High-barrier transparent composite packaging film applicable to boiling sterilization process

A composite packaging film, retort sterilization technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of opacity of high-barrier packaging films, broken aluminum foil, etc., to overcome the risk of food deterioration and cost. Low, good food safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

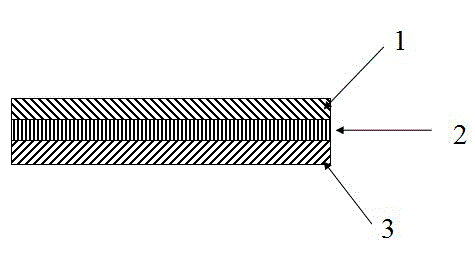

[0017] Such as figure 1 As shown, a high-barrier transparent composite packaging film suitable for retort sterilization process,

[0018] The composite packaging film is sequentially provided with an outer printing layer 1, a middle barrier layer 2 and an inner heat-sealing layer 3 from the outside to the inside, and the layers are bonded by a polyurethane adhesive;

[0019] The outer printing layer 1 is a bidirectional synchronously stretched grade nylon film;

[0020] The middle barrier layer 2 is a polyester film coated with polyvinylidene chloride emulsion;

[0021] The inner heat-sealing layer 3 is a retort-grade cast polypropylene film.

[0022] The thickness of the outer printing layer 1 is 0.015mm, the thickness of the middle barrier layer 2 is 0.014mm, and the thickness of the inner heat-sealing layer 3 is 0.075mm.

[0023] The thickness of the adhesive layer between the printing layer 1 and the barrier layer 2 and between the barrier layer 2 and the heat-sealing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com