Scrap iron separation and collection system and method applied to intermediate storage type pulverizing system

A pulverizing system and collection system technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of lowering the ash melting point, increasing the risk of coking of the water wall of the boiler, and increasing the wear and tear of the primary air pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

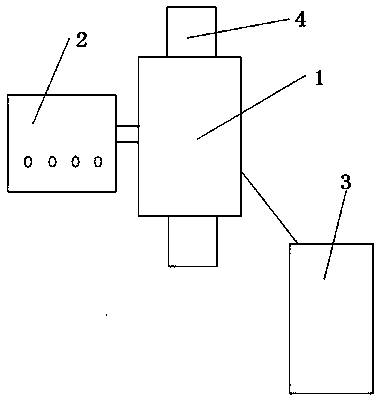

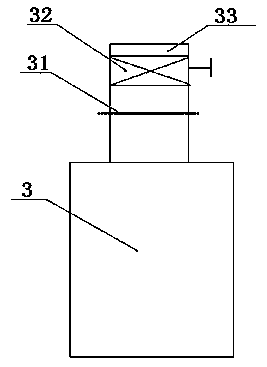

[0032] An iron filings separation and collection system applied to a mid-storage pulverizing system, comprising an iron filings separator 1, a control cabinet 2 for controlling the iron filings separator 1, and an iron filings collector 3 for collecting iron filings, the control The cabinet 2 is electrically connected with the chip separator 3 .

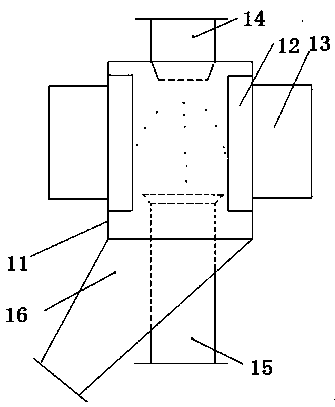

[0033] Further, the iron filings separator 1 includes an iron filings separator main body 11, the upper and lower ends of the iron filings separator main body 11 are respectively provided with an upper connecting pipe 14 and a lower connecting pipe 15, and the iron filings separator main body 11 The lower end is connected to the iron filings collection pipe 16, and the iron filings collection pipe 16 is connected to the iron filings collector 3. The two sides of the outer wall of the iron filings separator 1 are respectively provided with electromagnets 13, and the inner wall of the iron filings separator main body 11 is for adsorptio...

Embodiment 2

[0045] An iron filings separation and collection system applied to a mid-storage pulverizing system, comprising an iron filings separator 1, a control cabinet 2 for controlling the iron filings separator 1, and an iron filings collector 3 for collecting iron filings, the control The cabinet 2 is electrically connected with the chip separator 3 .

[0046] Further, the iron filings separator 1 includes an iron filings separator main body 11, the upper and lower ends of the iron filings separator main body 11 are respectively provided with an upper connecting pipe 14 and a lower connecting pipe 15, and the iron filings separator main body 11 The lower end is connected to the iron filings collection pipe 16, and the iron filings collection pipe 16 is connected to the iron filings collector 3. The two sides of the outer wall of the iron filings separator 1 are respectively provided with electromagnets 13, and the inner wall of the iron filings separator main body 11 is for adsorptio...

Embodiment 3

[0058] An iron filings separation and collection system applied to a mid-storage pulverizing system, comprising an iron filings separator 1, a control cabinet 2 for controlling the iron filings separator 1, and an iron filings collector 3 for collecting iron filings, the control The cabinet 2 is electrically connected with the chip separator 3 .

[0059] Further, the iron filings separator 1 includes an iron filings separator main body 11, the upper and lower ends of the iron filings separator main body 11 are respectively provided with an upper connecting pipe 14 and a lower connecting pipe 15, and the iron filings separator main body 11 The lower end is connected to the iron filings collection pipe 16, and the iron filings collection pipe 16 is connected to the iron filings collector 3. The two sides of the outer wall of the iron filings separator 1 are respectively provided with electromagnets 13, and the inner wall of the iron filings separator main body 11 is for adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com