Patents

Literature

31results about How to "Act as thermal protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

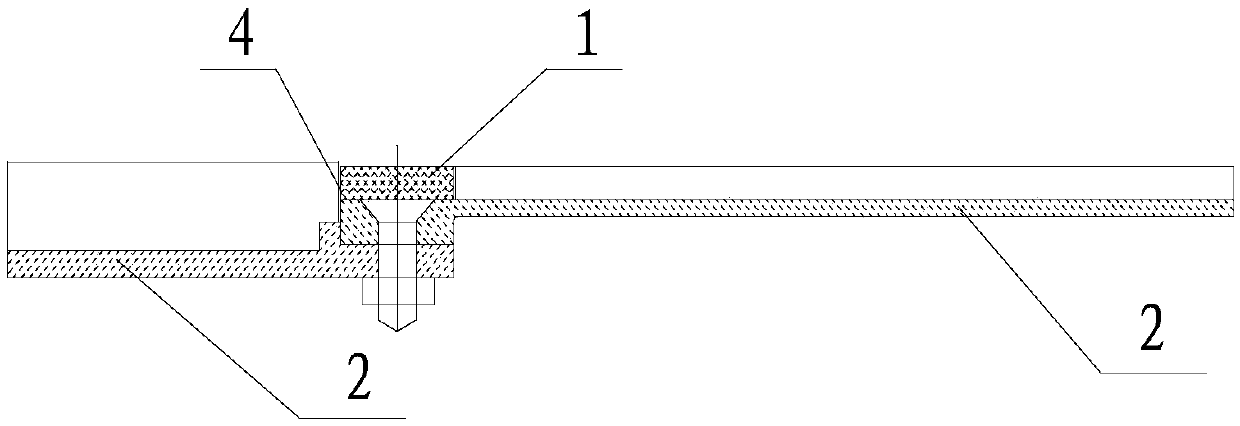

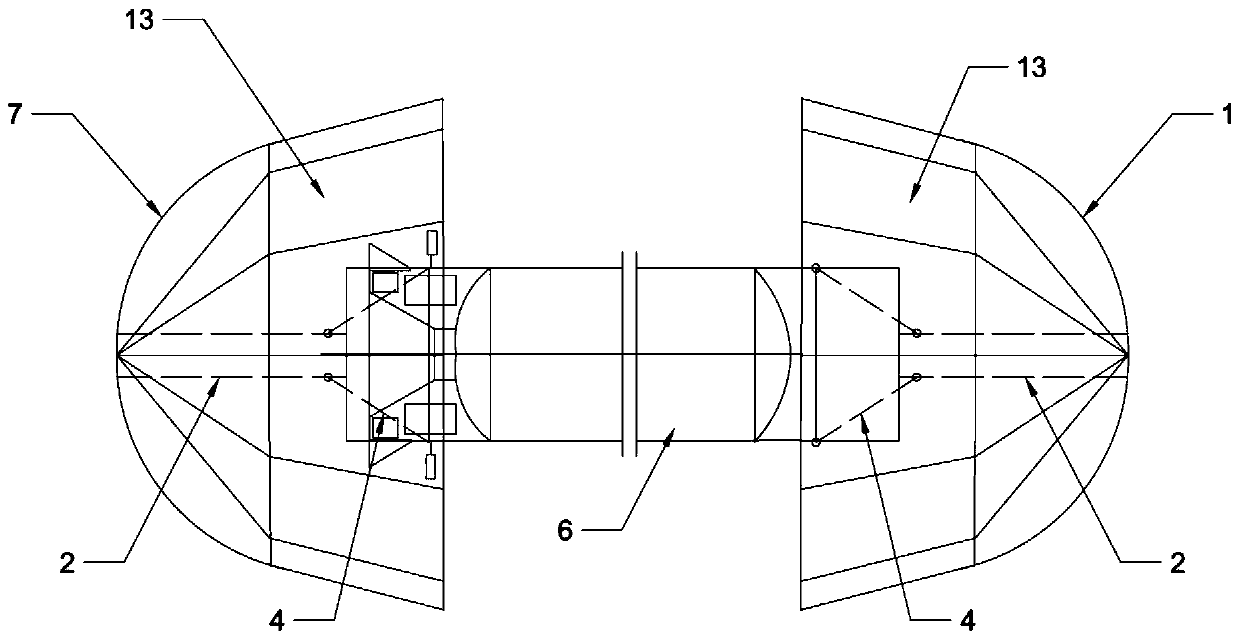

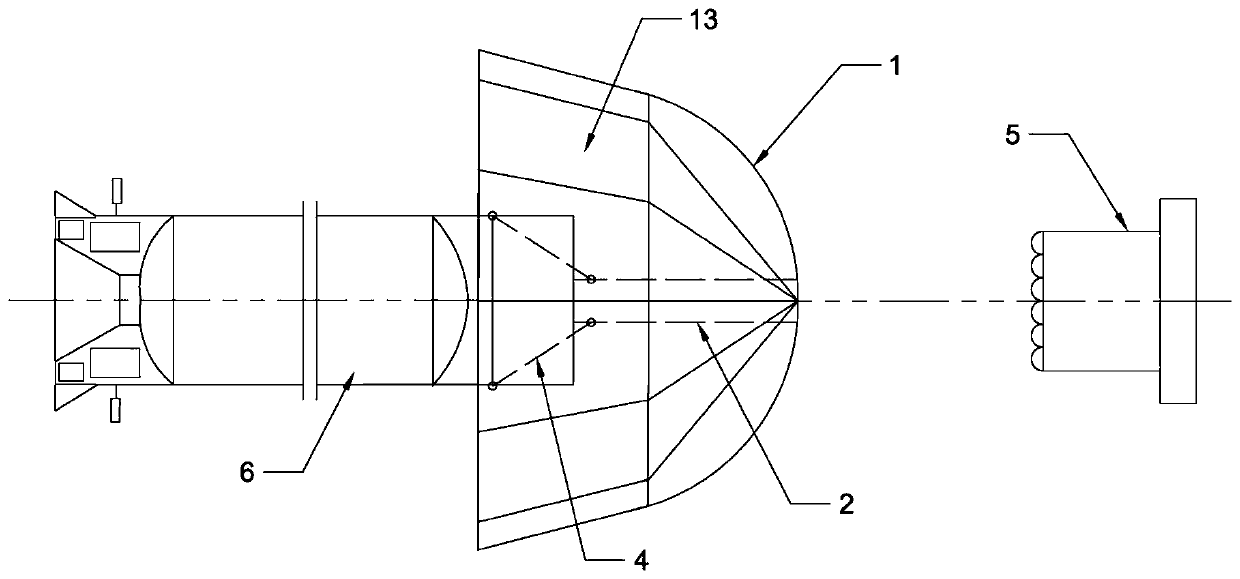

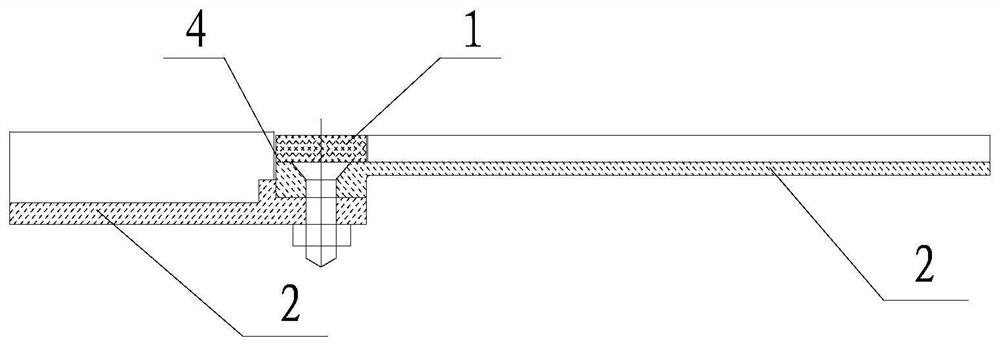

Aero-engine fuel nozzle structure

ActiveCN110726158AAct as thermal protectionAvoid cokingContinuous combustion chamberEngineeringAero engine

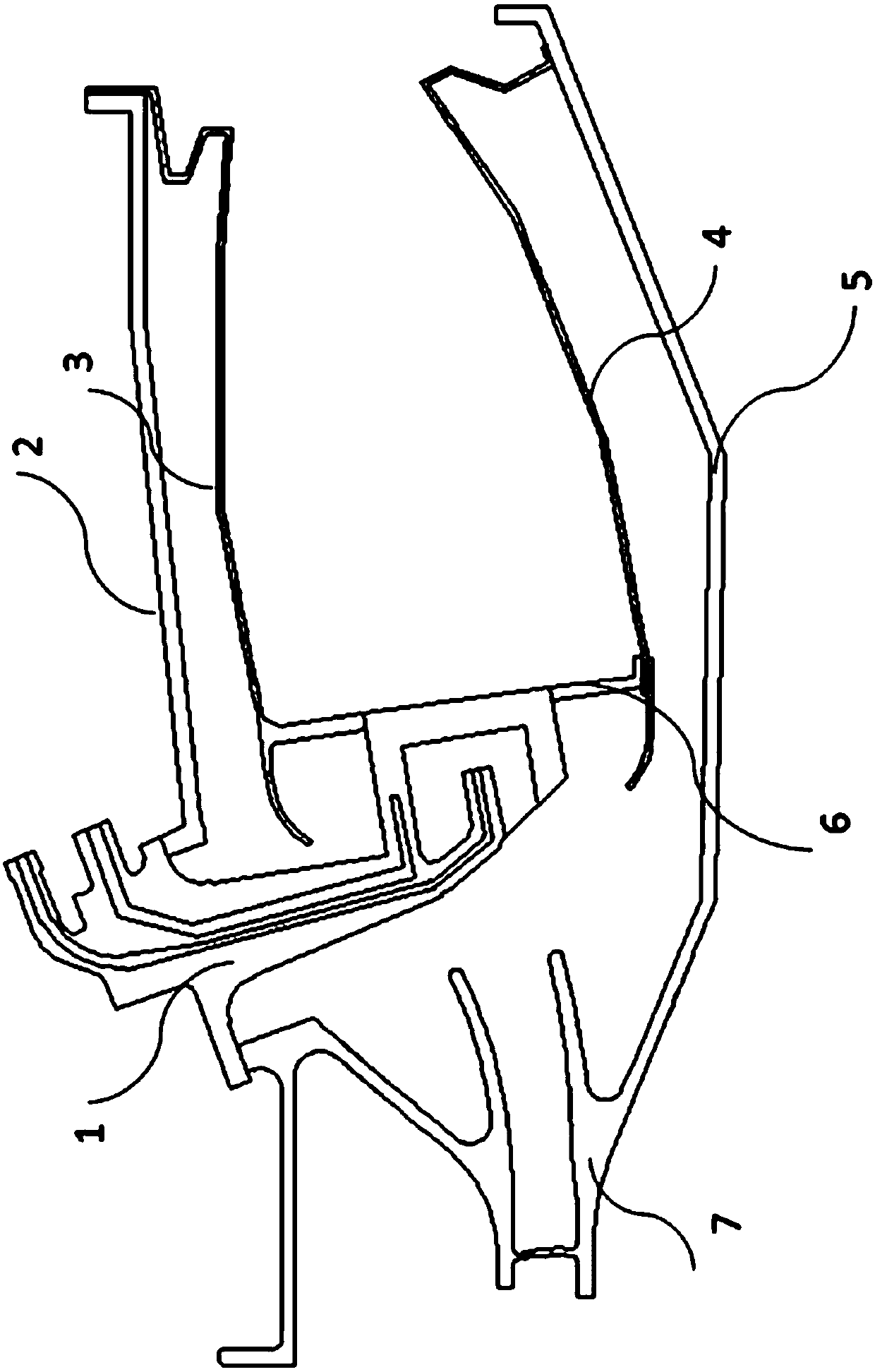

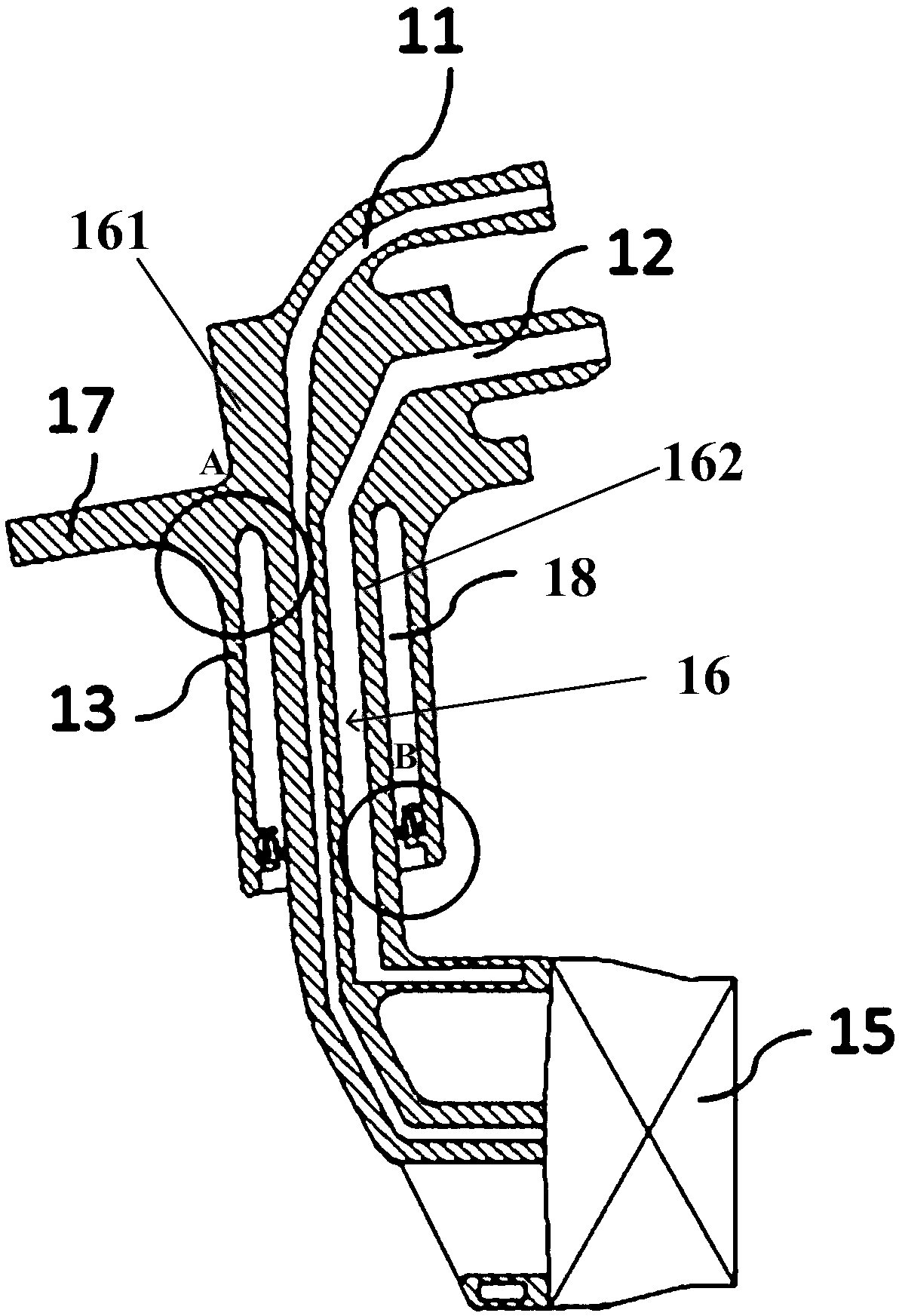

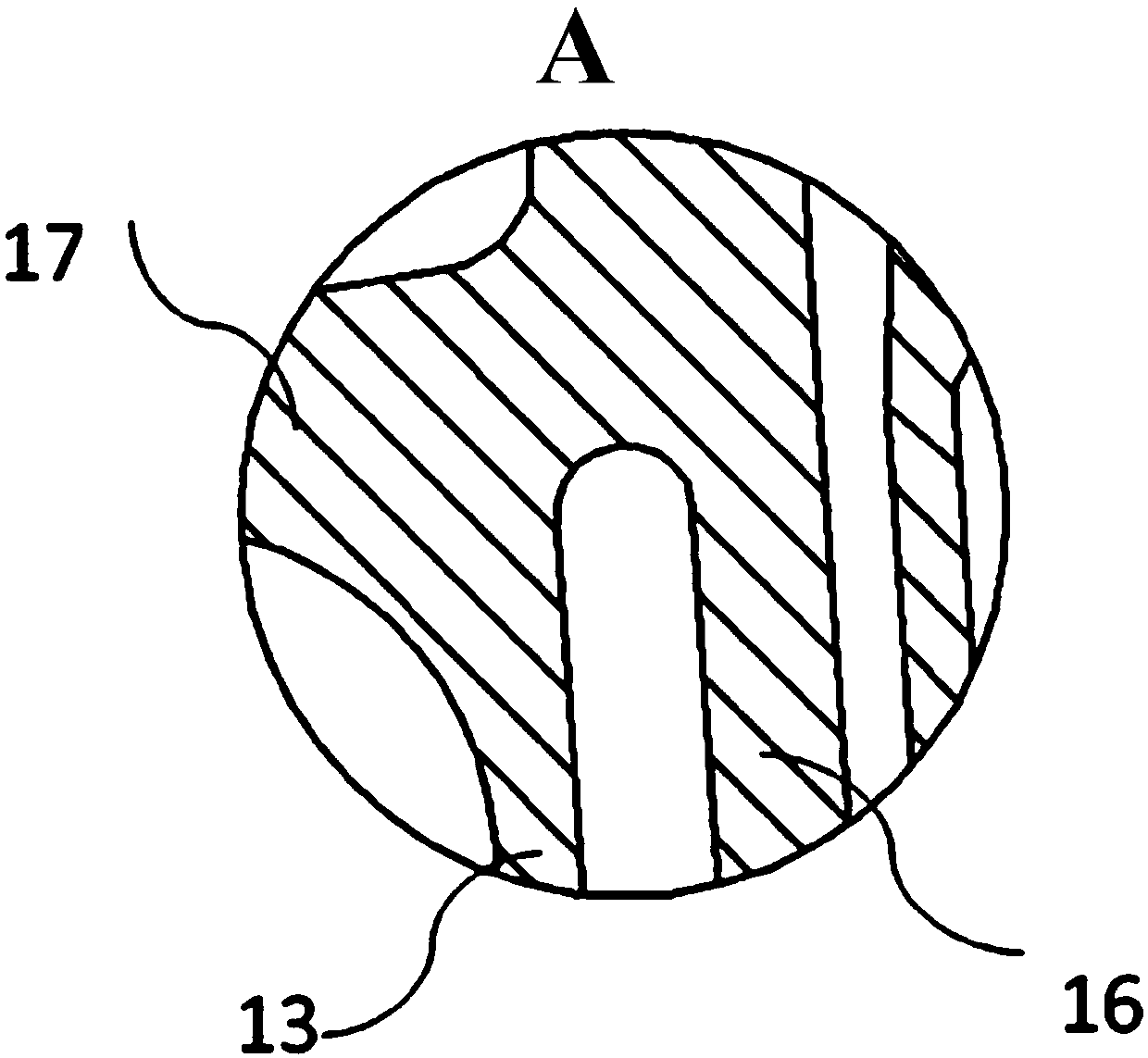

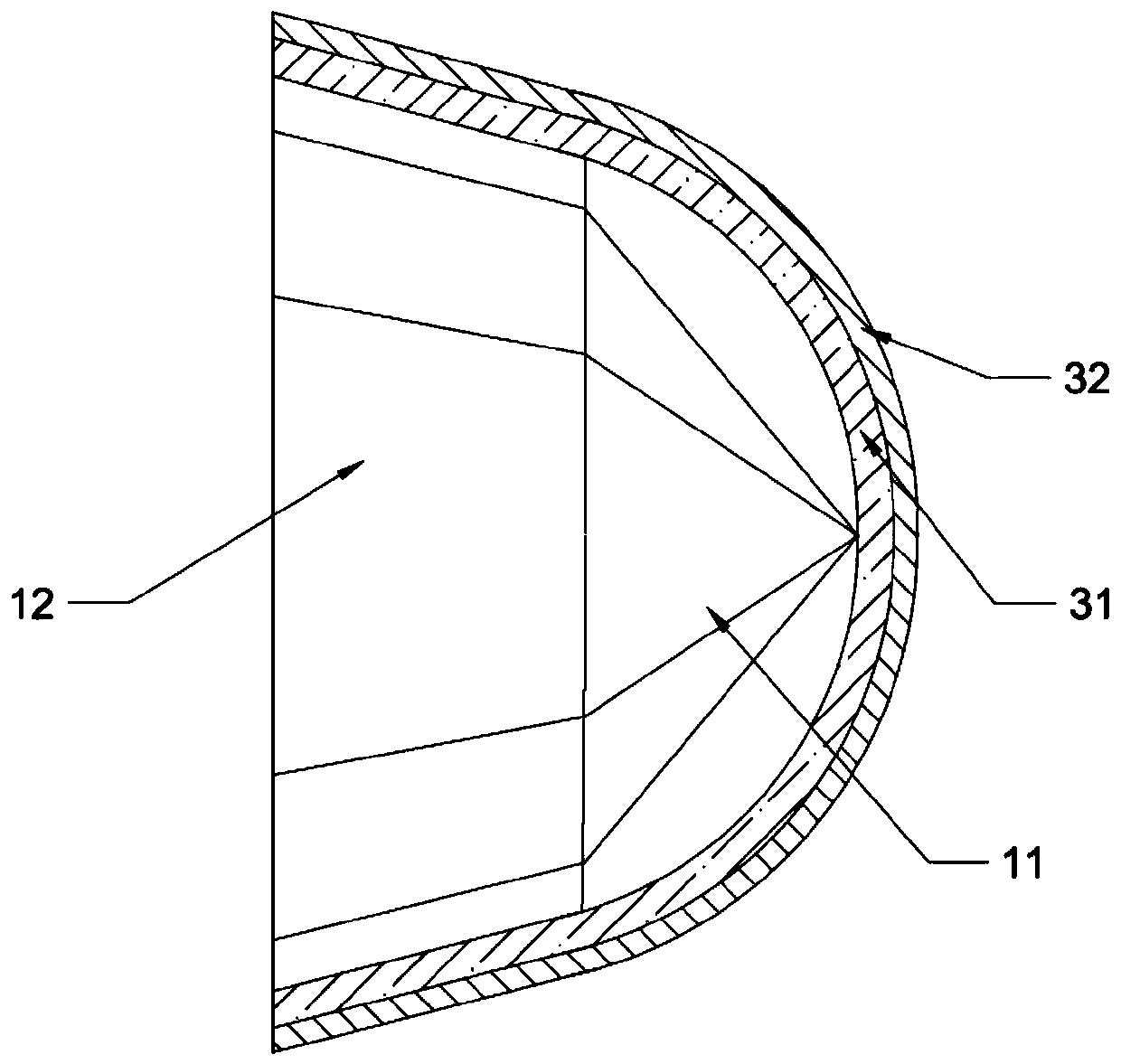

The invention discloses an aero-engine fuel nozzle structure. The fuel nozzle structure comprises a sleeve shell and an oil conveying part, wherein the oil conveying part comprises a first oil conveying part and a second oil conveying part, one end of the second oil conveying part is integrally connected with the first oil conveying part, and the other end of the second oil conveying part is connected with an auxiliary vortex device, the sleeve shell is integrally formed with the oil conveying part, a sleeve is arranged outside the second oil conveying part and is extended to the second oil conveying part from the boundary of the first oil conveying part and the second oil conveying part, a semi-closed air heat insulation cavity is provided with the radial space between the second oil conveying part and the sleeve, and elastic pieces which are in contact with the opposite side walls of the air heat insulation cavity are arranged on the open side of the air heat insulation cavity. The fuel nozzle structure has the advantages of stable and reliable structure, long service life and the like.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

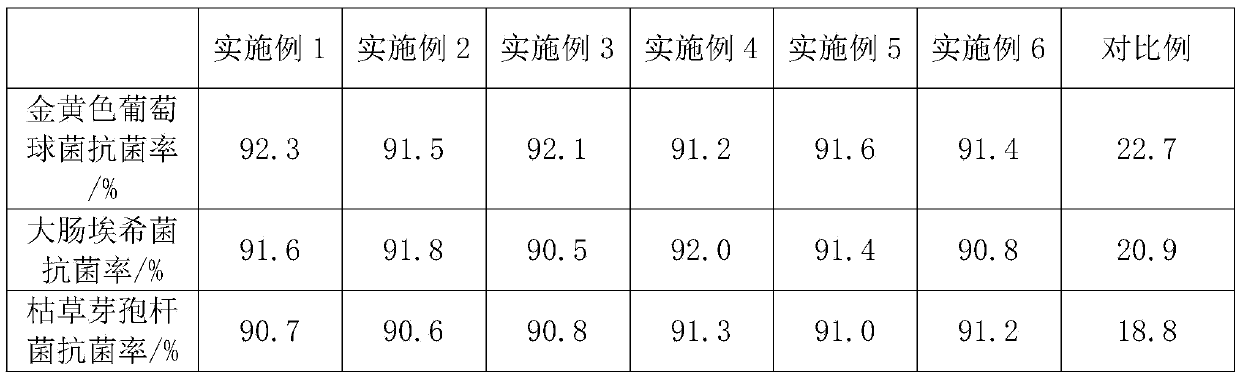

Method for preparing antibacterial epoxy resin pouring sealant

ActiveCN105368364AImprove thermal stabilityImprove heat resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryDiluent

The invention provides a method for preparing an antibacterial epoxy resin pouring sealant. The method comprises the following steps: 1) drying ginkgo leaves, crushing the ginkgo leaves and sieving to obtain the ginkgo leaves powder, adding an ethyl alcohol solution, performing ultrasonic extraction, standing and filtering the material, concentrating the material to obtain a ginkgo leaves extract product; 2) adding diatomite and the ginkgo leaves extract product in a mixer, heating the materials and performing magnetic stirring, taking the product out and drying the product, grinding the product and sieving the product to obtain a composite antiseptic; 3) preparing a mixed liquor by the composite antiseptic, heating the mixed liquor, adding an aluminic acid ester coupling agent, stirring the materials, performing pumping filtration, drying the materials to obtain the modified composite antiseptic; 4) adding epoxy resin, a flexibilizer, a diluents, a filling material and the modified composite antiseptic in a stirred tank for stirring the above materials, performing vacuum defoaming to obtain a component A; 5) adding a curing agent and a promoter in the stirred tank for stirring the above materials, performing vacuum defoaming to obtain a component B; and 6) uniformly mixing the component A and the component B to obtain the antibacterial epoxy resin pouring sealant. The prepared antibacterial epoxy resin pouring sealant has good antibacterial property.

Owner:TAIZHOU HONGLIN IND DESIGN CO LTD

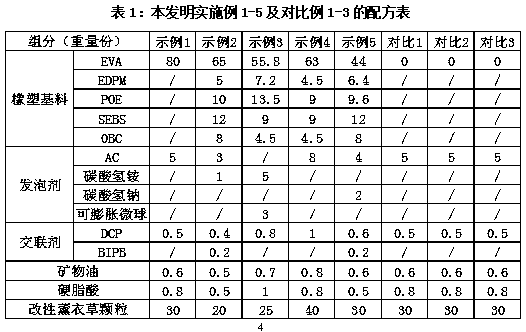

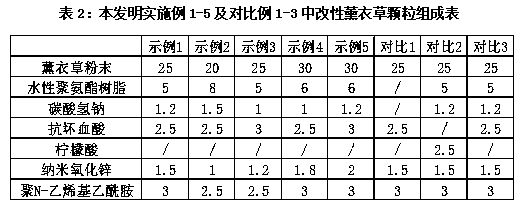

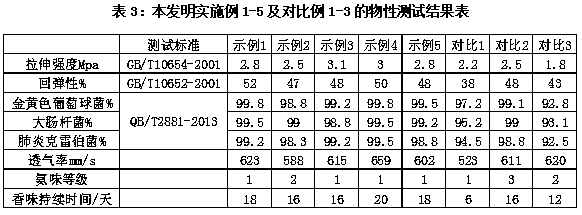

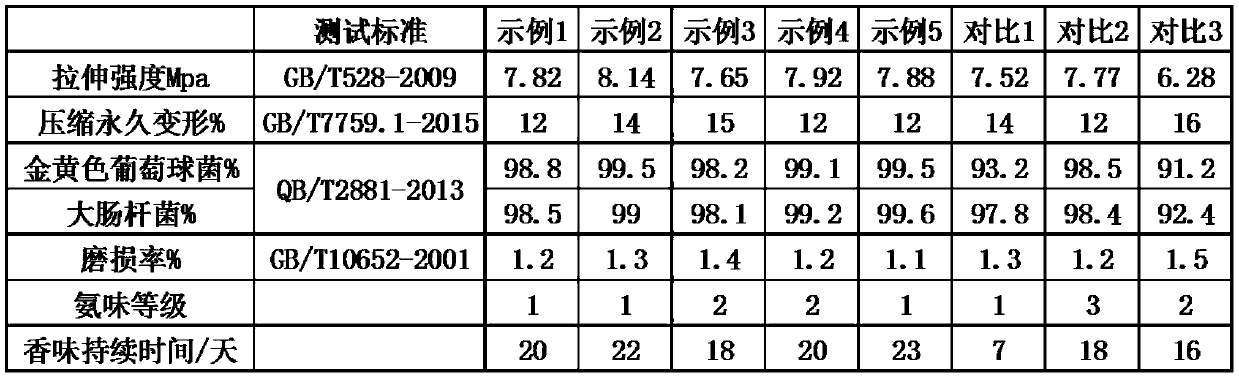

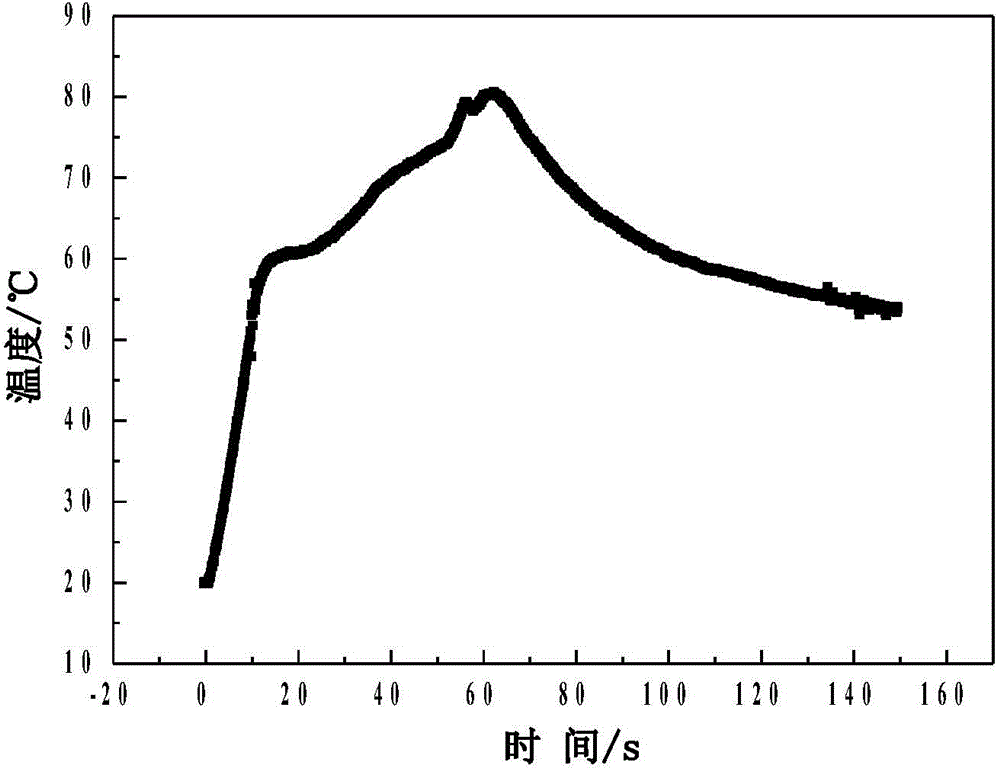

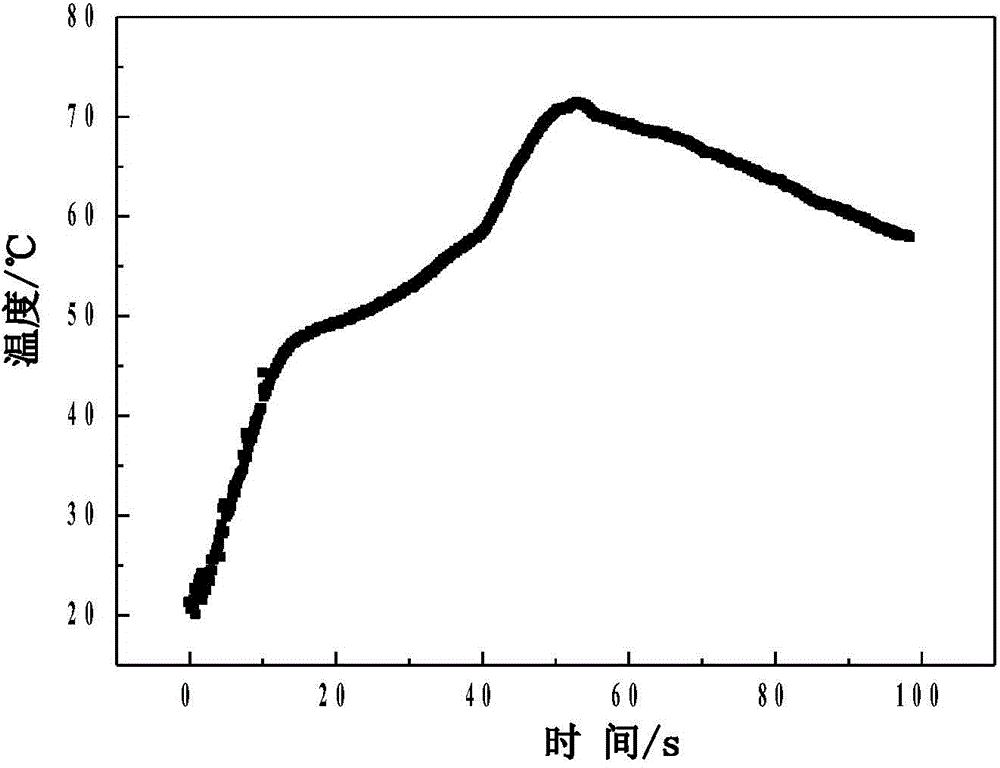

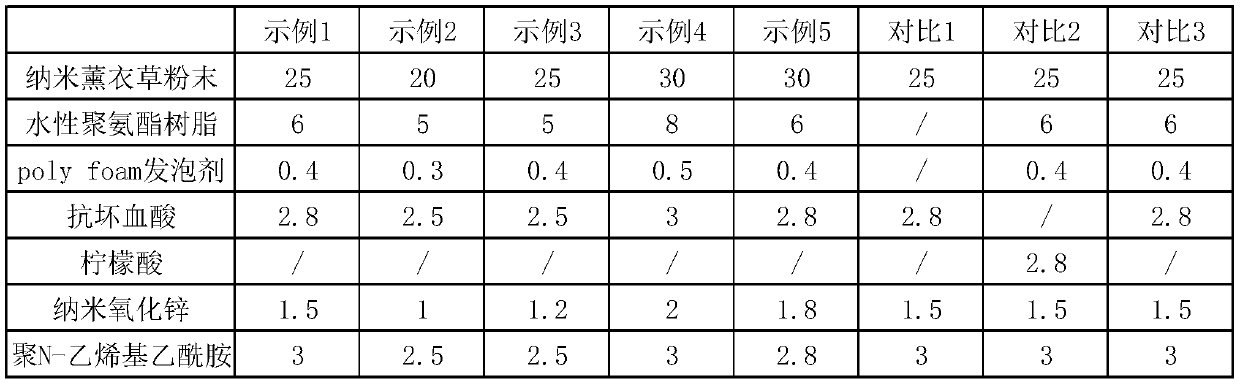

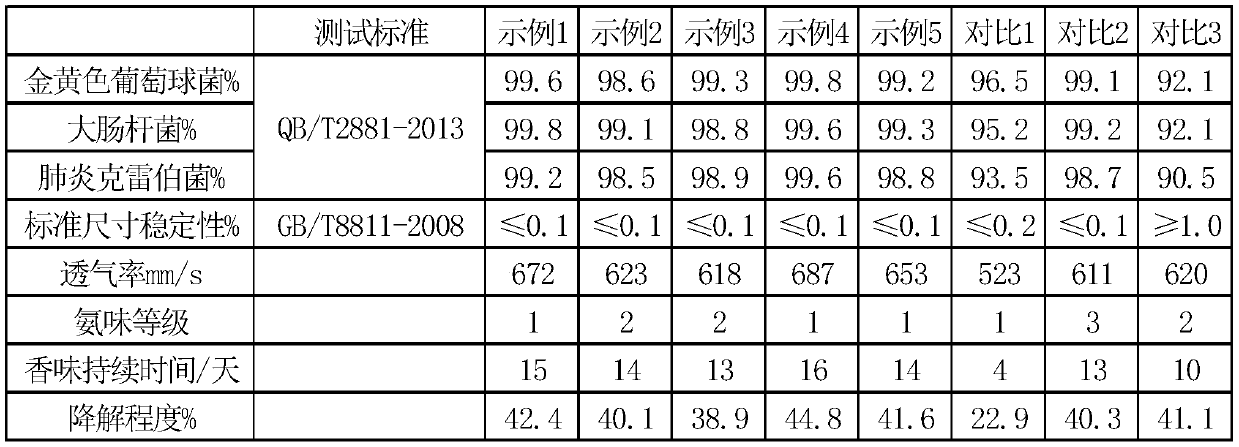

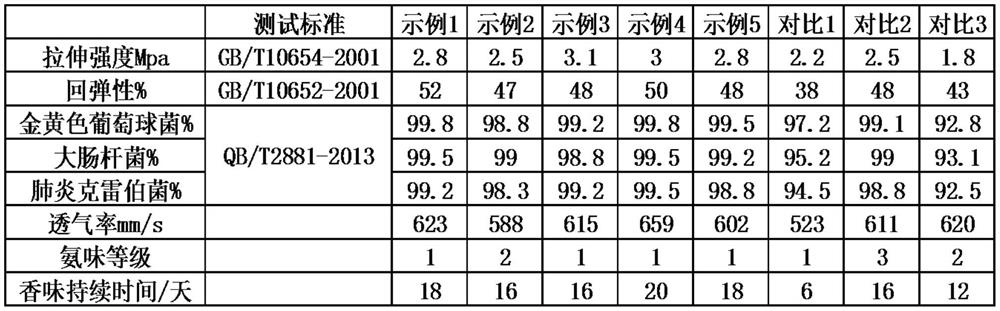

Natural aromatic environment-friendly EVA composite foam material and preparation method and application thereof

ActiveCN111423653AAct as thermal protectionReduce volatilityChemical industrySports equipmentEngineering

The invention relates to the technical field of EVA composite materials. The natural aromatic environment-friendly EVA composite foam material is prepared from the following components in parts by weight: 80-100 parts of a rubber and plastic base material, 4-8 parts of a foaming agent, 0.5-1 part of a cross-linking agent, 0.5-0.8 part of mineral oil, 0.5-1 part of stearic acid and 20-40 parts of modified lavender particles, and the rubber and plastic base material contains 40-100% of EVA. According to the invention, the modified lavender particles are adopted, volatilization of lavender aromacomponents can be effectively controlled, meanwhile, the antibacterial performance and deodorization of the foaming material and the product can be enhanced, the advantages of deodorizing, ventilating, refreshing, incensing, expelling parasites and the like are achieved, the utilization rate of lavender can be increased, waste and environmental pollution are reduced, and the lavender perfume is environmentally friendly and suitable for living goods and sports equipment such as soles, insoles, yoga mats and crawling mats.

Owner:泉州西米露新材料科技有限公司

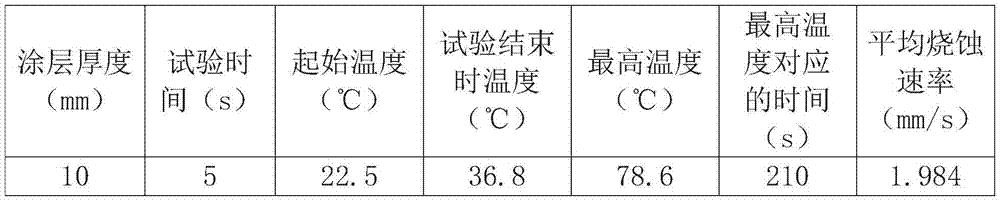

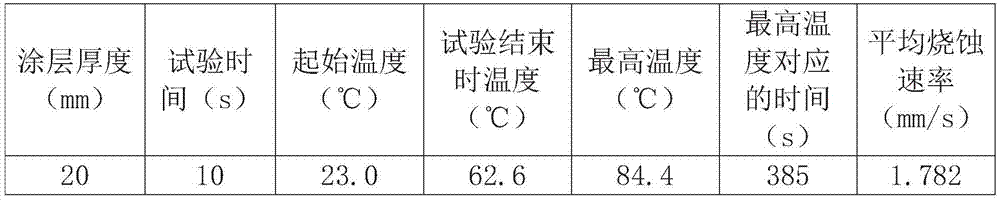

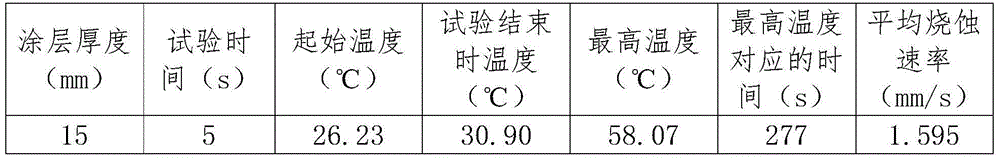

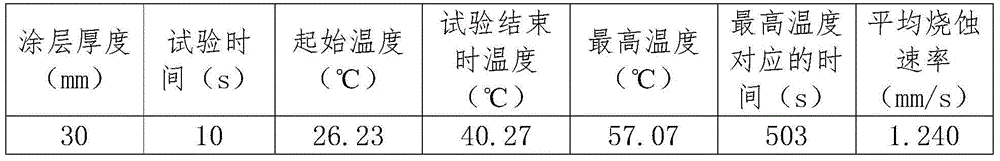

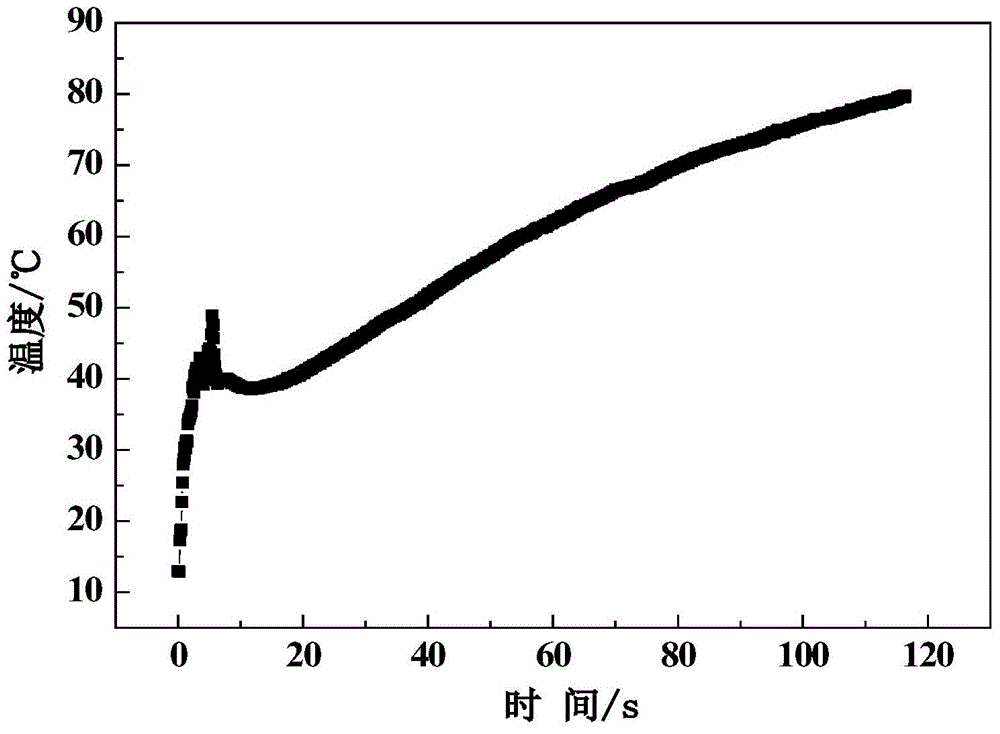

Structure for thermal protective coating of rocket launching pad and application thereof

ActiveCN103850355AReduce thermal ablationReduce shockClimate change adaptationHeat proofingEpoxyBrick

The invention discloses a structure for a thermal protective coating of a rocket launching pad and an application thereof. The thermal protective coating is composed of materials in three layers, namely, an organic bottom layer, refractory bricks and an organic-inorganic compound surface layer, wherein the organic bottom layer is composed of epoxy resin, solidifying agent polyamide and flexibilizer liquid rubber; clay refractory bricks are adopted as the refractory bricks; the organic-inorganic compound surface layer is composed of organic rubber epoxy resin, polyurethane curing agent, sand and cement. The material of the thermal protective coating provided by the invention can endure the scouring of the simulated fuel gas flow of a rocket; the temperature on a metal rear surface is not above 200 DEG C; the coating has an excellent heat-insulating property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Alpha-cyanoacrylate heat-conducting glue and preparation method thereof

ActiveCN105368330AImprove high temperature resistanceIncrease layer spacingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCross-linkHeat conducting

The invention provides alpha-cyanoacrylate heat-conducting glue. The alpha-cyanoacrylate heat-conducting glue comprises the following components in parts by weight: 100 parts of alpha-cyanoacrylate, 2-5 parts of a thickening agent, 2-4 parts of a plasticizer, 0.1-0.4 parts of a stabilizing agent, 0.5-1 part of a polymerization inhibitor, 20-30 parts of a cross-linking agent, 3-6 parts of a fire retardant, 1-2 parts of pigment, 100-110 parts of a heat-conducting filling material, 10-14 parts of magnesium hydrogen phosphate, and 8-10 parts of liquid polyisobutylene. The invention also provides a preparation method of the alpha-cyanoacrylate heat-conducting glue. The alpha-cyanoacrylate heat-conducting glue has good impact-resistance performance and heat-resistance performance.

Owner:绍兴市上虞舜东橡塑制品有限公司

Metal surface high-temperature-resistant coating structure and applications thereof

ActiveCN104924718AStrong adhesionGood heat insulationSynthetic resin layered productsWater-setting substance layered productEpoxyThermal insulation

The invention discloses a metal surface high-temperature-resistant coating structure and applications thereof. The high-temperature-resistant coating material is composed of two layers namely an organic bottom layer and an inorganic surface layer; wherein the organic bottom layer is composed of epoxy resin, a polyamide curing agent, and a toughening agent (liquid rubber); and the inorganic surface layer is composed of flint clay, cordierite, aluminate cement and silica fume. The adhesion force of the provided high-temperature-resistant coating material is strong, which can sustain the washing of rocket imitated combustion-gas stream. The metal backside temperature does not exceed 120 DEG C, and the coating has an excellent performance on resisting high-temperature combustion-gas stream brushing and thermal insulation property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

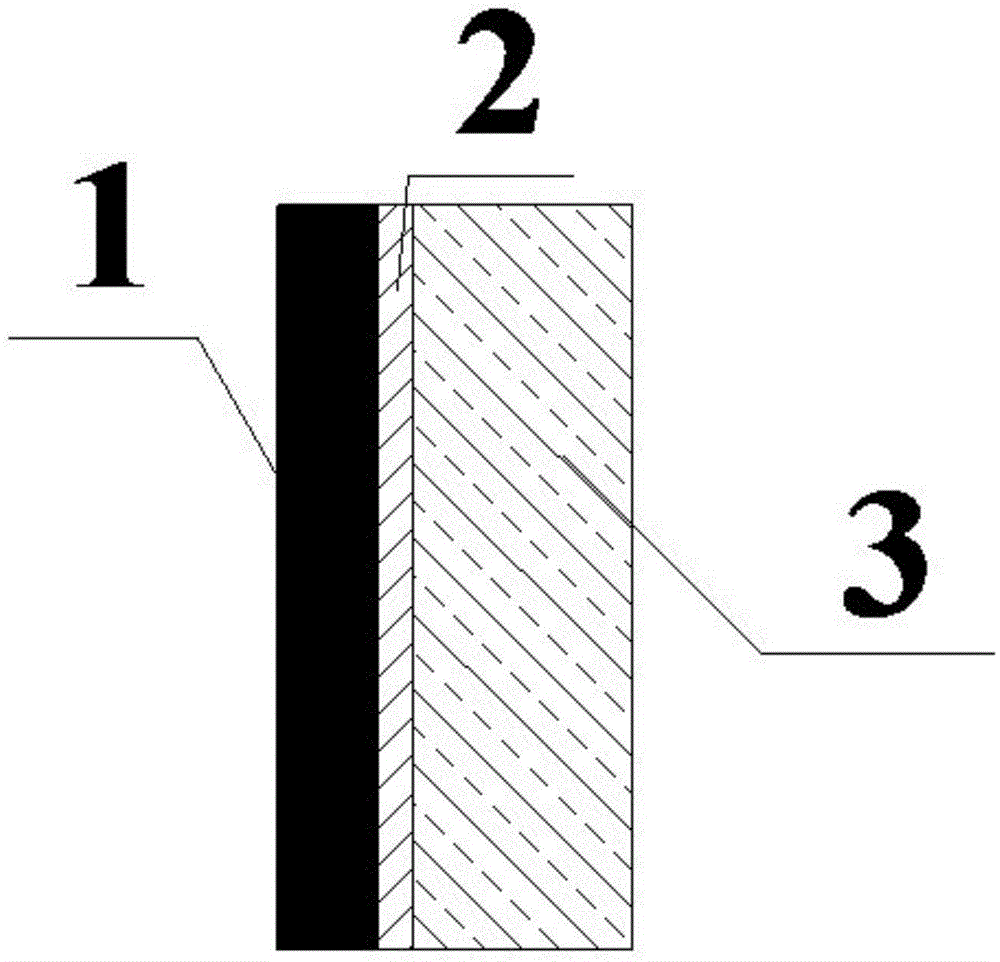

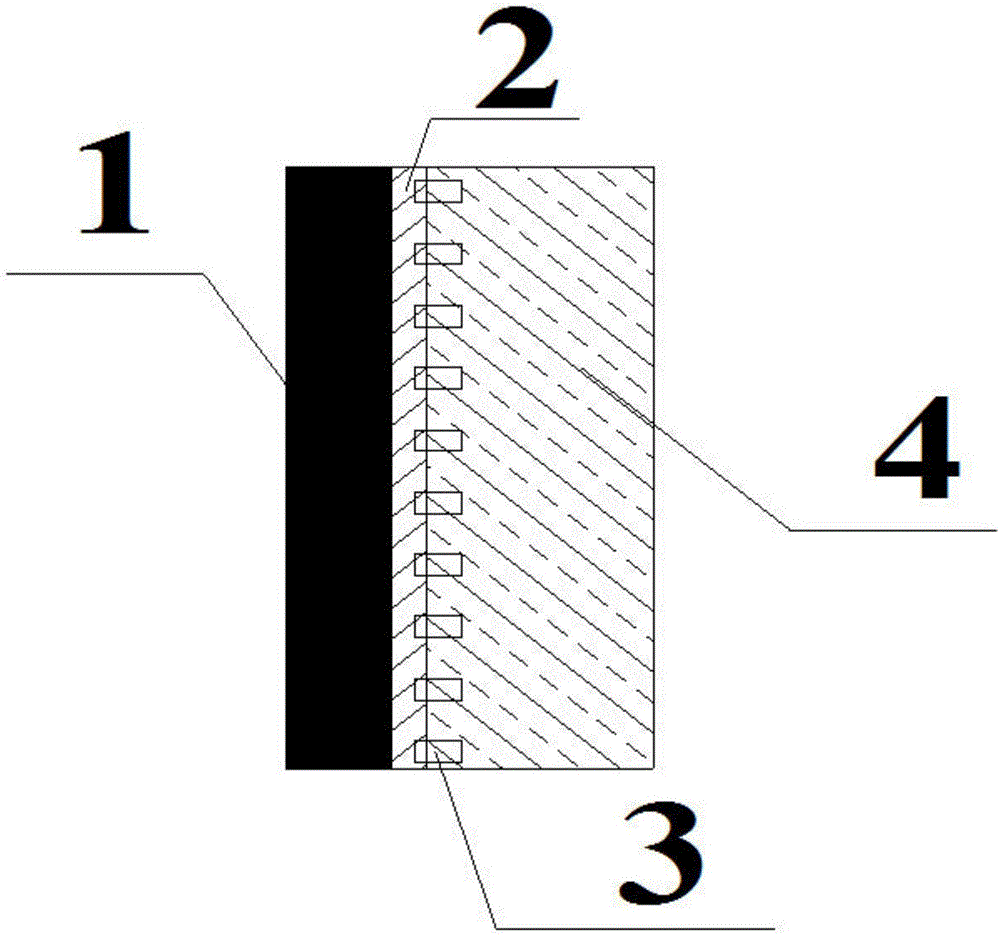

Structure of thermal protective coating material for metal surface and use thereof

InactiveCN107081941AGood heat insulationPlay the role of "pinning"LaminationLamination apparatusEpoxyOrganic base

The invention discloses a structure of a thermal protective coating material for a metal surface and a use thereof. The structure of the thermal protective coating material is composed of an organic base layer, a fire refractory light aggregate and an inorganic surface layer. A part of the fire refractory light aggregate is embedded in the organic base layer and a part of the fire refractory light aggregate is embedded in the inorganic surface layer. The organic base layer is composed of epoxy resin, a curing agent polyamide and a toughening agent liquid rubber. The inorganic surface layer is composed of water glass, a curing agent sodium fluorosilicate, sand and cement. The thermal protective coating material can resist rocker simulated gas flow erosion, the metal backside temperature does not exceed 150 DEG C, and the coating has good heat insulation performances.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

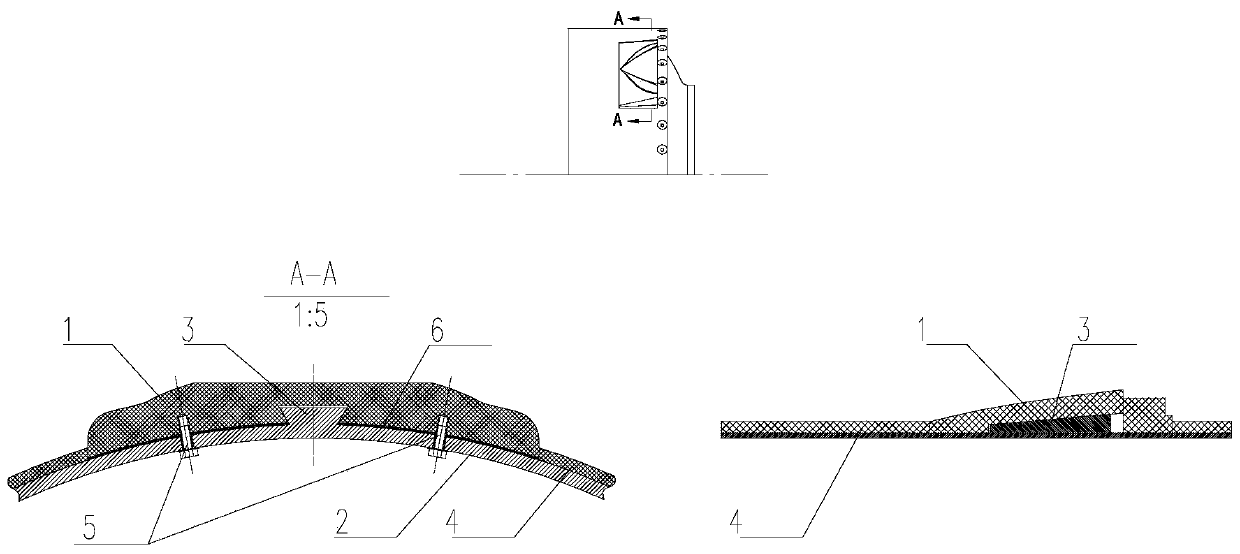

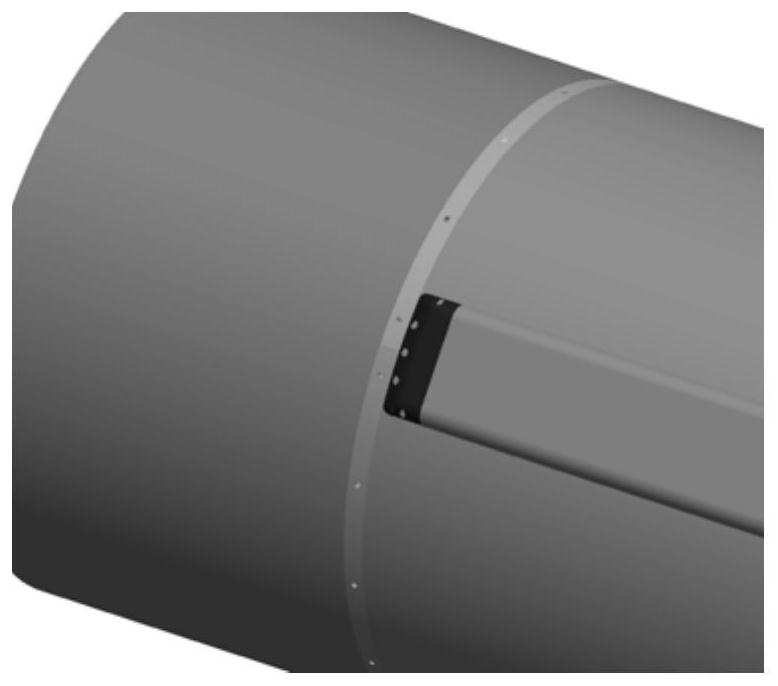

Detachable multivalve cabin section abutting heat protection structure

ActiveCN109596010AImprove responseAct as thermal protectionSelf-propelled projectilesEngineeringProtection ring

The invention relates to a detachable multivalve type cabin section abutting heat protection structure. Abutting frames of two cabin sections to be abutted are radially connected, an outer ring at theradial connecting part is provided with a multivalve type heat protection ring, and the multivalve type heat protection ring is in clearance fit with the outer heat protection structures of the two abutted cabin sections. With regard to the abutting structure between cabin sections with repeated disassembly and assembly requirements, the multivalve heat protection ring which is convenient to disassemble and assemble is adopted to prevent heat at the abutting part, that is, the abutting of the cabin sections still adopts a countersunk screw radial abutting mode, but the multivalve heat protection ring is only mounted in a screw joint mode after being abutted; and the multivalve heat protection ring covers all abutting screws and the abutting part to play a heat protection role, can be repeatedly disassembled and assembled, is simple and convenient to operate, and meets the requirement of rapid maintenance response.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

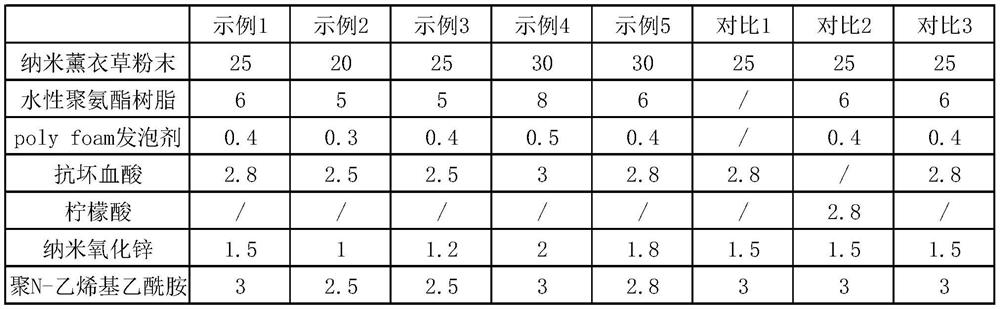

Environment-friendly antibacterial aromatic thermoplastic elastomer foaming material as well as preparation method and application thereof

PendingCN111548596AImprove antibacterial propertiesAct as thermal protectionSolesInsolesElastomerPolystyrene

The invention relates to the technical field of foam materials. The invention particularly discloses an environment-friendly antibacterial aromatic thermoplastic elastomer foaming material. The foaming material comprises the following components in parts by weight: 80-100 parts of SEBS, 8-15 parts of butadiene rubber, 5-8 parts of high-impact-resistance polystyrene, 5-10 parts of EVA, 3-5 parts ofa foaming agent, 2-4 parts of a cross-linking agent, 0.5-1 part of zinc stearate, 2-4 parts of white mineral oil and 10-20 parts of modified lavender particles. According to the invention, the modified lavender particles are adopted; volatilization of lavender aroma components can be effectively controlled; meanwhile, the antibacterial performance and deodorization of the foaming material and theproduct can be enhanced, and the advantages of deodorizing, ventilating, refreshing, incensing, expelling parasites and the like are achieved; the utilization rate of lavender can be increased, wasteand environmental pollution are reduced, and the lavender perfume is environmentally friendly and suitable for living goods and sports equipment such as soles, insoles, yoga mats and crawling mats.

Owner:泉州西米露新材料科技有限公司

High-temperature-resistant coating structure and application thereof to rocket launching pad

ActiveCN105291520AStrong adhesionImprove high temperature resistanceSynthetic resin layered productsEpoxyRocket launch

The invention discloses a high-temperature-resistant coating material for a rocket launching pad. The high-temperature-resistant coating material comprises two material layers, namely an organic bottom layer and an inorganic surface layer, wherein the organic bottom layer comprises epoxy resin, the curing agent of polyamide, and the toughening agent of liquid rubber; the inorganic surface layer comprises mullite, dichroite, aluminate cement and silica ash. The high-temperature-resistant coating material is high in adhesive force, and can bear rocket simulation gas stream impact; the temperature of metal back is lower than 100 DEG C, and the coating has excellent high-temperature gas stream impact resistance and heat-insulating performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

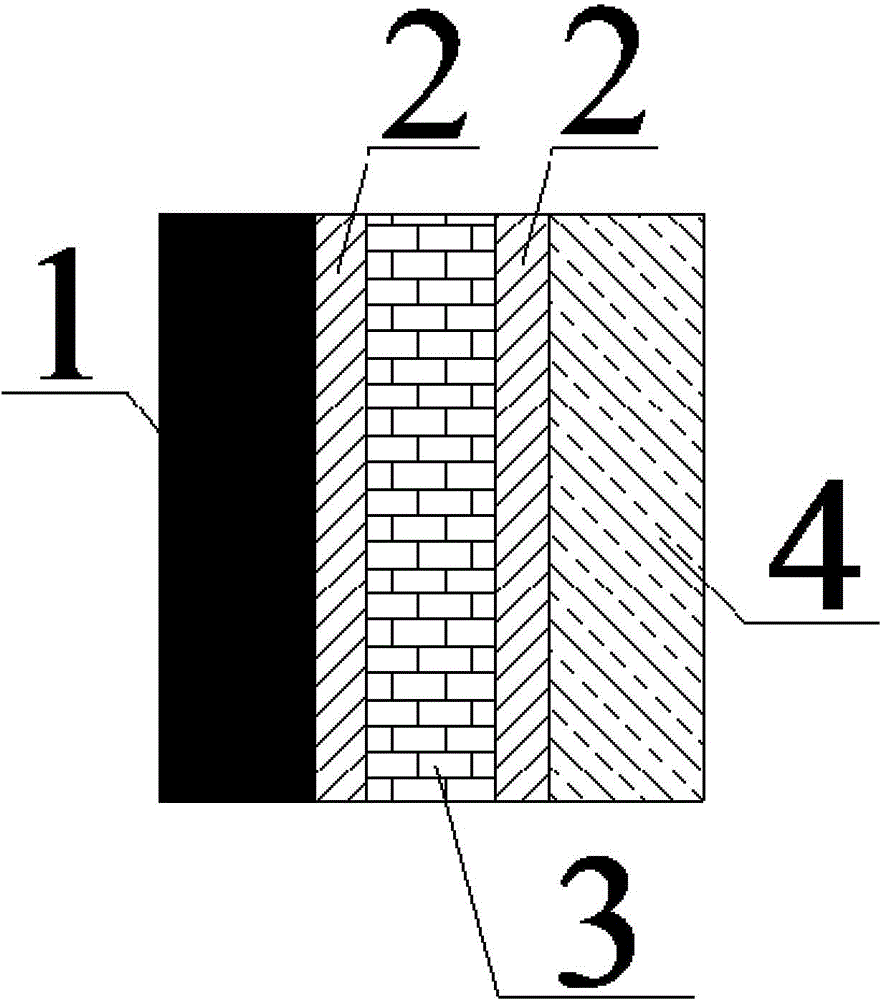

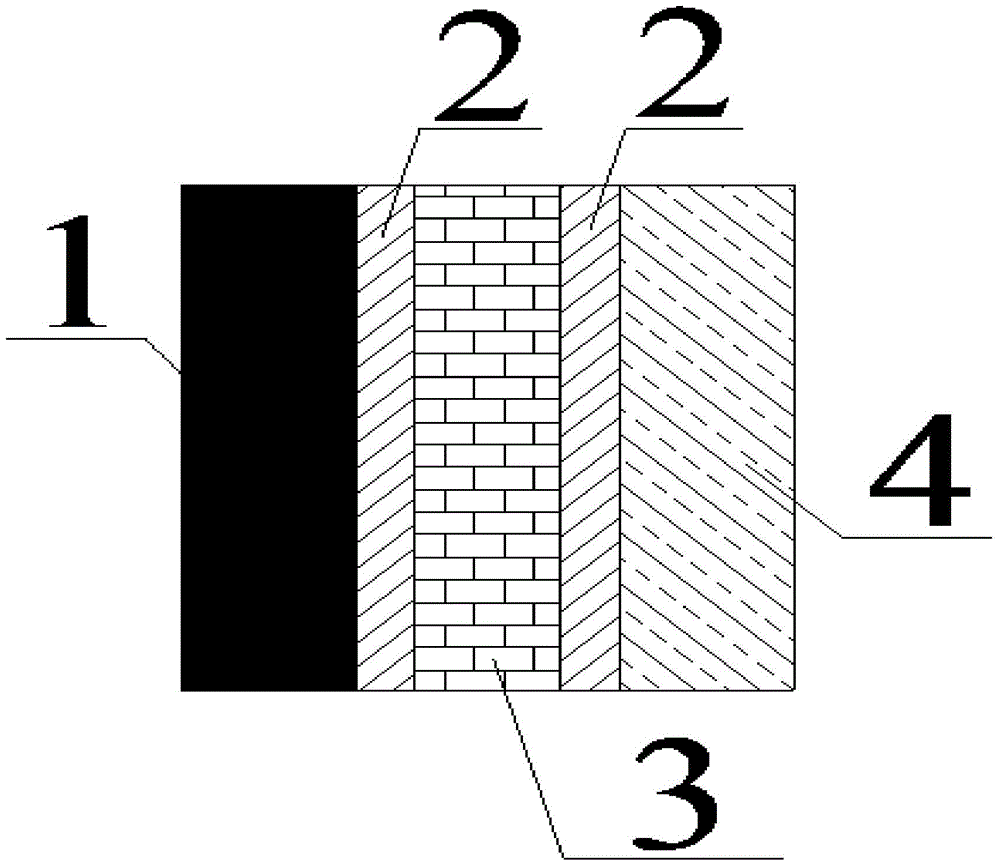

Thermal protection coating material structure for rocket launching pad and application of structure

InactiveCN105984182AStrong adhesionGood heat insulationSynthetic resin layered productsMetal layered productsEpoxyBrick

The invention discloses a thermal protection coating material structure for a rocket launching pad and application of the structure. The thermal protection coating material is composed of a first organic layer, a refractory brick layer, a second organic layer and an unshaped refractory material layer, wherein the two organic layers are same in composition and are both composed of epoxy resin, curing agent modified polyamine and toughening agent liquid rubber, and the unshaped refractory material layer is composed of mullite, cordierite, aluminate cement and silica fume. The thermal protection coating material is high in adhesive force and can bear simulated combustion-gas flow scour of a rocket and greatly reduce thermal ablation and thermal shock of a metallic substrate; the thermal protection coating material has good high-temperature combustion-gas flow scour resistance and thermal insulating performance, the temperature of the back face of metal does not exceed 80 DEG C, and therefore an effective thermal protection effect on the rocket launching pad is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of antibacterial epoxy resin potting glue

ActiveCN105368364BImprove thermal stabilityImprove heat resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAlcohol

The invention provides a method for preparing an antibacterial epoxy resin pouring sealant. The method comprises the following steps: 1) drying ginkgo leaves, crushing the ginkgo leaves and sieving to obtain the ginkgo leaves powder, adding an ethyl alcohol solution, performing ultrasonic extraction, standing and filtering the material, concentrating the material to obtain a ginkgo leaves extract product; 2) adding diatomite and the ginkgo leaves extract product in a mixer, heating the materials and performing magnetic stirring, taking the product out and drying the product, grinding the product and sieving the product to obtain a composite antiseptic; 3) preparing a mixed liquor by the composite antiseptic, heating the mixed liquor, adding an aluminic acid ester coupling agent, stirring the materials, performing pumping filtration, drying the materials to obtain the modified composite antiseptic; 4) adding epoxy resin, a flexibilizer, a diluents, a filling material and the modified composite antiseptic in a stirred tank for stirring the above materials, performing vacuum defoaming to obtain a component A; 5) adding a curing agent and a promoter in the stirred tank for stirring the above materials, performing vacuum defoaming to obtain a component B; and 6) uniformly mixing the component A and the component B to obtain the antibacterial epoxy resin pouring sealant. The prepared antibacterial epoxy resin pouring sealant has good antibacterial property.

Owner:TAIZHOU HONGLIN IND DESIGN CO LTD

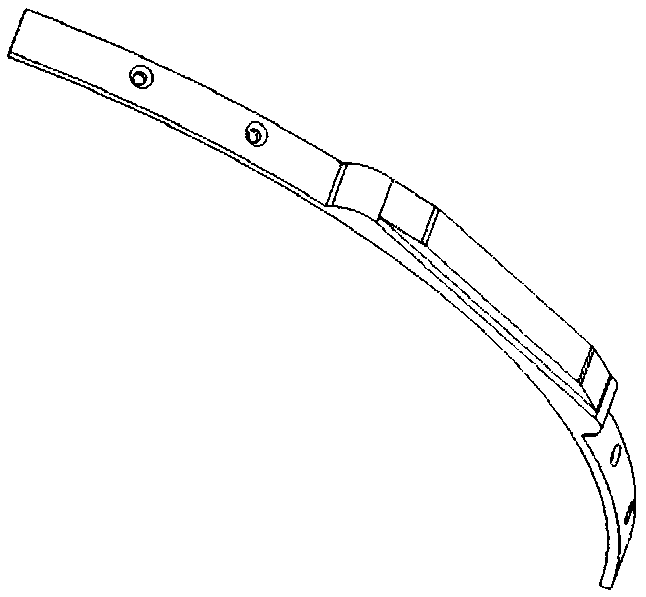

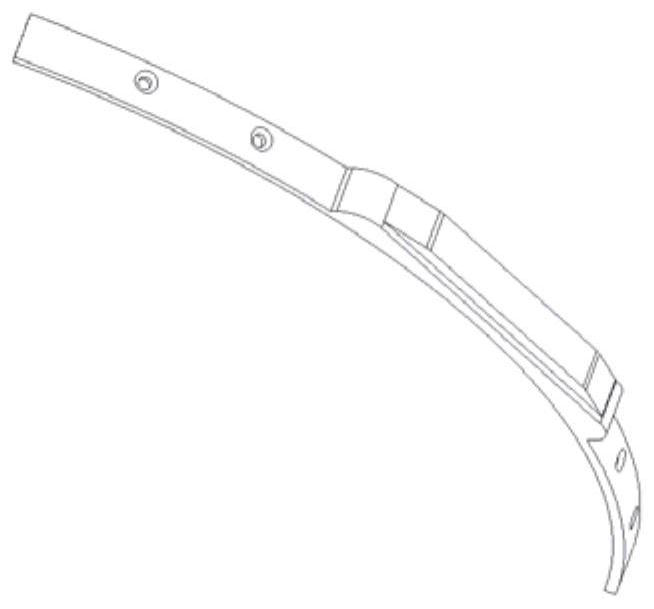

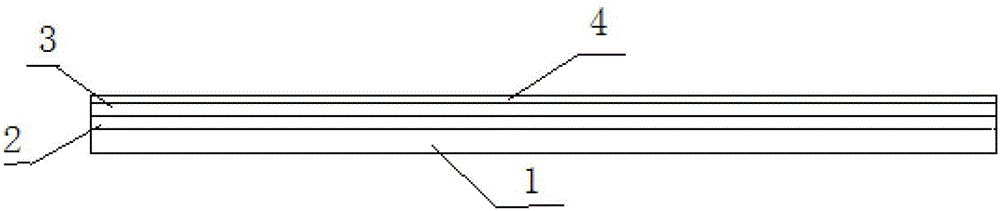

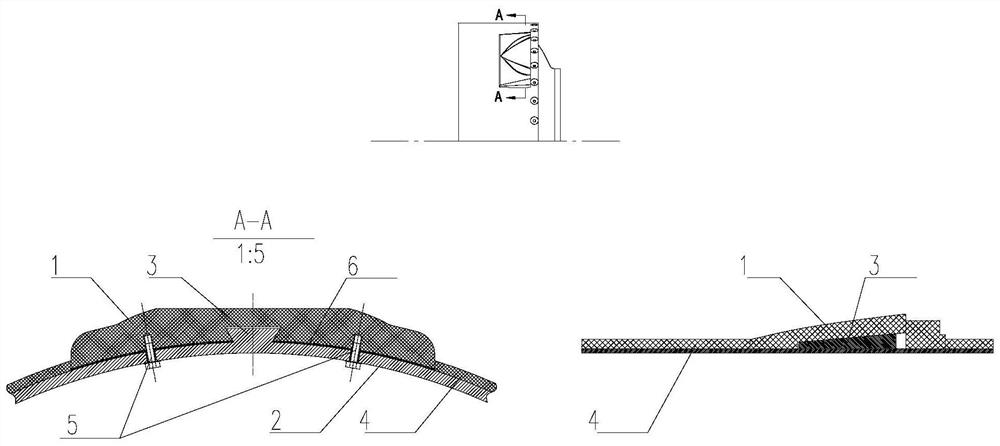

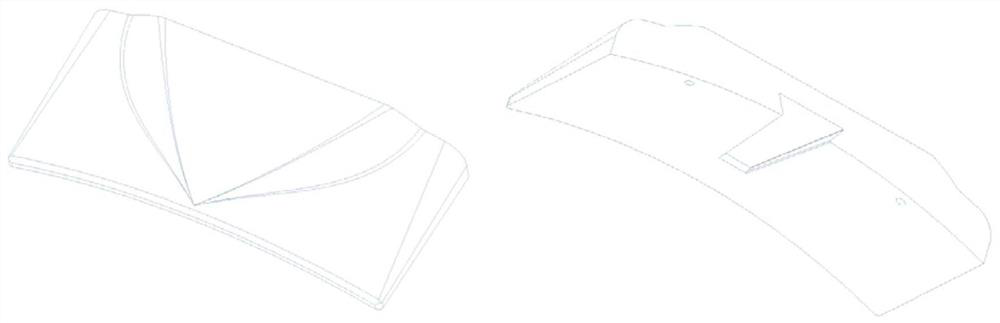

Triangular curved dovetail groove composite rudder substrate and installation method thereof

ActiveCN109927880AGuaranteed temperature requirementsGuaranteed reliabilityFuselage insulationEngineeringMechanical engineering

Provided is a triangular curved dovetail groove composite rudder substrate and an installation method thereof. The lower surface of the rudder substrate is conformed to the shape of a profile of an installation cabin shell; a dovetail groove is formed in the lower surface, and the center surface of the dovetail groove is used as a whole center surface of the rudder substrate; the center of the upper surface is a triangular plane, and both end surfaces of the upper surface are parallel to the center surface; smooth transition between the triangular plane and the both end surfaces is achieved; the triangular plane is inclined with respect to the lower surface of the rudder substrate, and the apex of the triangular plane is located on the outer heat prevention surface of the cabin shell. Thesubstrate improves the thermal environment around the rudder substrate by adopting the aerodynamic shape of a smooth triangular curved surface structure, and is mounted on the surface of an aircraft through the rudder substrate trapezoidal dovetail groove and a metal shell dovetail block inserting mode to simplify a traditional heat-proof plug and a multi-thread connection interface structure, thegrinding process is reduced and the production overall assembly operation is improved.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Environment-friendly degradable aromatic polyurethane foaming material and preparation method thereof

The invention particularly discloses an environment-friendly degradable aromatic polyurethane foaming material. The foaming material is formed by mixing and foaming a component A and a component B, wherein the component B is aliphatic isocyanate, and the component A comprises the following components in parts by weight: 80 to 100 parts of composite polyol, 4 to 8 parts of a foaming agent, 0.5-0.8parts of a catalyst, 0 to 1 part of a crosslinker, 0.5 to 1 part of a foam stabilizer and 15 to 25 parts of modified lavender particles; wherein the composite polyol consists of plant oil-based polyether polyol, polypropylene oxide ether and polyurethane insole alcoholysis product. According to the invention, the modified lavender particles are adopted; wherein the lavender antibacterial foam material can effectively control volatilization of lavender aroma components, so that the material achieves lasting aroma efficacy, covers peculiar smell, can enhance the antibacterial performance of thefoam material and products. The material has the advantages of odor removal, ventilation, refreshing, incense and insect expelling and the like, can improve the utilization rate of lavender, reduce waste and improve the degradation degree, and is green and environment-friendly.

Owner:泉州西米露新材料科技有限公司

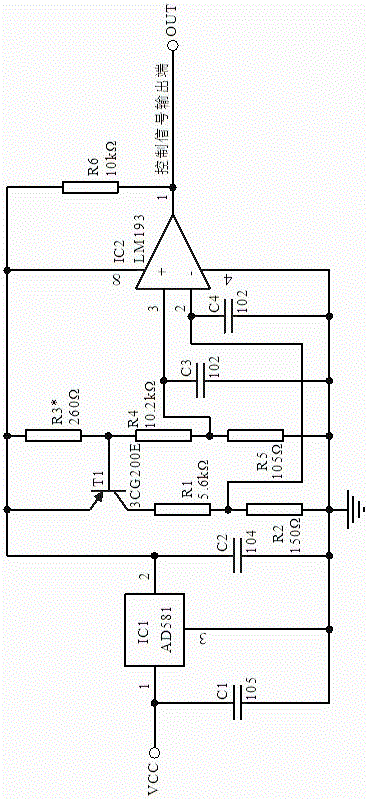

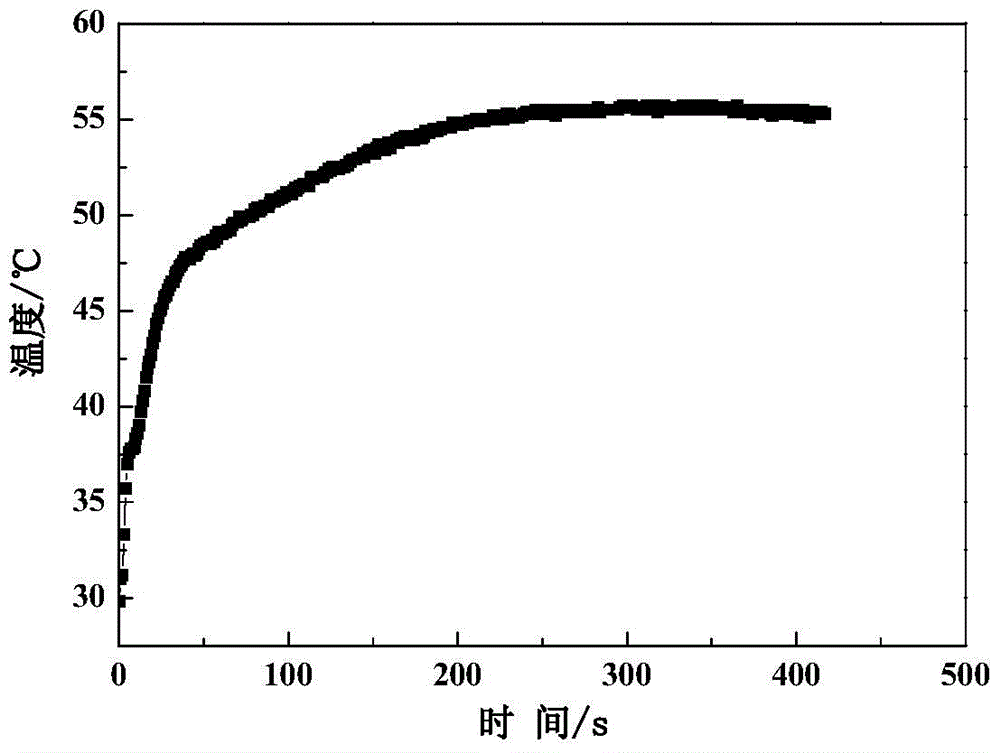

Overheating protection circuit based on p-n junction forward voltage drop temperature characteristic

InactiveCN106602512AGuaranteed stabilityHigh precisionEmergency protective arrangements for automatic disconnectionNegative temperatureControl signal

An overheating protection circuit based on a p-n junction forward voltage drop temperature characteristic comprises a voltage conversion circuit and an overheating control signal conversion circuit. The heating sensing element of the overheating control signal conversion circuit is a PNP triode, when the temperature detected by the PNP triode does not exceed a setting value, the emitter junction voltage set by the circuit for the emitter of the PNP triode in advance does not reach the minimum voltage of the conduction, the emitter of the PNP triode is located at a closing state, and a comparator outputs high level to control the normal work of the module required being protected; when the temperature detected by the PNP triode exceeds the setting value, because the emitter junction p-n junction forward voltage has the negative temperature characteristic, the emitter junction conduction voltage of the thermal detection triode is dropped to the circuit preset voltage to allow the emitter to be conducted, and the comparator overturns the output low level to control the closing of the module required being protected to play a thermal protection effect. The voltage conversion circuit employs a high-precision and low-temperature drift reference circuit which is taken as the power supply of the overheating control signal conversion circuit so as to improve the accuracy of the overheating protection.

Owner:TIANSHUI 749 ELECTRONICS

Stage structure

The invention discloses a stage structure comprising a rocket body, a pneumatic reduction mechanism and a pneumatic anti-collision mechanism. The pneumatic reduction mechanism comprises a pneumatic head and an ablation resisting layer. The pneumatic head is a second gas bag capable of being shrunk and spread. The second gas bag covers the head of the rocket body. The pneumatic anti-collision mechanism is provided with a first gas bag capable of being shrunk and spread. The first air bag covers the tail of the rocket body. After being inflated, the second gas bag is of a symmetrical structureand has good pneumatic stability. The outer wall of the second gas bag is provided with an ablation resisting layer, so that the second gas bag cannot be burned during flying aloft at high temperature. The second gas bag can reduce the speed of the rocket body at high temperature in high altitude; besides, during landing in low altitude, the second gas bag can achieve a buffering function on the rocket body; the second gas bag has the foldable capacity, so that the occupied space on the rocket body and the weight of the second gas bag can be reduced. Meanwhile, the first gas bag can achieve the flexible buffering function on the tail when the tail of the rocket body lands, and therefore the rocket body is prevented from being damaged.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

PET compound for packaging bottle and manufacturing method thereof

InactiveCN106221141AIncrease melanin contentImprove compatibility and bond strengthNatural dyesChemistryFire retardant

The invention provides a PET compound for a packaging bottle. The PET compound comprises the following components by weight part: 50-60 parts of PET resins, 0.6-1.1 parts of lubricating agents, 5-10 parts of fire retardants, 3-4 parts of flexibilizer, 0.5-1 part of dispersing agent, 1-2 parts of antistatic agents, 5-10 parts of reinforcing agents, 1-2 parts of low temperature-resisting modifying agents, 3-4 parts of compatilizer, 5-6 parts of epoxy resins, 7-8 parts of compound melanin capsules and 2 parts of nylon. The invention also provides a manufacturing method for the PET compound for the packaging bottle. The PET compound has higher radiation resistance.

Owner:陆志强

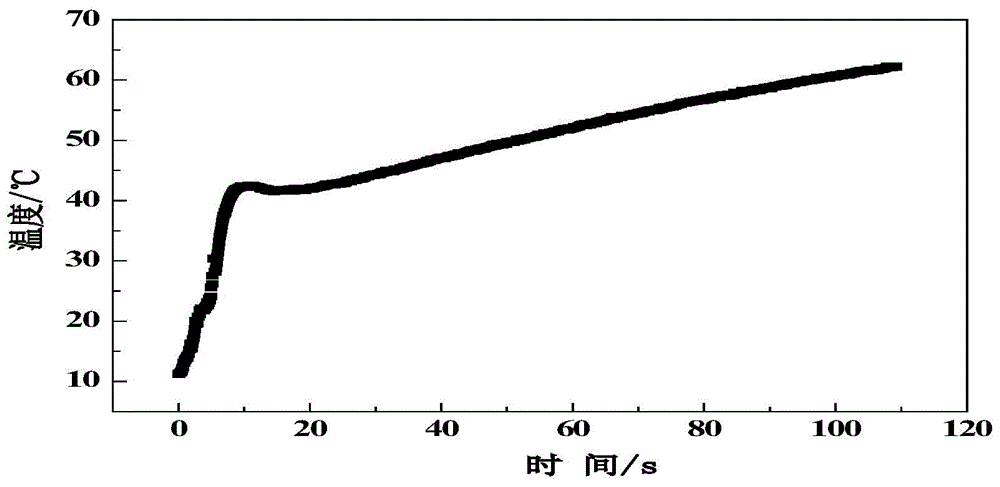

The structure and application of a thermal protection coating for steel structure surface

ActiveCN104691038BGood heat insulationPlay a role in heat insulationSynthetic resin layered productsEpoxyBrick

The invention discloses the structure and application of a heat protection coating material for steel structure surface. The thermal protective coating material of the invention is composed of three layers of materials: an organic bottom layer, a refractory brick and an inorganic surface layer. Among them, the organic bottom layer is composed of epoxy resin, curing agent polyamide and toughening agent liquid rubber. The refractory brick is made of clay refractory brick, and the inorganic surface layer is composed of water glass, curing agent sodium fluorosilicate, sand, cement and refractory aggregate. The heat protection coating material of the invention can withstand the scouring of simulated rocket gas flow, the temperature of the metal back does not exceed 150 DEG C, and the coating has good heat insulation performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A detachable multi-lobed cabin section butt joint heat protection structure

ActiveCN109596010BImprove responseAct as thermal protectionSelf-propelled projectilesButt jointEngineering

A detachable multi-lobed cabin section butt heat-proof structure, the docking frames of the two cabin sections to be docked are radially connected, and the outer ring at the radial connection is equipped with a multi-petal heat-proof ring. The heat ring is in clearance fit with the outer heat-proof structure of the above-mentioned butt joint two compartments. The present invention aims at the docking structure between the cabin sections that require repeated disassembly and assembly, and proposes that the docking place adopts a multi-lobed heat-proof ring that is easy to disassemble to prevent heat at the docking part—that is, the cabin section docking still uses countersunk head screws in the radial direction The docking form is just to install the multi-lobed heat-proof ring by screwing after the docking. The multi-lobed heat-proof ring covers all the docking screws and the docking parts to protect the heat, and can be disassembled and operated repeatedly. It is simple and meets the requirements of rapid maintenance response.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

High-temperature coating material structure for rocket launching pad and application of high-temperature coating material structure

InactiveCN105984183AHigh carbon rateImproves ablation resistanceSynthetic resin layered productsBuilding constructionsEpoxyRocket launch

The invention discloses a high-temperature-resistant coating material structure for a rocket launch pad and its application. Specifically, an organic bottom layer, a refractory lightweight aggregate and an organic-inorganic composite surface layer are sequentially arranged on the base surface of the launch pad, wherein the refractory lightweight The material is interspersed in the organic bottom layer and the organic-inorganic composite surface layer. The organic bottom layer is composed of epoxy resin, curing agent modified polyamine and toughening agent liquid rubber, and the organic-inorganic composite surface layer is composed of organic adhesive epoxy resin, polyurethane curing agent, sand and cement. The high-temperature-resistant coating material of the invention can withstand the scouring of simulated rocket gas flow, the temperature of the metal back does not exceed 180°C, and the coating has good heat insulation performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of α-cyanoacrylate thermally conductive adhesive and preparation method thereof

ActiveCN105368330BImprove high temperature resistanceIncrease layer spacingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCross-linkHeat conducting

The invention provides alpha-cyanoacrylate heat-conducting glue. The alpha-cyanoacrylate heat-conducting glue comprises the following components in parts by weight: 100 parts of alpha-cyanoacrylate, 2-5 parts of a thickening agent, 2-4 parts of a plasticizer, 0.1-0.4 parts of a stabilizing agent, 0.5-1 part of a polymerization inhibitor, 20-30 parts of a cross-linking agent, 3-6 parts of a fire retardant, 1-2 parts of pigment, 100-110 parts of a heat-conducting filling material, 10-14 parts of magnesium hydrogen phosphate, and 8-10 parts of liquid polyisobutylene. The invention also provides a preparation method of the alpha-cyanoacrylate heat-conducting glue. The alpha-cyanoacrylate heat-conducting glue has good impact-resistance performance and heat-resistance performance.

Owner:绍兴市上虞舜东橡塑制品有限公司

High-temperature-resistant coating structure for steel structure surface and applications thereof

InactiveCN104924704AStrong adhesionGood heat insulationSynthetic resin layered productsMetal layered productsEpoxyThermal insulation

The invention discloses a structure and applications of a high-temperature-resistant coating material for steel structure surface. The high-temperature-resistant coating material is composed of an organic layer, a shaped firebrick layer, an organic layer, and an amorphous refractory material layer. The two organic layers have the same components and are composed of epoxy resin, a polyamide curing agent, and a toughening agent (liquid rubber). The firebrick is clay-based firebrick. The amorphous refractory material is composed of flint clay, cordierite, aluminate cement, and silica fume. The adhesion force of the provided high-temperature-resistant coating material is strong, which can sustain the washing of rocket imitated combustion-gas stream. The metal backside temperature does not exceed 120 DEG C, and the coating has an excellent performance on resisting high-temperature combustion-gas stream brushing and thermal insulation property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

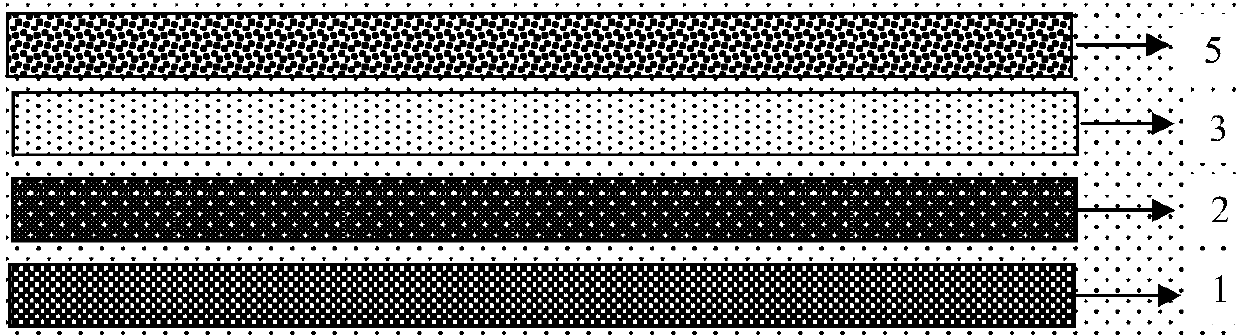

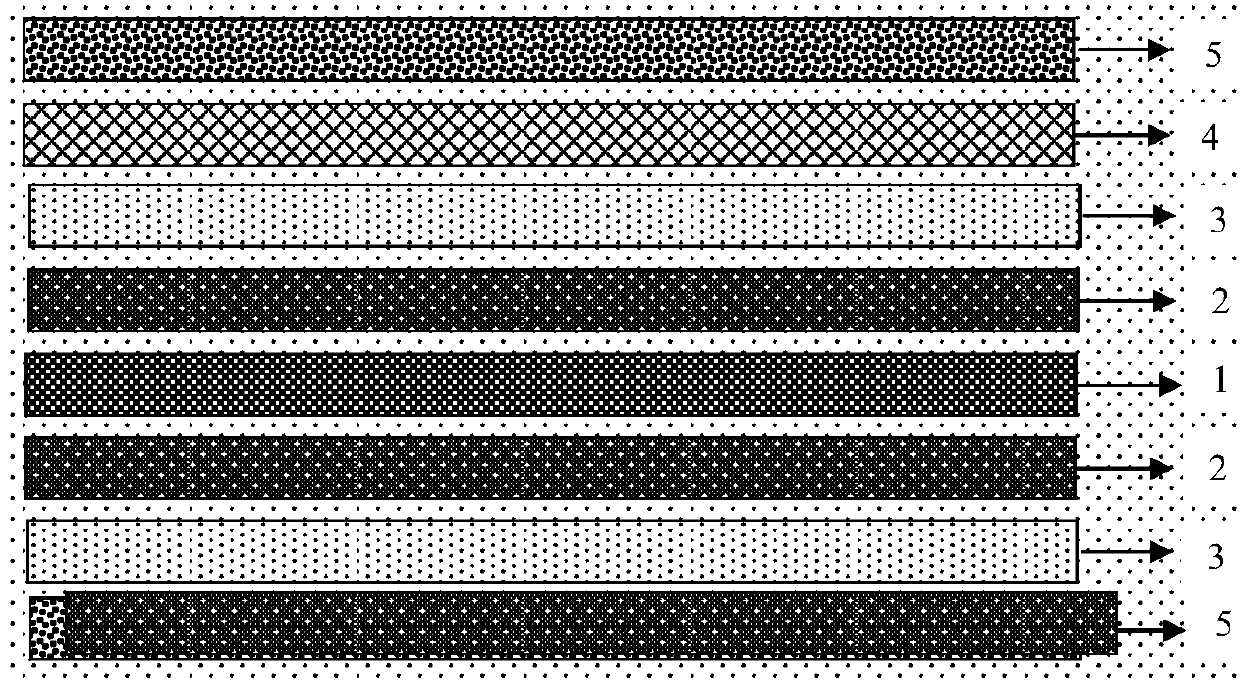

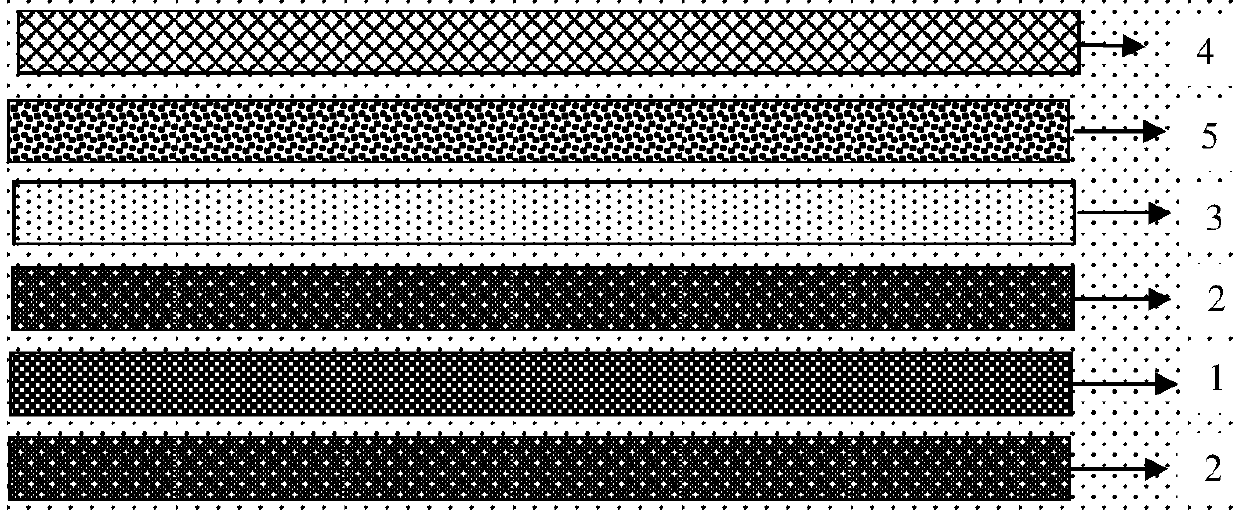

A kind of surface protective conductive composite material and preparation method thereof

ActiveCN109291575BEffective isolation of contactsIsolated contactSynthetic resin layered productsGlass/slag layered productsRubber materialAdhesive cement

The invention relates to a surface-protection-type conductive composite material and a preparation method thereof. The composite material is prepared by carrying out compounding and mould pressing ona resin-based composite material, an adhesive layer, a conductive layer, a reinforcing layer and a protective layer, wherein the adhesive layer is an inorganic or organic adhesive, the conductive layer is a pure conductive metal mesh or a high-molecular resin conductive adhesive film or a high-molecular resin insulating adhesive film / conductive metal mesh composite adhesive film or a high-molecular resin conductive adhesive film / conductive metal mesh composite adhesive film, the reinforcing layer is made of a fabric, and the protective layer is made of a rubber material. The preparation methodcomprises the following steps: firstly, cutting a prepreg, the adhesive layer, the conductive layer, the reinforcing layer and the protective layer in a layer-by-layer mode according to the shape andsize of the composite material product, and then carrying out integral curing and forming on the conductive layer with the resin-based composite material, then preparing the resin-based composite material with the adhesive layer, the reinforcing layer and the protective layer into blanks, and finally carrying out compression molding.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

The structure and application of a heat protection coating for rocket launch pad

ActiveCN103850355BImproves ablation resistanceHigh carbonation rateClimate change adaptationHeat proofingEpoxyBrick

The invention discloses a structure for a thermal protective coating of a rocket launching pad and an application thereof. The thermal protective coating is composed of materials in three layers, namely, an organic bottom layer, refractory bricks and an organic-inorganic compound surface layer, wherein the organic bottom layer is composed of epoxy resin, solidifying agent polyamide and flexibilizer liquid rubber; clay refractory bricks are adopted as the refractory bricks; the organic-inorganic compound surface layer is composed of organic rubber epoxy resin, polyurethane curing agent, sand and cement. The material of the thermal protective coating provided by the invention can endure the scouring of the simulated fuel gas flow of a rocket; the temperature on a metal rear surface is not above 200 DEG C; the coating has an excellent heat-insulating property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

A triangular surface type dovetail groove composite material rudder substrate and its installation method

ActiveCN109927880BGuaranteed temperature requirementsGuaranteed reliabilityFuselage insulationFlight vehicleMechanical engineering

A triangular surface type dovetail groove type composite material rudder base plate and its installation method, the lower surface of the rudder base plate is in the same shape as the profile of the cabin shell where it is installed; the lower surface is provided with a dovetail groove, and the central surface of the dovetail groove is used as the whole The center plane of the rudder base plate; the center of the upper surface is a triangular plane, and the two end faces of the upper surface are parallel to the central plane; a smooth transition between the triangular plane and the above-mentioned two end faces; the lower surface of the triangular plane relative to the rudder base plate is inclined and The apex of the triangular plane is located on the outer heat-resistant surface of the cabin shell. The invention improves the thermal environment around the rudder base plate by adopting the aerodynamic shape of the smooth triangular surface structure; it is installed on the surface of the aircraft through the trapezoidal dovetail groove of the rudder base plate and the dovetail block of the metal shell, simplifying the traditional heat-proof plug and multi-thread connection interface structure, Reduce the grinding process and improve the operability of production assembly.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

Environmentally friendly and degradable aromatic polyurethane foam material and preparation method thereof

The invention specifically discloses an environmentally friendly and degradable aromatic polyurethane foaming material, which is formed by mixing and foaming components A and B, wherein: component B is aliphatic isocyanate, and component A includes the following parts by weight Components: 80-100 parts of complex polyol, 4-8 parts of foaming agent, 0.5-0.8 parts of catalyst, 0-1 part of cross-linking agent, 0.5-1 part of foam stabilizer and 15-25 parts Parts of modified lavender particles, wherein the complex polyol is composed of vegetable oil-based polyether polyol, polypropylene oxide ether and polyurethane insole alcoholysis product. The invention adopts modified lavender granules, which can effectively control the volatilization of lavender aroma components, achieve long-lasting aroma effect and cover up peculiar smell, and at the same time enhance the antibacterial performance of foam materials and products, and have the functions of deodorization, breathability, refreshing, and aromatherapy. The advantages of repelling insects can improve the utilization rate of lavender, reduce the waste of waste and improve the degree of degradation, which is green and environmentally friendly.

Owner:泉州西米露新材料科技有限公司

Structure and application of a high temperature resistant coating for metal surface

ActiveCN104924718BStrong adhesionGood heat insulationSynthetic resin layered productsWater-setting substance layered productEpoxyThermal insulation

The invention discloses the structure and application of a high-temperature-resistant coating material for metal surfaces. The high temperature resistant coating material of the invention is composed of two layers of materials, an organic bottom layer and an inorganic surface layer. Among them, the organic bottom layer is composed of epoxy resin, curing agent polyamide and toughening agent liquid rubber. The inorganic surface consists of pyrite, cordierite, aluminate cement and silica fume. The high-temperature-resistant coating material of the invention has strong adhesion, can withstand the scouring of simulated rocket gas flow, the temperature of the metal back does not exceed 120°C, and the coating has good high-temperature gas-flow scouring performance and heat insulation performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A High Temperature Resistant Coating Structure and Its Application on Rocket Launch Pad

ActiveCN105291520BStrong adhesionImprove high temperature resistanceSynthetic resin layered productsEpoxyRocket launch

The invention discloses a high temperature resistant coating material for a rocket launch platform. The high temperature resistant coating material of the invention is composed of two layers of materials, an organic bottom layer and an inorganic surface layer. Among them, the organic bottom layer is composed of epoxy resin, curing agent polyamide and toughening agent liquid rubber. The inorganic surface layer consists of mullite, cordierite, aluminate cement and silica fume. The high-temperature-resistant coating material of the invention has strong adhesion, can withstand the scouring of simulated rocket gas flow, the temperature of the metal back does not exceed 100°C, and the coating has good high-temperature gas-flow-resistant scouring performance and heat insulation performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

High-temperature-resistant composite color steel tile and production equipment thereof

InactiveCN113308193AImprove high temperature resistanceImprove mechanical propertiesFireproof paintsShaping toolsPrepolymerOrganosilicon

The invention discloses a high-temperature-resistant composite color steel tile. The high-temperature-resistant composite color steel tile comprises a high-temperature-resistant coating and a composite color steel tile body, wherein the surface of the composite color steel tile is coated with a layer of the high-temperature-resistant coating. The invention relates to the technical field of color steel tiles. According to the invention, the high-temperature-resistant coating is prepared by matching an organic silicon prepolymer and modified resin and adding an auxiliary agent; after the organic silicon prepolymer and the modified resin undergo a reaction, a large number of Si-O bonds are formed in a reaction product, and the Si-O bonds have high bond energy, so the reaction product has high heat resistance, and the coating prepared from the reaction product has high resistance to high temperature; and in addition, aluminum oxide powder, titanium dioxide powder and talcum powder are added into the coating to serve as auxiliary agents, the mechanical performance of the coating can be improved, silicon dioxide and aluminum oxide in the coating can generate a performance protection layer to achieve thermal protection effect, and the high-temperature-resistant performance of the composite color steel tile is further improved.

Owner:杭州富阳捷鑫彩钢有限公司

Natural aromatic environment-friendly EVA composite foam material and its preparation method and application

ActiveCN111423653BAct as thermal protectionReduce volatilityChemical industrySports equipmentEngineering

The invention relates to the technical field of EVA composite materials, and specifically discloses a natural aromatic and environment-friendly EVA composite foam material, which is prepared from the following components in parts by weight: 80-100 parts of rubber-plastic base material, 4-8 parts of hair Foaming agent, 0.5-1 part of cross-linking agent, 0.5-0.8 part of mineral oil, 0.5-1 part of stearic acid and 20-40 parts of modified lavender particles, the rubber-plastic base material contains 40%-100 % EVA. The present invention adopts modified lavender particles, which can effectively control the volatilization of lavender aroma components, achieve lasting aroma effect, and at the same time can enhance the antibacterial performance and deodorization of foaming materials and products, and has the advantages of deodorization, ventilation, refreshing, incense and fragrance. It has the advantages of repelling insects, can improve the utilization rate of lavender, reduce waste and environmental pollution, and is green and environmentally friendly. It is suitable for daily necessities and sports equipment such as shoe soles, insoles, yoga mats, and crawling mats.

Owner:泉州西米露新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com