A kind of multifunctional microcapsule type corrosion inhibitor and preparation method thereof

A technology of microcapsules and corrosion inhibitors, which is applied in the field of multifunctional microcapsule corrosion inhibitors and their preparation, can solve the problems of reducing the ablative property of the gun barrel and the single component, and achieves the reduction of chemical erosion, reduction of ablative effect, The effect of enhancing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

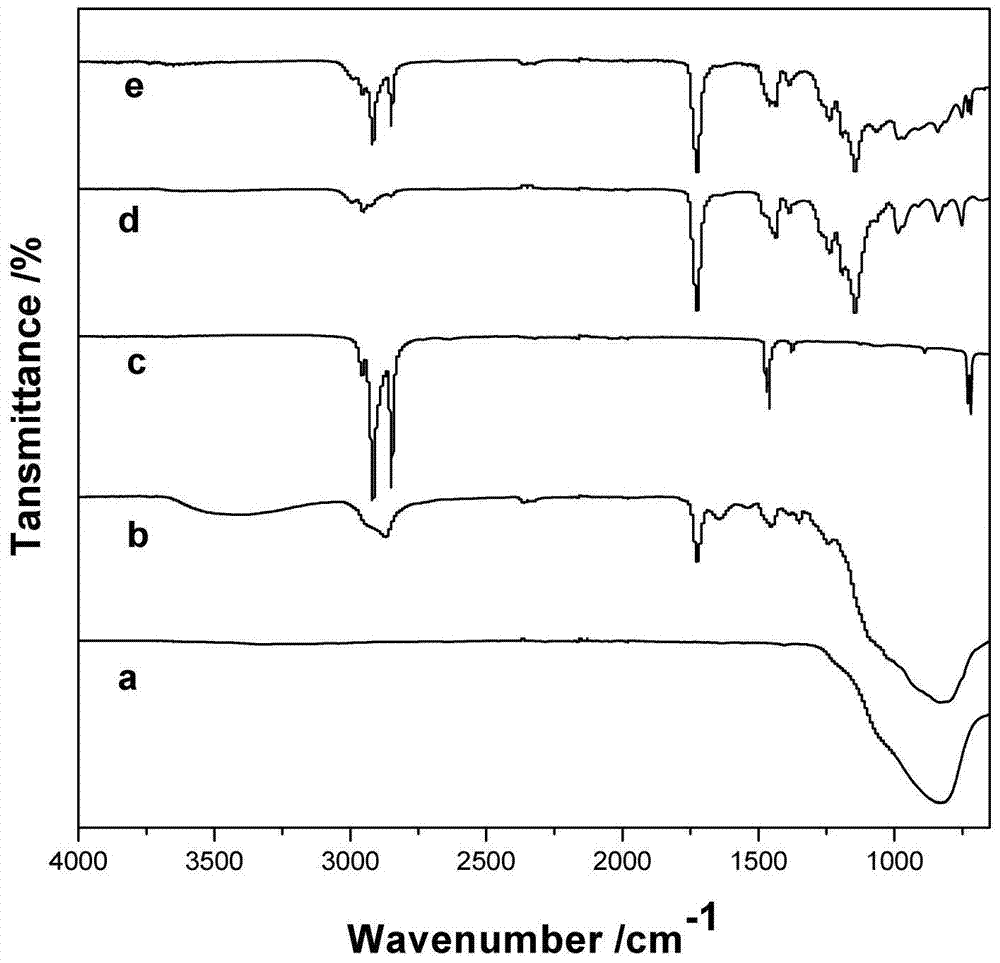

[0029] 1g inorganic Si 3 N 4 Nanoparticles were dispersed in 150ml of ethyl acetate by high-speed shearing, then 0.33g of silane coupling agent KH550 and α-bromoisobutyryl bromide were added, stirred at 75°C for 3 hours, and then centrifuged, and the centrifuged product was polymerized with a hydrophilic monomer (Ethylene glycol) methacrylate and hydrophobic monomer methyl methacrylate are mixed evenly, then add CuBr / pentamethyldiethylenetriamine as a catalyst system, under nitrogen protection, stir until the reaction is complete, and obtain the modified Inorganic Si 3 N 4 Nanoparticles.

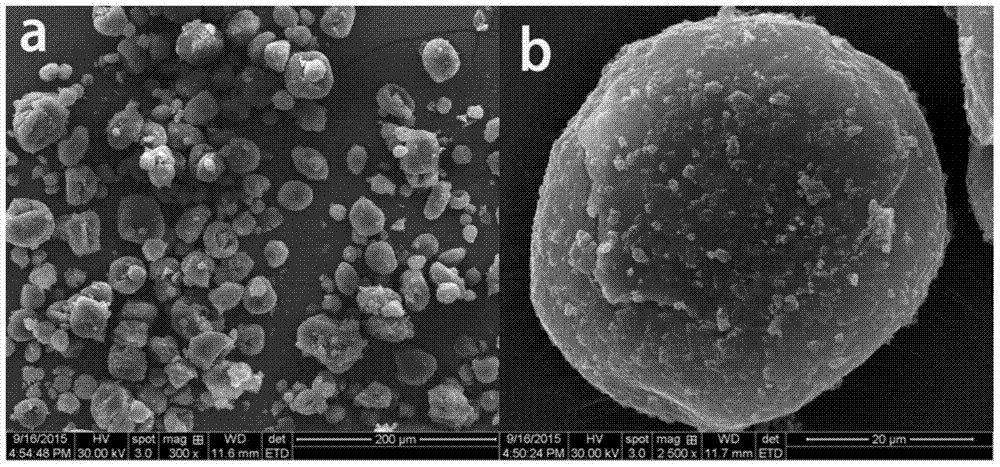

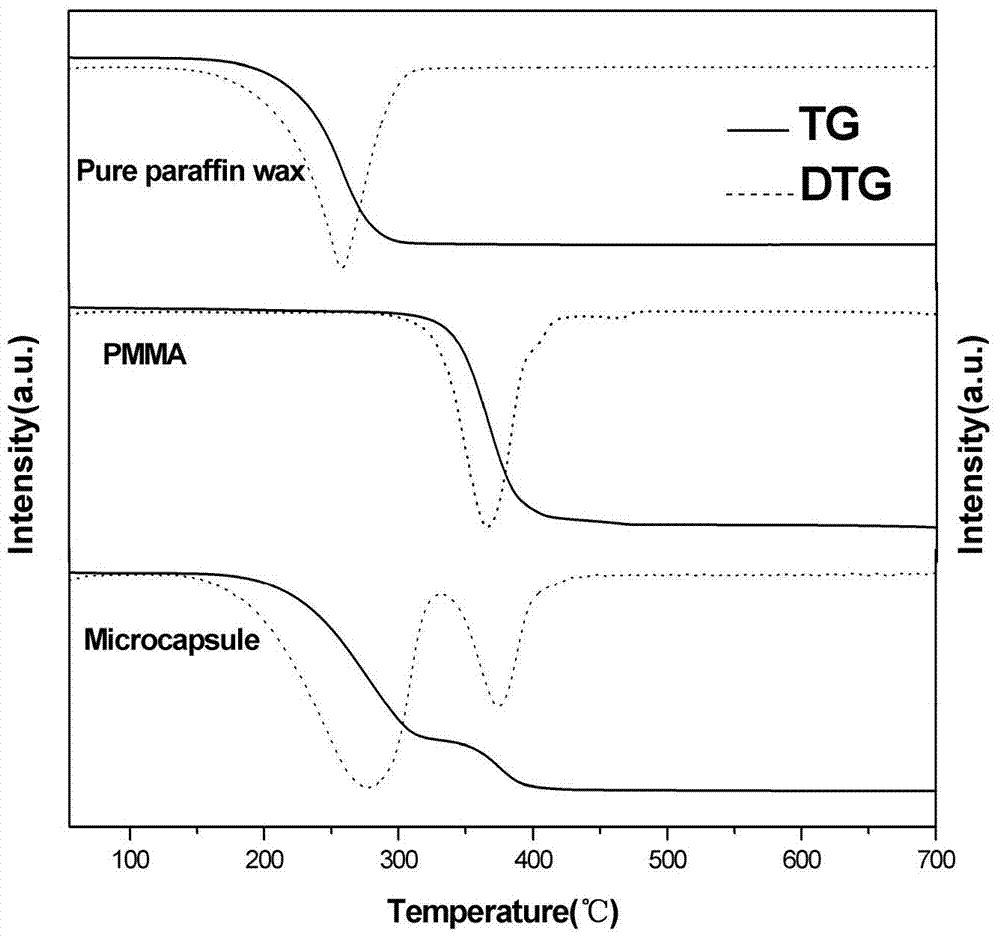

[0030] Weigh 1g of emulsifier sodium dodecylbenzenesulfonate and 0.02g of co-emulsifier polyvinyl alcohol into 100g of deionized water, stir to dissolve and heat to 80°C to obtain solution A; take another beaker and add 3g of endothermic material solid paraffin and placed in a constant temperature water bath at 80°C for heating. After the paraffin wax was completely melted, 3 g of monome...

Embodiment 2

[0037] Disperse 1g of inorganic titanium dioxide nanoparticles in 150mL of ethyl acetate by high-speed shearing, then add 0.33g of silane coupling agent KH550 and α-bromoisobutyryl bromide, stir at 70°C for 5h and centrifuge, and mix the centrifuged product with hydrophilic The neutral monomer poly(ethylene glycol) methacrylate and the hydrophobic monomer methyl acrylate were mixed evenly, then CuBr / pentamethyldiethylenetriamine was added as a catalyst system, and stirred until the reaction was complete under the protection of nitrogen to obtain the improved Inorganic titanium dioxide nanoparticles.

[0038] Weigh 0.5g of emulsifier sodium dodecylbenzenesulfonate and 0.01g of co-emulsifier polyvinyl alcohol into 100g of deionized water, stir to dissolve and heat to 80°C to obtain solution A; take another beaker and add 3g of endothermic material solid The paraffin was placed in a constant temperature water bath at 80°C and heated. After the paraffin was completely melted, 2.4 ...

Embodiment 3

[0040] Disperse 1 g of inorganic boron nitride nanoparticles in 150 mL of ethyl acetate under high-speed shear, then add 0.33 g of silane coupling agent KH550 and α-bromoisobutyryl bromide, stir at 80°C for 3 h, and then centrifuge, and the centrifuged product is mixed with The hydrophilic monomer poly(ethylene glycol) methacrylate and the hydrophobic monomer styrene are mixed evenly, then CuBr / pentamethyldiethylenetriamine is added as a catalyst system, and stirred until the reaction is complete under nitrogen protection to obtain Modified inorganic boron nitride nanoparticles.

[0041] Weigh 2g of emulsifier sodium dodecylbenzenesulfonate and 0.02g of co-emulsifier polyvinyl alcohol into 100g of deionized water, stir to dissolve and heat to 80°C to obtain solution A; take another beaker and add 3g of endothermic material solid paraffin and heated in a constant temperature water bath at 80°C. After the paraffin was completely melted, 6 g of monomeric styrene and 0.39 g of mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com