Hydrotreating sulfur supplementing method

A technology for hydrotreating and supplementing sulfur, which is used in the treatment of hydrogen-producing compounds, etc., to achieve the effects of multiple steps, alleviating corrosion problems, and saving investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

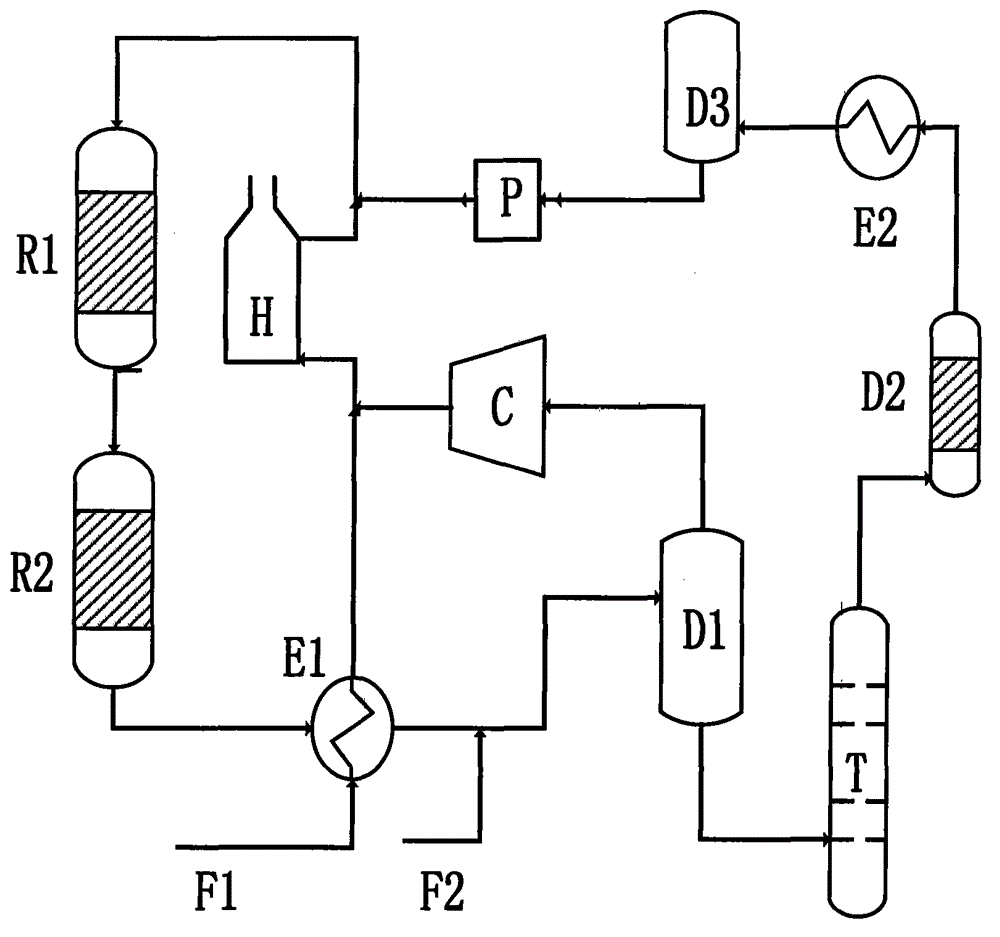

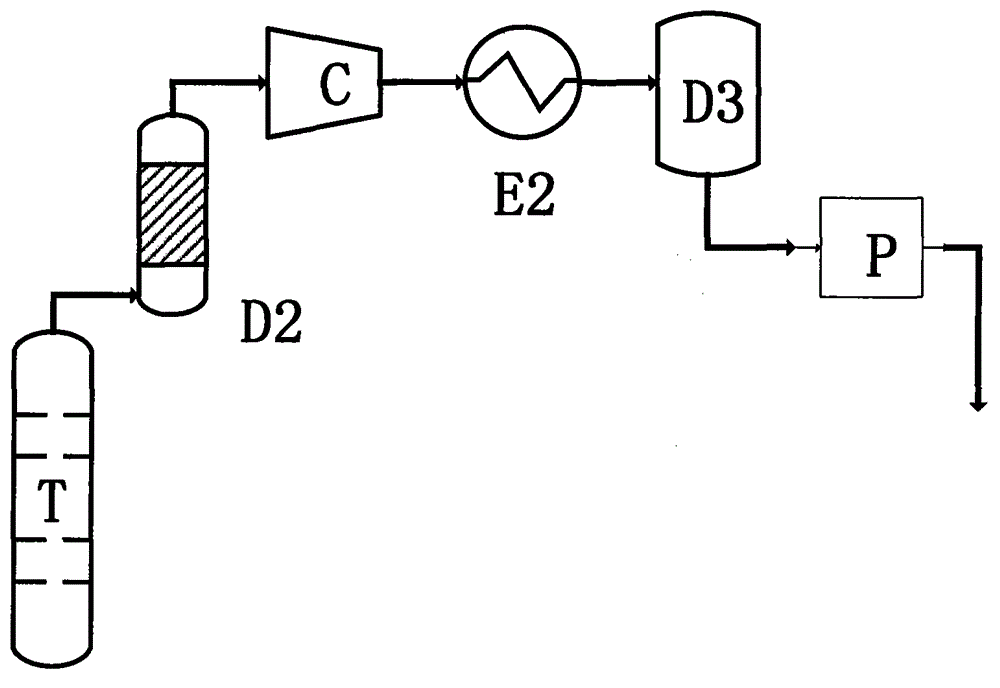

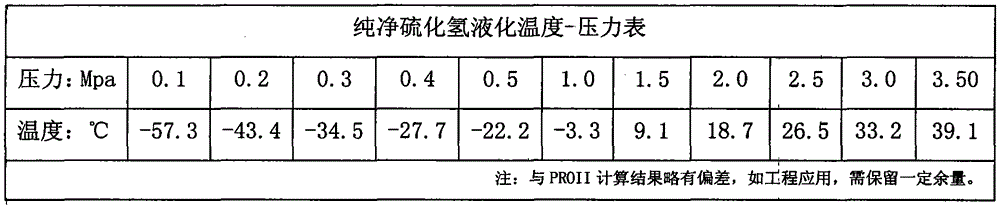

[0047] Example 1: Under the condition of heating the bottom of the stripping tower for sulfur-containing sewage, components such as hydrogen sulfide, water vapor, and methane in the sulfur-containing sewage flow out from the top of the tower to form hydrogen sulfide-containing gas. The gas enters the storage tank D2 filled with an acid gas-resistant molecular sieve desiccant, and after removing the water vapor therein, enters the hydrogen sulfide-containing gas condenser E2. On the other side of the condenser E2, the liquid propylene is heated and vaporized to form a low temperature of -47°C to realize the condensation and cooling of the gas containing hydrogen sulfide. (The refrigerant is not limited to propylene). After the propylene gas is vaporized, it can be pumped back by the screw compressor to be repressurized, cooled, expanded and cooled, and recycled (same as ordinary refrigeration, not described in detail). The gas containing hydrogen sulfide is condensed and coole...

Embodiment 2

[0050] Example 2: The sulfur-containing sewage stripping tower T strips hydrogen-sulfide-containing gas, enters the lower part of the storage tank D2 filled with phosphorus pentoxide, penetrates the phosphorus pentoxide bed from bottom to top, and removes water vapor therein After that, it flows out from the top of D2 to form dried hydrogen sulfide-containing gas. The gas is pressurized by the zero-leakage diaphragm compressor C, then cooled by the water cooler E2, and then enters the storage tank D3, hydrogen sulfide forms a liquid and enriches at the bottom of the storage tank, and non-condensable gas such as methane is enriched at the top of the storage tank and discharged . The liquid hydrogen sulfide at the bottom of the storage tank D3 is pressurized by a hydraulic diaphragm metering pump, and is directly transported to the inlet of the first reactor for hydrotreating.

[0051] The hydrogen sulfide gas circulation process of this sulfur replenishing method is briefly de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com