High-acid-resistance and high-corrosion-resistance grease special for sintering machine

A corrosion-resistant, sintering machine technology, applied in the direction of lubricating compositions, etc., can solve the problems of grease loss, blockage of pipelines, etc., and achieve the effects of prolonging service life, reducing air leakage rate and energy consumption, and avoiding oxidation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

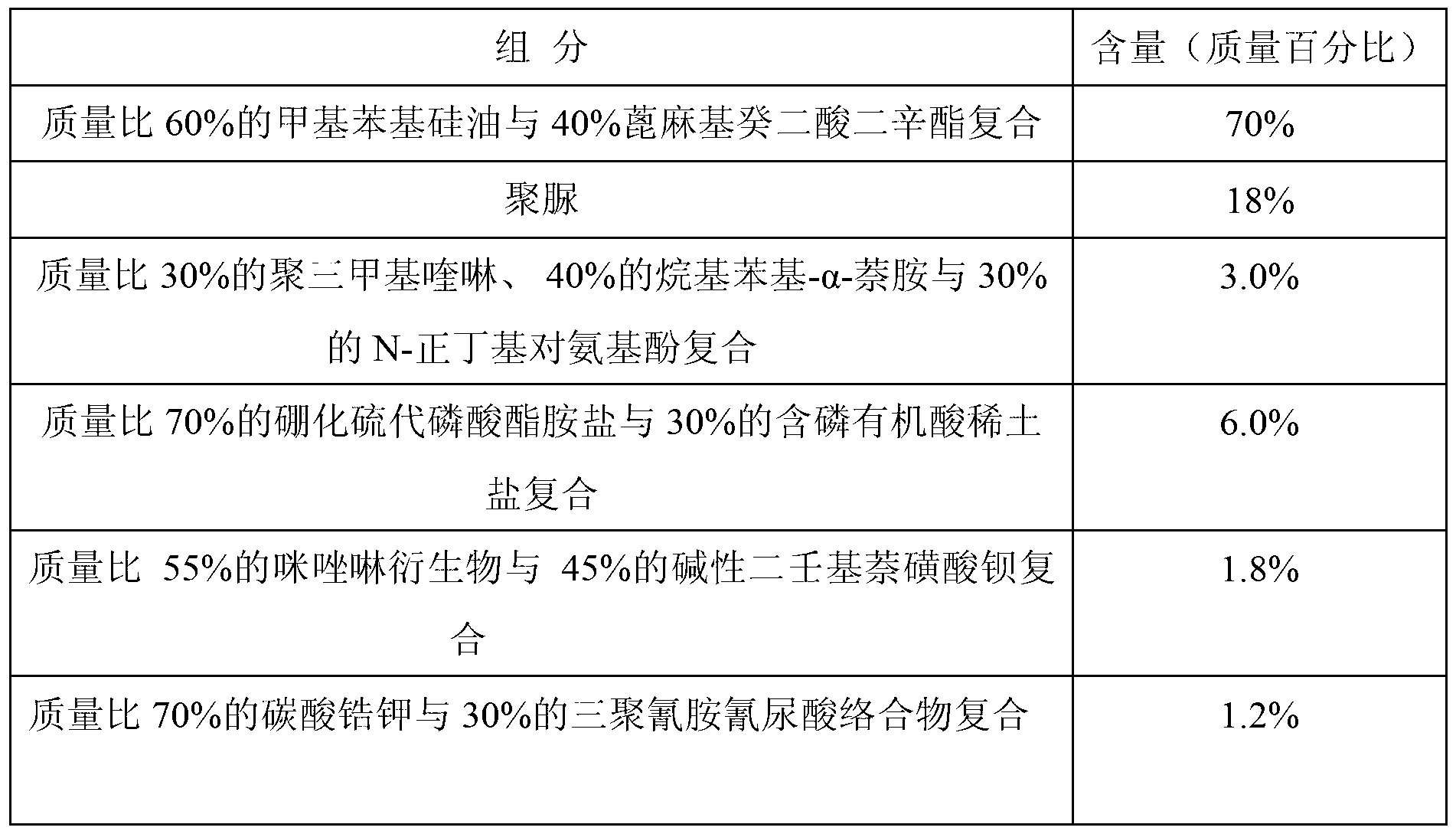

Embodiment 1

[0019] Blend the following components in mass percentage:

[0020]

[0021] The sum of the above components is 100%.

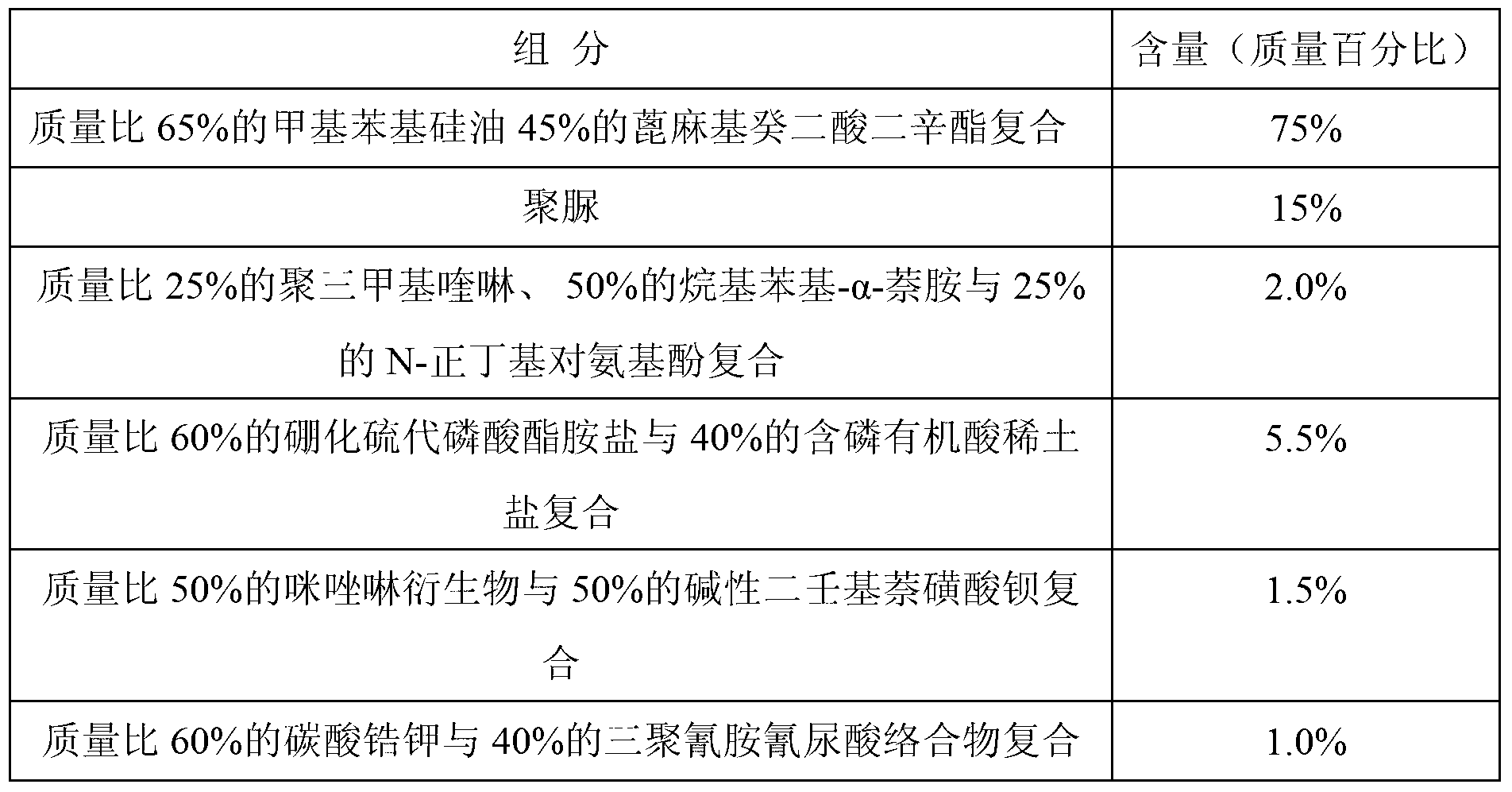

Embodiment 2

[0023] Blend the following components in mass percentage:

[0024]

[0025] The sum of the above components is 100%.

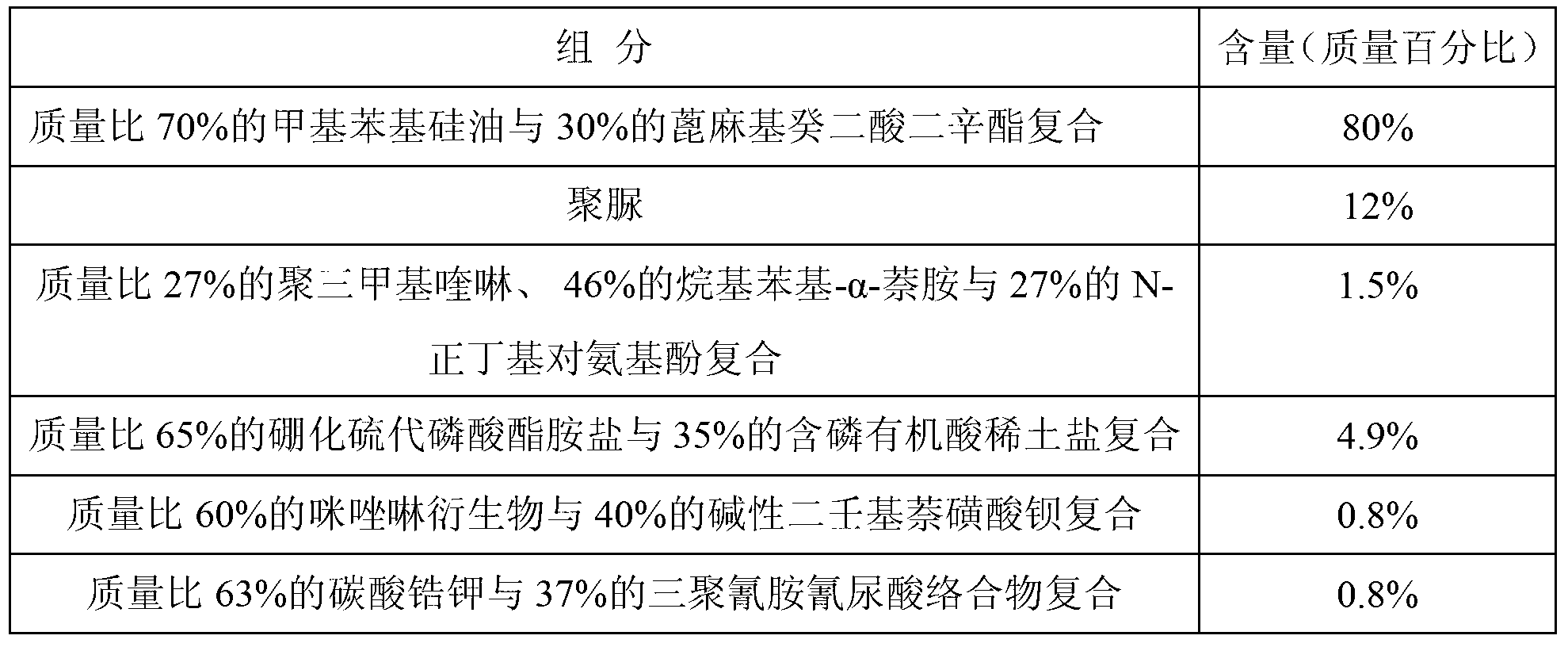

Embodiment 3

[0027] Blend the following components by mass percentage:

[0028]

[0029] The sum of the above components is 100%

[0030] Through the comprehensive evaluation of the physical and chemical indicators of the lubricating grease, all the physical and chemical indicators of the product of the present invention meet the requirements for use. The typical physical and chemical indicators of Example 2 are shown in Table 1.

[0031] Table 1 Typical physical and chemical indicators of special grease for high acid corrosion resistance sintering machine

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com