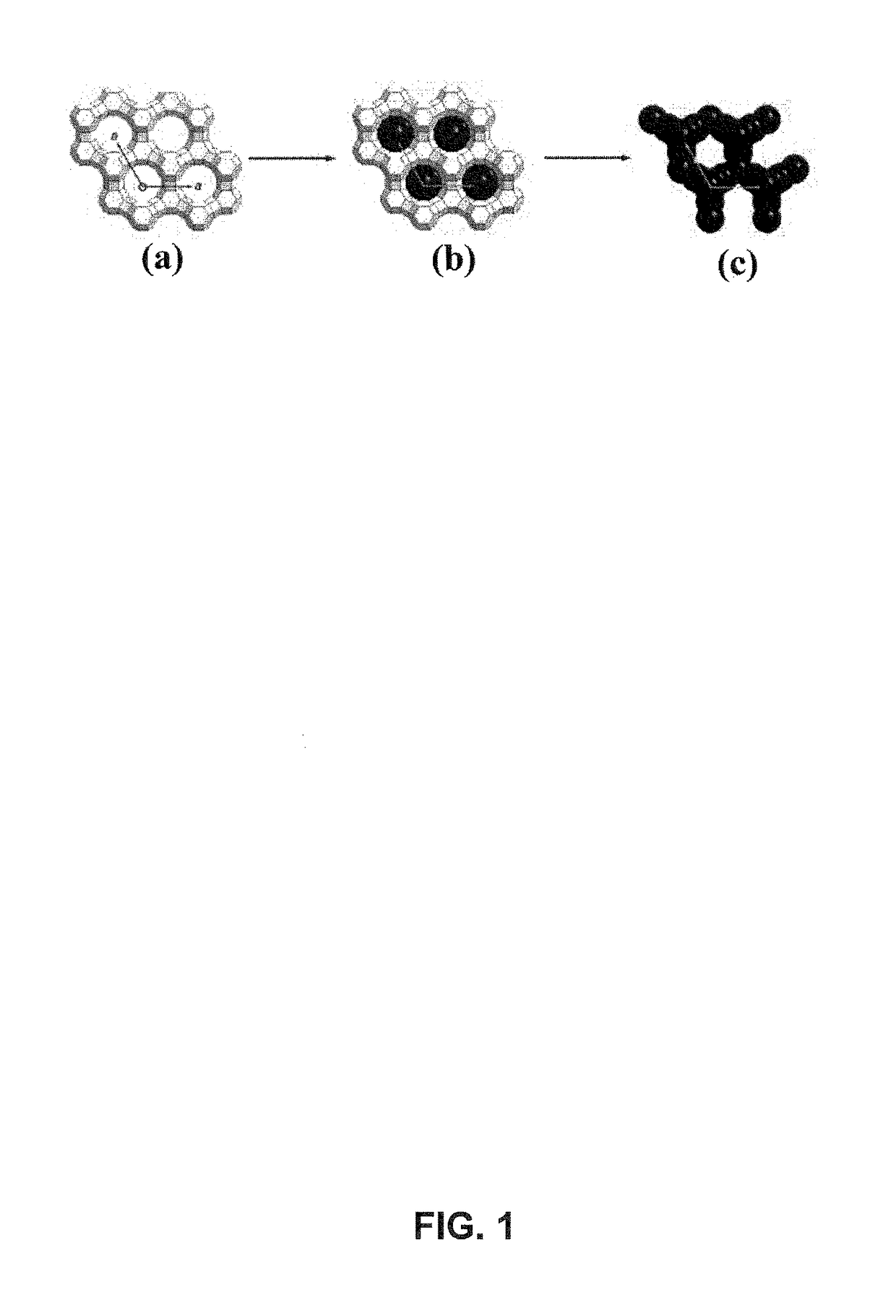

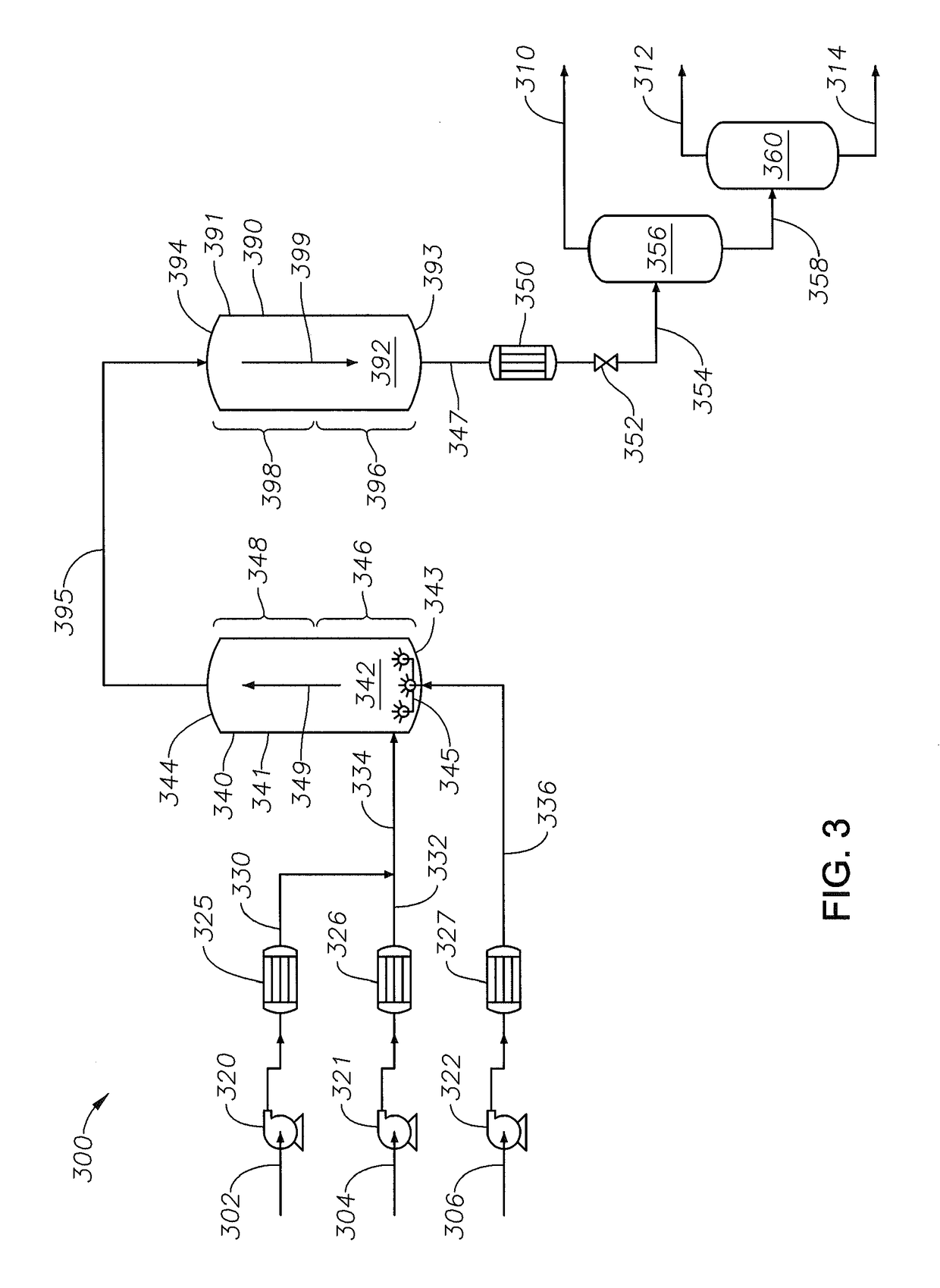

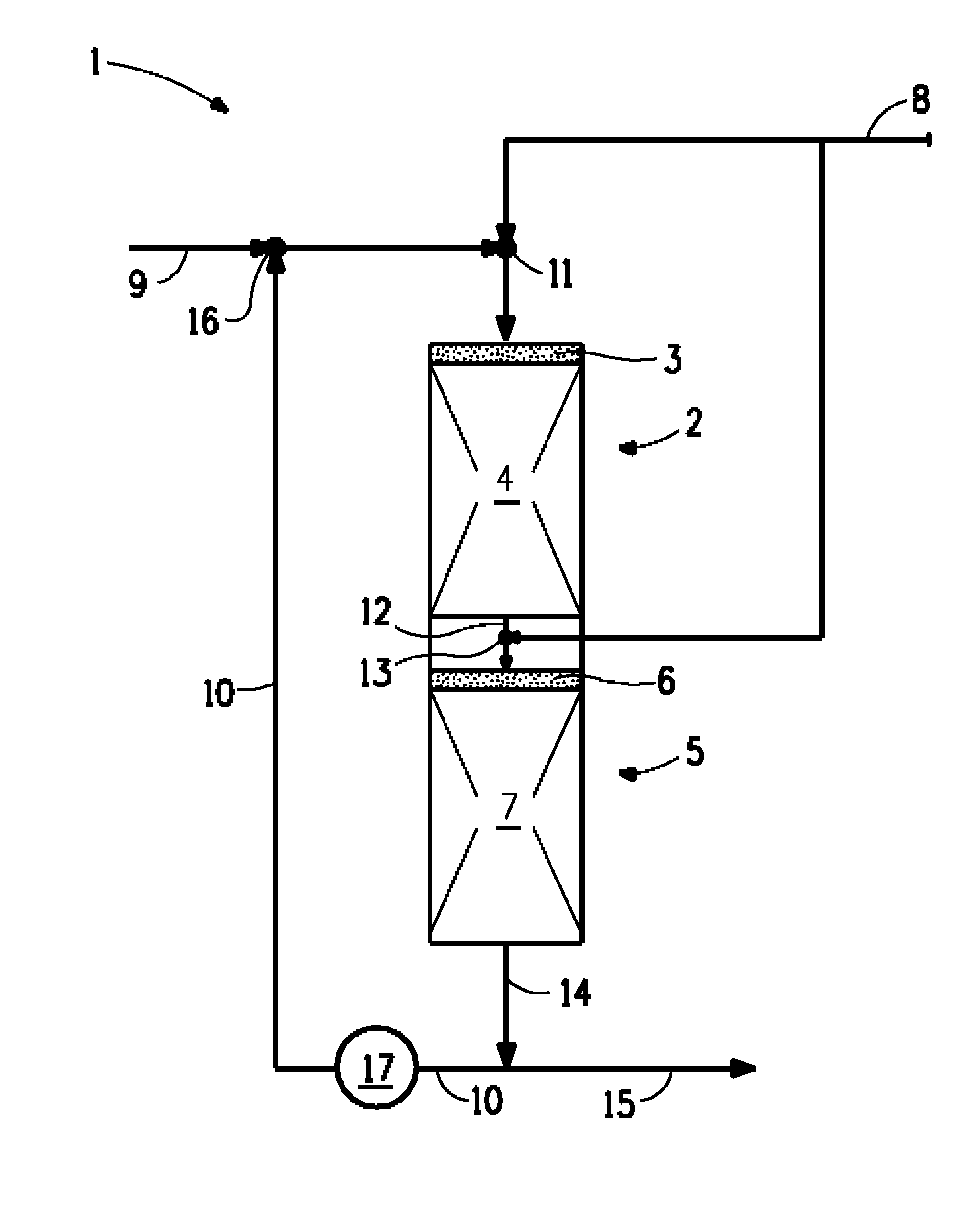

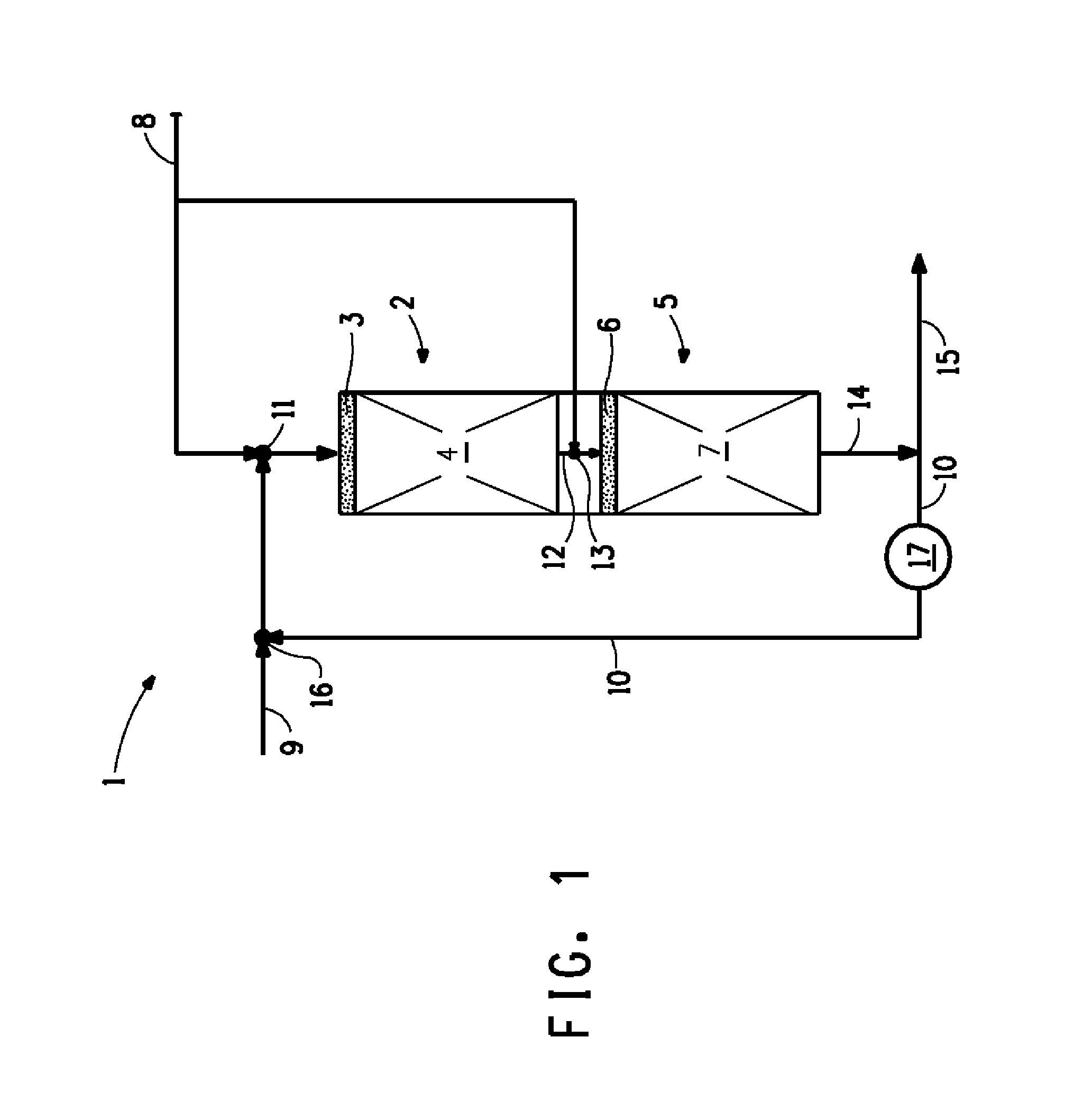

Process for heavy oil upgrading in a double-wall reactor

ActiveUS20160145499A1Reduces coke formationMaintain reaction temperatureThermal non-catalytic crackingCatalytic crackingHeat flowReaction temperature

A process for reducing coke formation during hydrocarbon upgrading reactions using a double-wall reactor comprising the steps of feeding a heated feed water to a shell-side volume of the double-wall reactor to produce a heat transfer stream, the double-wall reactor comprising an exterior wall and an interior wall, a reaction section volume, a heating element configured to heat the heat transfer stream, wherein heat is transferred from the heat transfer stream to the reaction section volume, feeding the hot water return exiting the shell-side volume through a filter; mixing the filtered water stream with a heated hydrocarbon feedstock; feeding the mixed stream to the reaction section volume in a configuration counter-current to the heat transfer stream; reacting the reaction flow stream at a reaction temperature, wherein the heat transferred to the reaction section volume is operable to maintain the reaction temperature above the critical temperature of water.

Owner:SAUDI ARABIAN OIL CO

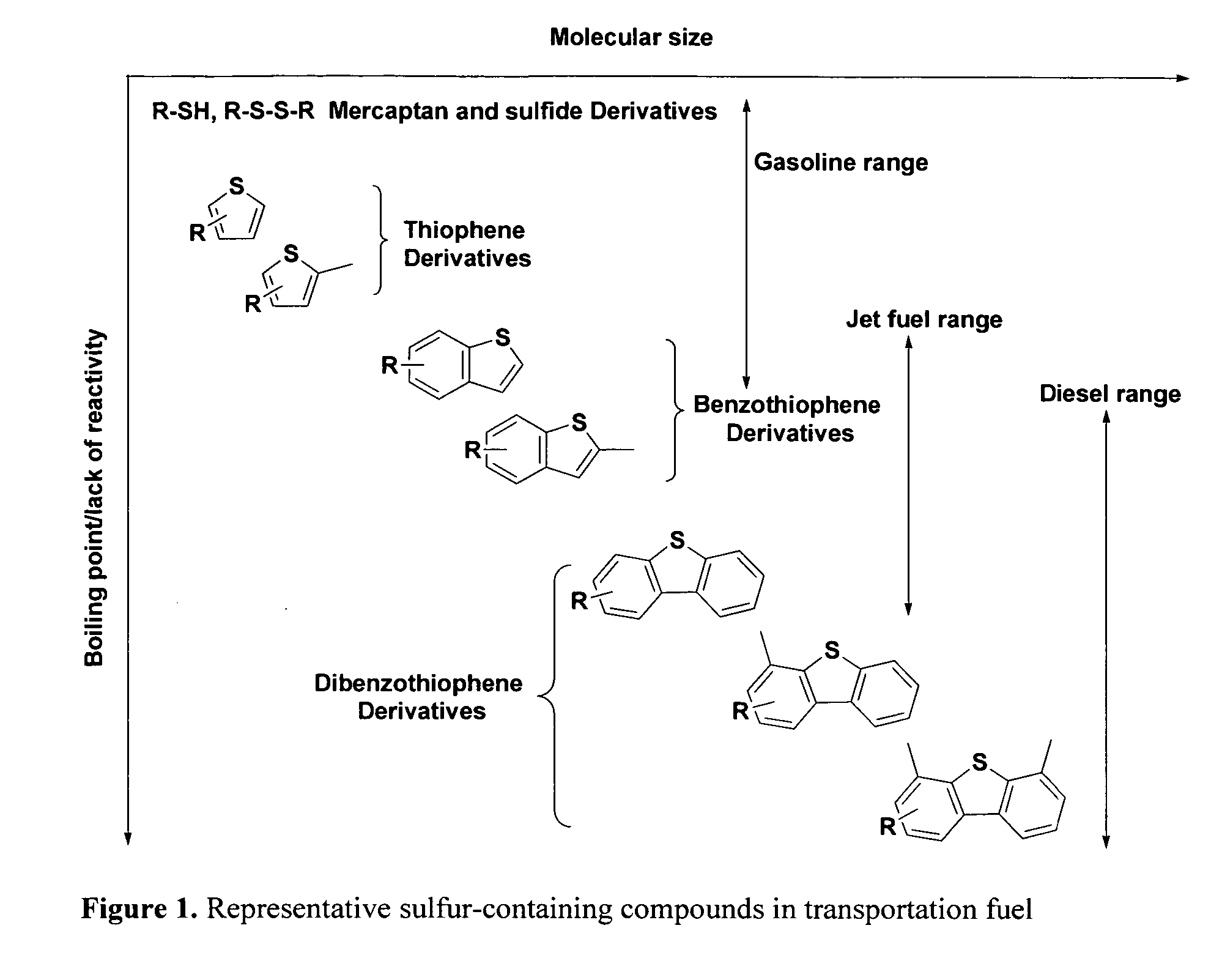

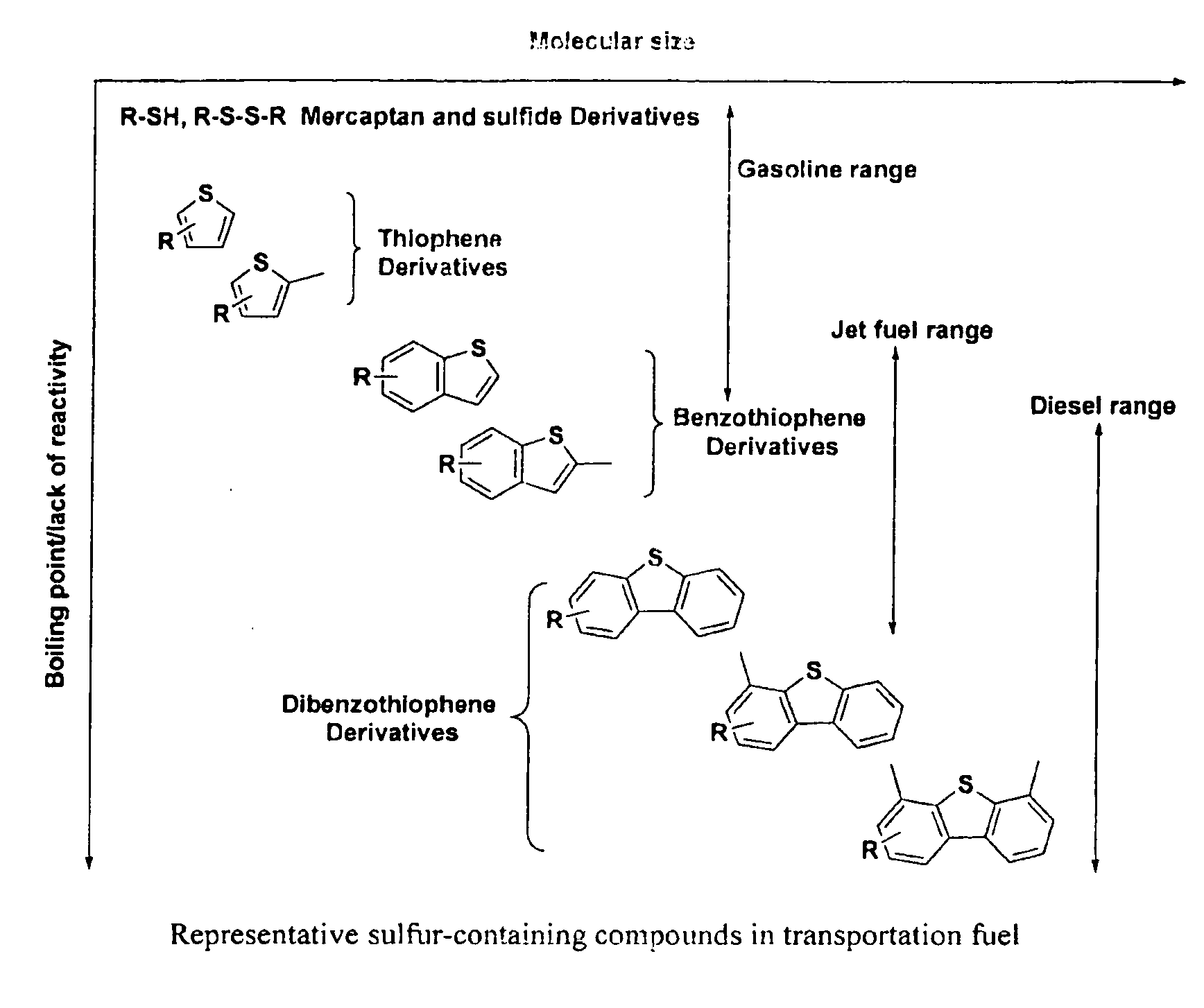

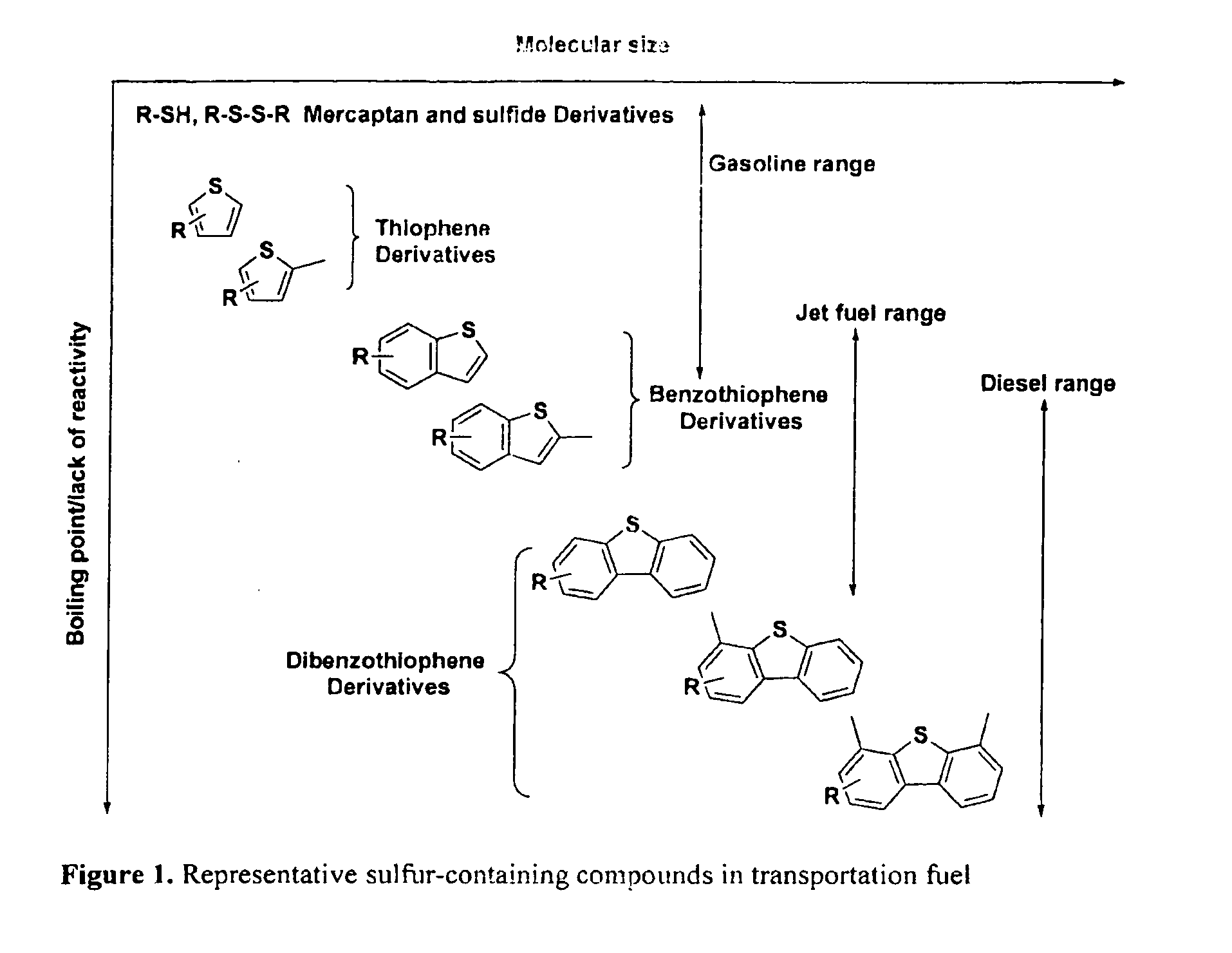

Sorbent compositions and desulfurization method using same

InactiveUS20070138062A1Reduce compoundingOther chemical processesHydrocarbon oil crackingMetal nitrateNitrate

The disclosed sorbents are for adsorbing sulfur compounds, particularly sulfur-containing aromatic compounds, from liquid hydrocarbon fuels such as gasoline, cracked gasoline, diesel, high sulfur liquid fossil fuels, ultra-low sulfur fuel (ULSF) in fuel cell applications, and mixtures thereof. The sorbent compositions comprise one or more silicates having one or more metal nitrates admixed together. The one or more metal nitrates include iron (II) or (III), zinc (II), cadmium (II) and mercury (II) nitrate. The method of preparing and using the sorbents is also provided.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE THE

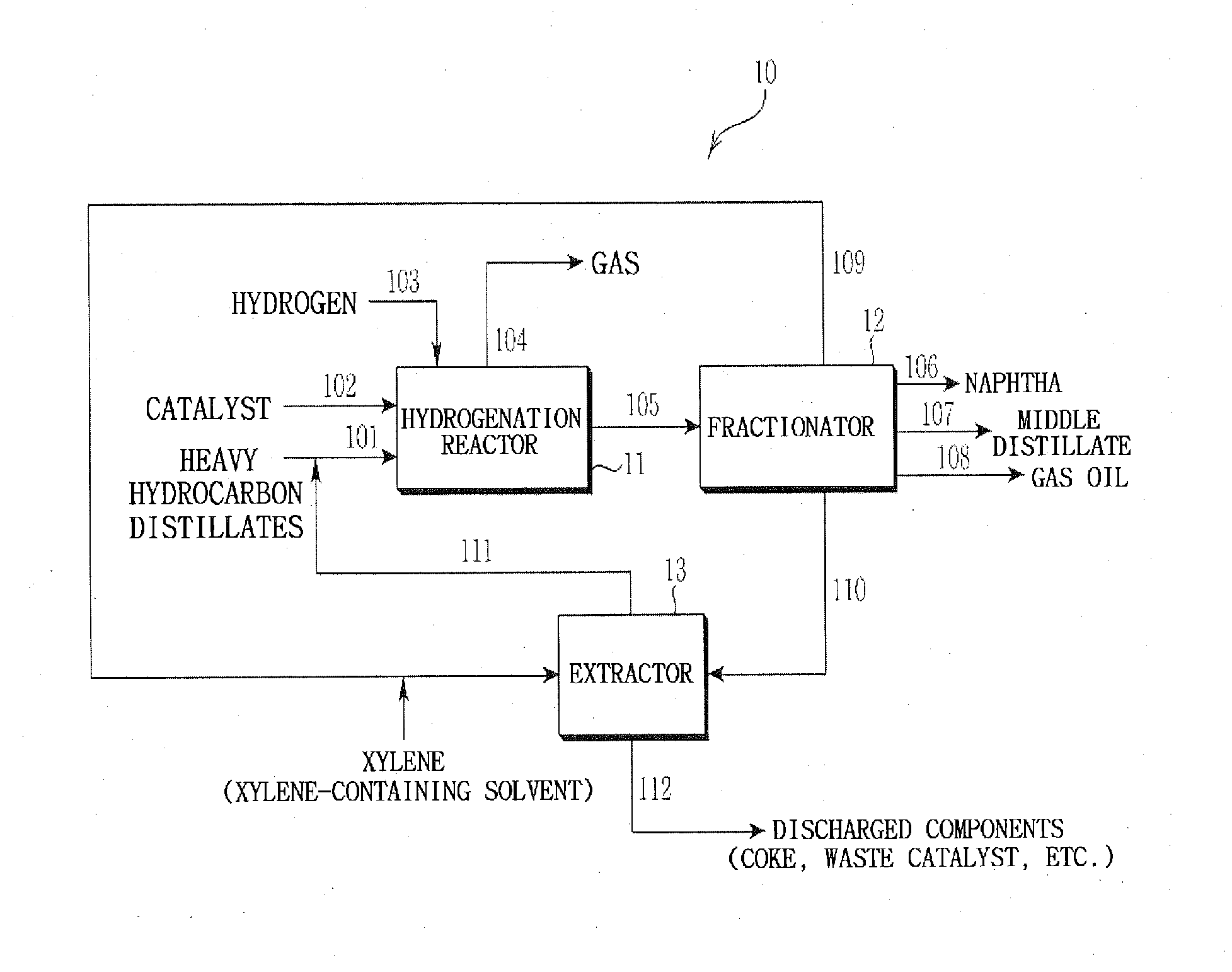

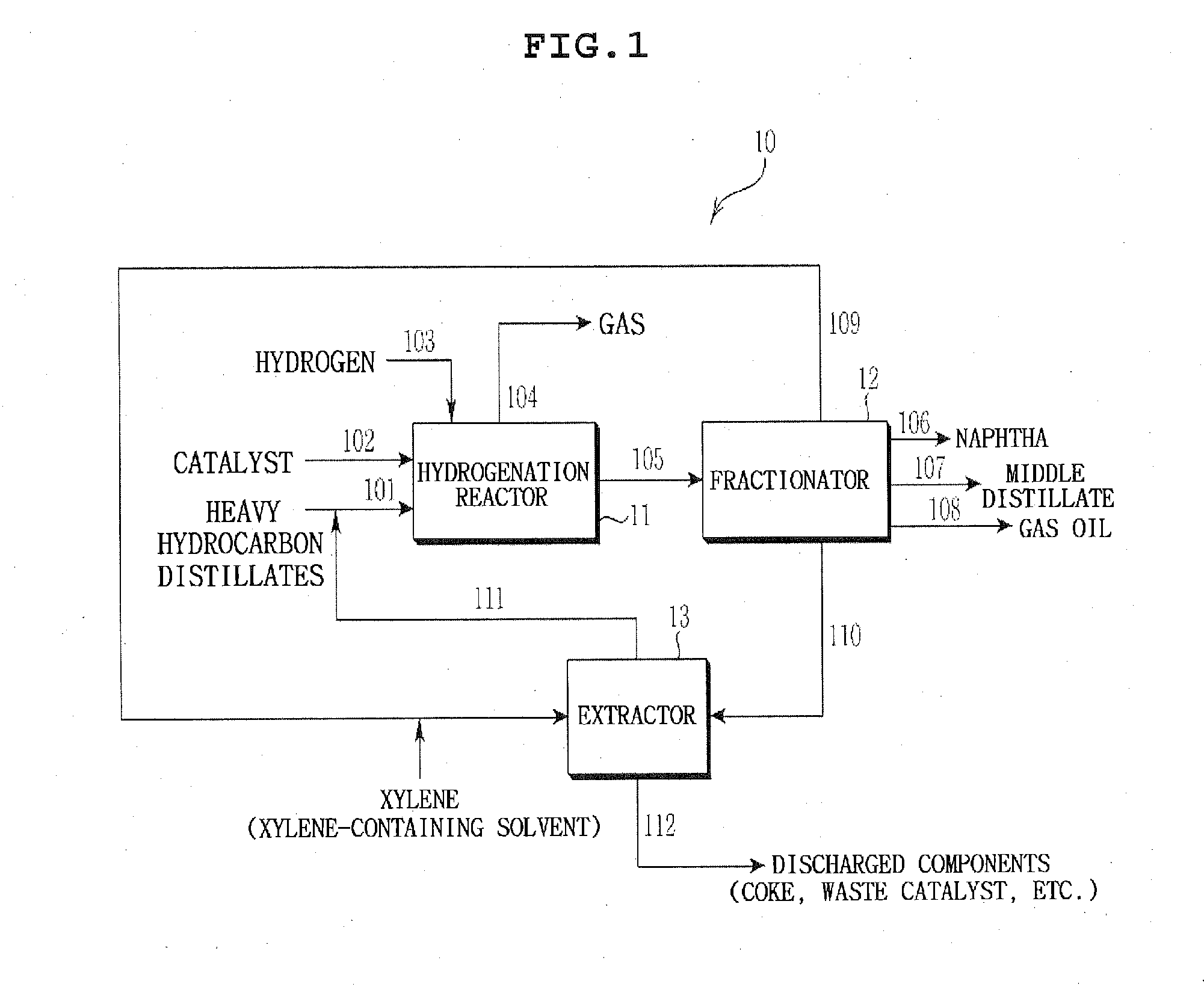

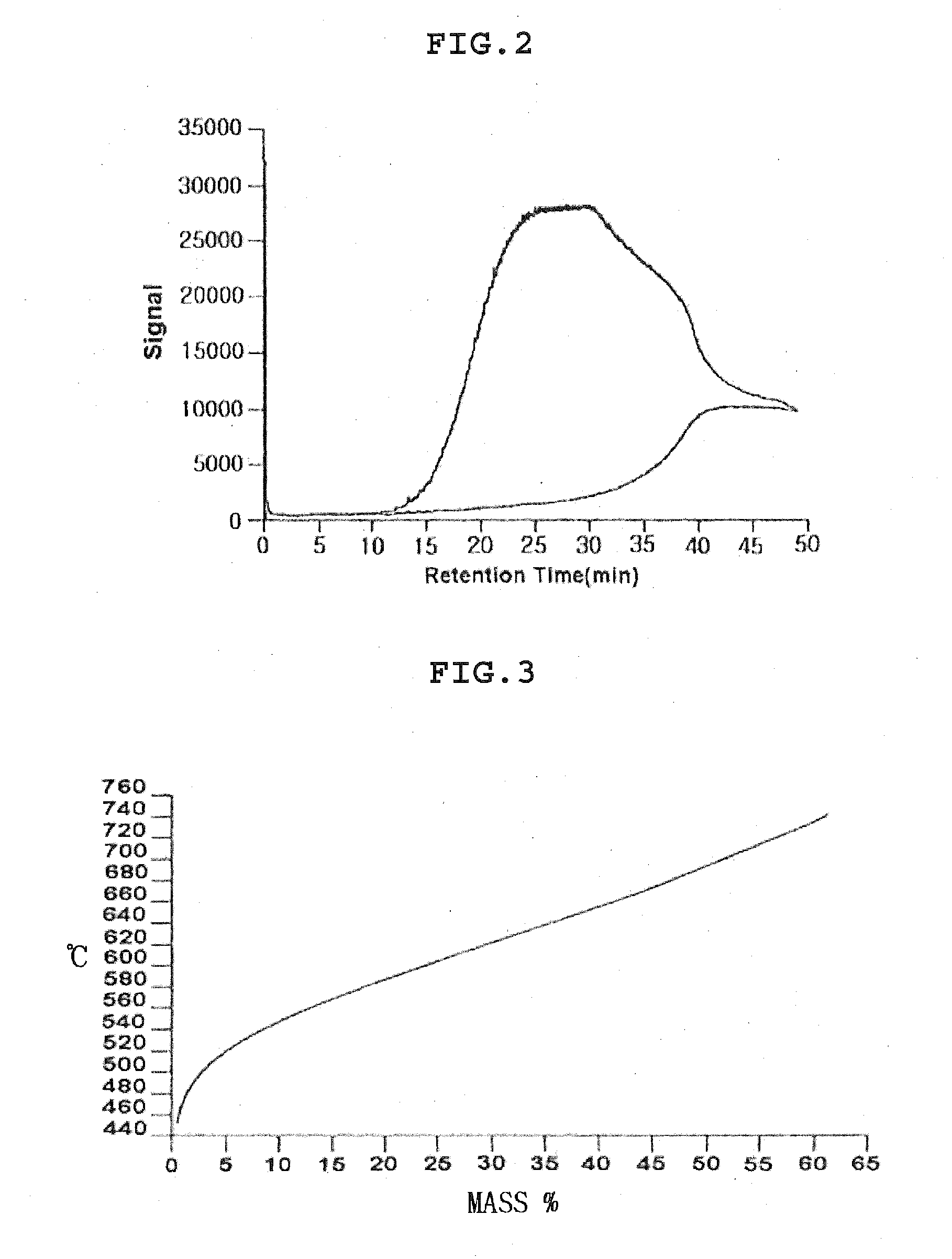

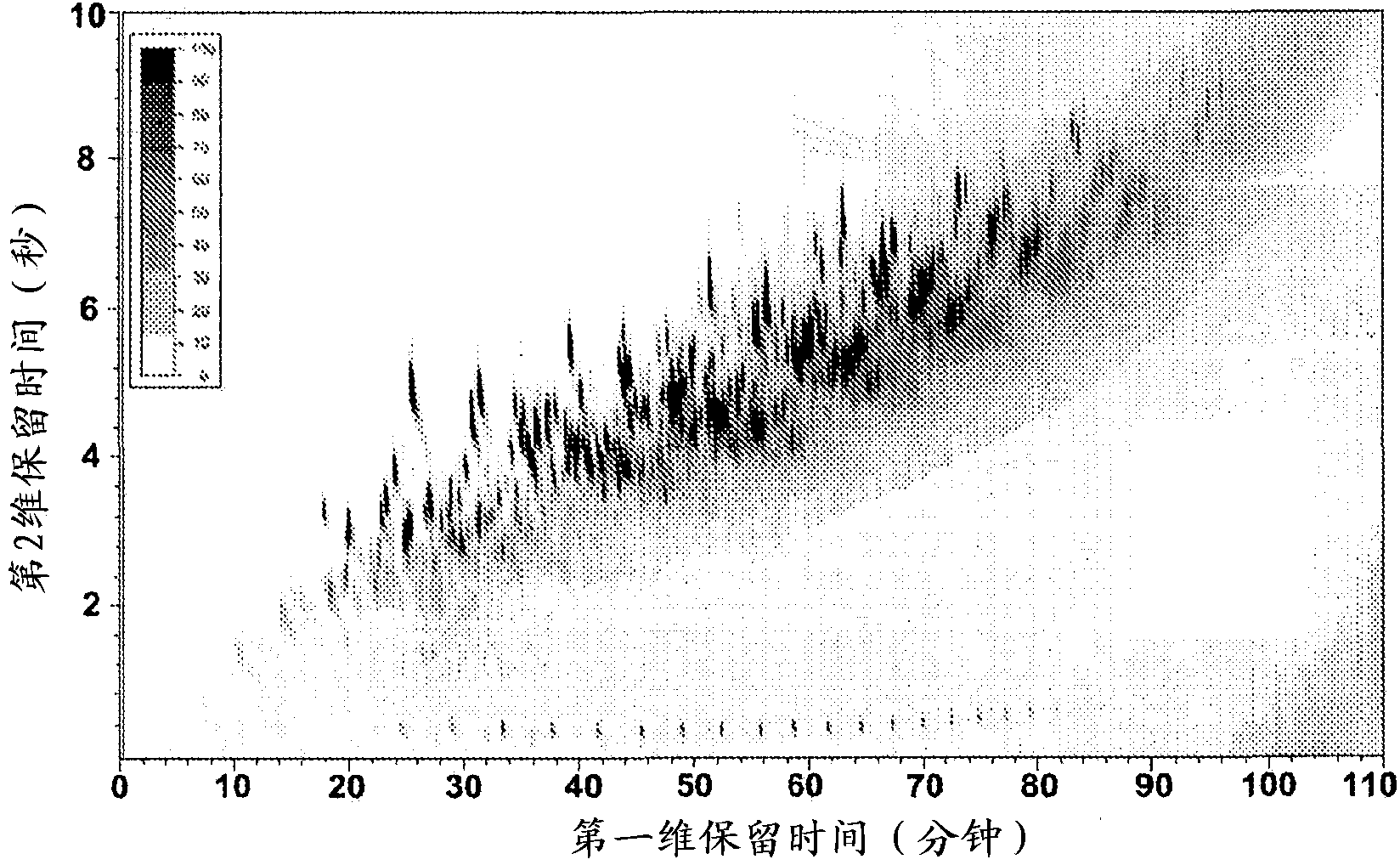

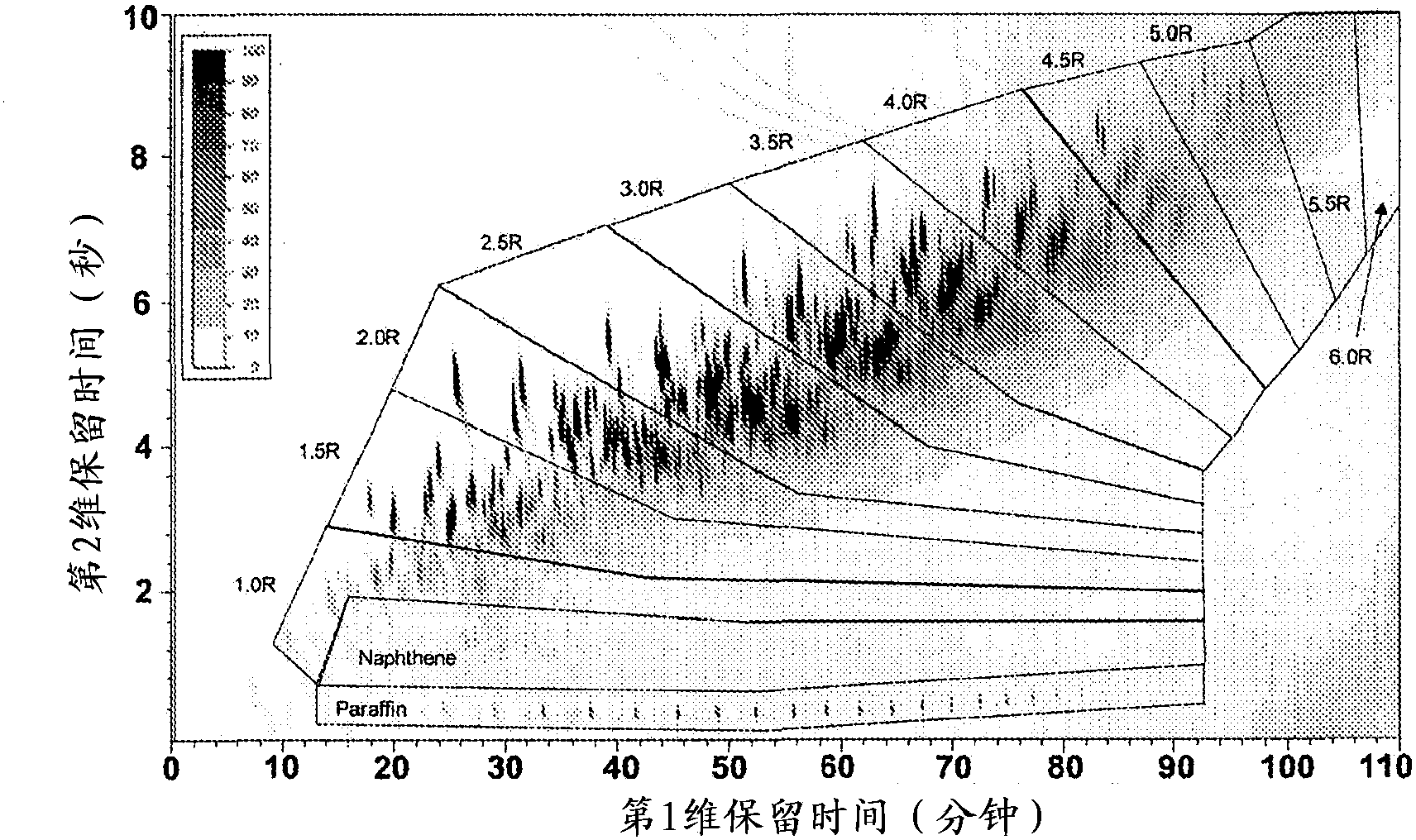

Hydrocracking process of heavy hydrocarbon distillates using supercritical solvent

Specific embodiments of the present invention provide a hydrocracking process for converting low value-added heavy hydrocarbon distillates into high value-added hydrocarbon distillates using a supercritical solvent as a medium.

Owner:SK INNOVATION CO LTD +1

Sorbent compositions and desulfurization method using the same

The disclosed sorbents are for adsorbing sulfur compounds, particularly sulfur-containing aromatic compounds, from liquid hydrocarbon fuels such as gasoline, cracked gasoline, diesel, high sulfur liquid fossil fuels, ultra-low sulfur fuel (ULSF) in fuel cell applications, and mixtures thereof. The sorbent compositions comprise one or more silicates having one or more metal nitrates admixed together. The one or more metal nitrates include iron (II) or (III), zinc (II), cadmium (II) and mercury (II) nitrate. The method of preparing and using the sorbents is also provided.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

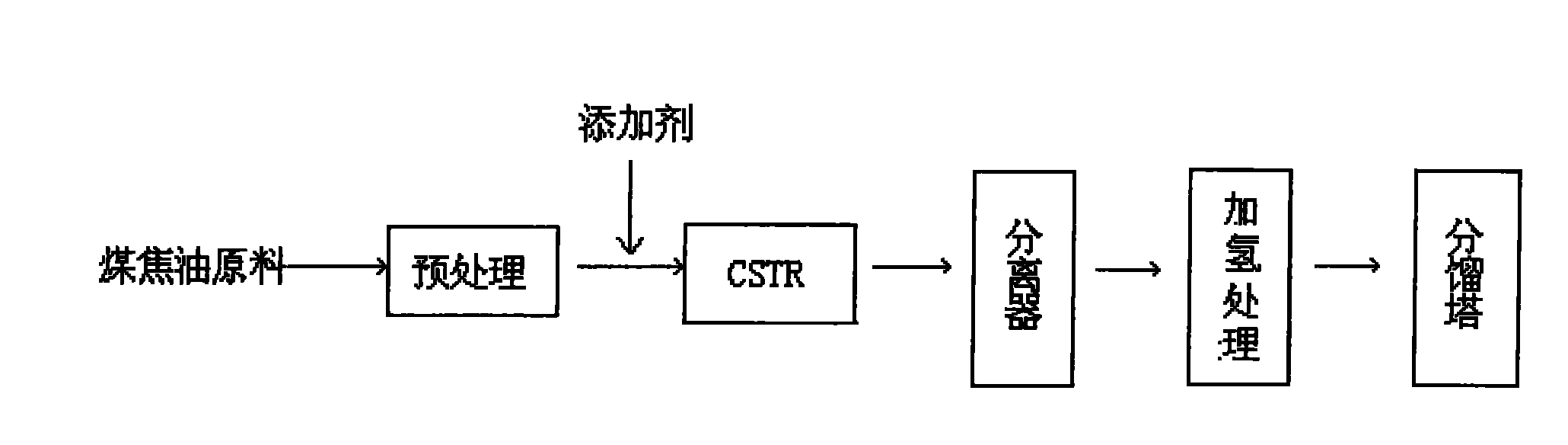

Coal tar processing method

ActiveCN102041053AEfficient processingReduce dosageTreatment with hydrogen-generating compoundsHydrogenSolvent

The invention discloses a coal tar processing method which comprises the following steps: mixing coal tar and a hydrogen-donor solvent, wherein the hydrogen-donor solvent comprises tetrahydronaphthalene or decahydronaphthalene, and the weight ratio of the coal tar to the hydrogen-donor solvent is (1:0.5)-(1:10); processing the mixture of the coal tar and the hydrogen-donor solvent for 0.2-5 hoursat the pressure of 15-40 MPa and the temperature of 200-500 DEG C; separating solid impurities from the processed product; and then, hydrogenating. The coal tar processing method provided by the invention is implemented in the supercritical state or approximately-critical state of the hydrogen-donor solvent, thus the mixing effect and reaction effect of the hydrogen-donor solvent and the coking precursor in the coal tar are improved, the coking tendency is reduced, the comprehensive reaction effect is enhanced in combination with hydrogenation, the impurity removing capability and long-term operation stability of the device are improved, and the more inferior coal tar can be processed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment process

InactiveUS8043600B2Simpler and not least safer production of additional hydrogenReduce capacityHydrogenLiquid hydrocarbon mixture productionHydrogenHydrocarbon

A process for the hydrotreating of fuels with co-production of hydrogen during operation of the process, which enables i.e. reduced need of make-up hydrogen in the hydrotreating stage. The hydrocarbon fuel introduced to the hydrotreatment stage is a fuel containing renewable organic material which generates carbon monoxide during operation of the process. The carbon monoxide is then converted to hydrogen in the recycle loop by a water gas shift stage.

Owner:HALDOR TOPSOE AS

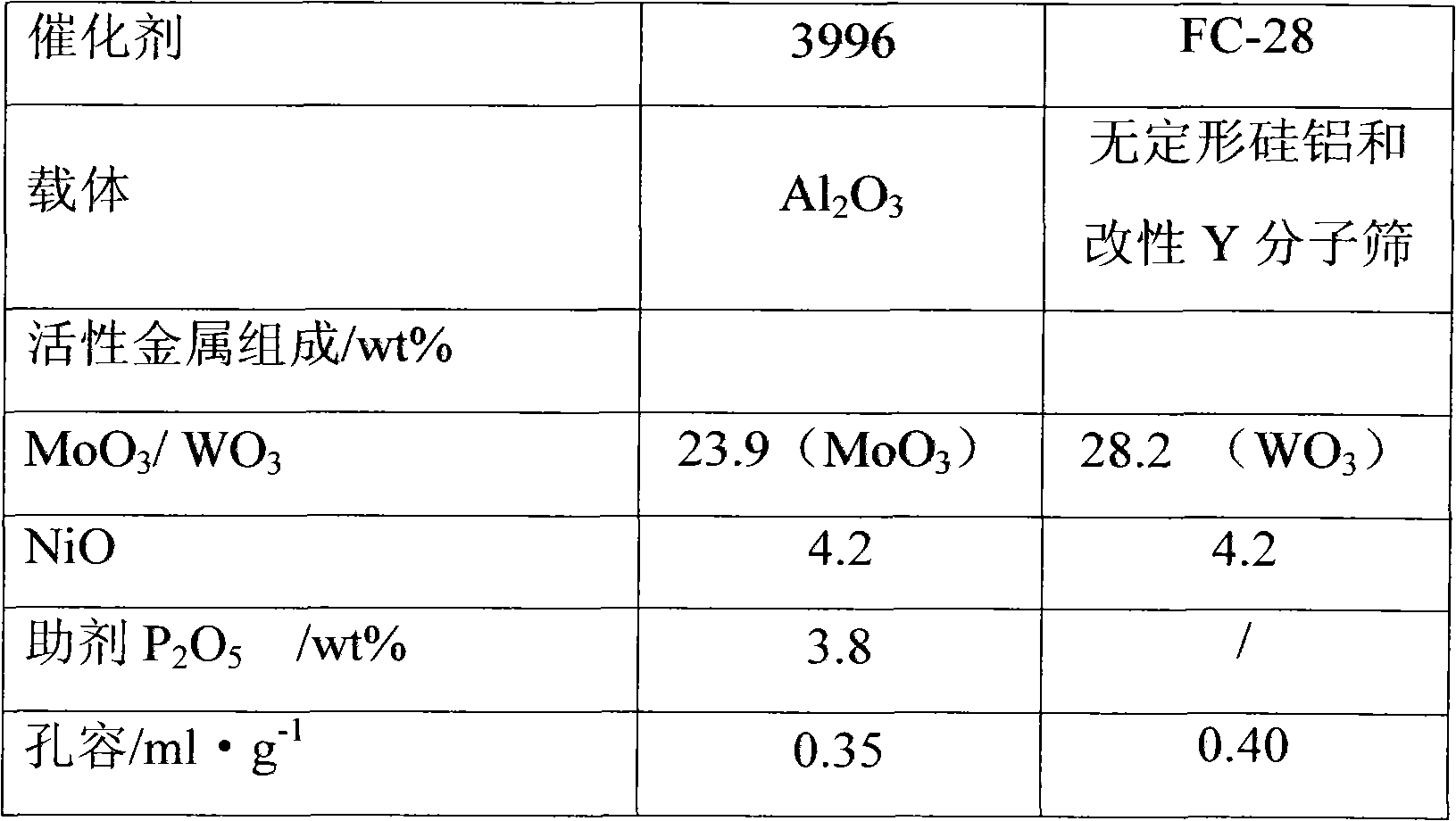

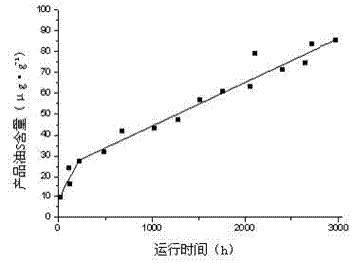

Coal tar hydrogenation method

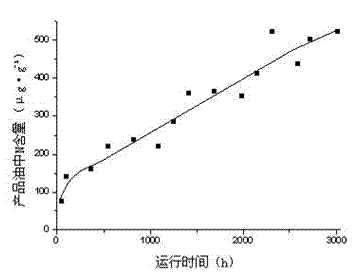

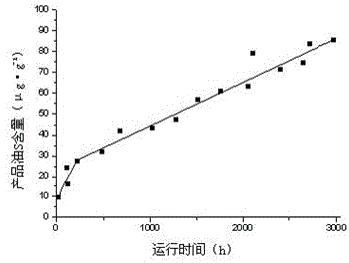

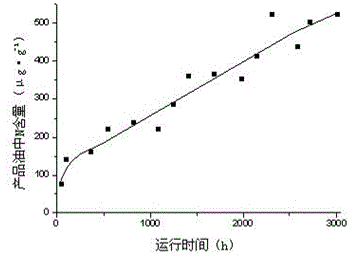

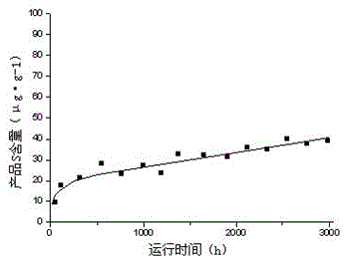

InactiveCN102899071AExtended operating cycleExtend your lifeTreatment with hydrogen-generating compoundsHydrogenSulfur

The invention discloses a method for prolonging the coal tar hydrogenation catalyst life by continuously adding sulfur, characterized in that: in the operation process of coal tar hydrogenation, the addition of a vulcanizing agent is controlled by taking H2S volume content which is 0.05-0.1% in recycle hydrogen as the indicators, by continuously on-line adding sulfur, the hydrogenation impurity removal rate and product quality can be maintained without shutting down the device, the catalyst activity is kept, thus the operation period of the catalyst is prolonged.

Owner:陕西双翼石油化工有限责任公司

Transport of heavy oil

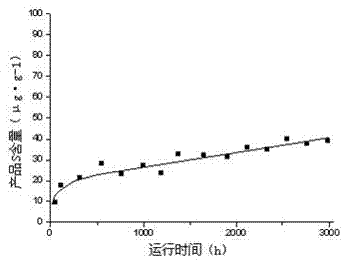

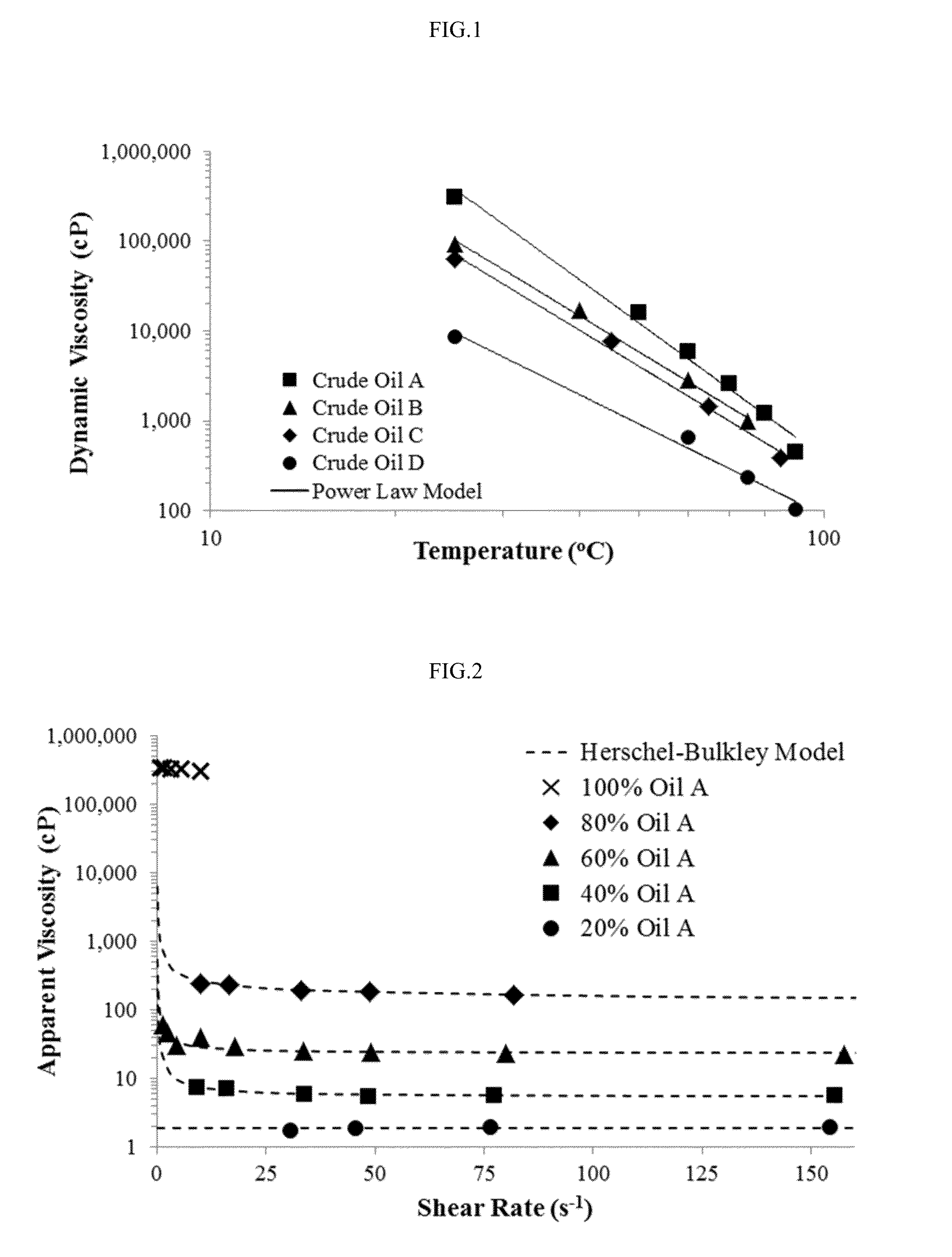

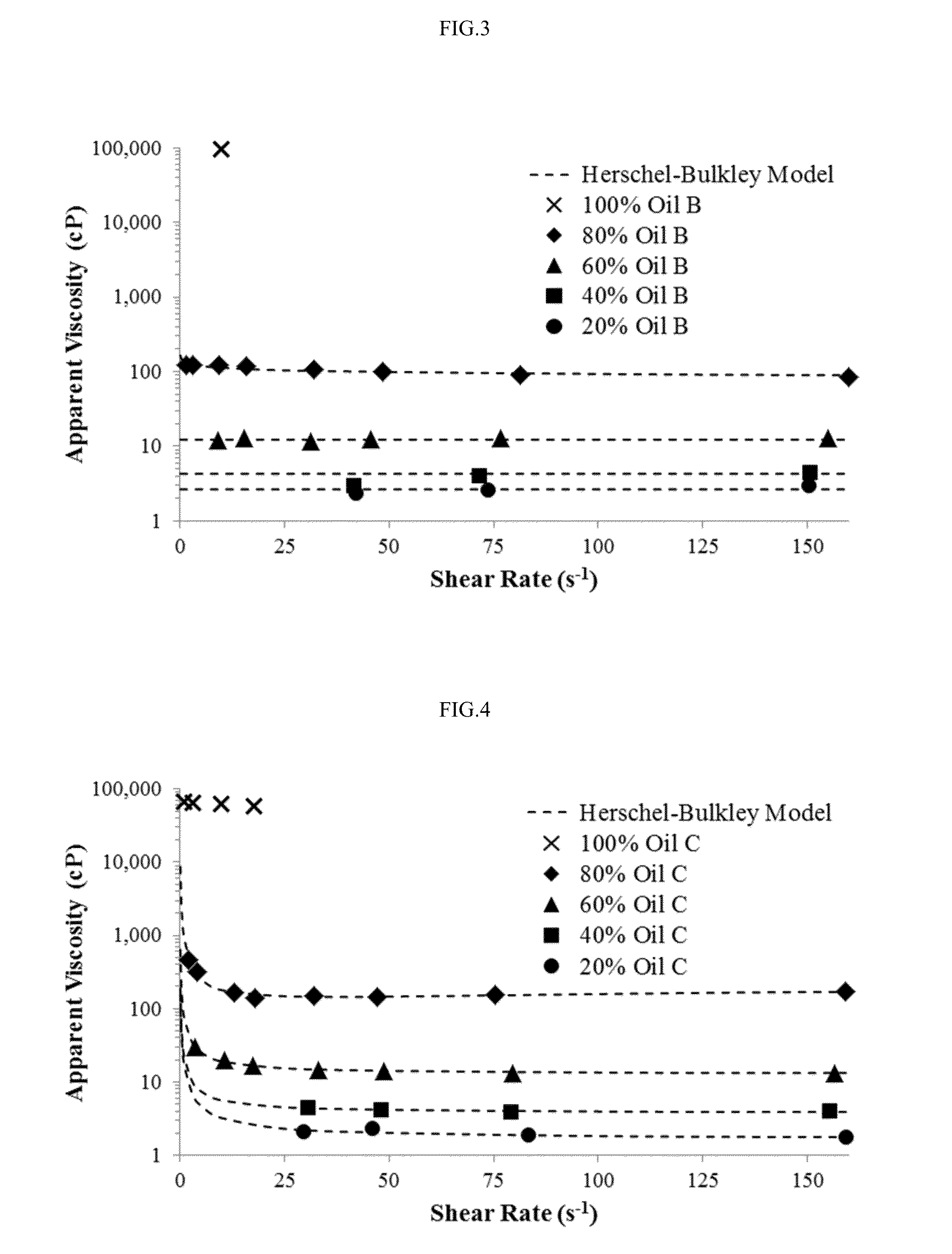

InactiveUS20140238679A1Low viscosityReduce water contentHydrocarbon purification/separationPipeline systemsEmulsionHeavy crude oil

Provided herein are, inter alia, heavy crude oil emulsion compositions and methods of making the same. The compositions and methods provided herein are particularly useful for the transport of heavy crude oils.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Preheating feeds to hydrocarbon pyrolysis products hydroprocessing

InactiveCN103764800ATreatment with hydrotreatment processesTreatment with hydrogen-generating compoundsTarHydrocarbon

The invention relates to processes for upgrading products obtained from hydrocarbon pyrolysis, equipment useful for such processes, and the use of upgraded pyrolysis products. A tar-containing stream recovered from the pyrolysis effluent is mixed with a utility fluid, preheated and subsequently hydroprocessed.

Owner:EXXONMOBIL CHEM PAT INC

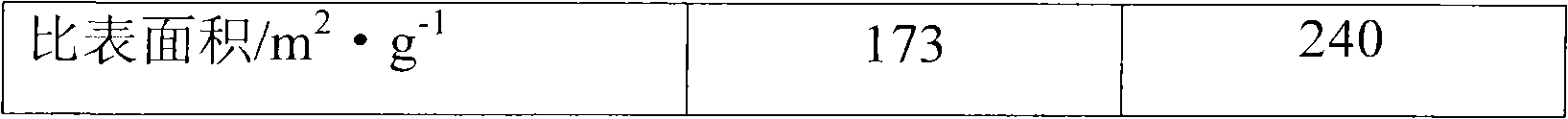

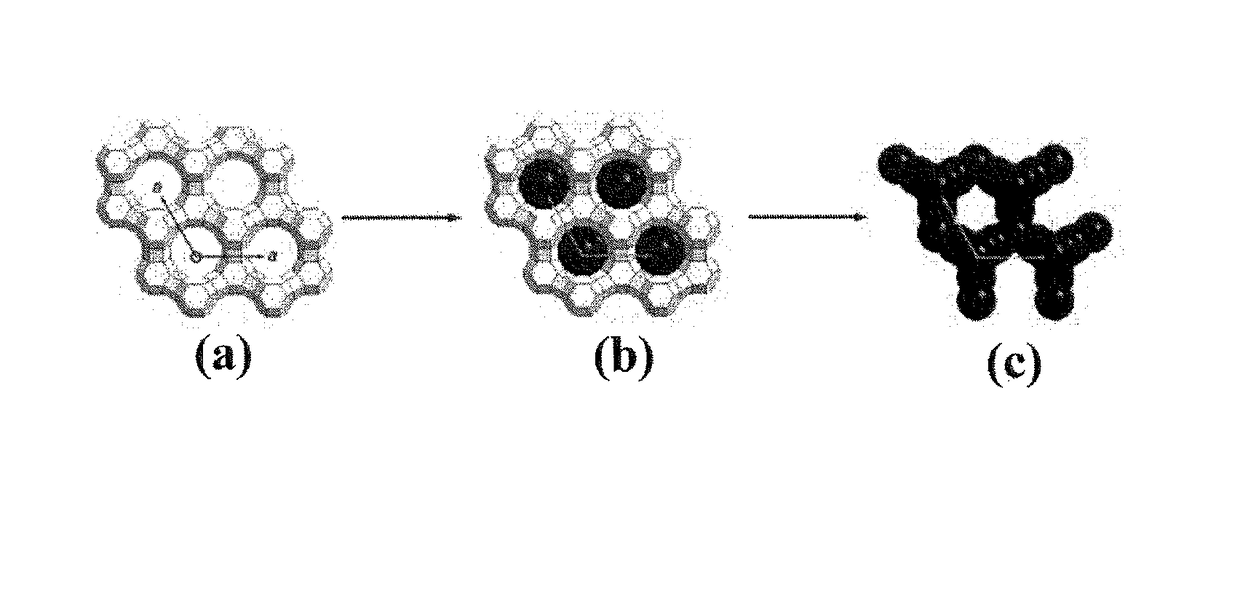

Synthesis of ordered microporous carbons by chemical vapor deposition

A methane microporous carbon adsorbent comprising a thermally-treated CVD carbon having a shape in the form of a negative replica of a crystalline zeolite has a BET specific surface area, a micropore volume, a micropore to mesopore volume ratio, a stored methane value and a methane delivered value and a sequential carbon synthesis method for forming the methane microporous carbon adsorbent. Introducing an organic precursor gas for a chemical vapor deposition (CVD) period to a crystalline zeolite that is maintained at a CVD temperature forms the carbon-zeolite composite. Introducing a non-reactive gas for a thermal treatment period to the carbon-zeolite composite maintained at a thermal treatment temperature forms the thermally-treated carbon-zeolite composite. Introducing an aqueous strong mineral acid mixture to the thermally-treated carbon-zeolite composite forms the methane microporous carbon adsorbent.

Owner:SAUDI ARABIAN OIL CO +1

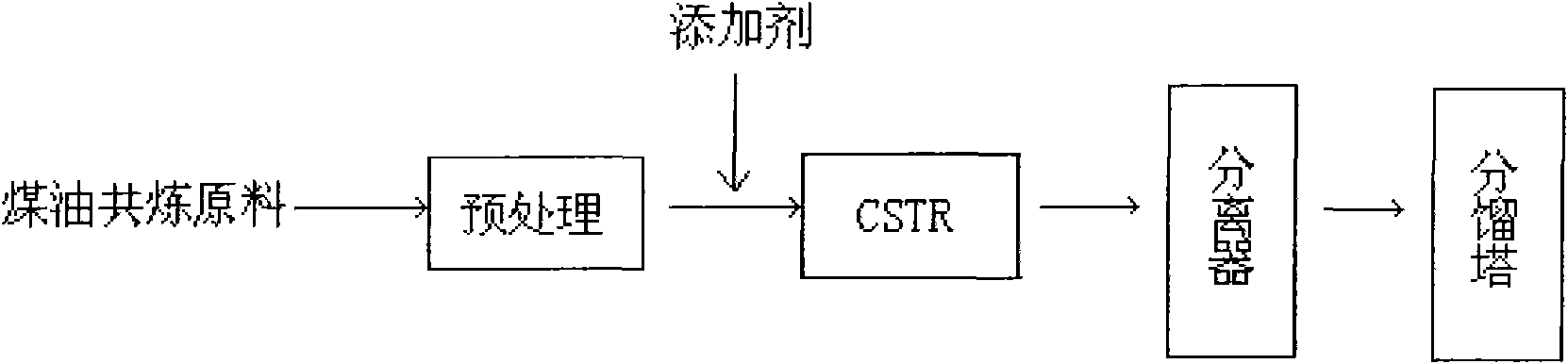

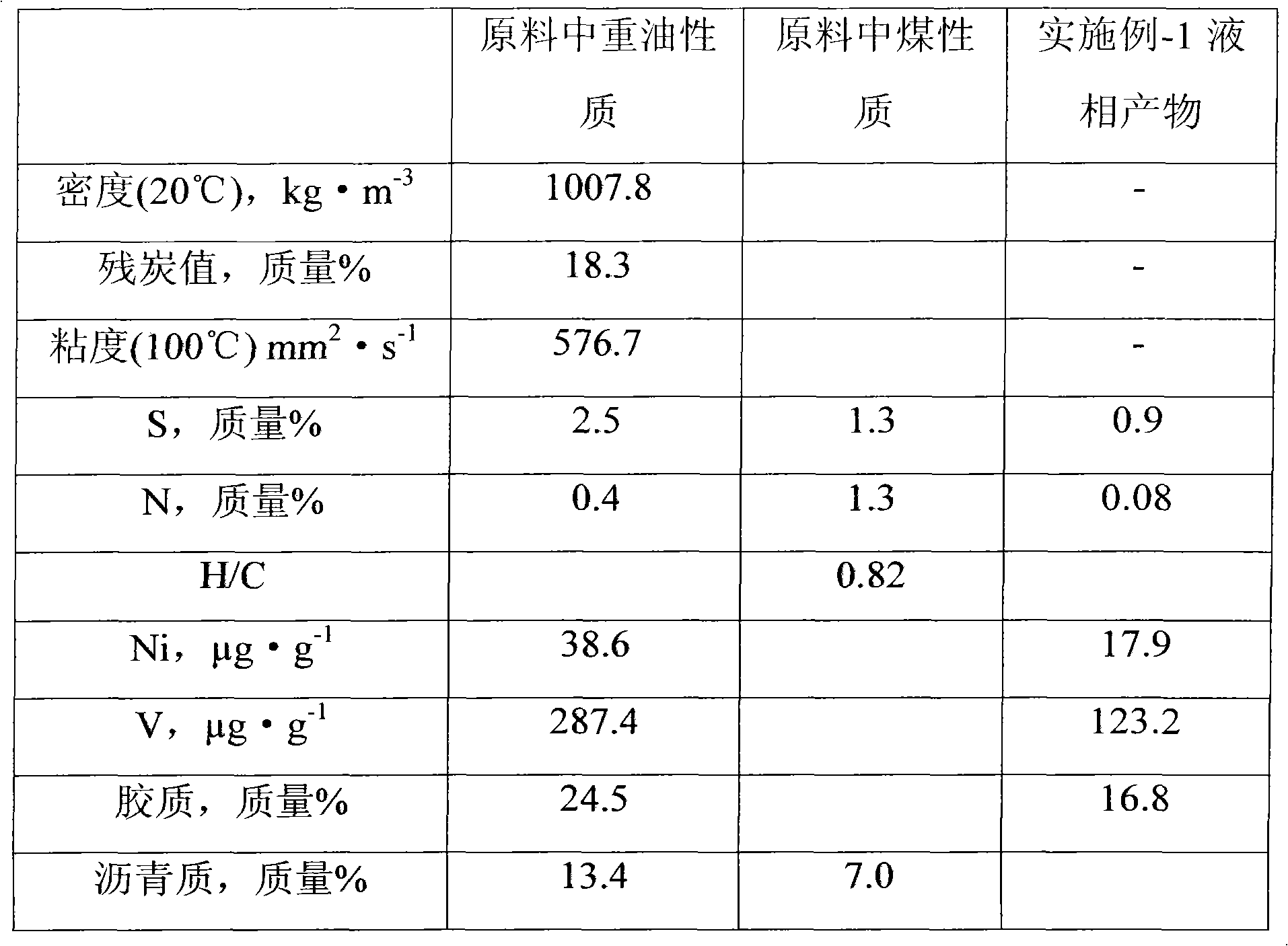

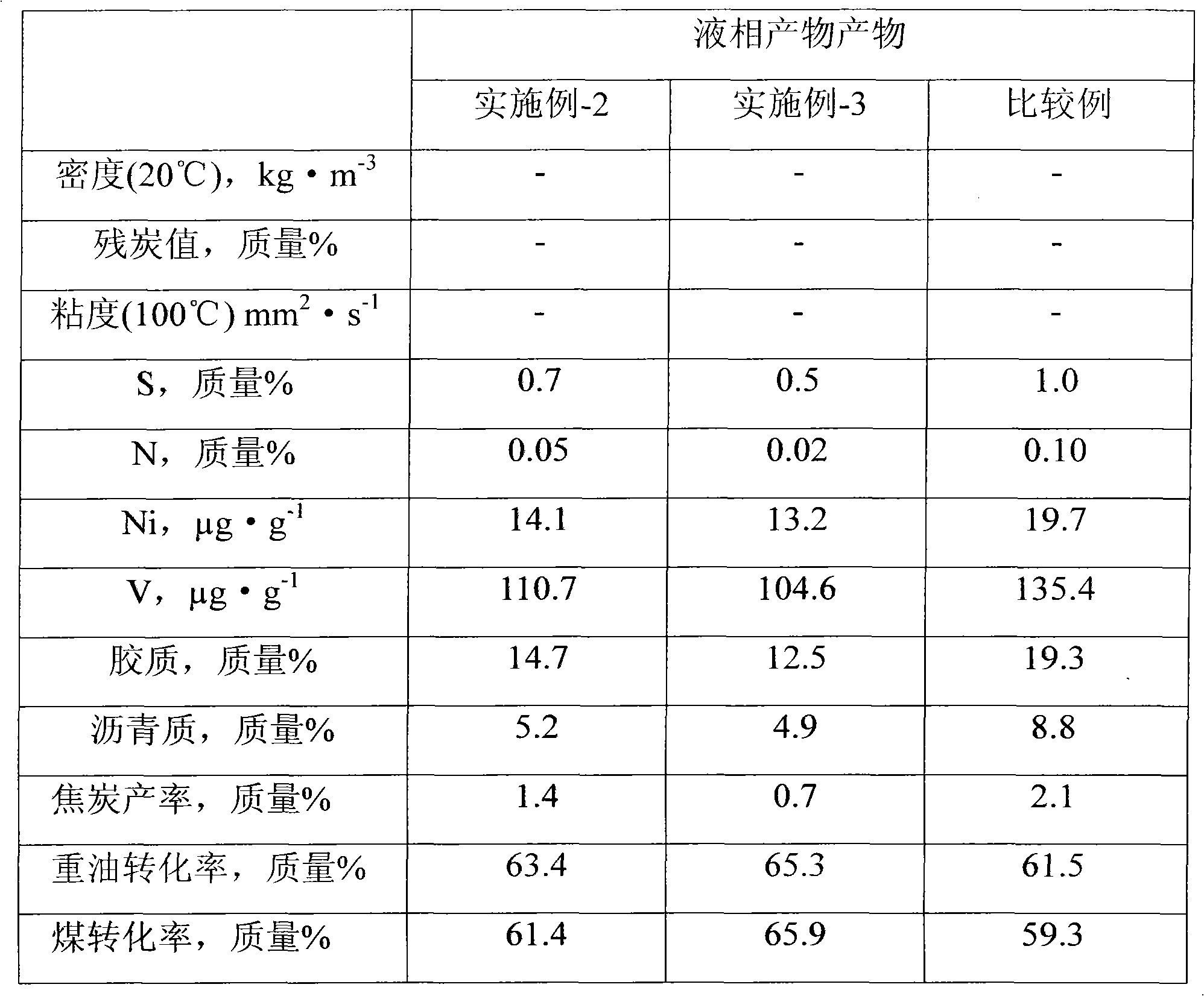

Processing method of coal and oil co-refining

ActiveCN102041018AReduce dosageImprove fusion effectLiquid hydrocarbon mixture productionTreatment with hydrogen-generating compoundsHydrogenFuel oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for heavy oil upgrading in a double-wall reactor

ActiveUS9567530B2Improve heat transfer performanceReduce amountThermal non-catalytic crackingMethane captureHeat flowWater flow

Owner:SAUDI ARABIAN OIL CO

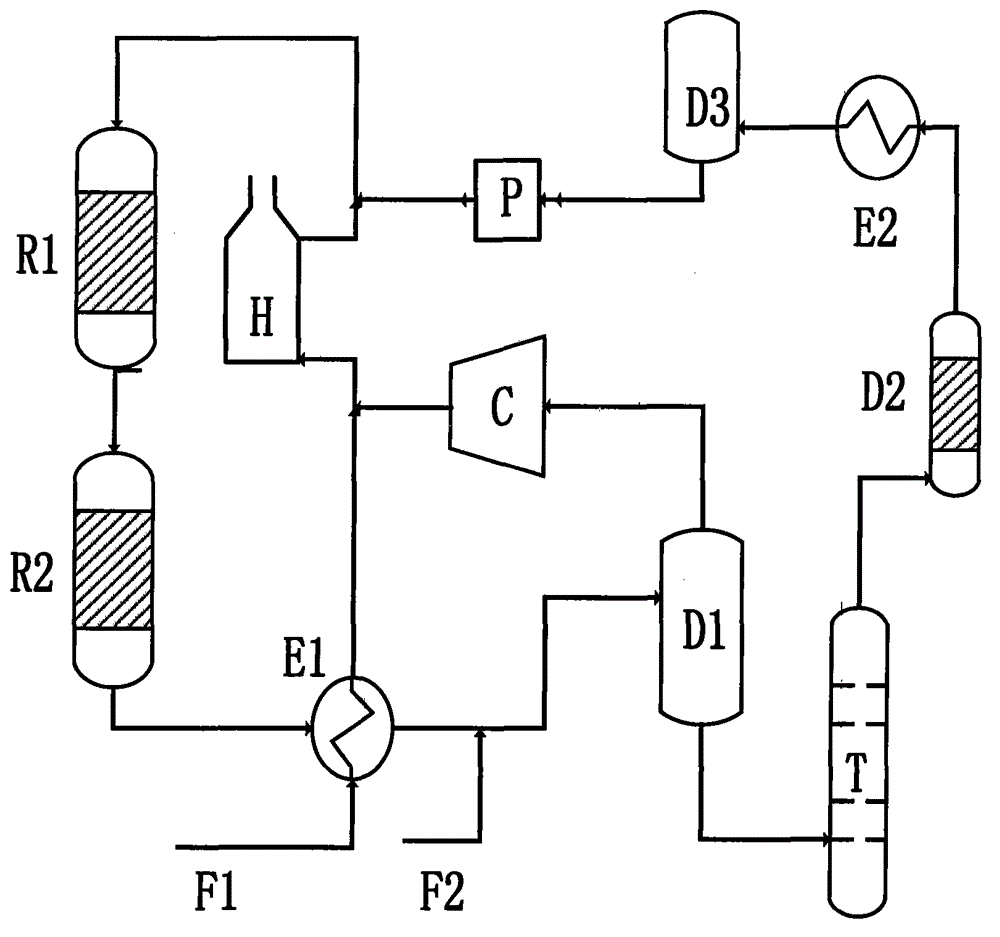

Coal tar hydrogenation method

InactiveCN102899071BExtended operating cycleExtend your lifeTreatment with hydrogen-generating compoundsHydrogenSulfur

The invention discloses a method for prolonging the coal tar hydrogenation catalyst life by continuously adding sulfur, characterized in that: in the operation process of coal tar hydrogenation, the addition of a vulcanizing agent is controlled by taking H2S volume content which is 0.05-0.1% in recycle hydrogen as the indicators, by continuously on-line adding sulfur, the hydrogenation impurity removal rate and product quality can be maintained without shutting down the device, the catalyst activity is kept, thus the operation period of the catalyst is prolonged.

Owner:陕西双翼石油化工有限责任公司

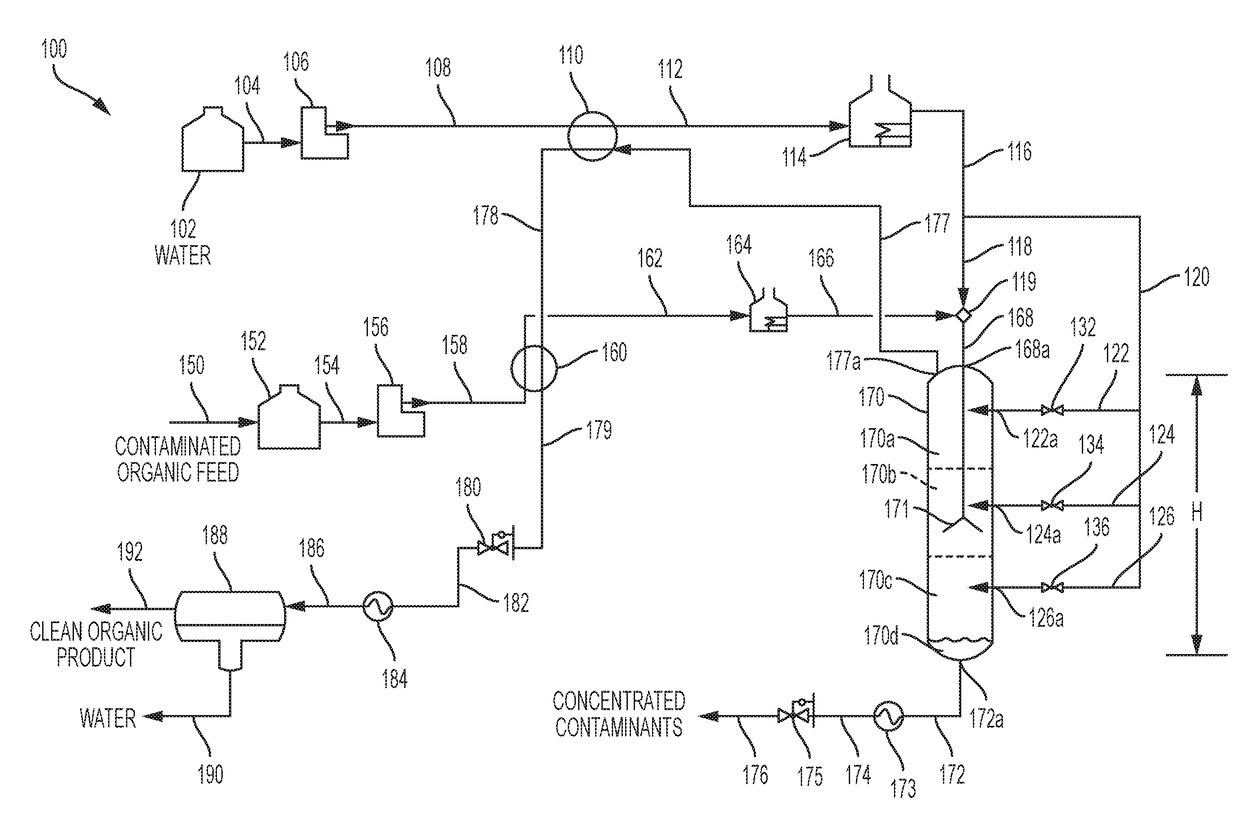

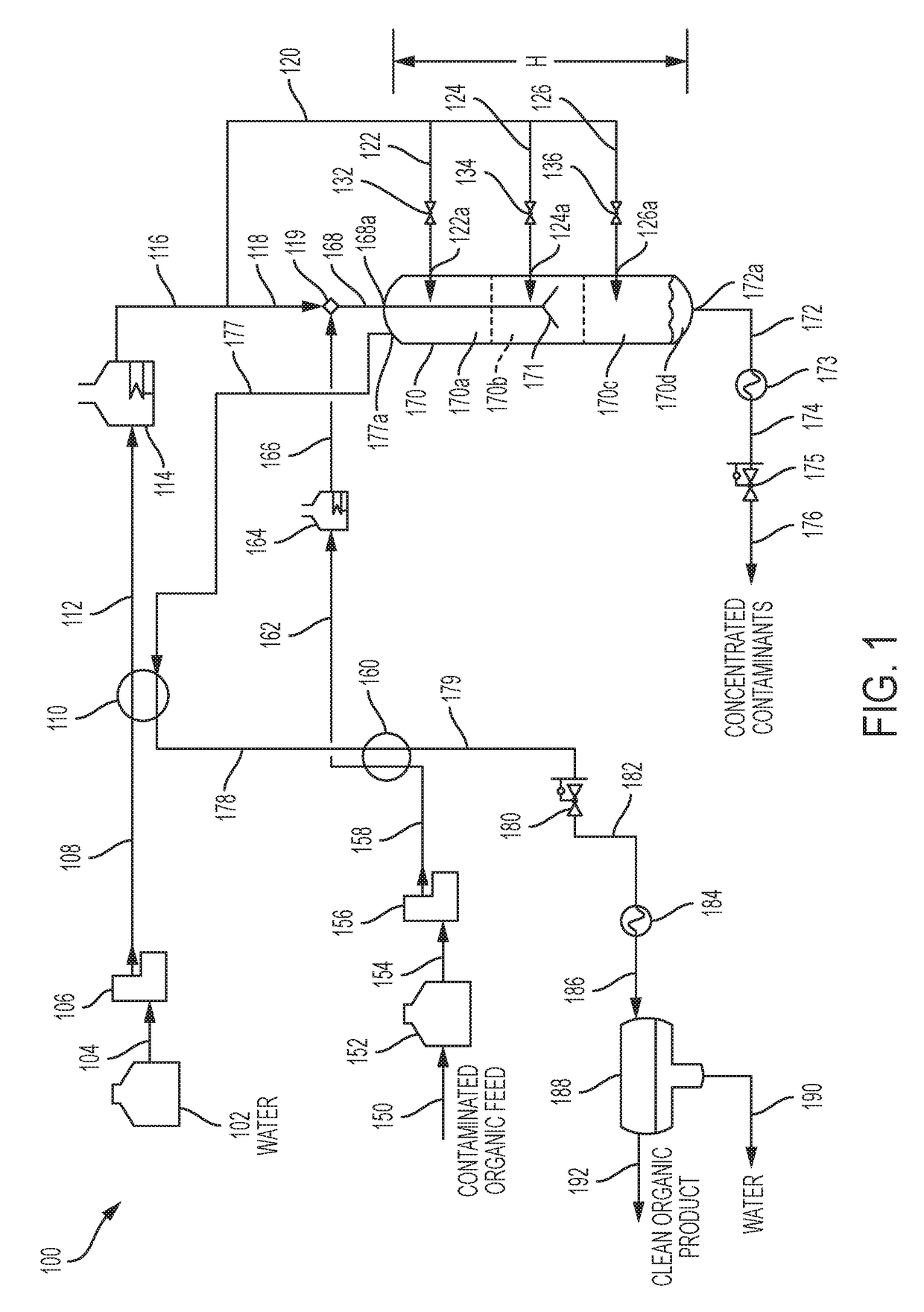

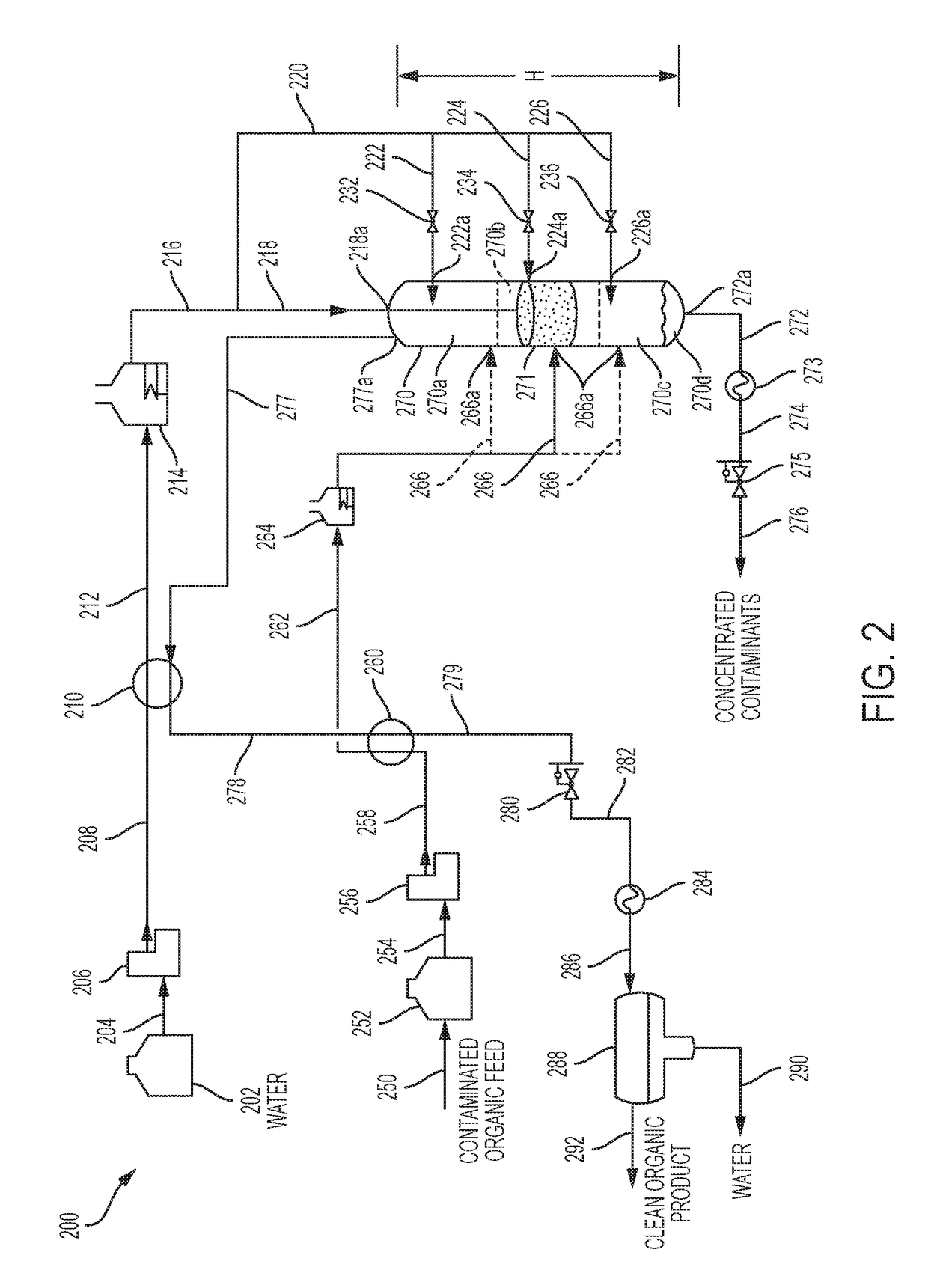

Supercritical Water Separation Process

ActiveUS20180010057A1Low densityFast separationTreatment with plural serial stages onlySolid fuelsParticulatesSimple Organic Compounds

A supercritical water separation process and system is disclosed for the removal of metals, minerals, particulate, asphaltenes, and resins from a contaminated organic material. The present invention takes advantage of the physical and chemical properties of supercritical water to effect the desired separation of contaminants from organic materials and permit scale-up. At a temperature and pressure above the critical point of water (374° C., 22.1 MPa), nonpolar organic compounds become miscible in supercritical water (SCW) and polar compounds and asphaltenes become immiscible. The process and system disclosed continuously separates immiscible contaminants and solids from the supercritical water and clean oil product solution. The present invention creates a density gradient that enables over 95% recovery of clean oil and over 99% reduction of contaminants such as asphaltenes and particulate matter depending on the properties of the contaminated organic material.

Owner:APPLIED RES ASSOCS INC

Upgrading crude oil using electrochemically-generated hydrogen

InactiveUS8002969B2Lower cost of capitalReduce operating costsThermal non-catalytic crackingCellsHydrogen atomHydrogen

A method for upgrading a petroleum oil by a hydroprocessing reaction in which the oil is hydrogenated, includes the steps of:a. forming a liquid reaction mixture of the oil with water and an amphiphilic liquid in predetermined proportions to thereby render the oil and water miscible;b. introducing the liquid reaction mixture into an electrolytic reactor having one or more cathodic elements formed from a porous high surface area, conductive material;c. operating the reactor to form reactive hydrogen atoms whereby the oil is hydrogenated by the hydrogen atoms;d. removing the liquid mixture from the reactor; ande. separating the hydrogenated upgraded oil from the amphiphilic liquid and any remaining water, e.g., by distillation, recovering and recycling the amphiphilic liquid for use.

Owner:SAUDI ARABIAN OIL CO

Production of upgraded petroleum by supercritical water

ActiveUS9771527B2Easy to moveKeep for a long timeHydrocarbon oil crackingLiquid solutions solvent extractionPetroleumPetroleum engineering

A method for upgrading a petroleum feedstock using a supercritical water petroleum upgrading system includes introducing the petroleum feedstock, water and an auxiliary feedstock. The method includes operating the system to combine the petroleum feedstock and the water to form a mixed petroleum feedstock and introducing separately and simultaneously into a lower portion of an upflowing supercritical water reactor. The auxiliary feedstock is introduced such that a portion of a fluid contained within the upflowing reactor located proximate to the bottom does not lack fluid momentum. An embodiment of the method includes operating the supercritical water petroleum upgrading system such that the upflowing reactor product fluid is introduced into an upper portion of a downflowing supercritical water reactor. The supercritical water petroleum upgrading system includes the upflowing supercritical water reactor and optionally a downflowing supercritical water reactor.

Owner:SAUDI ARABIAN OIL CO

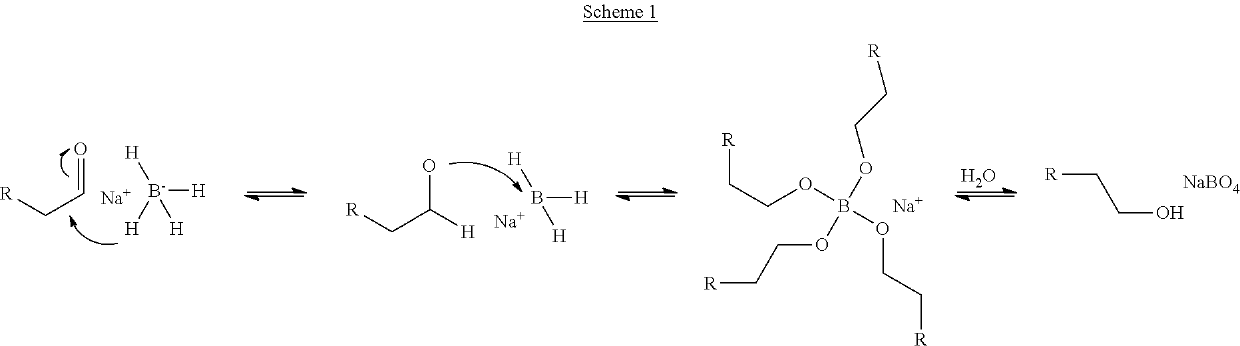

Process for modifying bio-oil

ActiveUS20140250774A1Alters compositionImprove stabilityOrganic compound preparationCarboxylic acid esters preparationHeating oilSolvent

Disclosed is a process for modifying of bio-oil, the process including the steps where feedstock including bio-oil is allowed react with a reducing agent in at least one polar solvent, to obtain modified bio-oil. Also disclosed is the use modified bio-oil, obtainable by the process, as heating oil, as starting material in processes for producing fuels, fuel components, fine chemicals, chemical building-blocks, and solvents.

Owner:UPM-KYMMENE OYJ

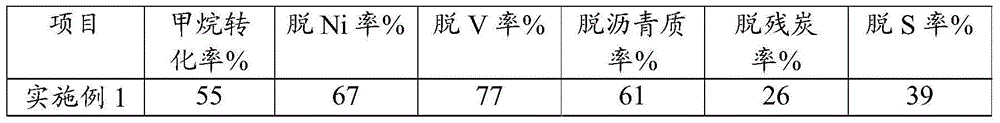

Methanation method of heavy hydrocarbon

ActiveCN105176577ALow costEmission reductionTreatment with hydrogen-generating compoundsMethanationSulfur

The invention provides a methanation method of heavy hydrocarbon, and belongs to the technical field of petroleum chemical engineering. Under the conditions of methanation of heavy hydrocarbon, heavy hydrocarbons and methane are simultaneously filled into a heavy hydrocarbon methanation reactor, then the mixture is contacted with a methane activation catalyst and a hydrogenation catalyst in sequence; under the effect of the methane activation catalyst, the methane is cut into CH3. and H., a hydrogen source is provided for the post hydrogenation reactions, and the directional assembly of CH3. and H. can be realized. The provided methanation method of heavy hydrocarbon can provide hydrogen for hydrogenation reactions, at the same time, can remove most of impurity atoms such as sulfur, oxygen, nitrogen, metals, and the like in heavy oil, and reduces the carbon residue. Moreover, the directional assembly of CH3. can convert heavy oil into light oil products, and increase the H / C ratio.

Owner:SINOPEC ENG GRP CO LTD

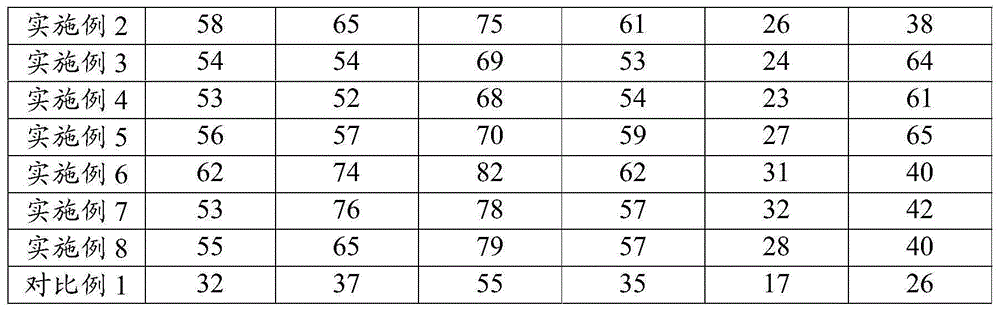

Method for controlling concentration of sulfureted hydrogen in circulating hydrogen of hydrogenation unit

ActiveCN101003747AImprove responsivenessExtend the stable operation periodHydrocarbon oils treatment control/regulationTreatment with hydrogen-generating compoundsSolventChemistry

This invention relates to a method for controlling H2S concentration in circulating H2 in hydrogenation apparatus. The method comprises: continuously or intermittently adding an appropriate amount of alkaline solvent into the water-injection pump inlet of hydrogenation apparatus, neutralizing H2S in circulating H2 when ammonium salt crystal is generated, and further dissolving H2S in water phase to reduce H2S concentration to an appropriate value. The method can reduce H2S concentration in circulating H2, and improve catalyst hydrogenation activity and stability. Besides, the method also has such advantages as low cost and easy operation, and can be used in the process of high-quality clean fuel production from fraction oil by hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

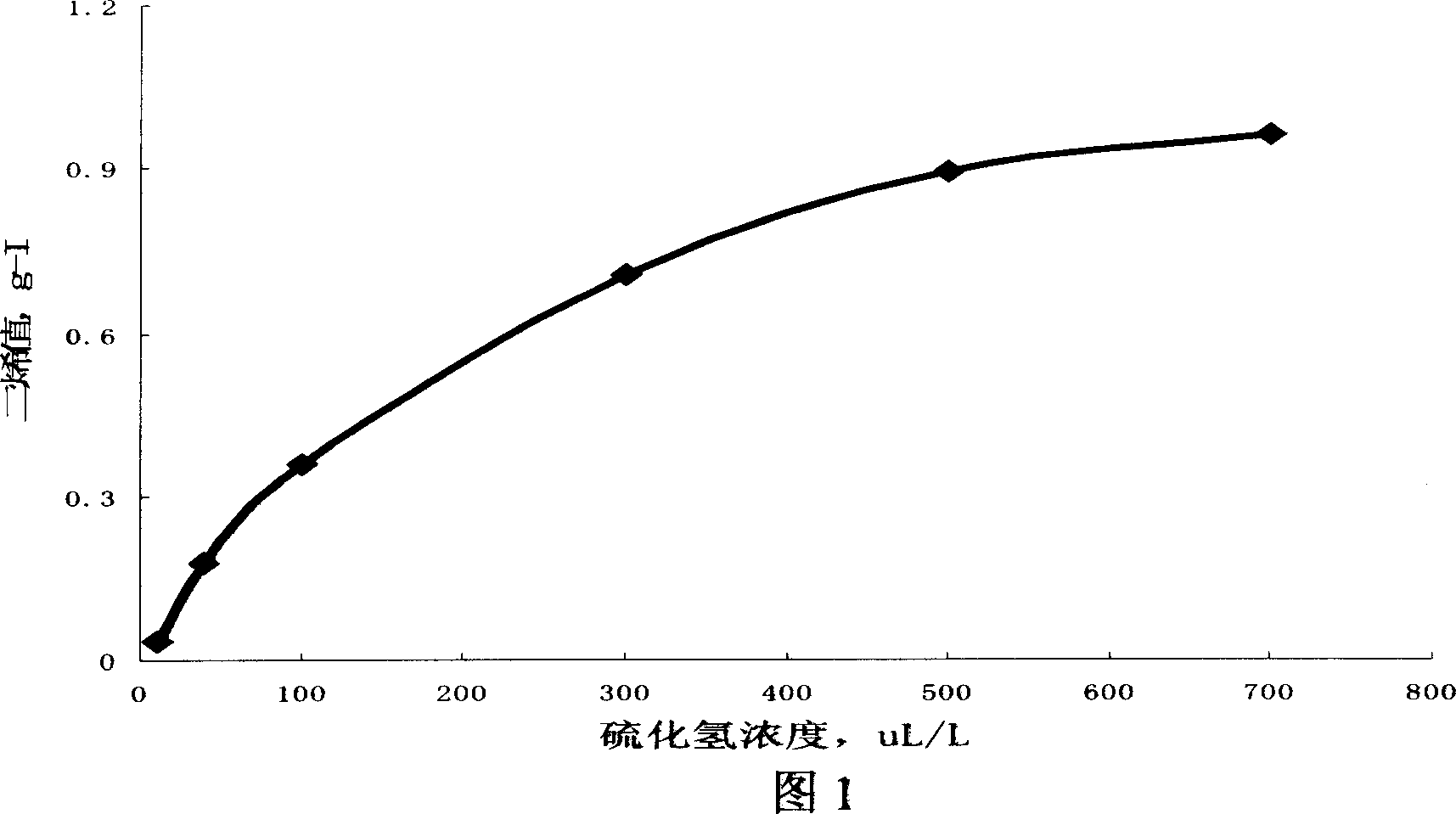

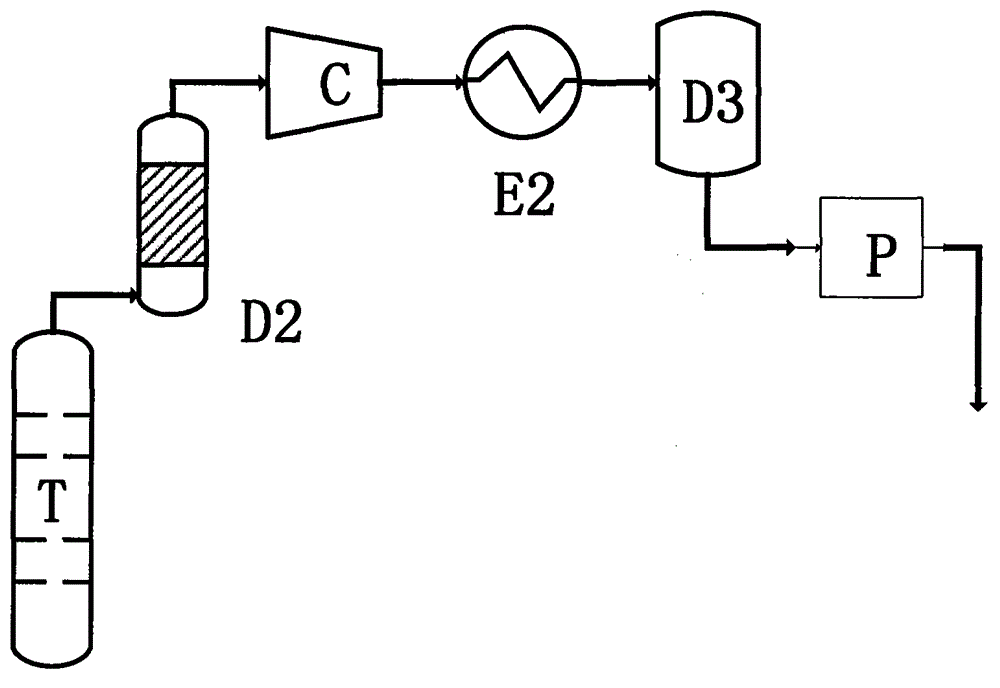

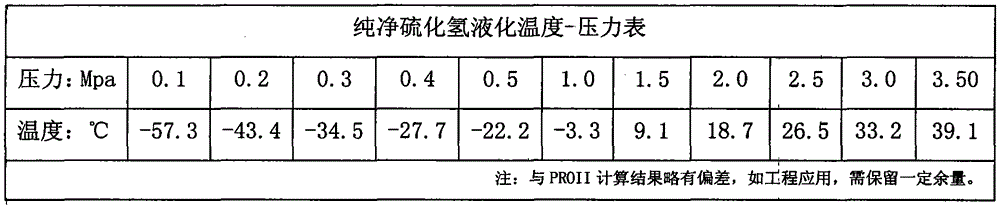

Hydrotreating sulfur supplementing method

ActiveCN104927904AReduce corrosionConducive to liquefactionTreatment with hydrogen-generating compoundsSulfur supplementSulfide

The invention provides a sulfur supplement technology for hydrogenation treatment. The sulfur supplementing technology comprises the following steps: conducting steam stripping to sulfur-containing sewage, emitted by a factory, through a steam stripping tower, and / or drying or cooling hydrogen sulfide regenerated by a desulfuration amine liquid regeneration tower so as to remove water, then conducting compressional cooling or deep cooling to liquidify a hydrogen sulfide gas, and finally delivering the liquid hydrogen sulfide to a high-pressure system for hydrogenation treatment through a pump, so as to maintain the hydrogen sulfide concentration required by the catalyst of the system.

Owner:王荣超

Method for reducing acids in crude oil

InactiveUS20140378718A1Reduce acidityDecrease acidLiquid organic insulatorsLiquid carbonaceous fuels9,10-DihydroanthraceneHydrogen

Introducing an additive into a crude oil may result in the crude oil having comparatively lower acid levels as compared to an otherwise identical crude oil absent the additive. The additive may include nanoparticles of metal oxides, oil soluble hydrogen donors, and / or heavy amines. The oil soluble hydrogen donors may be or include 1,2,3,4-tetrahydronaphthalene; 1,2,3,4-tetrahydrdroquinoline; 9,10-dihydroanthracene; 9,10-dihydrophenanthrene; and combinations thereof. The heavy amines may be or include alkyl amines, alkanolamines, polyethylene amines, polypropylene amines, and combinations thereof.

Owner:BAKER HUGHES INC

Process for modifying bio-oil

ActiveUS10633605B2Alters compositionImprove stabilityOrganic compound preparationCarboxylic acid esters preparationHeating oilProcess engineering

Disclosed is a process for modifying of bio-oil, the process including the steps where feedstock including bio-oil is allowed react with a reducing agent in at least one polar solvent, to obtain modified bio-oil. Also disclosed is the use modified bio-oil, obtainable by the process, as heating oil, as starting material in processes for producing fuels, fuel components, fine chemicals, chemical building-blocks, and solvents.

Owner:UPM-KYMMENE OYJ

Hydroprocessed product

ActiveCN103764797ATreatment with hydrotreatment processesTreatment with hydrogen-generating compoundsTarFuel oil

The invention relates to a hydroprocessed product that can be produced by hydroprocessing tar, such as a tar obtained from hydrocarbon pyrolysis. The invention also relates to methods for producing such a hydroprocessed product, and the use of such a product, e.g., as a fuel oil blending component.

Owner:EXXONMOBIL CHEM PAT INC

Process for improving cold flow properties and increasing yield of middle distillate feedstock through liquid full hydrotreating and dewaxing

ActiveUS20140262945A1Robust and economical processImprove cold flowRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsProcess engineering

Owner:REFINING TECH SOLUTIONS LLC

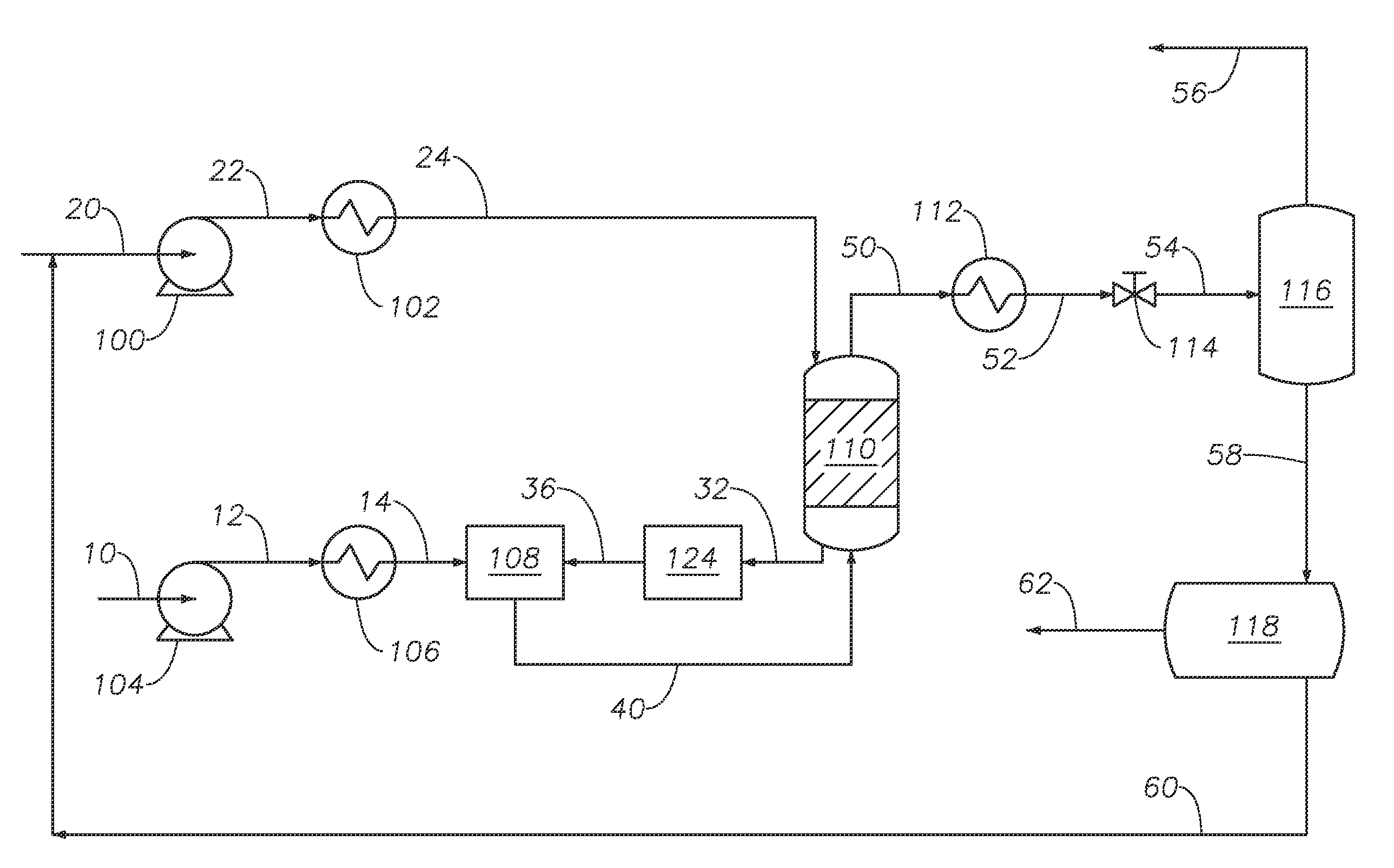

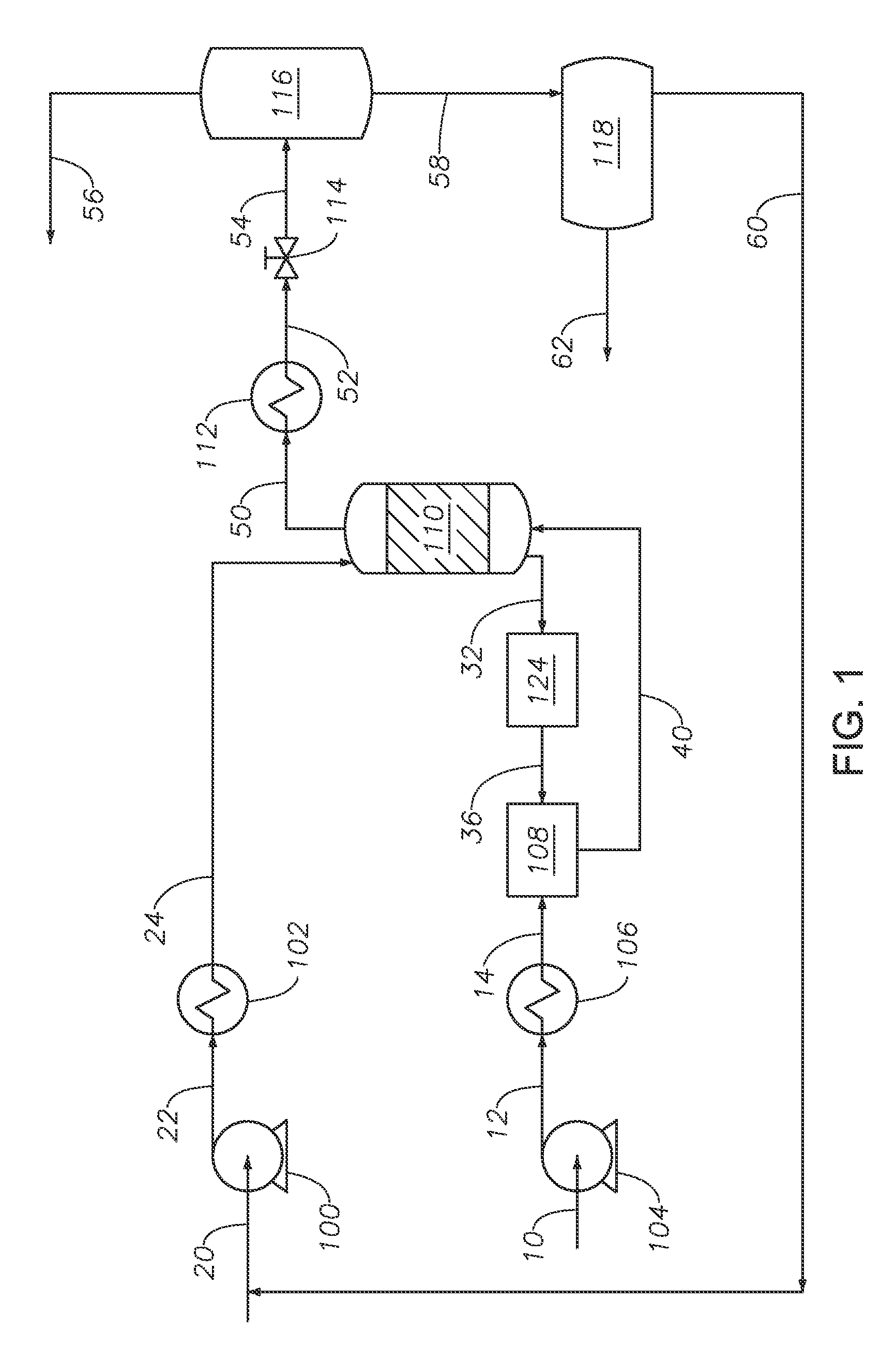

Upgrading of hydrocarbons by hydrothermal process

ActiveUS9039889B2Low costDifficult to recoverThermal non-catalytic crackingTreatment with plural serial cracking stages onlyHydrogenWater flow

A hydrocarbon feedstock upgrading method is provided. The method includes supplying the hydrocarbon feedstock, water and a pre-heated hydrogen donating composition to a hydrothermal reactor where the mixed stream is maintained at a temperature and pressure greater than the critical temperatures and pressure of water in the absence of catalyst for a residence time sufficient to convert the mixed stream into a modified stream. The hydrogen donating composition is pre-heated and maintained at a temperature of greater than about 50° C. for a period of at least about 10 minutes. The modified stream includes upgraded hydrocarbons relative to the hydrocarbon feedstock. The modified stream is then separated into a gas stream and a liquid stream and the liquid stream is separated into a water stream and an upgraded hydrocarbon product stream.

Owner:SAUDI ARABIAN OIL CO

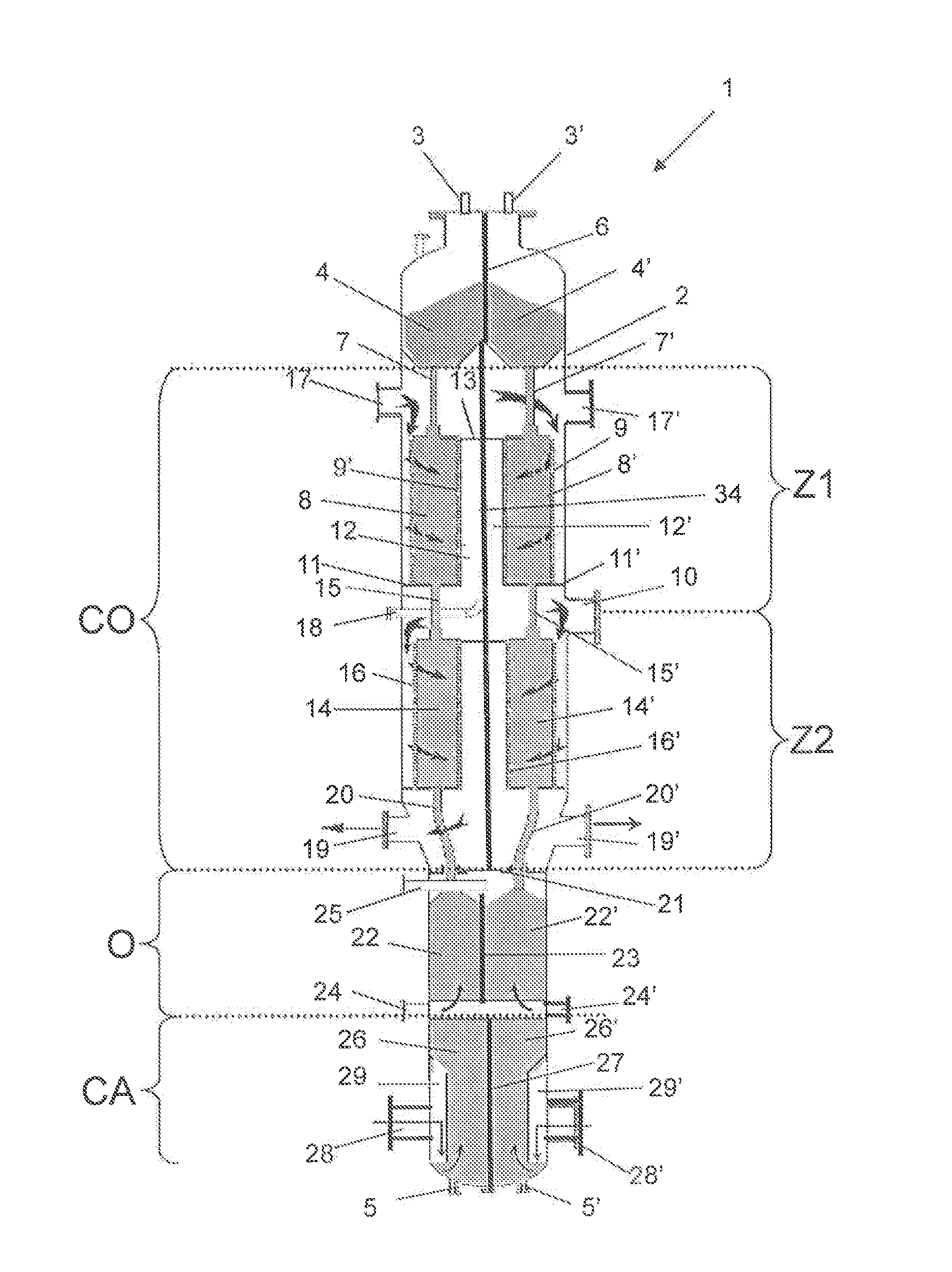

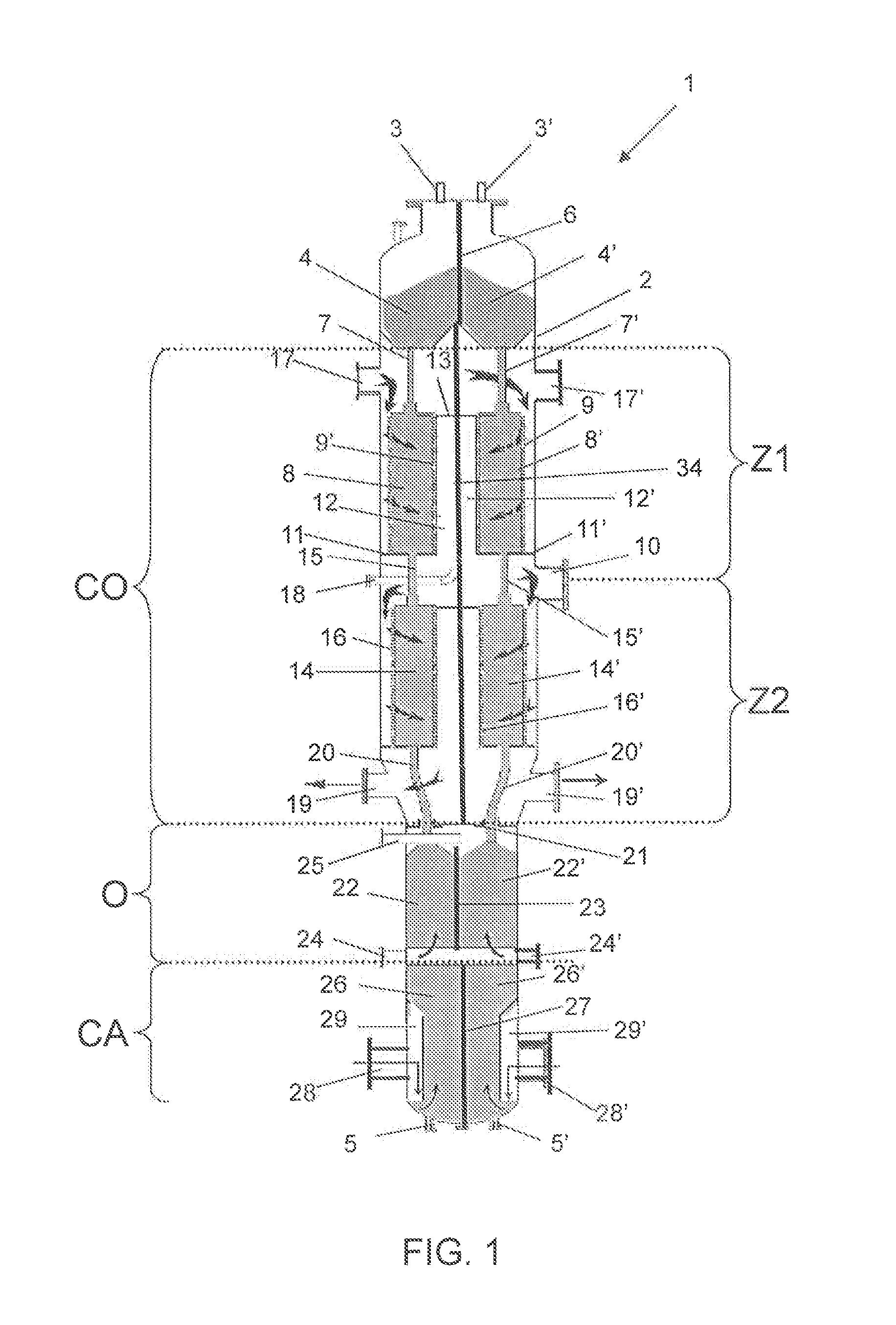

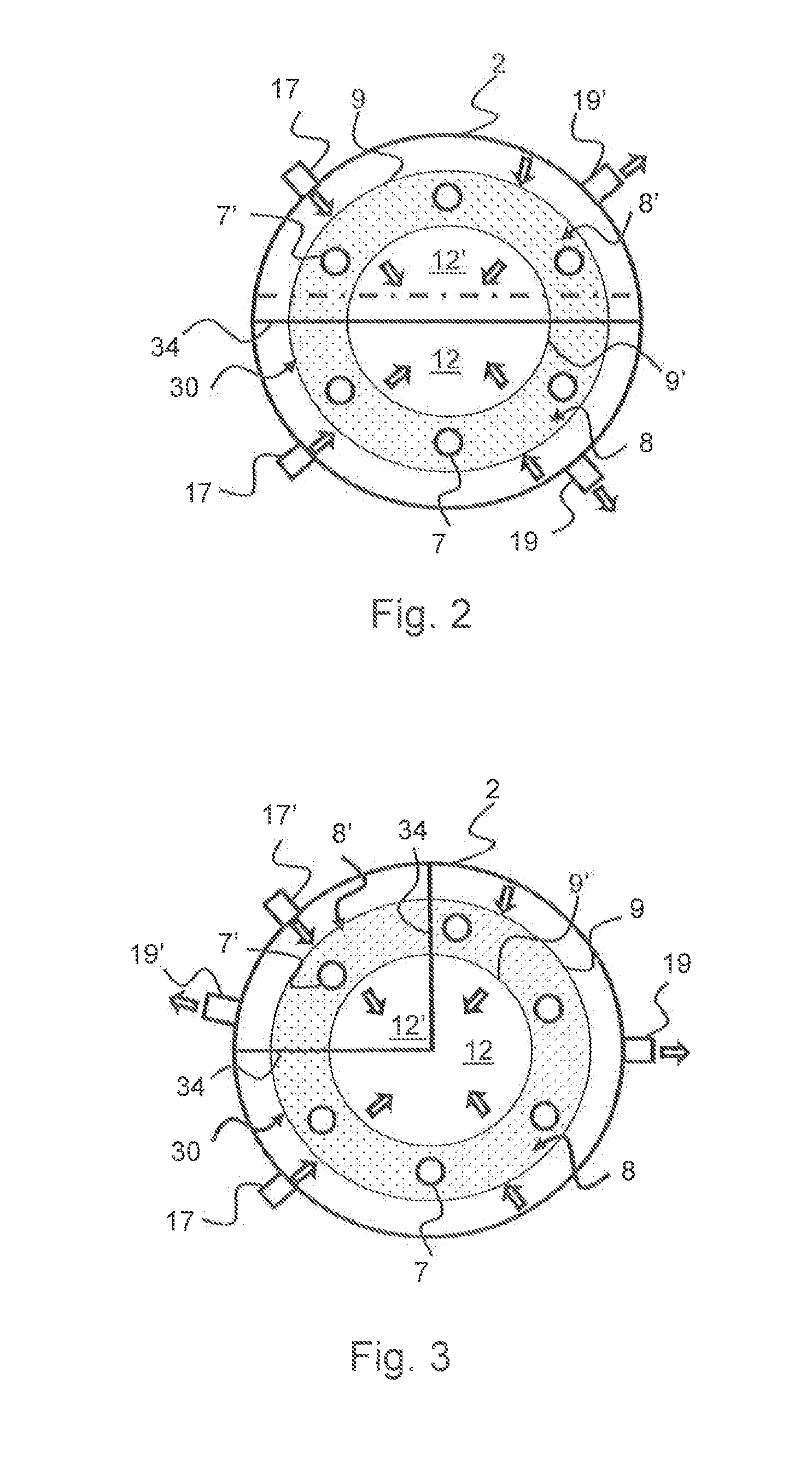

Regenerator for regenerating catalysts under different operating conditions

ActiveUS20160068766A1Catalytic naphtha reformingCatalyst regeneration/reactivationCombustionEngineering

The present invention concerns a moving bed catalyst regenerator (1) comprising a vessel (2) extending in a vertical direction, said vessel being divided into at least two regeneration zones extending along the vertical height of said vessel, in which particles of catalyst move under gravity, in which each regeneration zone comprises, in succession and in the order in which the catalysts move:a) a combustion section (CO);b) an oxychlorination section (O) disposed below the combustion section and comprising means for bringing catalyst from the combustion section (CO) to the oxychlorination section (O);c) a calcining section (CA) disposed below the oxychlorination section;characterized in that the regeneration zones are separated from each other by a separation means which is impermeable to catalysts and to gases in a manner such that the catalysts of each of the zones are capable of being regenerated under different operating conditions.

Owner:INST FR DU PETROLE

Method of simultaneously removing sulfur and mercury from hydrocarbon material using catalyst by means of hydrotreating reaction

ActiveUS8980082B2Easily and cheaply removedEfficient removalGaseous fuelsCatalyst activation/preparationActive siteCatalyst support

Disclosed herein is a method of simultaneously removing sulfur and mercury from a hydrocarbon material, including: hydrotreating the hydrocarbon material containing sulfur and mercury in the presence of a catalyst including a metal supported with a carrier to convert sulfur into hydrogen sulfide, and adsorb mercury on a metal active site or a carrier of the catalyst in the form of mercury sulfide.

Owner:SK INNOVATION CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com