A kind of α-cyanoacrylate thermally conductive adhesive and preparation method thereof

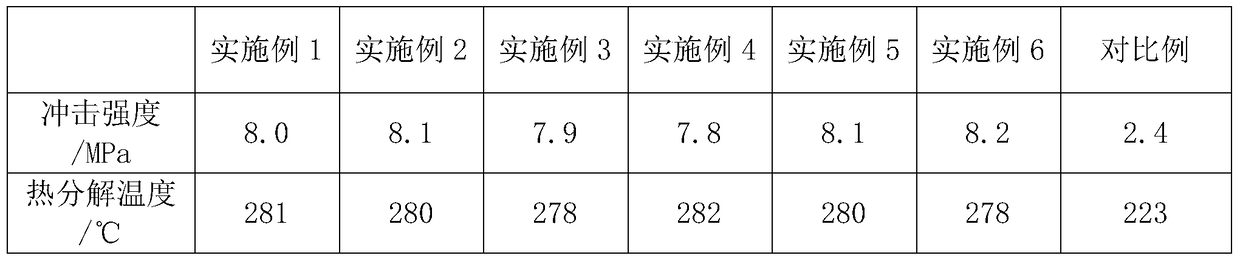

A cyanoacrylate and thermally conductive adhesive technology, applied in the field of thermally conductive adhesives, can solve the problems of limited application range, poor impact resistance and heat resistance, and achieve the effects of avoiding high temperature damage, increasing thermal decomposition temperature and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] α-cyanoacrylate thermal conductive adhesive, in parts by weight, is made of the following components: 100 parts of α-cyanoacrylate, 3 parts of PMMA, 2 parts of DOP, 0.1 part of sulfur dioxide, 1 part of hydroquinone, cyanoacrylate 25 parts of ethyl acrylate, 3.5 parts of aluminum hydroxide, 1.2 parts of organic pigments, 104 parts of quartz powder, 13 parts of magnesium hydrogen phosphate, and 8.5 parts of liquid polyisobutylene.

[0027] The steps of its preparation method are as follows:

[0028] (1) Magnesium hydrogen phosphate is added into distilled water and dispersed evenly to obtain a mass fraction of 10% magnesium hydrogen phosphate solution, and the octadecyltrimethylammonium chloride with a weight of 1.8 times of magnesium hydrogen phosphate is added in the magnesium hydrogen phosphate solution , heated to 90°C by microwave, then magnetically stirred for 3 hours, taken out, filtered with absolute ethanol, washed 5 times with distilled water, dried in an oven ...

Embodiment 2

[0032] α-cyanoacrylate thermal conductive adhesive, in parts by weight, is made of the following components: 100 parts of α-cyanoacrylate, 2 parts of PMMA, 4 parts of DOP, 0.4 parts of sulfur dioxide, 0.7 parts of hydroquinone, cyanoacrylate 27 parts of ethyl acrylate, 4 parts of aluminum hydroxide, 1.4 parts of organic pigments, 108 parts of aluminum oxide, 14 parts of magnesium hydrogen phosphate, and 8.8 parts of liquid polyisobutylene.

[0033] The steps of its preparation method are as follows:

[0034] (1) Magnesium hydrogen phosphate is added into distilled water and dispersed evenly to obtain a mass fraction of 10% magnesium hydrogen phosphate solution, and the octadecyltrimethylammonium chloride with a weight of 1.8 times of magnesium hydrogen phosphate is added in the magnesium hydrogen phosphate solution , heated to 90°C by microwave, then magnetically stirred for 3 hours, taken out, filtered with absolute ethanol, washed 5 times with distilled water, dried in an ov...

Embodiment 3

[0038] α-cyanoacrylate thermal conductive adhesive, in parts by weight, is made of the following components: 100 parts of α-cyanoacrylate, 4 parts of PMMA, 2.5 parts of DOP, 0.2 parts of sulfur dioxide, 0.5 parts of hydroquinone, cyanide 20 parts of ethyl acrylate, 6 parts of aluminum hydroxide, 1.5 parts of organic pigments, 105 parts of aluminum oxide, 12.5 parts of magnesium hydrogen phosphate, and 9 parts of liquid polyisobutylene.

[0039] The steps of its preparation method are as follows:

[0040] (1) Magnesium hydrogen phosphate is added into distilled water and dispersed evenly to obtain a mass fraction of 10% magnesium hydrogen phosphate solution, and the octadecyltrimethylammonium chloride with a weight of 1.8 times of magnesium hydrogen phosphate is added in the magnesium hydrogen phosphate solution , heated to 90°C by microwave, then magnetically stirred for 3 hours, taken out, filtered with absolute ethanol, washed 5 times with distilled water, dried in an oven a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com