A triangular surface type dovetail groove composite material rudder substrate and its installation method

A composite material and installation method technology, applied in the direction of fuselage insulation, etc., can solve the problems of many structural threaded connections, increase the complexity of the assembly process, etc., to reduce the harsh thermal environment, ensure temperature requirements and reliability of use, and good heat insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

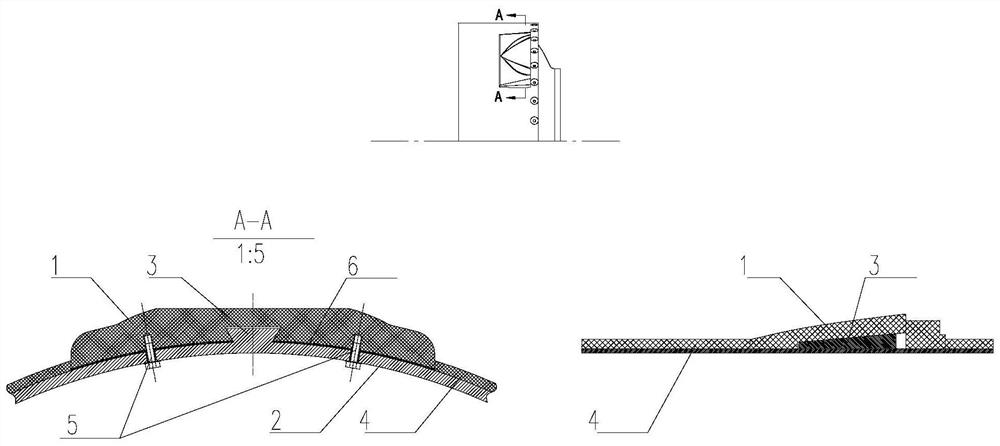

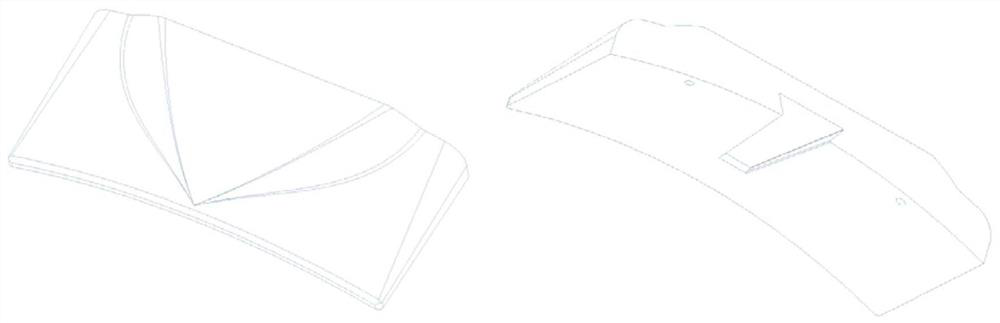

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0028] The invention improves the thermal environment around the rudder base plate by adopting the aerodynamic shape of the smooth triangular surface structure; it is installed on the surface of the aircraft through the trapezoidal dovetail groove of the rudder base plate and the dovetail block of the metal shell, simplifying the traditional heat-proof plug and multi-thread connection interface structure, The grinding process is reduced, and the operability of production assembly is improved; the composite material rudder substrate structure can play a role in heat protection for the rudder system of the aircraft actuator. Specifically, a hypersonic aircraft triangular curved dovetail groove composite material rudder substrate structure is generally located at the front end of the leading edge structure of the rudder system and installed on the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com