A kind of preparation method of antibacterial epoxy resin potting glue

A technology of epoxy resin and potting glue, applied in the field of potting glue, can solve the problems of not having antibacterial properties and being unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

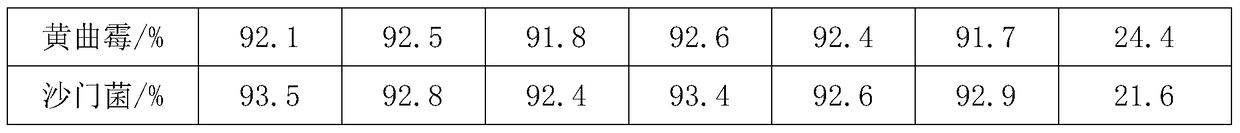

Examples

Embodiment 1

[0029] The preparation method of antibacterial epoxy resin potting glue, its steps are as follows:

[0030] (1) Ginkgo biloba is placed in an oven at 70° C. and dried for 2 hours, and after being pulverized with a pulverizer, 50 mesh sieves are obtained to obtain Ginkgo biloba powder, and the Ginkgo biloba powder is added to the ethanol solution with a mass concentration of 75%, and Ginkgo biloba and The weight-to-volume ratio of the ethanol solution is 1:9g / mL, the temperature is 40°C, and the ultrasonic frequency is 40KHz, ultrasonic extraction is performed for 1 hour, and the filtrate is obtained by filtering after standing for 3 hours, and the filtrate is concentrated in a constant temperature water bath at 50°C 2 hours, obtain the Ginkgo biloba extract for subsequent use;

[0031] (2) Add diatomaceous earth with a weight ratio of 1:2 and the ginkgo biloba extract obtained in step (1) into a mixer, heat to 70°C and stir magnetically for 3 hours, take it out and place it in...

Embodiment 2

[0037] The preparation method of antibacterial epoxy resin potting glue, its steps are as follows:

[0038] (1) Ginkgo biloba is placed in an oven at 70° C. and dried for 2 hours, and after being pulverized with a pulverizer, 50 mesh sieves are obtained to obtain Ginkgo biloba powder, and the Ginkgo biloba powder is added to the ethanol solution with a mass concentration of 75%, and Ginkgo biloba and The weight-to-volume ratio of the ethanol solution is 1:9g / mL, the temperature is 40°C, and the ultrasonic frequency is 40KHz, ultrasonic extraction is performed for 1 hour, and the filtrate is obtained by filtering after standing for 3 hours, and the filtrate is concentrated in a constant temperature water bath at 50°C 2 hours, obtain the Ginkgo biloba extract for subsequent use;

[0039] (2) Add diatomaceous earth with a weight ratio of 1:2 and the ginkgo biloba extract obtained in step (1) into a mixer, heat to 70°C and stir magnetically for 3 hours, take it out and place it in...

Embodiment 3

[0045] The preparation method of antibacterial epoxy resin potting glue, its steps are as follows:

[0046] (1) Ginkgo biloba is placed in an oven at 70° C. and dried for 2 hours, and after being pulverized with a pulverizer, 50 mesh sieves are obtained to obtain Ginkgo biloba powder, and the Ginkgo biloba powder is added to the ethanol solution with a mass concentration of 75%, and Ginkgo biloba and The weight-to-volume ratio of the ethanol solution is 1:9g / mL, the temperature is 40°C, and the ultrasonic frequency is 40KHz, ultrasonic extraction is performed for 1 hour, and the filtrate is obtained by filtering after standing for 3 hours, and the filtrate is concentrated in a constant temperature water bath at 50°C 2 hours, obtain the Ginkgo biloba extract for subsequent use;

[0047] (2) Add diatomaceous earth with a weight ratio of 1:2 and the ginkgo biloba extract obtained in step (1) into a mixer, heat to 70°C and stir magnetically for 3 hours, take it out and place it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com