Structure for thermal protective coating of rocket launching pad and application thereof

A technology for rocket launch and thermal protection, applied in coatings, fire protection, building components, etc., can solve the problems of heavy weight, no relevant reports on the launch pad, and the launch pad cannot be moved, so as to reduce thermal ablation and thermal shock. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

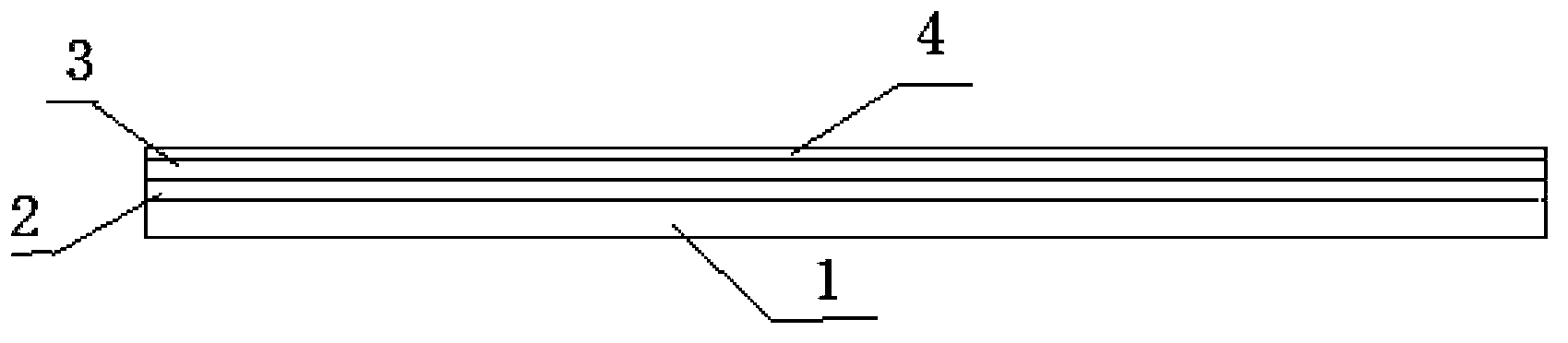

[0019] The preparation of embodiment 1 thermal protective coating structure

[0020] 1. Preparation of organic bottom layer: mix epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber in a ratio of 7:2:1, and then coat it on the 190×120×5mm surface after removing rust and paint. On the steel plate, the coating thickness is 2mm.

[0021] 2. Preparation of the middle layer: Clay refractory bricks (NZ)-2 with a thickness of 5 mm were pasted on the organic bottom layer.

[0022] 3. Preparation of organic-inorganic composite surface layer: First, mix the filler sand and cement evenly in a ratio of 2:1, and then add it to the mixed glue of organic adhesive epoxy resin SM815 and polyurethane curing agent 735 in a ratio of 3:1, solid The ratio to liquid is 3:1. Coat the surface layer material on the refractory brick with a coating thickness of 3mm to prepare a thermal protective coating with a total thickness of 10mm.

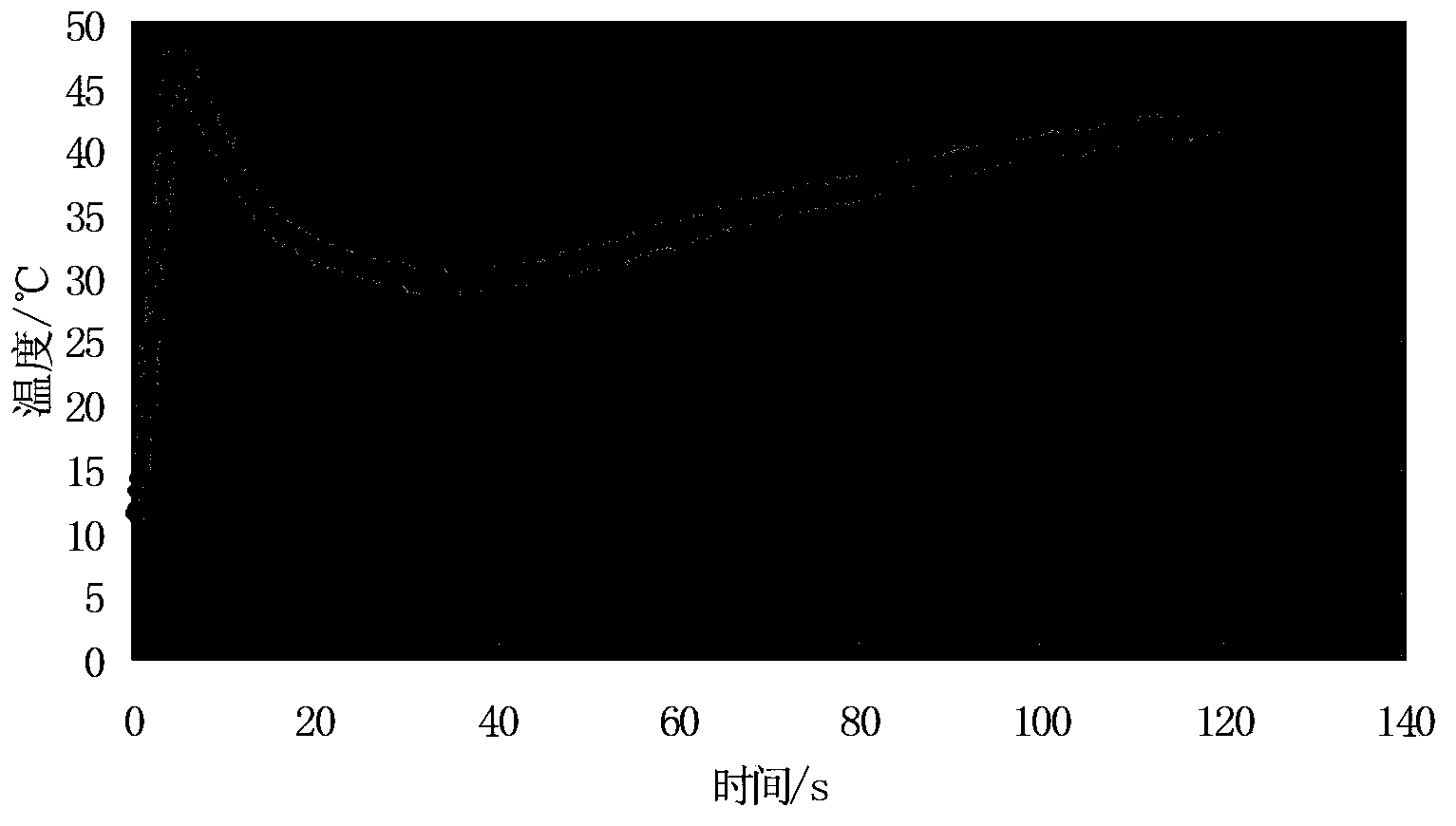

[0023] Tests on the thermal protect...

Embodiment 2

[0025] The preparation of embodiment 2 thermal protection coating structure

[0026] 1. Preparation of organic bottom layer: mix epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber in a ratio of 7:2:1, and then coat it on the 190×120×5mm surface after removing rust and paint. On the steel plate, the coating thickness is 4mm.

[0027] 2. Preparation of the middle layer: Paste the clay refractory brick (NZ)-2 with a thickness of 15mm on the organic bottom layer.

[0028] 3. Preparation of organic-inorganic composite surface layer: First, mix the filler sand and cement evenly in a ratio of 2:1, and then add it to the mixed glue of organic adhesive epoxy resin SM815 and polyurethane curing agent 735 in a ratio of 3:1, solid The ratio to liquid is 3:1. Coat the surface layer material on the refractory brick with a coating thickness of 6mm to prepare a thermal protective coating with a total thickness of 15mm.

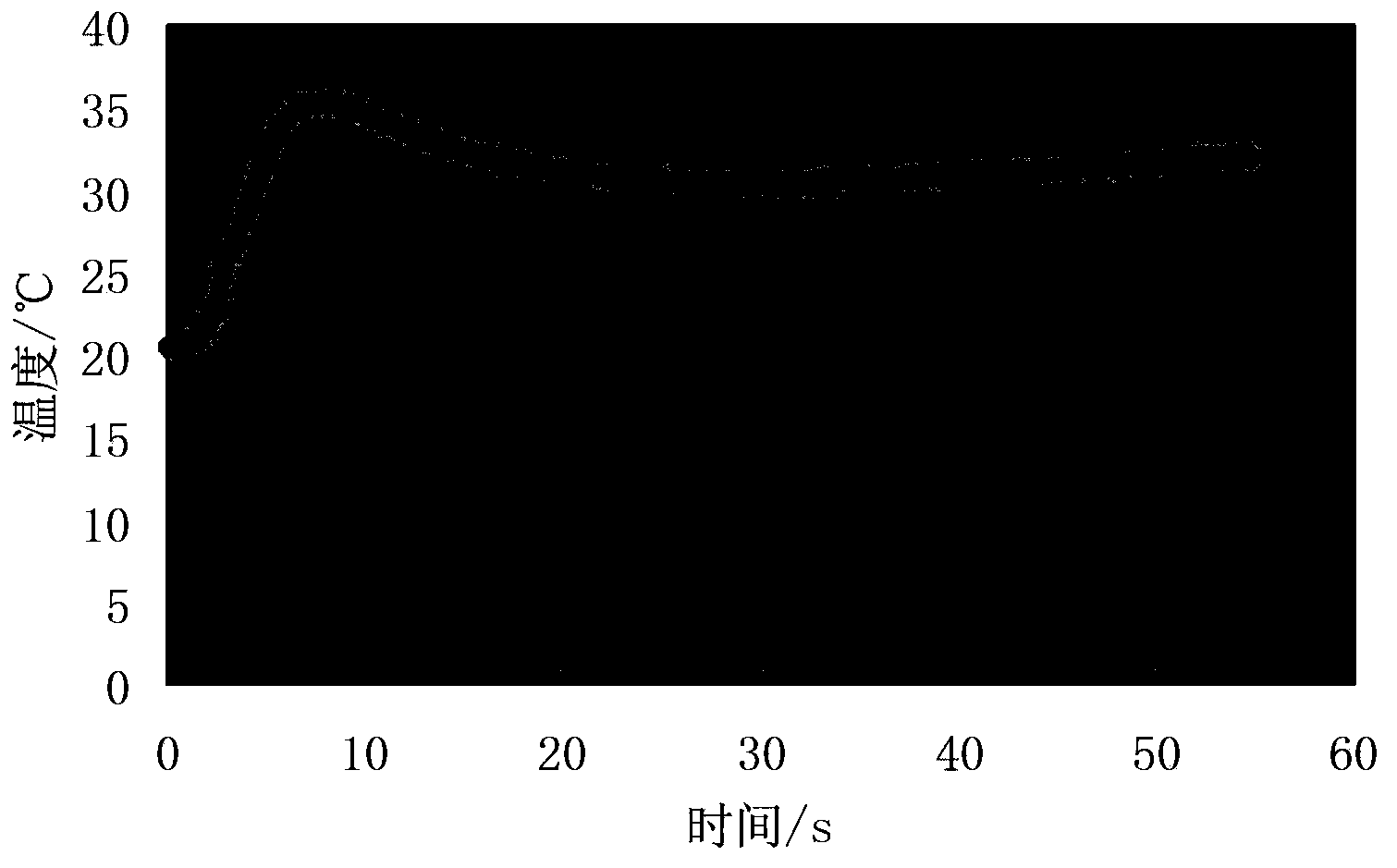

[0029] Tests on the thermal protection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com