Boiler for small house, with automatic feeding device and adopting bundled straw fuel

A technology of automatic feeding and housing, which is applied in the field of boilers for heating water, can solve the problems of energy increasing operating costs and limiting the scale of biomass energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

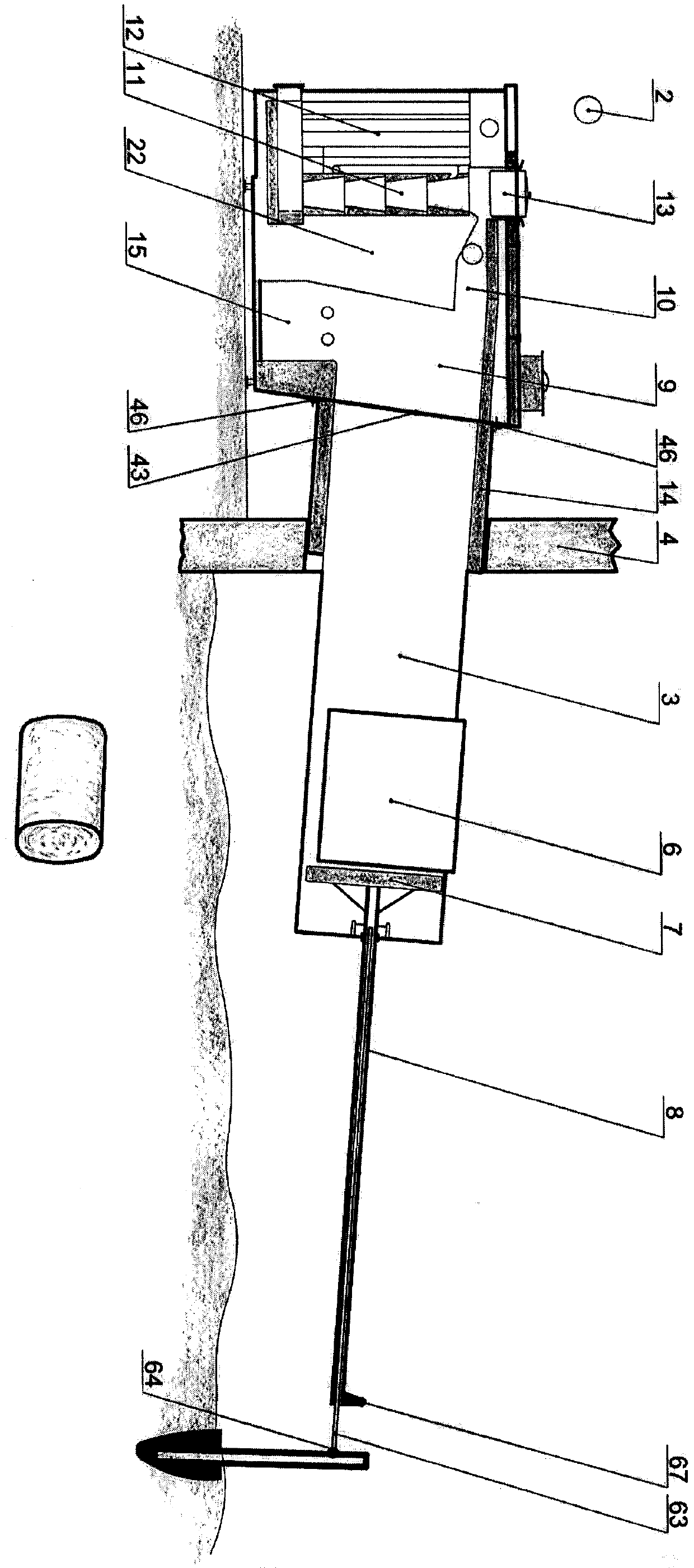

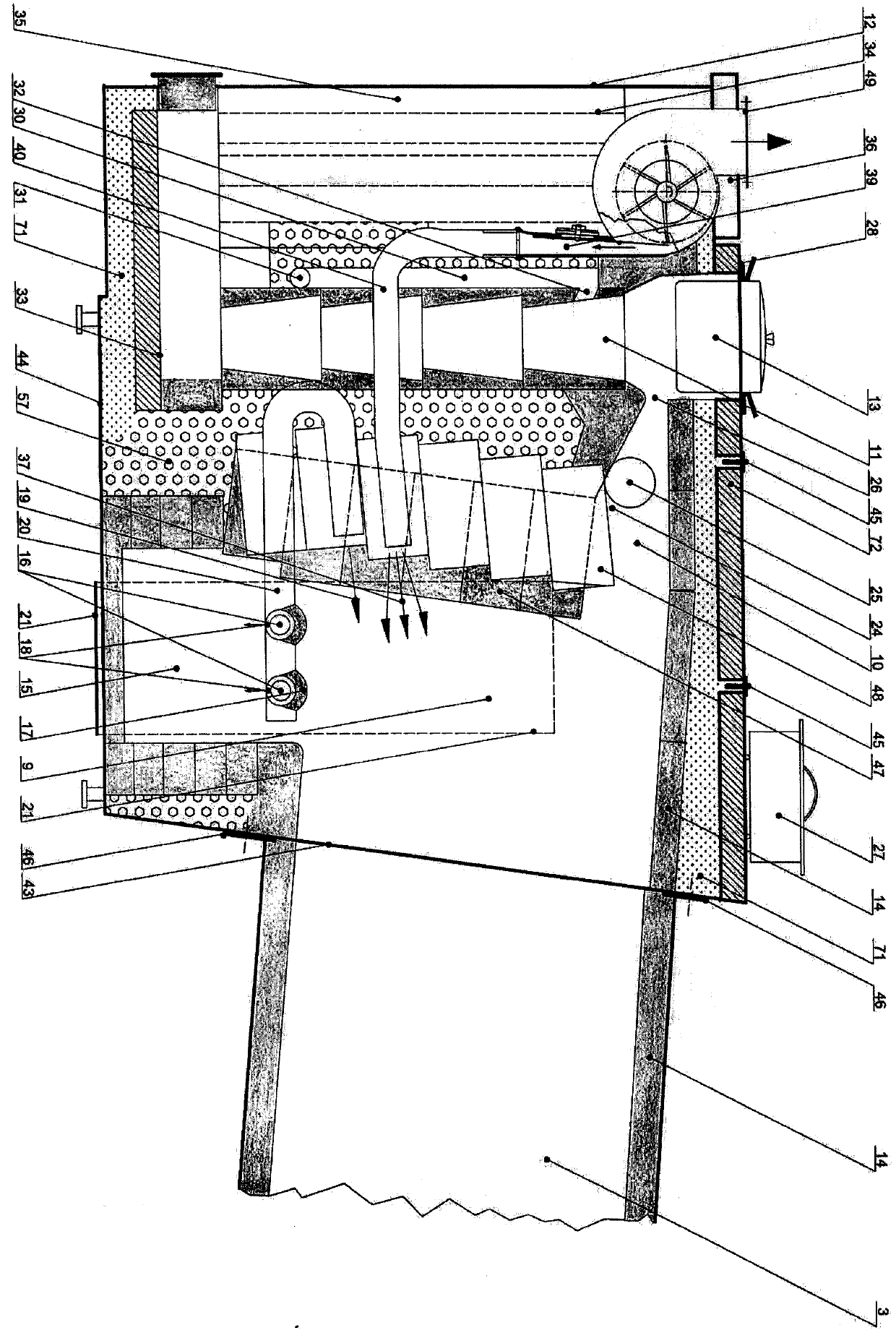

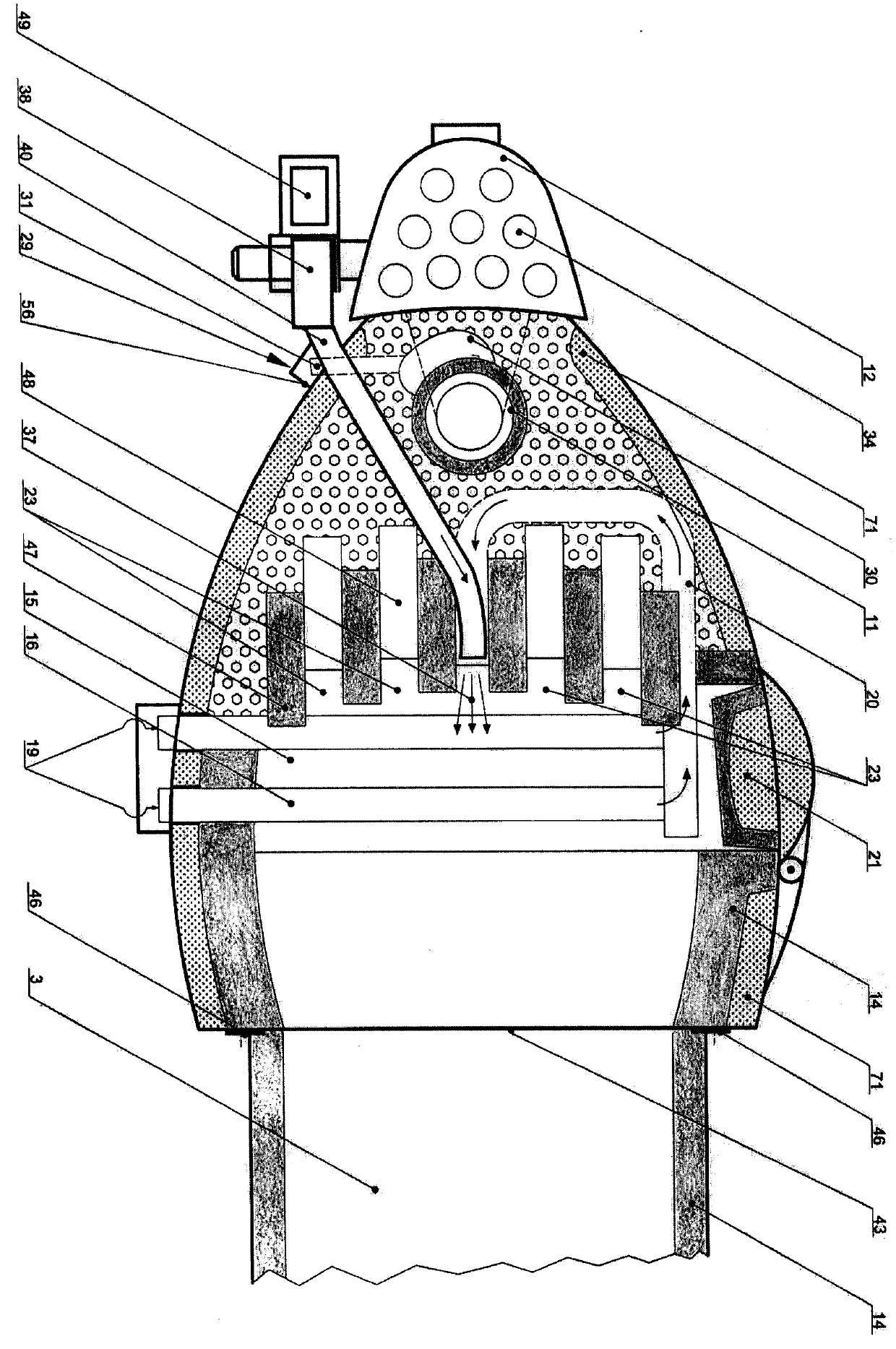

[0048] Application examples of the present invention will be explained in more detail below with reference to the drawings.

[0049] figure 1 A schematic description of an automated boiler for small houses fueled by whole bundles of straw bales, the fuel used in this example is a round straw bundle with a diameter of 65 cm and a length of about 90 cm, with a boiler thermal power of 21 ~30kW. The boiler is mainly composed of a straw bale combustion unit (1) and an automatic feeding device (3), which can be screwed together with bolts during installation. The straw bale combustion unit (1) is preferably placed indoors (2) of the house, and most of the automatic feeding device (3) passes through the house wall (4) and is placed outdoors.

[0050] Put the straw bales (5) into the automatic feeding device (3) which is also in a sealed state through the feeding door (6) by hand, and the inner diameter of the automatic feeding device (3) can be designed to adapt to straw bales of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com