Combined process method for modifying heavy oil

A combined process and heavy oil upgrading technology, applied in the petroleum industry, hydrotreating process, hydrocarbon oil cracking, etc., can solve the problem of high coking rate, improve the yield of light oil, reduce the dosage, and improve the fusion effect and reaction. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

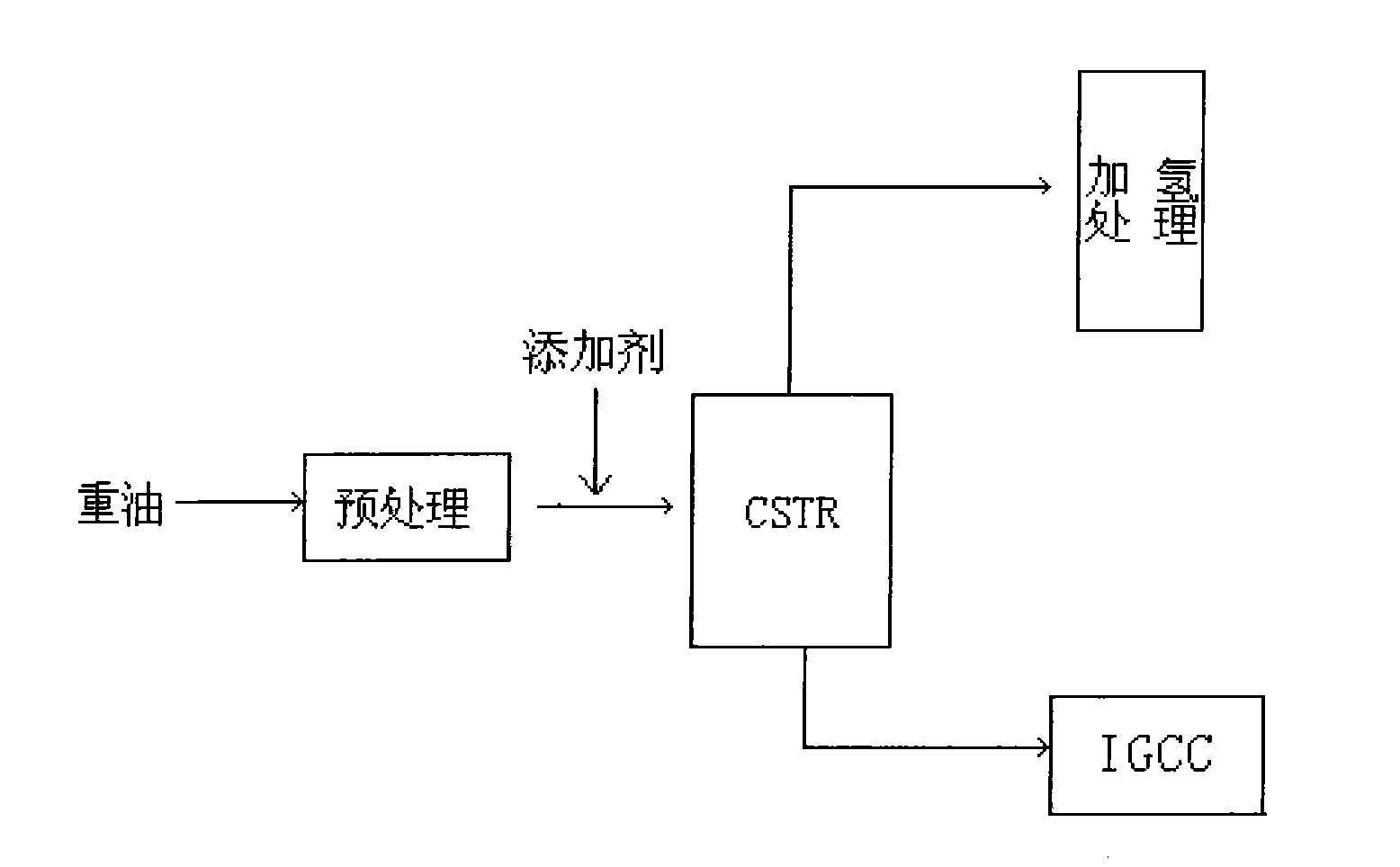

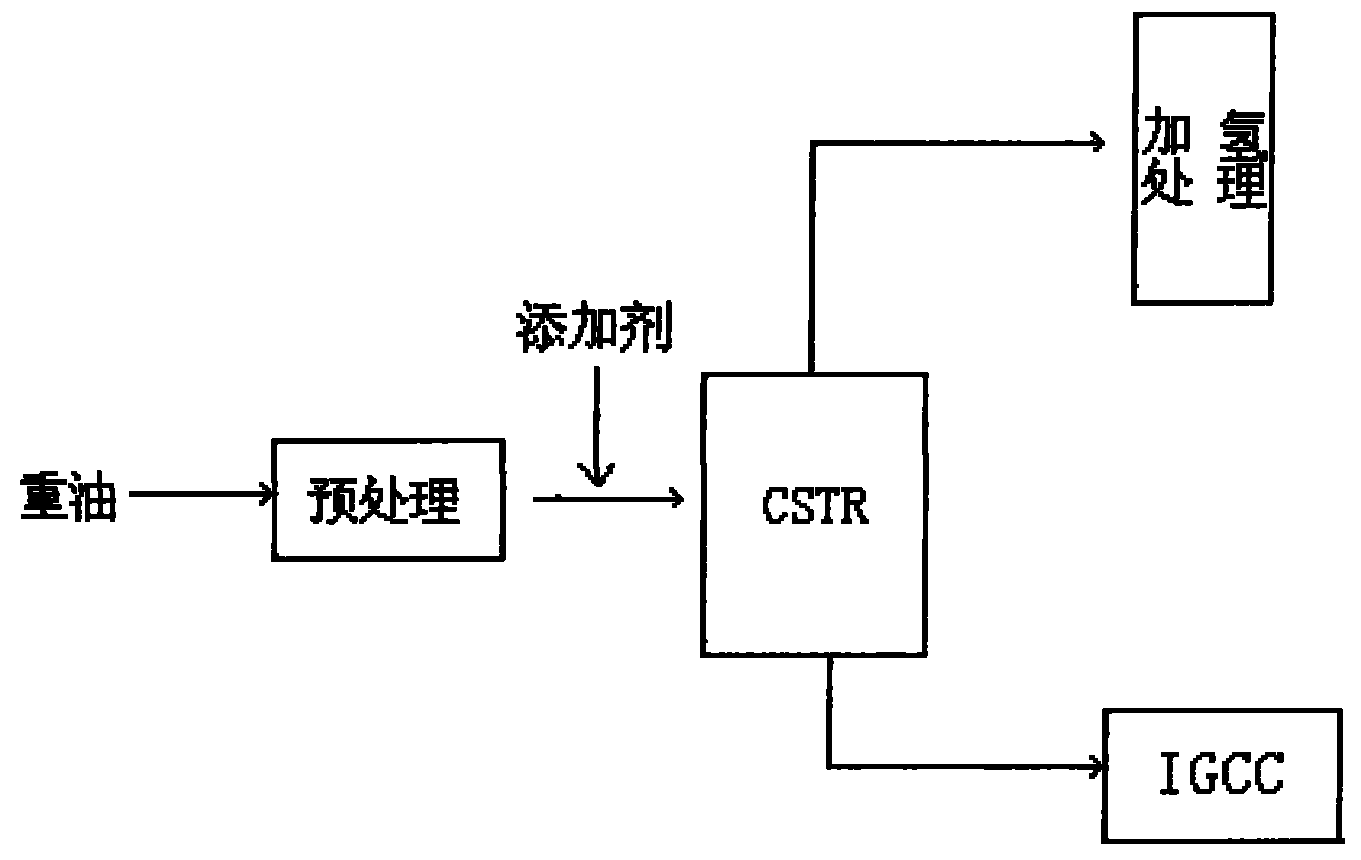

Method used

Image

Examples

Embodiment -1

[0023] After the Tahe residual oil is treated with the same filtration as the conventional process, it is added to the static mixer with tetralin (keep excess tetralin, the weight ratio of heavy oil to tetralin is 1:6), Then perform supercritical treatment. For example, after the material is heated, it enters the CSTR (Continuously Stirred Tank Reactor), pressurizes, heats up and starts stirring at a speed of 800 rpm, pressurizes to 20MPa, and heats up to 400°C. The reaction time is 3h. The material after supercritical treatment is separated, and the light part is subjected to hydrogenation treatment. The conditions are: temperature: 400°C, pressure 15MPa, space velocity 1.5h -1 , The volume ratio of hydrogen to oil is 800:1. The heavy part is used for IGCC gasification power generation, and the conditions are conventional process operating conditions, such as gasification, heat recovery, purification and several parts of gas turbine and steam turbine power generation. Excess...

Embodiment -2

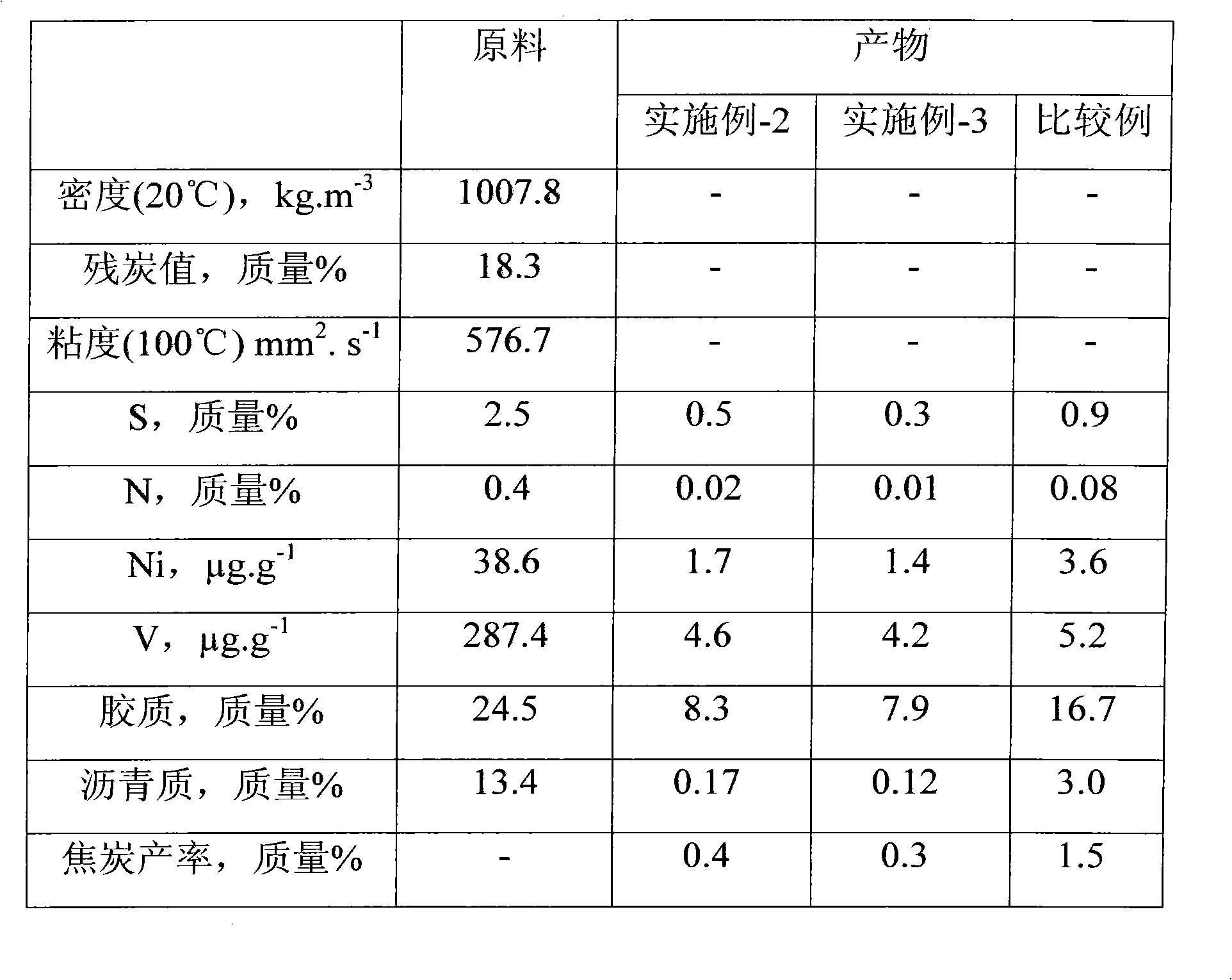

[0025] Using Tahe residual oil as raw material, the steps are the same as in Example-1. Perform supercritical treatment, the hydrogen-donating solvent is decahydronaphthalene, the weight ratio of Tahe residual oil and hydrogen-donating solvent is 1:2, the reaction pressure is 35MPa, the reaction temperature is 450°C, and the reaction time is 0.5h (CSTR is a continuous feed Discharging, the reaction time is the average residence time of the material), after being processed by the method of the present invention, the reaction results are shown in Table 2.

Embodiment -3

[0027] By the same method of embodiment 2, water is also added when using decahydronaphthalene, and the weight ratio of water and supercritical treatment feed is 1: 1, and reaction result is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com