Patents

Literature

79results about How to "Reduced wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

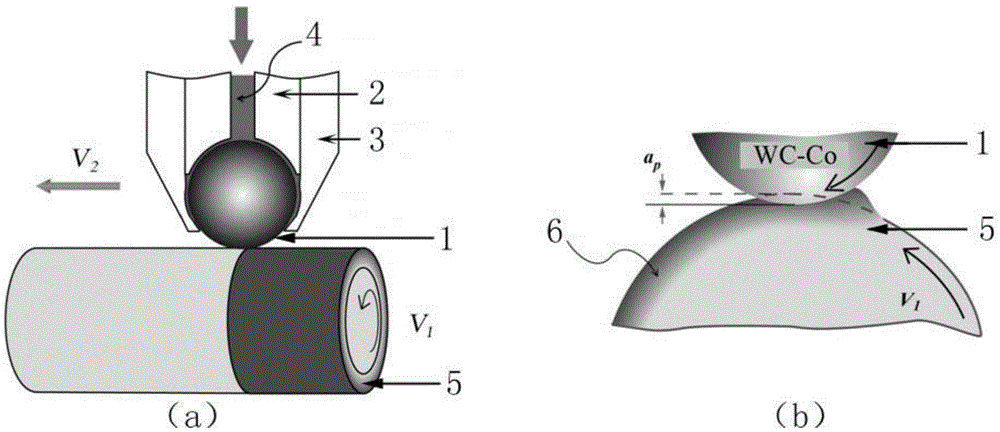

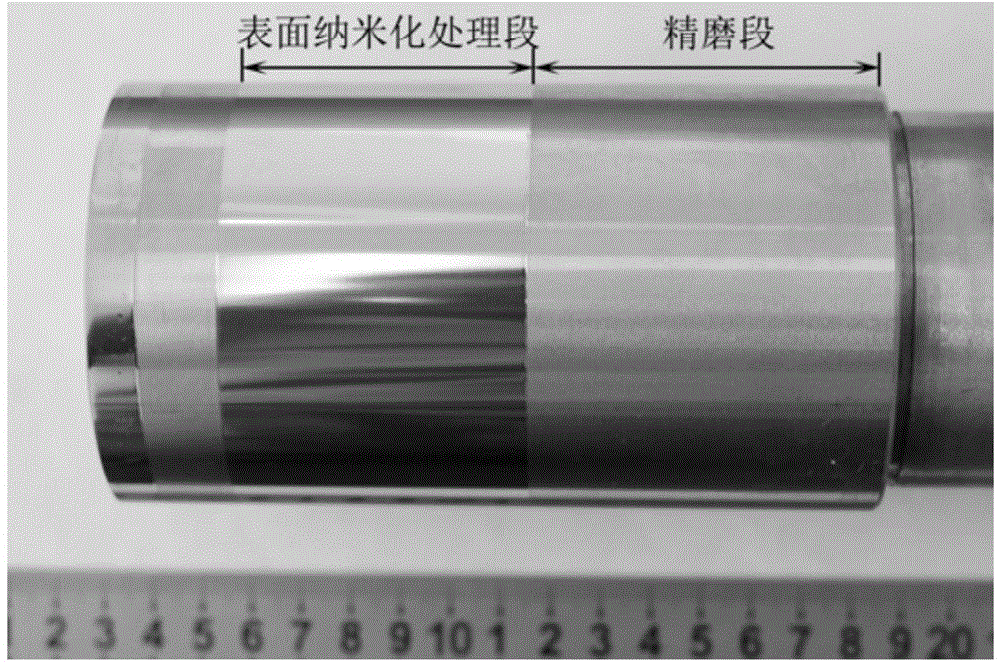

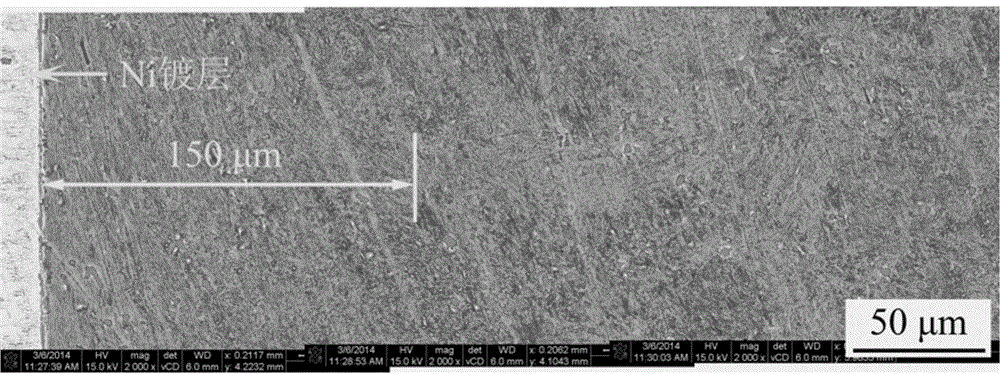

Method for producing gradient nanometer structure on martensitic steel surface

ActiveCN105369024AImprove surface propertiesEasy to scale production and applicationSurface layerSurface roughness

The present invention discloses a method for producing a gradient nanometer structure on the martensitic steel surface, and belongs to the technical field of metal material surface nanocrystallization. According to the method, a martensitic steel rotation member is treated by using a surface mechanical rolling processing technology (SMGT), the SMGT processing cutter hard ball capable of freely rolling performs high speed rolling and pressing on the martensitic steel rotation member surface, the martensitic steel surface to be treated is subjected to high speed plasticity deformation, and under the conditions of high strain, high strain rate and high strain gradient, the coarse grain structure on the surface layer is converted into the gradient structure sequentially comprising nano-grains, submicron grains and micro-scale grains. According to the present invention, the surface roughness Ra value of the martensitic steel being subjected to the SMGT surface nanocrystallization treatment is less than 0.30 [mu]m, and the surface property is significantly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

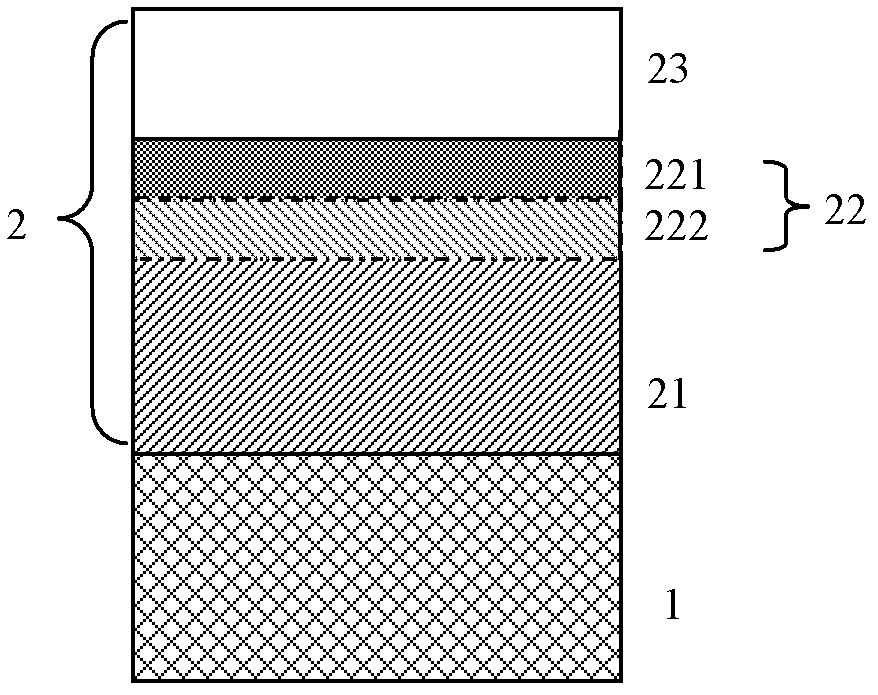

Cutting tool for improving coating structure and preparation method thereof

ActiveCN103173761AExcellent oxidation and crater wear resistanceImprove uniformityTurning toolsSuperimposed coating processSingle phaseCast iron

The invention discloses a cutting tool for improving a coating structure. The cutting tool comprises a matrix and a coating covering the matrix. The coating comprises an inner layer B, a transitional layer C and an outer layer D from inside to outside. The inner layer B consists of transitional elements and nonmetal compounds. The transitional layer C comprises a transitional layer C1 and / or a transitional layer C2. The transitional layer C1 and C2 are mainly formed by carbon oxynitride with titanium. The outer layer D has a single phase alpha-Al2O3 structure. The thickness d of the outer layer D is 0.5-4 mu m. The mean grain size S is greater than or equal to 0.2 mu m but less than or equal to 0.5 mu m. The preparation method comprises the following steps of: first, preparing the tool matrix; then, sequentially depositing the inner layer B, the transitional layer C2, the transitional layer C1 and the outer layer D in a same coating period; and then, performing surface treatment to manufacture the cutting tool. The cutting tool provided by the invention is high in hardness and good in wear resistance, and has excellent cutting performance in cutting materials such as steel, stainless steel and cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

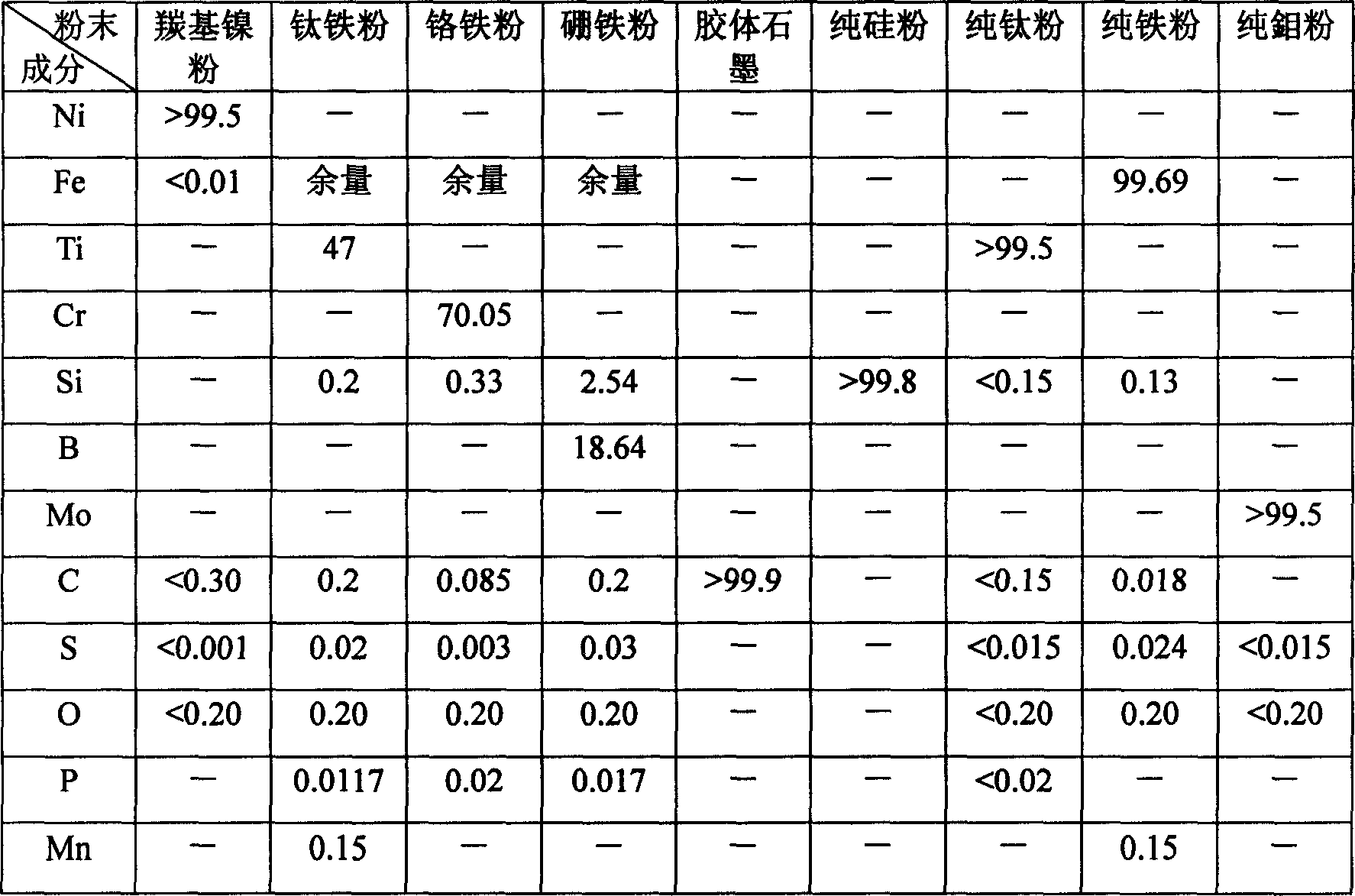

Carbonide / iron-base alloy composite coating and its reaction brass coating technology

The present invention is one kind of composite (titanium carbide+chromium carbid) / ferroalloy coating and its reaction coating process, and belongs to the field of composite ceramic / metal coating. Industry Ti-Fe powder, Cr-Fe powder, B-Fe powder, Fe powder, etc. as main material, alcohol and organic adhesive are mixed to form slurry; the slurry is sprayed or painted onto the surface of base body; and through in-situ reaction and alloying under vacuum condition and at certain temperature, composite coating with hard phase of titanium carbide and chromium carbide and base phase of ferroalloy is formed after lowering the temperature. The present invention has low cost of forming the composite coating, and the composite coating has high heat resistance, high oxidation resistance, high corrosion resistance, high antiwear, etc. and may be used widely in metallurgy, thermal power generation and other fields.

Owner:UNIV OF SCI & TECH BEIJING

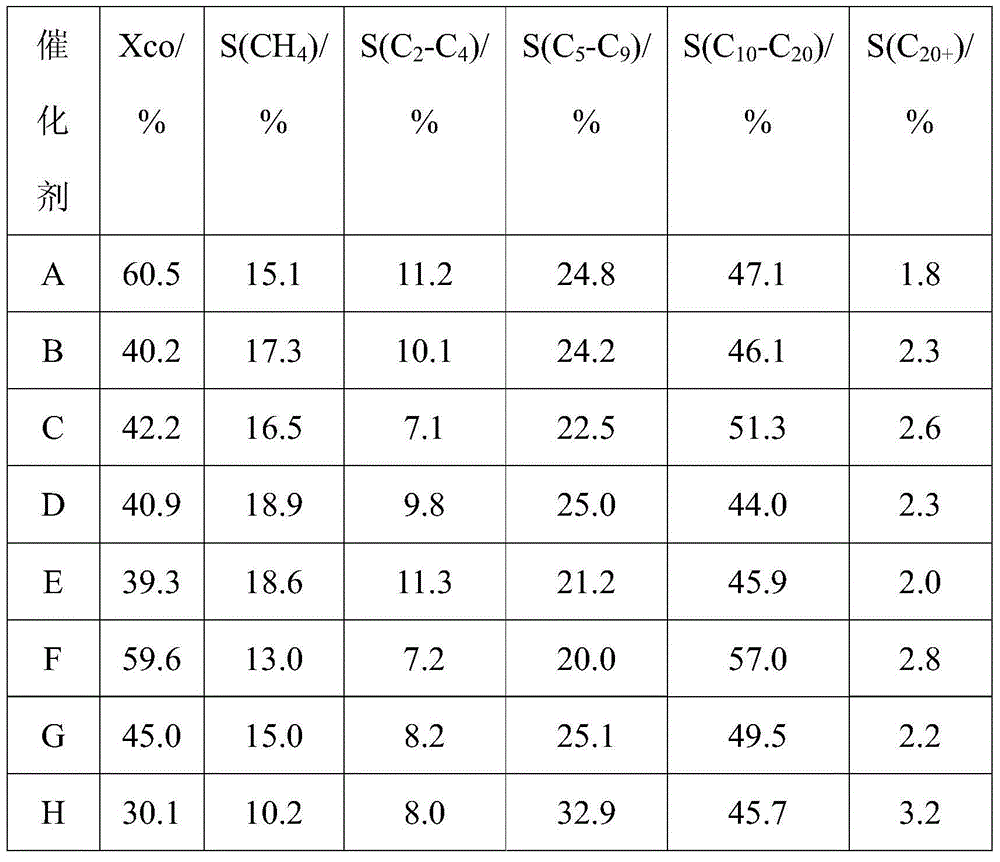

Cobalt-base Fischer-Tropsch synthesis catalyst and preparation method and application thereof

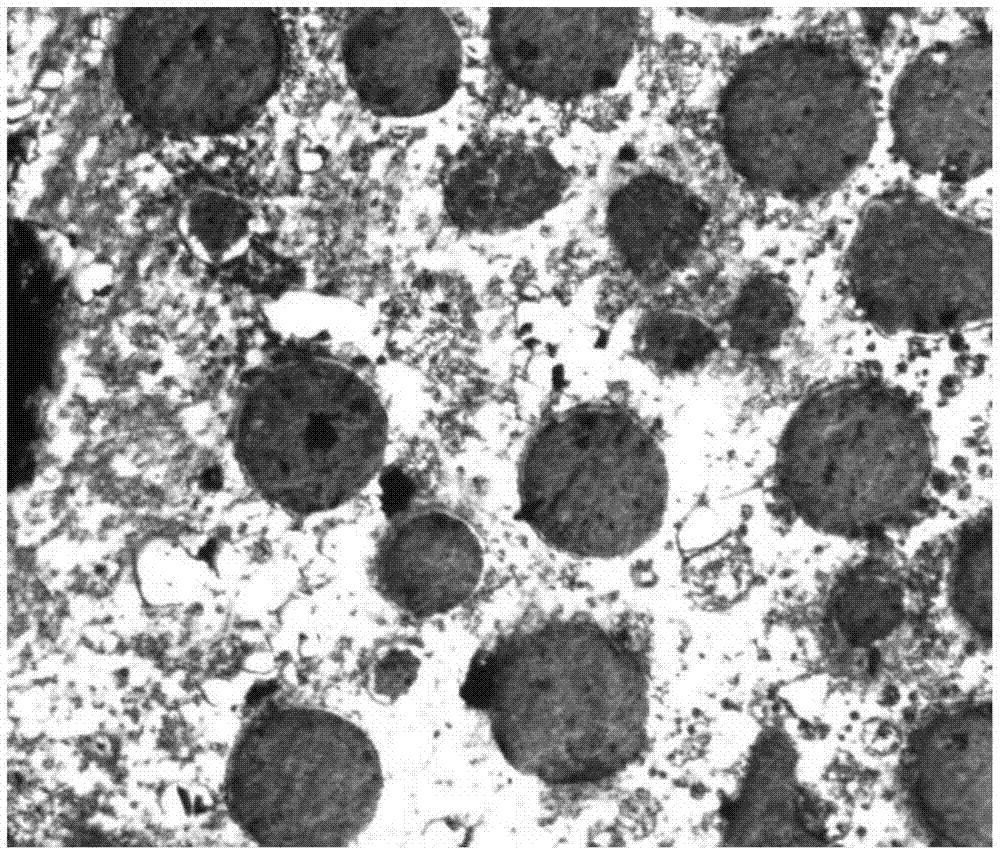

ActiveCN104368344AUniform size distributionFine particleLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsFischer–Tropsch processSol-gel

The invention discloses a cobalt-base Fischer-Tropsch synthesis catalyst and a preparation method and application thereof. The catalyst comprises a mesoporous carbon carrier and an active component cobalt, wherein the active component cobalt is confined in the mesoporous carbon carrier. The catalyst has specific surface area of 220-400 m<2> / g and particle diameter of 50-150 um. The preparation method employs phenolic resin solution as an organic precursor, and then a sol-gel method is employed to embed the active component Co into the mesoporous carbon carrier. The catalyst prepared by the invention before usage only requires introduction of inert gas into at a certain temperature without hydrogen reduction, so as to obtain the catalyst containing cobalt. The catalyst of the invention has the advantages of high reduction degree, high dispersity, good stability, uniform size of active component, controllable carrier aperture and high selectivity on diesel, and can meet the requirements of a slurry bed reactor on the wear resistance of the catalyst.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

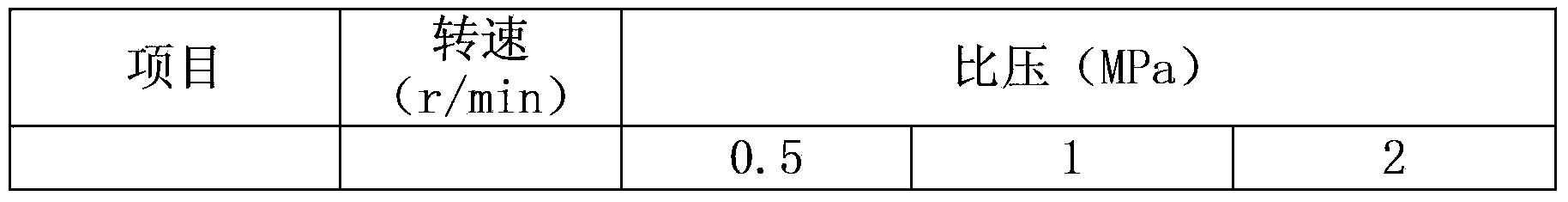

Elastic friction particle and preparation method thereof

ActiveCN103450522AGood compression resilienceHigh temperature resistantOther chemical processesPaper/cardboardLow noisePolymer science

The invention relates to an elastic friction particle and a preparation method thereof, and aims at providing an elastic friction particle which has the characteristics of good compression resilience, high temperature resistance, wear resistance, low noise, high and stable dynamic / static friction coefficient, close dynamic / static friction coefficient ratio and environmental friendliness. The provided method has the characteristics of simple and convenient preparation and relatively low cost. The technical scheme is as follows: an elastic friction particle for a wet paper-based friction sheet is a rubber elastic friction particle and comprises fluorine rubber, nitrile rubber, natural rubber, an accelerant DM, an anti-aging agent, stearic acid, polytetrafluoroethylene suspension resin, sulphur, nanometer SiO2 modified phenolic resin, boron carbide, antimony sulfide and a silicon carbide whisker. The preparation method comprises the following steps: (1) weighing all the raw materials according to the formula for later use; (2) feeding the raw materials into a rubber mixer for mixing, then feeding sulphur into the rubber mixer for mixing, and then taking a product out; (3) carrying out hot milling molding in an open mill; (4) crushing the particle; and (5) modifying the rubber elastic particle.

Owner:杭州汉乐科新材料科技有限公司

Polycrystalline diamond composites

InactiveCN101743091AReduced wear resistanceImprove thermal stabilityPolycrystalline material growthSingle crystal growth detailsPolycrystalline diamondCarbide

Owner:ELEMENT SIX PRODION

Abrasive, grinding member and preparation method thereof

InactiveCN104726061AReduced wear resistanceWon't scratchOther chemical processesAbrasion apparatusDiacrylate esterWear resistance

Owner:3M INNOVATIVE PROPERTIES CO

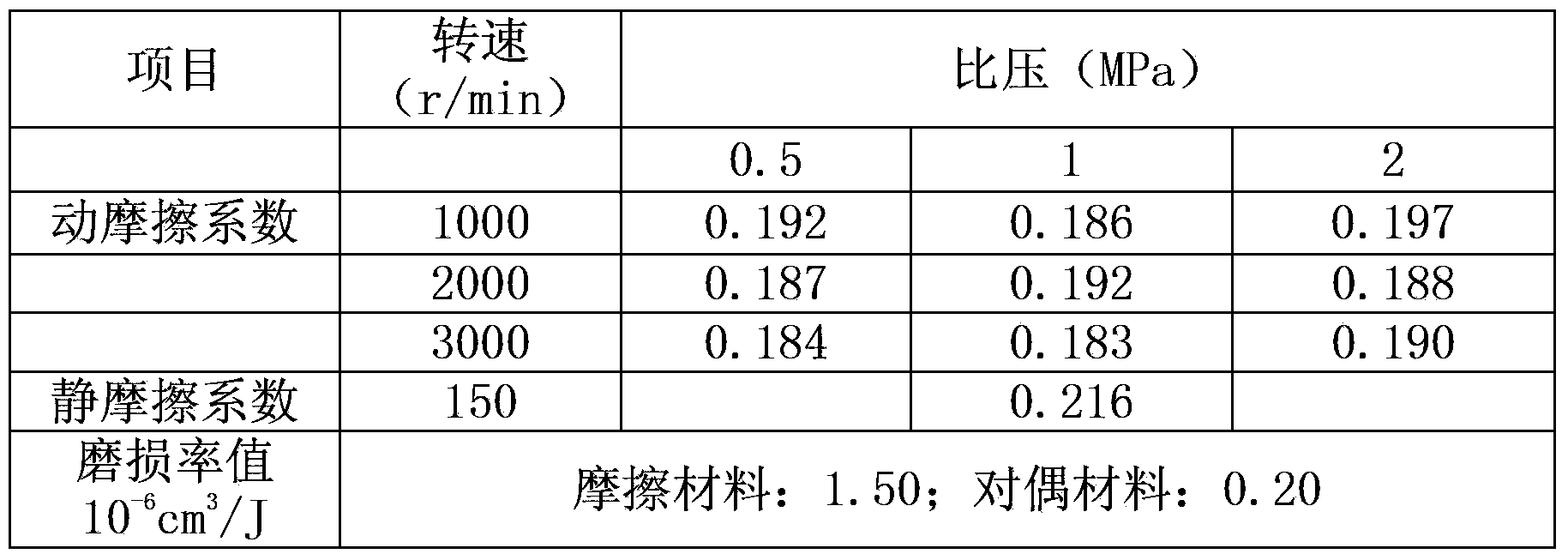

Automobile brake lining

InactiveCN105202075AGood strengthExcellent wear resistanceOther chemical processesBraking membersBrake liningOxide

An automobile brake lining is prepared from, by weight, 14%-18% of ceramic fibers, 3%-6% of carbon fibers, 3%-7% of cellulose fibers, 8%-13% of aramid fibers, 8%-13% of modified phenolic resin, 2%-4% of aluminium oxide, 3%-5% of barium sulphide, 6%-9% of graphite, 4%-6% of zirconite, 8%-12% of quartz sand, 1%-2% of bauxite, 1%-2% of zinc oxide, 2%-4% of chemigum, 1%-4% of antimony sulfide, 7%-10% of friction powder and 6%-9% of nanometer silicon carbide. According to the automobile brake lining, a ceramic brake pad is kept to be stable in braking, low in noise and the like, the mechanical strength of the brake lining is further improved, and the service life of the brake lining is prolonged; meanwhile, recession and expansion of the high temperature can be avoided, and the automobile brake lining has the advantages of being good in braking performance and abrasion resistance, stable in braking, less in dust, moderate in hardness and good in high temperature recovery performance.

Owner:刘桂华

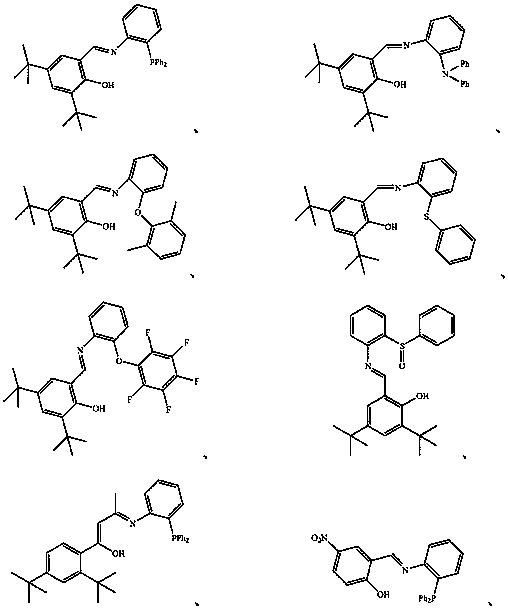

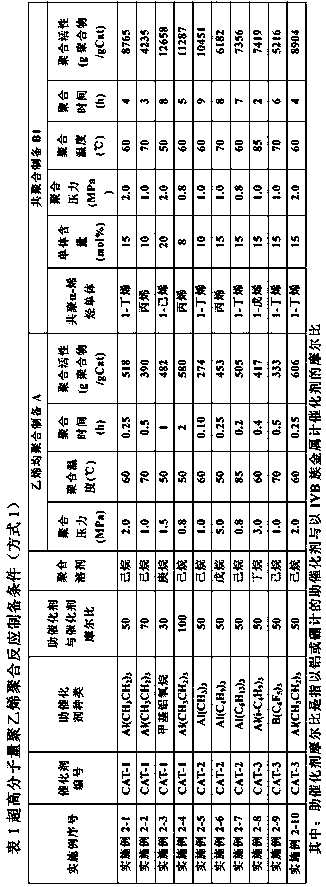

Ultra-high molecular weight polyethylene, production method and applications

ActiveCN107936161AUnit content is adjustable and controllableParticles in good shapePolymer sciencePolymer chemistry

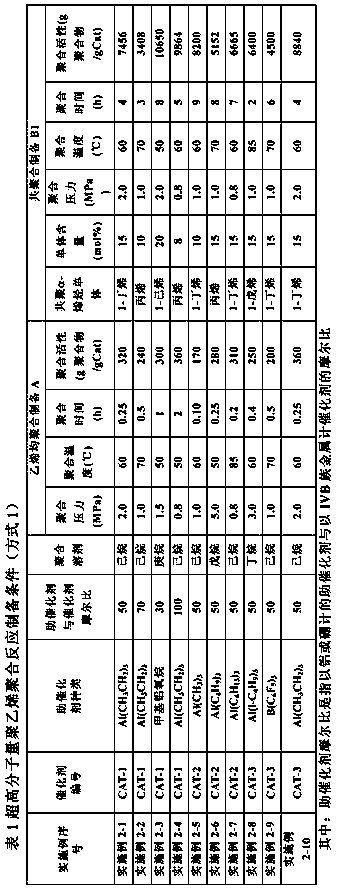

The invention relates to copolymerized ultra-high molecular weight polyethylene, a production method and applications. Compared to the homopolymerized ultra-high molecular weight polyethylene in the prior, the copolymerized ultra-high molecular weight polyethylene of the present invention has the significantly-improved processability, and further has improved wear resistance and improved impact strength.

Owner:SINOPEC YANGZI PETROCHEM +1

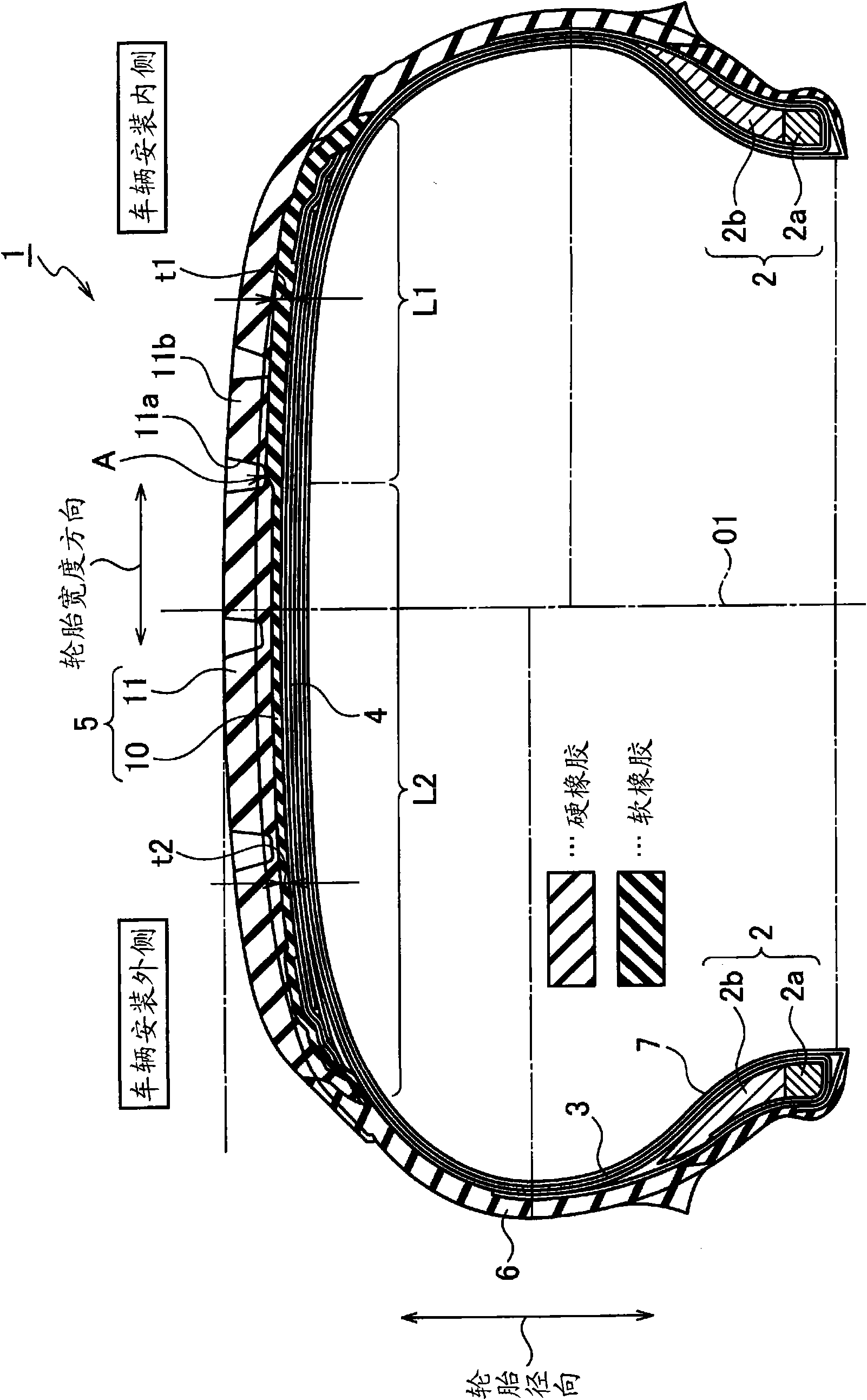

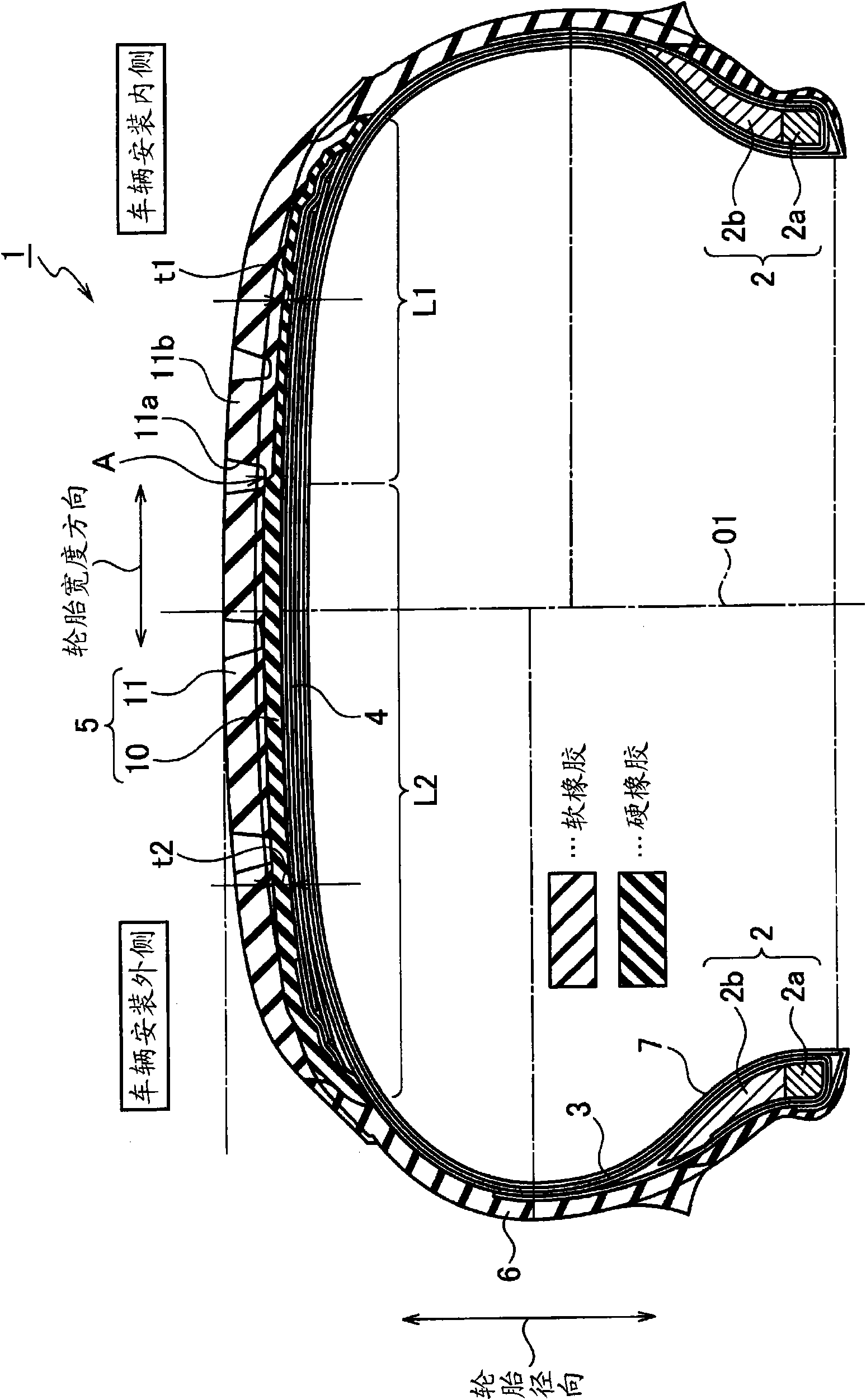

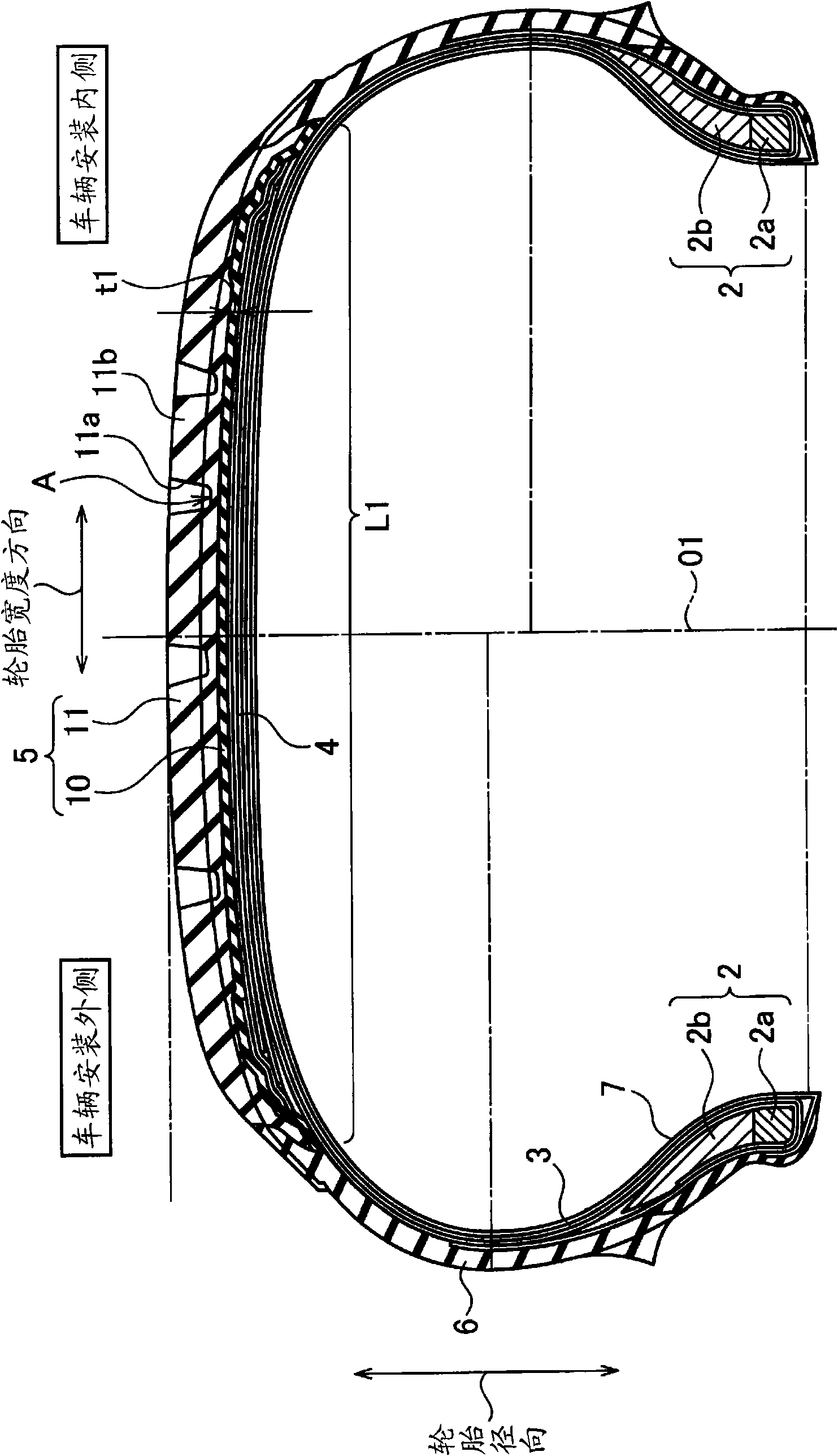

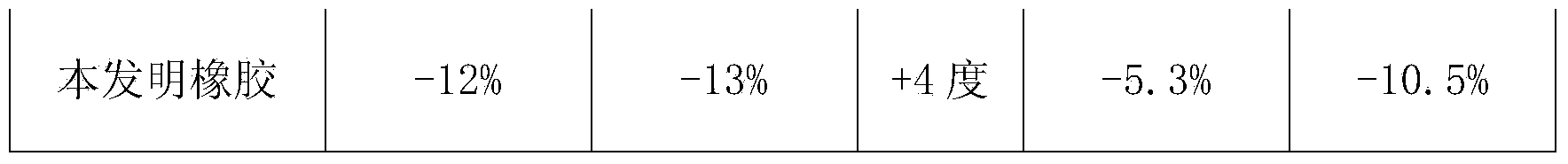

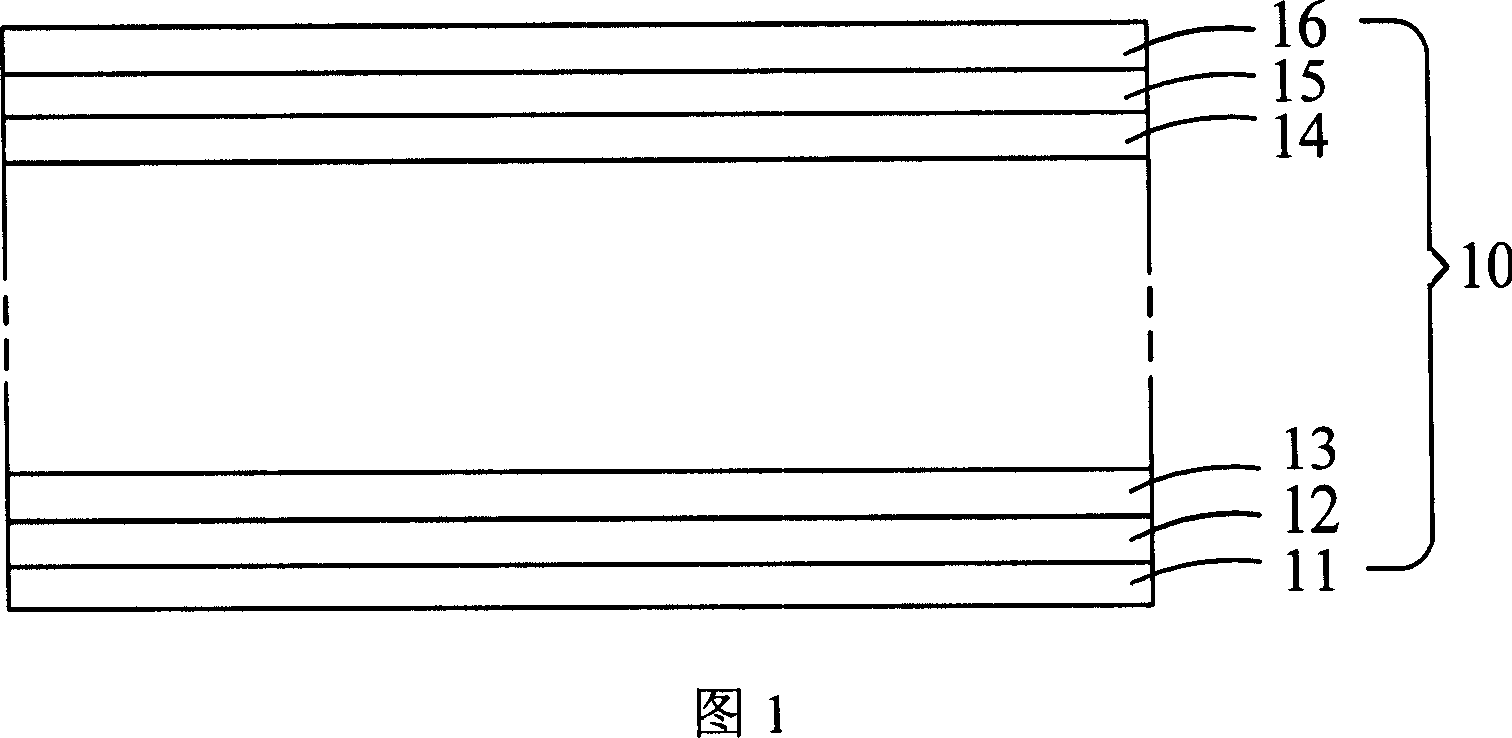

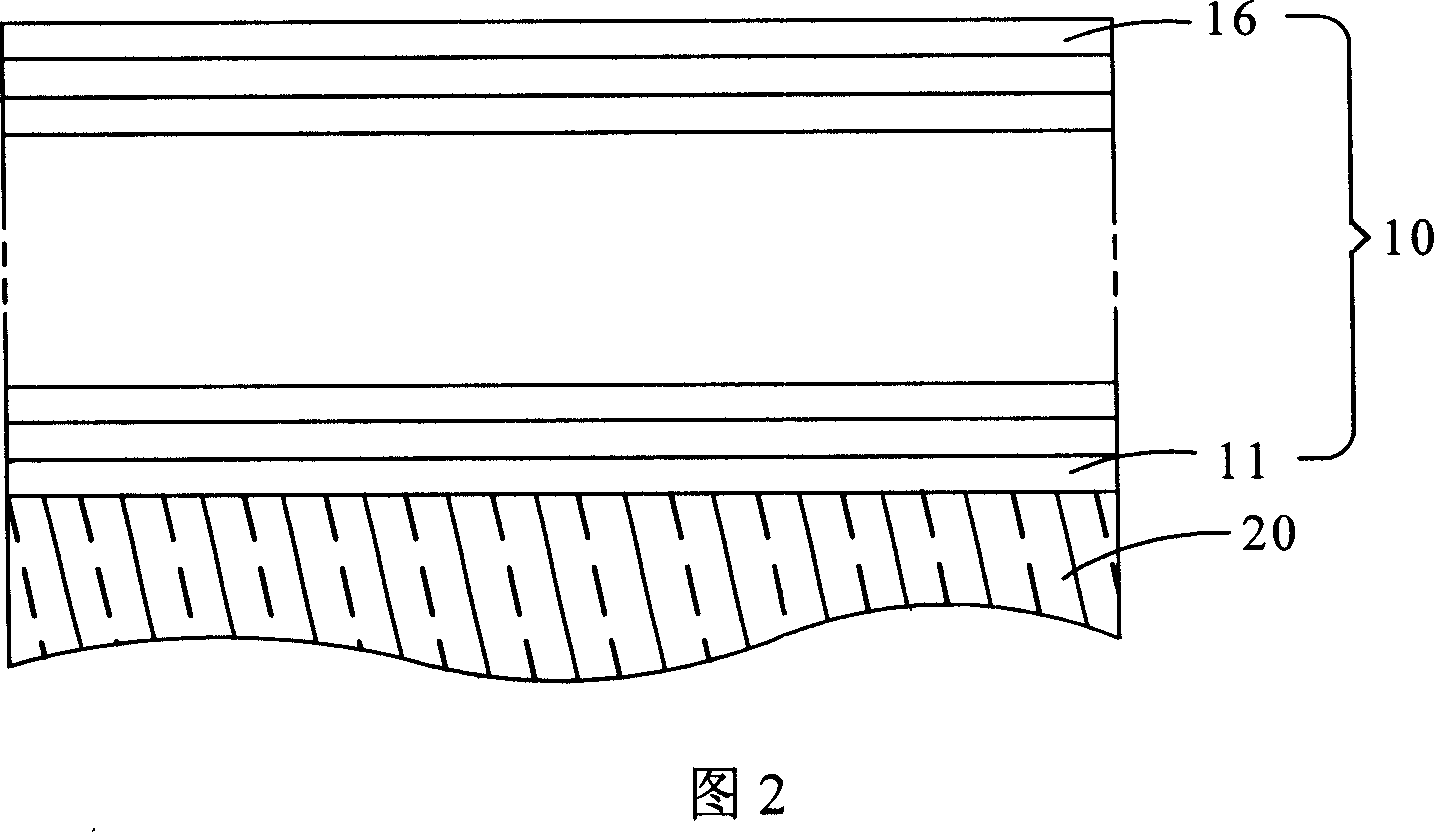

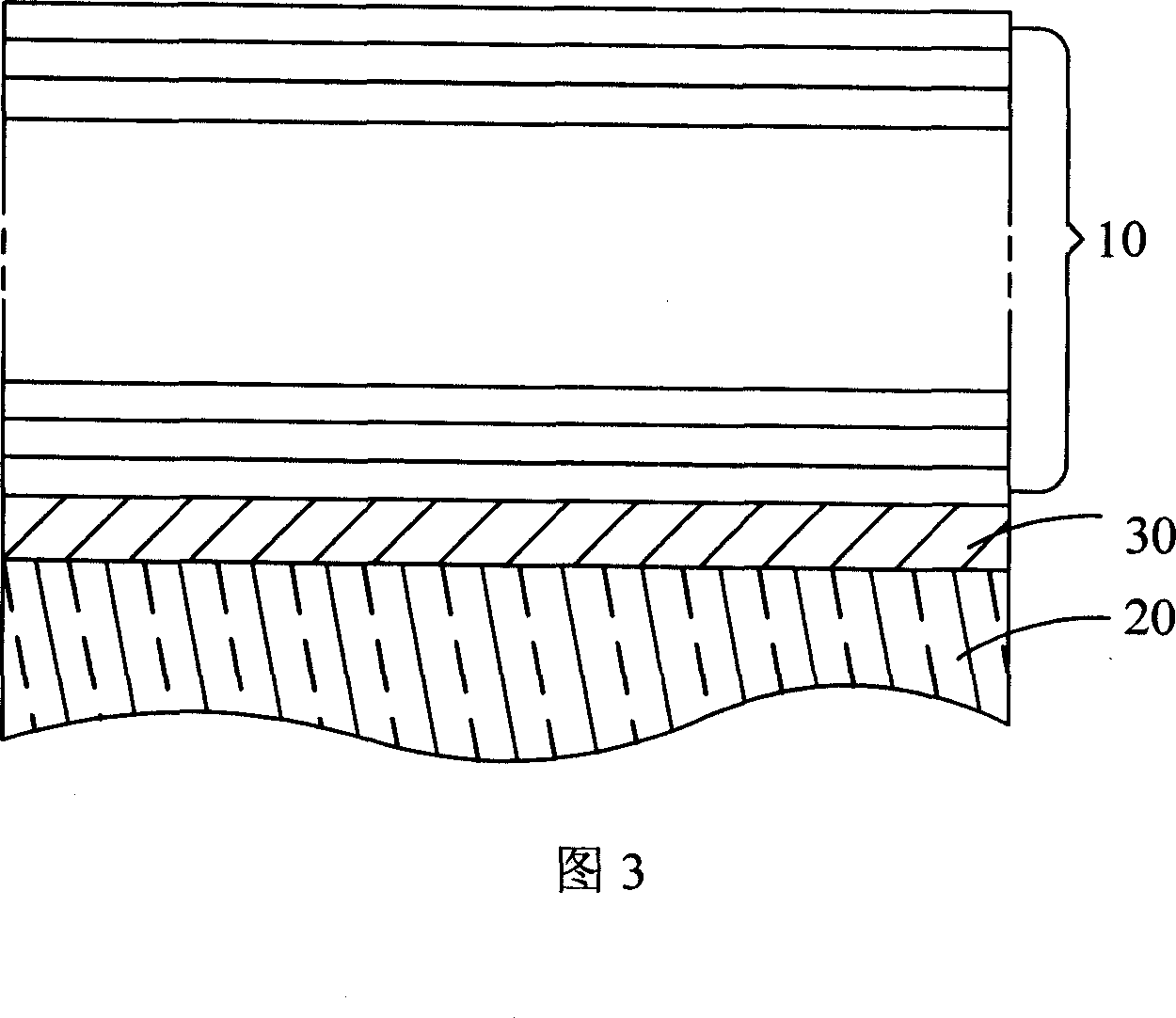

Pneumatic tire

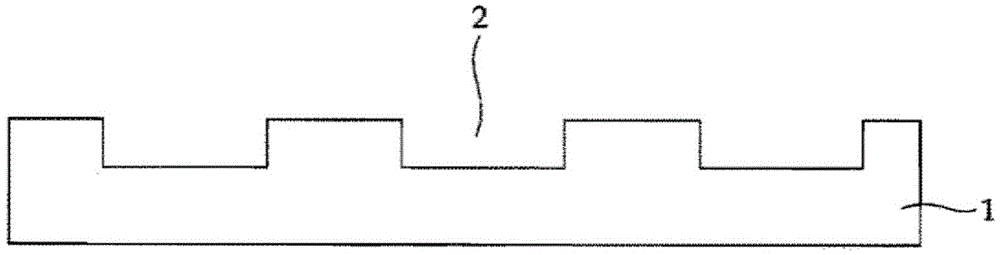

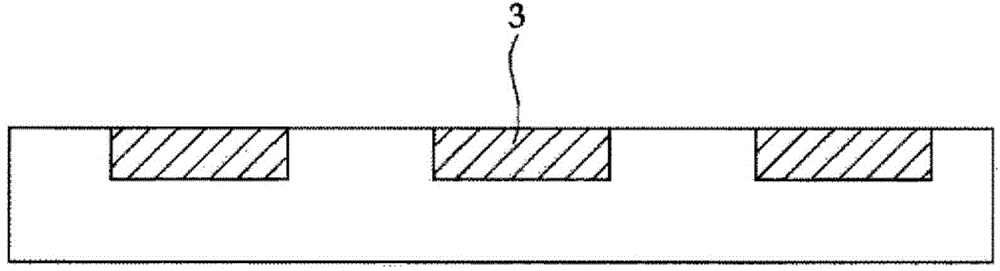

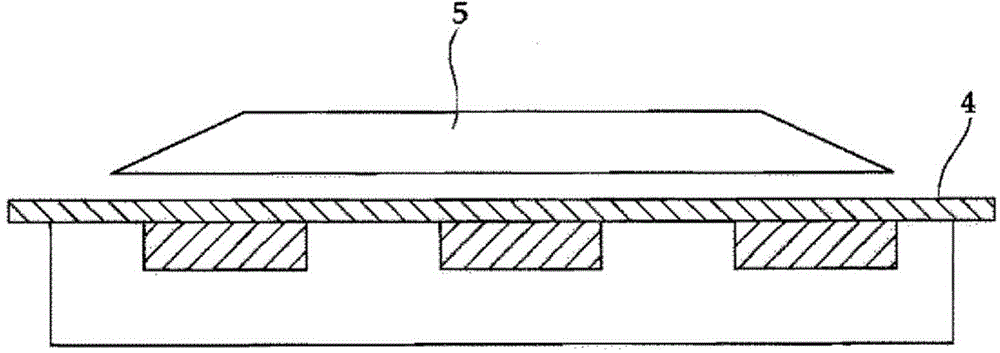

InactiveCN101678720ADecreased handling stabilityReduced wear resistanceSpecial tyresInflatable tyresEngineeringUpper floor

The outside and inside at mounting on a vehicle are designated.A tread section (5) consists of a base rubber layer (10) laid inside in the radial direction of the tire and a cap rubber layer (11) laidoutside in the radial direction of the tire. The base rubber layer (10) consists of a rubber of storage elasticity modulus lower than that of the cap rubber layer (11). The thickness (t1) of the baserubber layer (10) is large in the zone (L1) of inside at vehicle mounting from a boundary location (A) being an arbitrary location in the tire width direction of the tread section while the thickness(t2) of the base rubber layer (10) is small in the zone (L2) of the outside therefrom.

Owner:BRIDGESTONE CORP

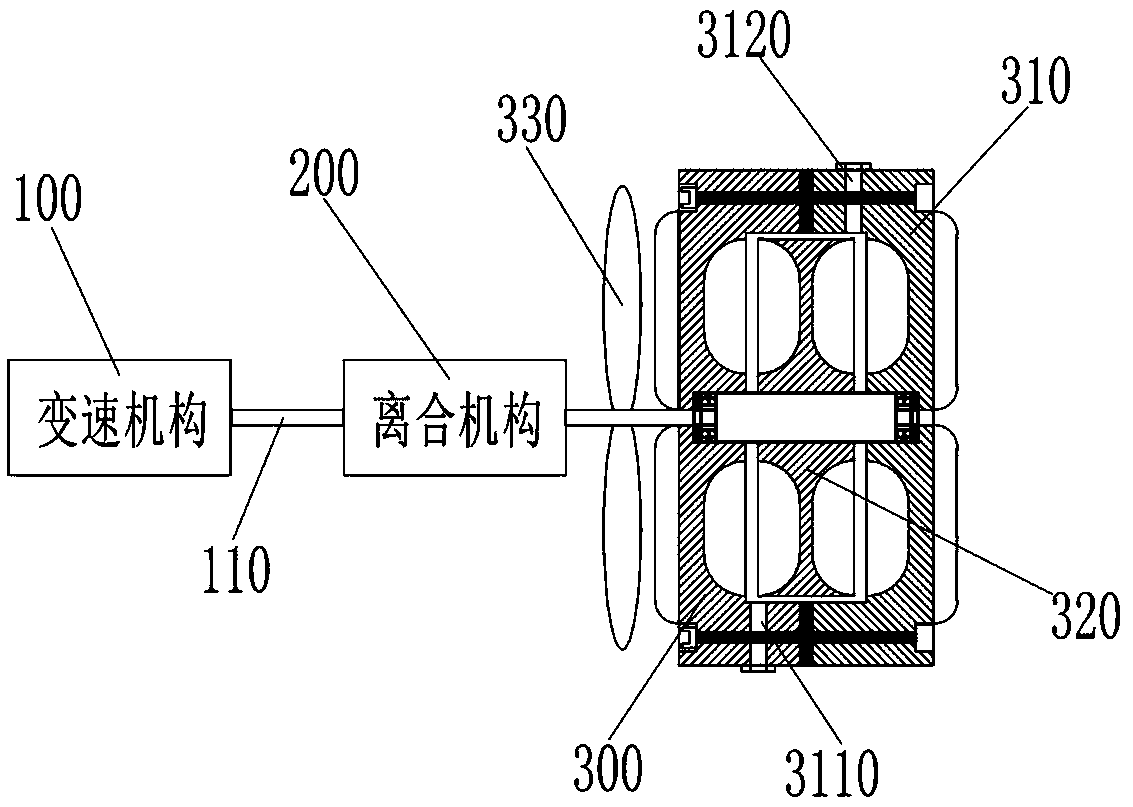

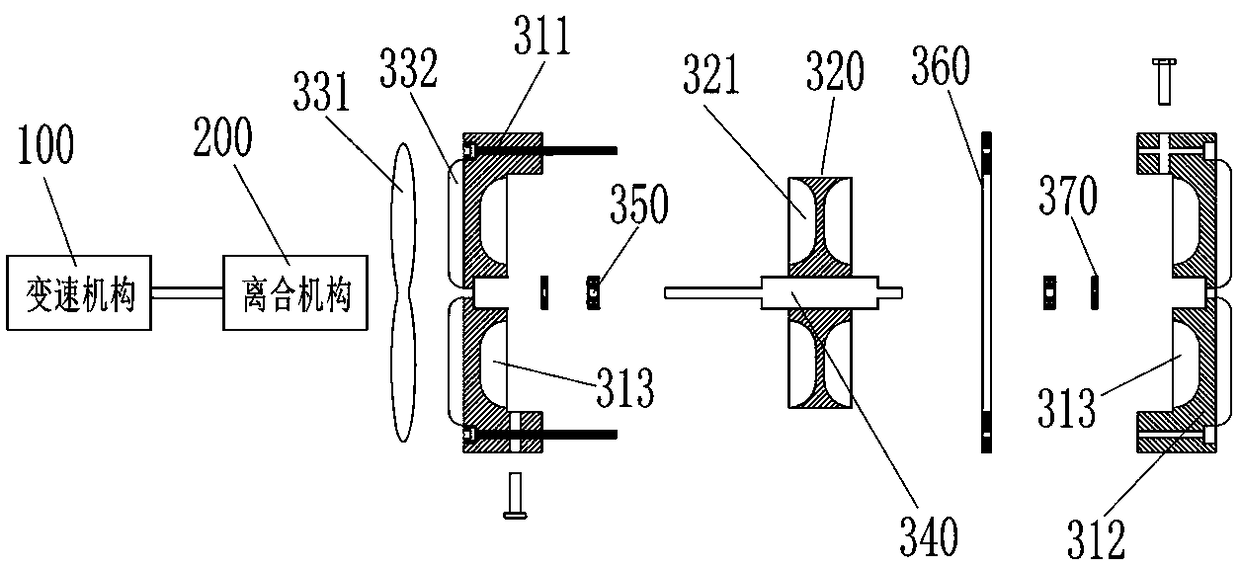

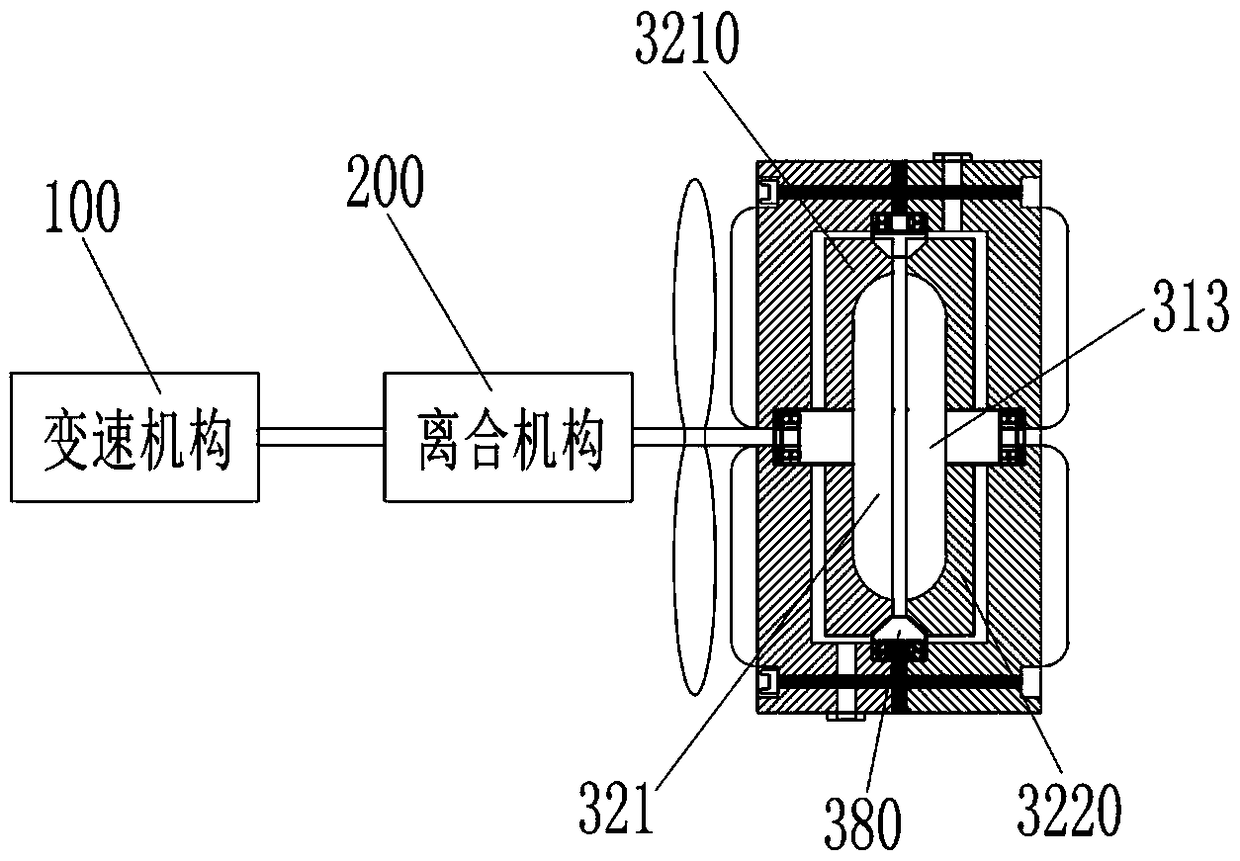

Emergency manual slow-descenting device and lifting equipment thereof

The invention discloses an emergency manual slow-descenting device and lifting equipment thereof. The emergency manual slow-descenting device comprises a speed change mechanism, a clutch mechanism anda slow-descenting mechanism, wherein the clutch mechanism is connected to the output end of the speed change mechanism through a high-speed shaft; the clutch mechanism is connected to the input end of the slow-descenting mechanism through an input shaft; the slow-descenting mechanism comprises a shell and a rotor, and the rotor is arranged in the shell and is connected with the input shaft; and the input shaft can freely rotate in the shell through a bearing arranged in the shell; and the rotor is provided with a first blade, and damping liquid is placed in the shell. Through the cooperativeaction of the speed change structure, the clutch mechanism and the slow-descenting mechanism, and the emergency manual slow-descenting device can be fully applicable to the low-speed, medium-speed andhigh-speed lifting equipment and enables the emergency slow-descenting of the lifting equipment to have the advantages of high efficiency, safety, stability, low noise, abrasion resistance and low maintenance cost.

Owner:CONSTR MECHANIZATION INST CHINESE ACAD OF ARCHITECTURE SCI +1

Ultra-high molecular weight polyethylene, production method and applications

ActiveCN107936162AUnit content is adjustable and controllableParticles in good shapePolymer scienceWear resistance

The invention relates to copolymerized ultra-high molecular weight polyethylene, a production method and applications. Compared to the homopolymerized ultra-high molecular weight polyethylene in the prior, the copolymerized ultra-high molecular weight polyethylene of the present invention has the significantly-improved processability, and further has improved wear resistance and improved impact strength.

Owner:SINOPEC YANGZI PETROCHEM +1

Low-alloy medium-silicon vermicular graphite cast iron glass mold material and preparation method thereof

The invention discloses a low-alloy medium-silicon vermicular graphite cast iron glass mold material and a preparation method thereof. The low-alloy medium-silicon vermicular graphite cast iron glassmold material comprises, by mass, 87.5-92.12% of iron, 2.8-2.89% of silicon, 3.4-3.6% of carbon, 0.4-0.5% of manganese, 0.2-0.29% of chromium, 0.1-0.15% of vanadium, 0.08-0.1% of titanium, 0.4-0.5% ofnucleating agent and 0.5-0.6% of vermiculizer. Through the optimized formula, the oxidation resistance and wear resistance of a mold are greatly improved. Meanwhile, through the mutual cooperative effect of the added materials, the toughness, oxidation resistance and wear resistance of the glass mold are greatly improved. Thus, the service life of the mold is prolonged.

Owner:CHENGDU XINZHI IND

High-performance alloy steel and manufacturing method thereof

ActiveCN104120350ALow temperature brittle fractureLow delayed fracture performanceProcess efficiency improvementManganeseAnalysis center

The invention discloses high-performance alloy steel which is characterized by being prepared from the following components and the weight ratio: iron:carbon:manganese:molybdenum:silicon:titanium:nickel:phosphorus:sulfur:copper=93.12-96.92:0.10-0.30:1.80-3.20:0.20-0.45:0.90-2.30:0.03-0.30:0.05-0.25:0-0.03:0-0.03:0.01-0.02. The high-performance alloy steel has the product properties: the tensile strength Rm is greater than or equal to 1350 MPa, the yield strength Rel is greater than or equal to 1050 MPa, the elongation rate A (%) is greater than or equal to 10, the cross section shrinking percentage Z (%) is greater than or equal to 50, the room temperature (42 DEG C) impact toughness aku is greater than or equal to 100 J / cm<2>, the low temperature (-40 DEG C) impact toughness aku is greater than or equal to 50 J / cm<2>, and the hardness HRC is 40-50; the product is detected by the national analysis center for iron and steel, and indicators such as non-metallic inclusions and the grain size all accord with national standard high-level requirements.

Owner:SICHUAN YIHENG MACHINERY MFG CO LTD

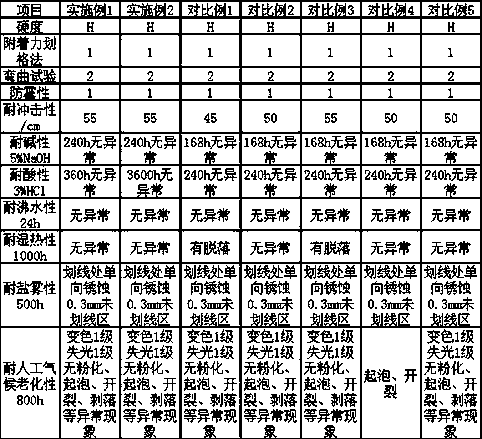

Preparation method of wear-resistant, heat-insulation and corrosion-resistant powder coating

InactiveCN110760234AMeet the needs of efficient operationReduce harmFireproof paintsCarboxyl rubber coatingsNitrile rubberFirming agent

The invention discloses a preparation method of a wear-resistant, heat-insulation and corrosion-resistant powder coating. The powder coating is prepared from the following raw materials: benzoxazine resin, epoxy resin, chlorinated polyether, carboxylated-terminated acrylonitrile-polybutadiene rubber, a curing agent, barite powder and wollastonite powder. The wear-resistant, heat-insulation and corrosion-resistant powder coating can be prepared by processes such as melting, mixing and extruding, cooling for tabletting, crushing and sieving and has excellent wear and corrosion resistance and heat insulation properties, the surface of a processed coating meets the national and industrial standards on the aspects such as adhesive force, flexibility, impact strength, smoothness, hardness and chemical resistance, and the wear-resistant, heat-insulation and corrosion-resistant powder coating is low in curing temperature, convenient to use and capable of reducing the cost.

Owner:孙振龙

Lubricant composition for low-friction sliding material and sliding mechanism using same

InactiveCN103003402AReduce frictionReduced wear resistanceBearing componentsAdditivesDlc coatingNitrogen

Disclosed is a lubricant composition which contains an organic molybdenum compound that has a nitrogen (N) atom and / or an oxygen (O) atom and optionally has a sulfur (S) atom in each molecule. The sulfur content in the organic molybdenum compound is 0.5% by mass or less based on the compound. If the lubricant composition is used as a lubricant for a low-friction sliding material, the lubricant composition has an extremely low coefficient of friction. In addition, a sliding mechanism having low friction and excellent wear resistance can be obtained by combining the lubricant composition and a sliding member that has a DLC coating film on the sliding surface.

Owner:IDEMITSU KOSAN CO LTD +1

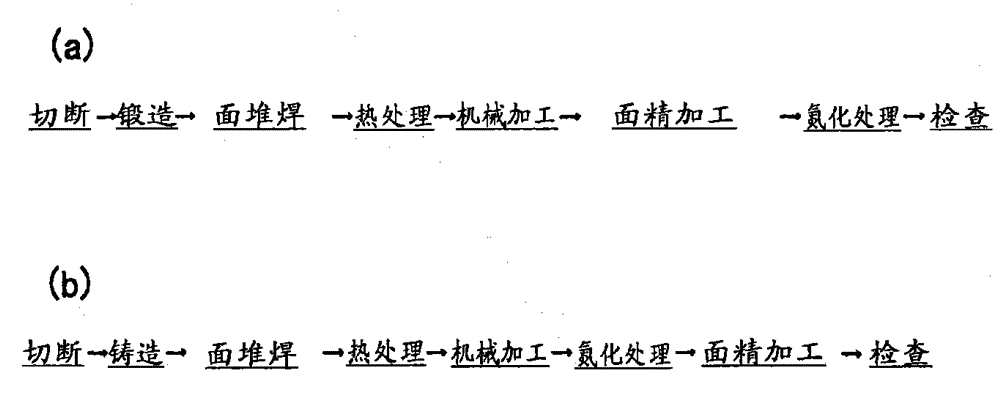

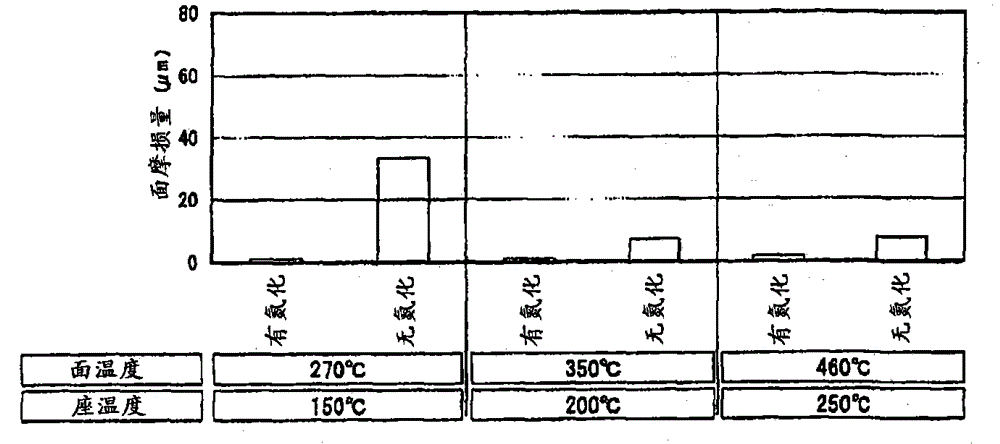

Engine valve

ActiveCN104919150AInhibition composition ratioGuaranteed durabilitySolid state diffusion coatingMachines/enginesMachined surfaceEngineering

[Problem] To provide an engine valve which satisfies predetermined characteristics with respect to impact resistance, abrasion resistance and high-temperature corrosion resistance all of which meet or exceed predetermined levels required to resist severe use environments, while also minimizing the content ratios of predetermined rare metals. [Means for Solving the Problem] An engine valve is configured to include an engine valve base body having a stem portion and a head portion provided at one end portion of the stem portion, which engine valve comprises: a build-up portion formed by seat welding to encircle the head portion; and a seat obtained by forming a surface-hardened layer on the build-up portion, wherein the build-up portion is formed of a seat weld material constituted of a Ni-Fe-Cr alloy containing W at 8.0 to 40.0 mass %, Mo at a total together with W in a range of 20.0 to 40.0 mass %, Fe at 20.0 to 50.0 mass %, Cr at 12.0 to 36.0 mass %, B at 1.0 to 2.5 mass %, and a balance of Ni and inevitable impurities, and wherein the surface-hardened layer is formed by effecting nitriding treatment on the entire valve to form a nitride layer on a machined surface formed on the seat, thereby ensuring predetermined characteristic while minimizing rare metal content ratio.

Owner:NITTAN CORP

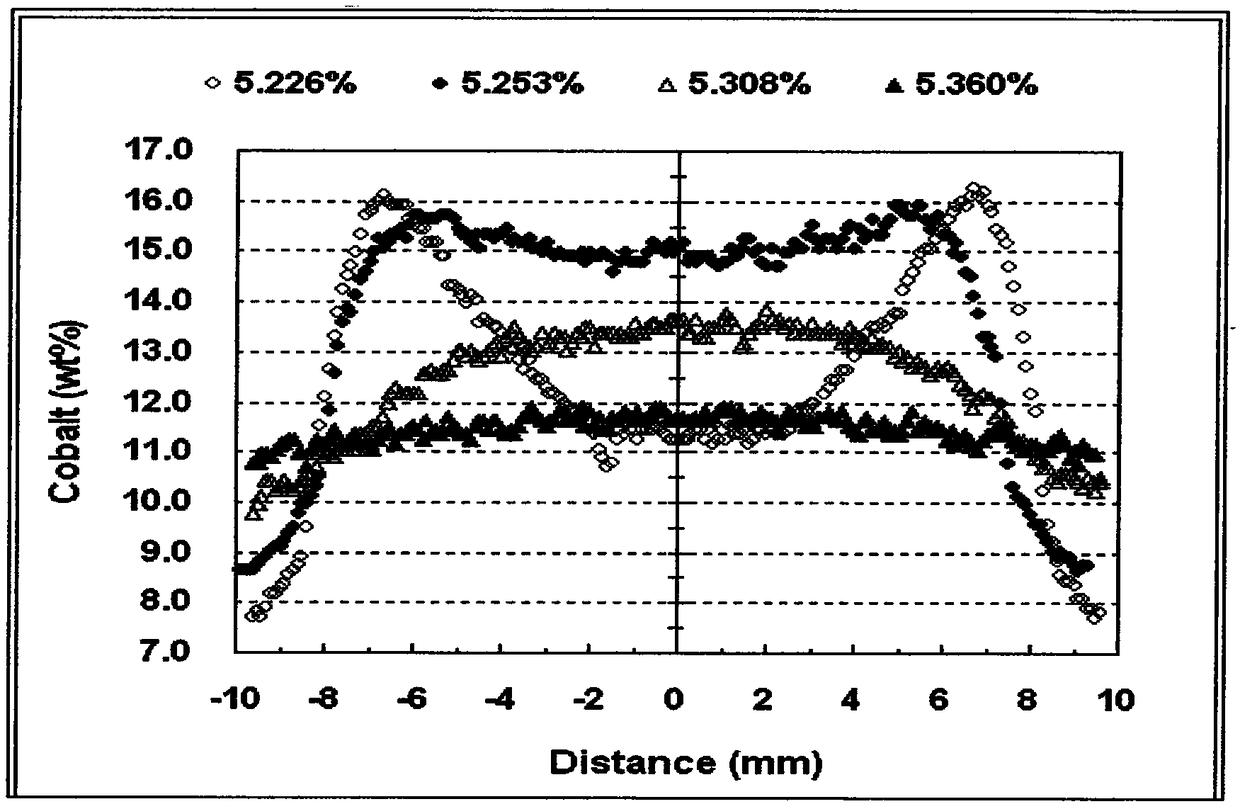

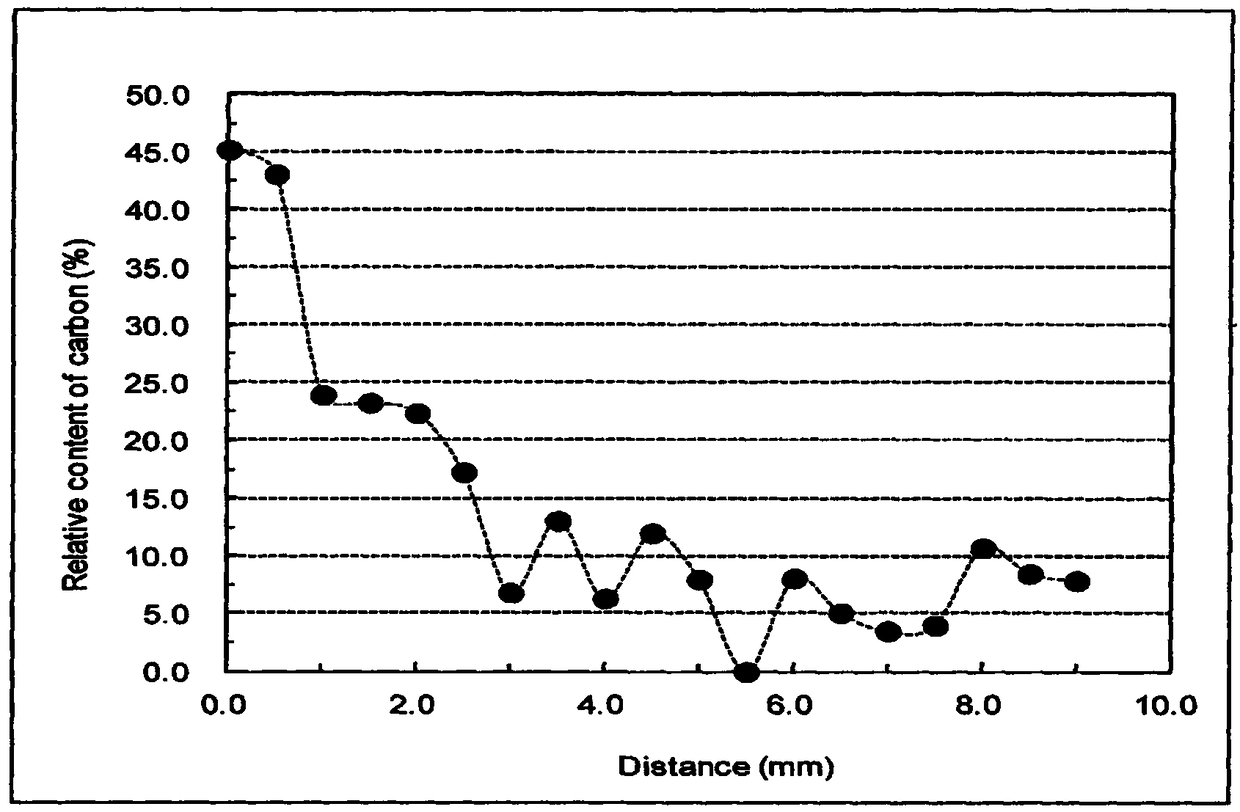

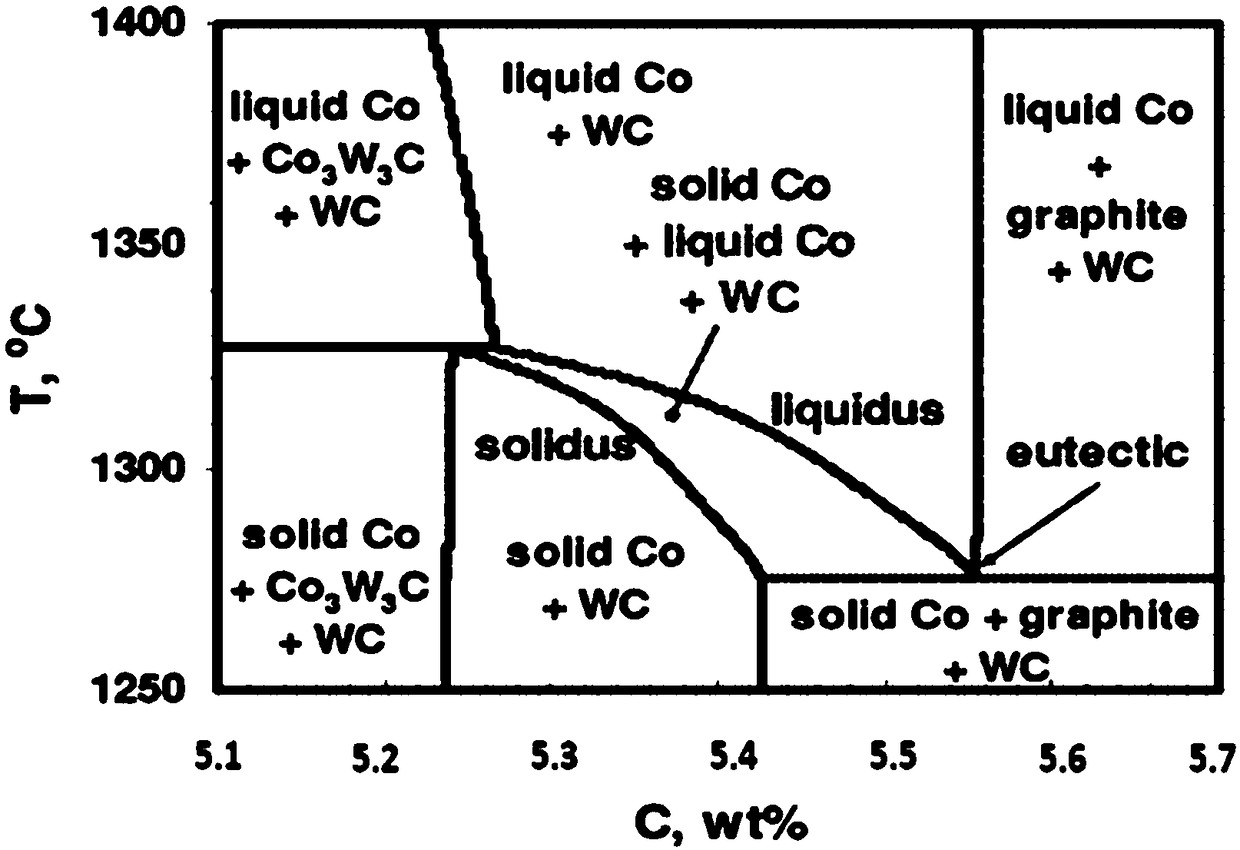

Gradient cemented carbide with gradient change of binder phase and preparation method thereof

ActiveCN107267837BUniform toughnessImprove performanceTransportation and packagingMetal-working apparatusRoom temperaturePulsed mode

A gradient cemented carbide with a gradient change in the binder phase and a preparation method thereof, is characterized in that it includes the following steps in sequence: preparing WC-Co powder; adjusting the carbon content of the WC-Co powder, calculating the upper limit of the carbon content with substoichiometric equivalents and Lower limit; add molding agent; press into billet; remove molding agent; vacuum sintering; carburizing heat treatment, heat up to 900~1200°C, carry out carburizing heat treatment on the vacuum sintered body, pass gas in pulse mode; heat up to 1275~1325°C , carry out Co phase migration treatment; raise the temperature to 1380~1450°C, feed Ar gas, and keep the pressure at 10~20 mbar; pressure sintering; rapidly cool to 1270°C; alloy. The cobalt content in the gradient cemented carbide of the present invention is in a gradient distribution, the cobalt content on the surface is low, there is no infiltration of C phase, the hardness is high, the cobalt content in the core is high, the η phase is not contained, the toughness is high, and the overall performance is good.

Owner:武汉新锐合金工具有限公司

Moist cross-linking finishing method for high-strength wear-resistant and non-ironing fabric

InactiveCN110924158AHigh strengthImprove cohesionAbrasion resistant fibresTextile printerPolymer science

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a moist cross-linking finishing method for a high-strength wear-resistant and non-ironing fabric. The technological processes are sequentially fabric preparation, singeing, desizing, scouring, bleaching, mercerizing, liquid ammonia adding, whitening washing, pre-softening, moist cross-linking,moist cross-linking washing, post-washing tentering, and inspecting and packaging; and a moist cross-linking auxiliary agent in the moist cross-linking process comprises 220-240 g / l of moist cross-linking resin Mix1, 2-3 g / l of a catalyst SP-2 and 110-120 g / l of a catalyst SP-3. According to the moist cross-linking finishing method for the high-strength wear-resistant and non-ironing fabric disclosed by the invention, the appearance flatness of the fabric reaches the grade-3.5 of the AATCC 124-2001 standard, the wearability meets the condition that the ISO12947-1 standard is greater than or equal to 10,000R, the breaking strength meets the condition that the ASTM D5034 standard is greater than or equal to 25 LB, and the tearing strength meets the condition that the ASTM D1424 standard is greater than or equal to 1.6 LB.

Owner:鲁丰织染有限公司

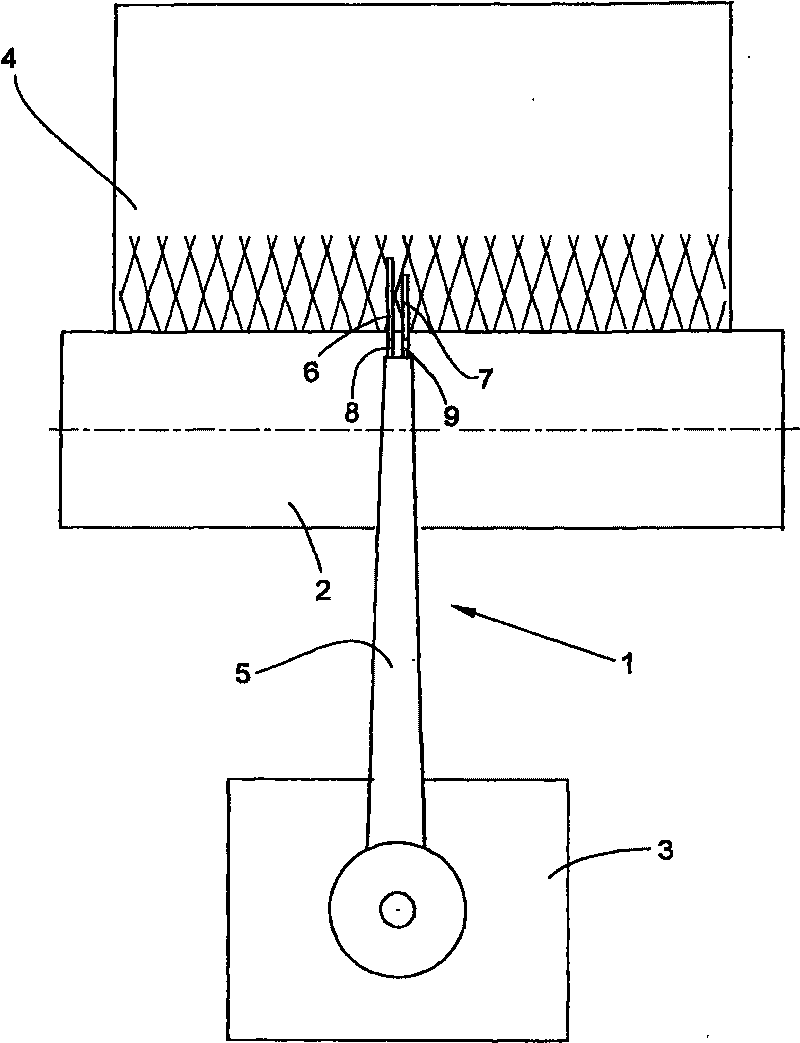

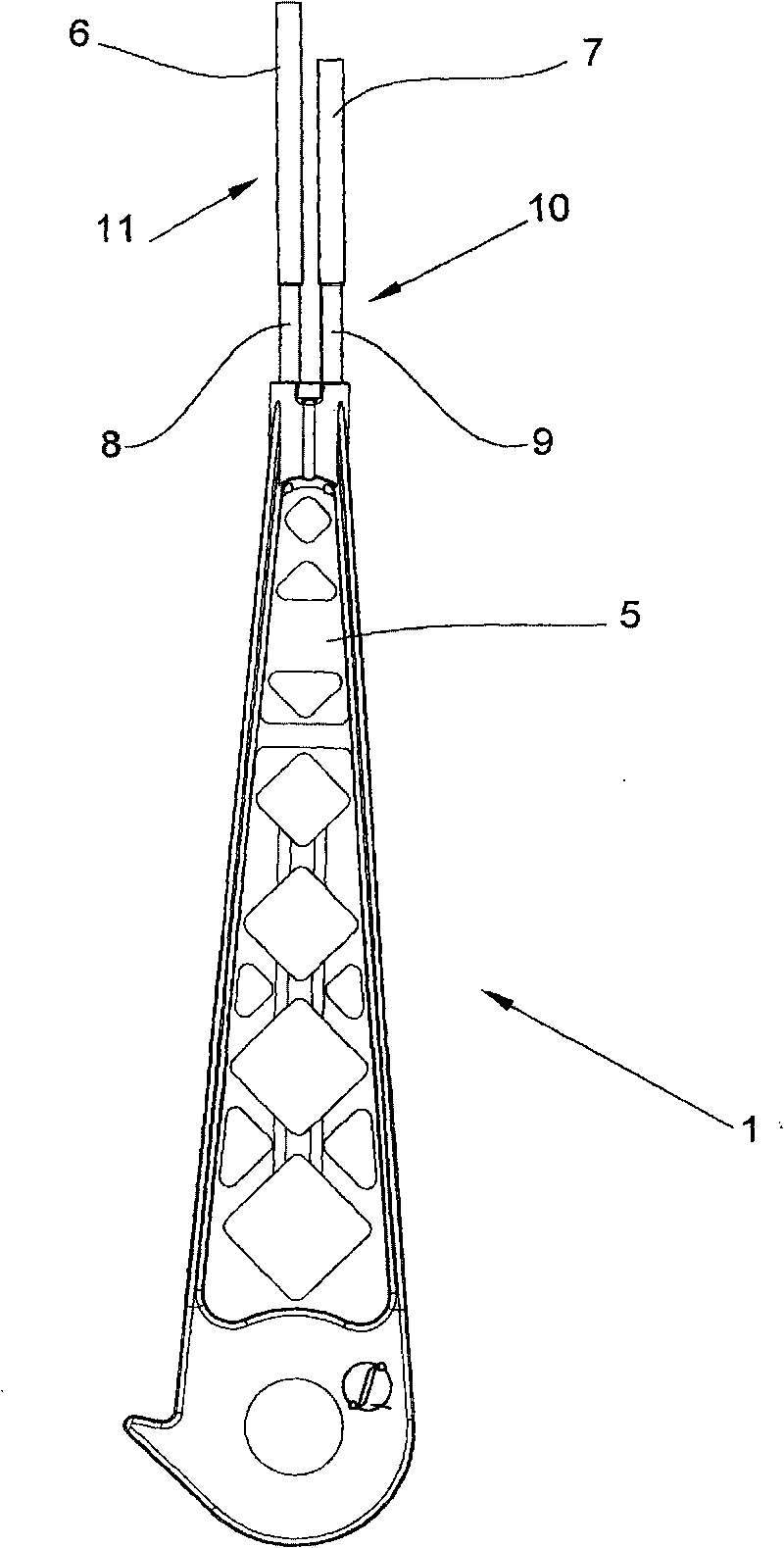

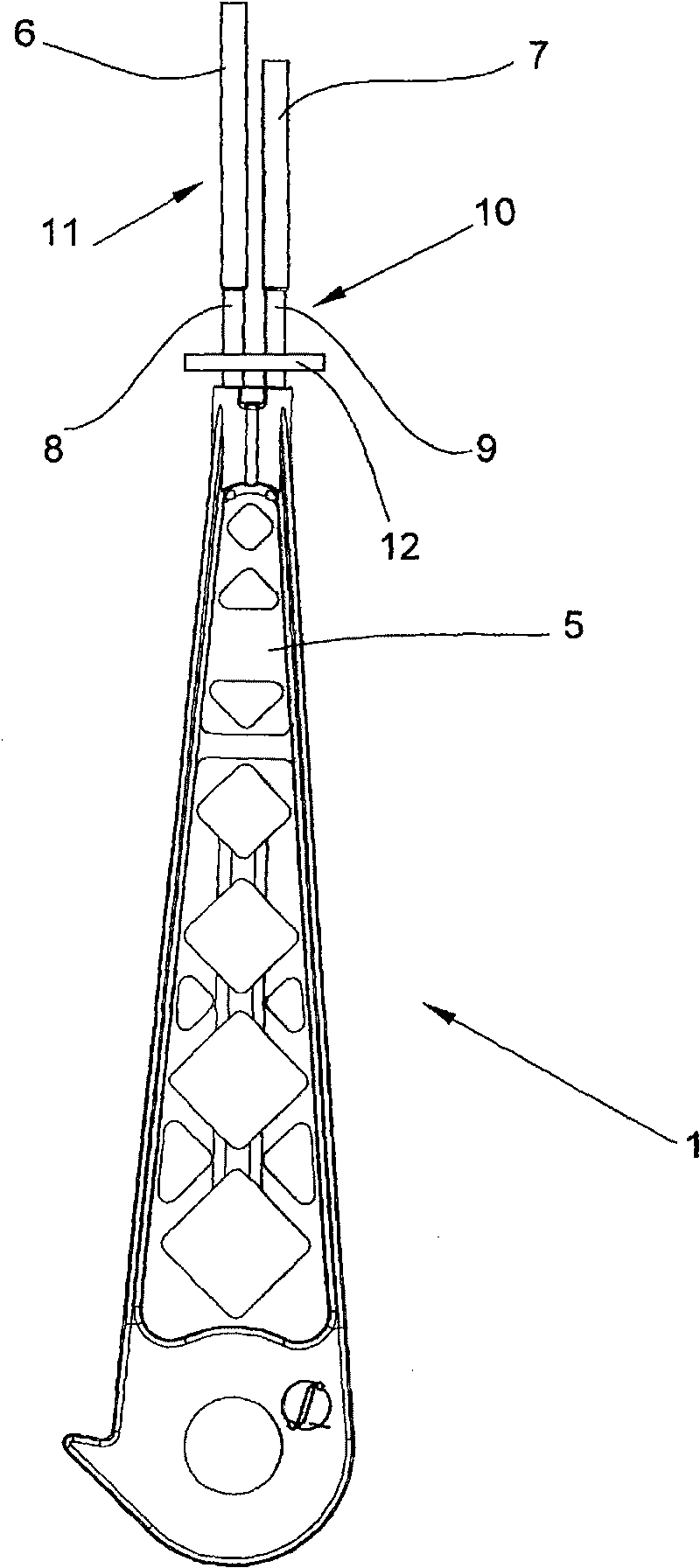

Thread guide

The invention relates to a thread guide (1) having a finger or needle shaped arm (5), where one end of needle shaped arm (5) is connected with a drive device (3). The free end of the needle shaped arm (5) has guiding elements (6, 7) that are formed as hollow body made of ceramic for threading a thread on a rotating coil (4) that is parallel to coil axis. The guide elements (6, 7) are connected with free end of the arm (5) by flexible elastic rods (8, 9).

Owner:OERLIKON TEXTILE GMBH & CO KG

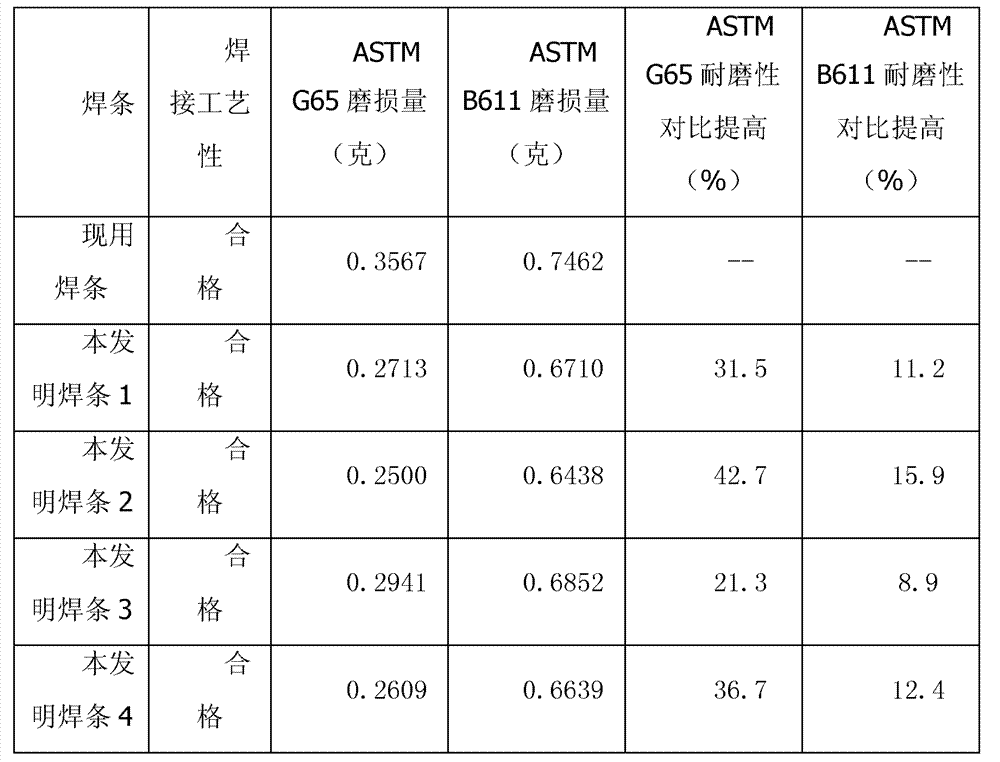

A pipe welding rod with low stress wear resistance

ActiveCN103228402BImprove welding processabilityAdvanced technologyDrill bitsWelding/cutting media/materialsMacrocrystallineAlloy

Owner:KINGDREAM PLC CO +1

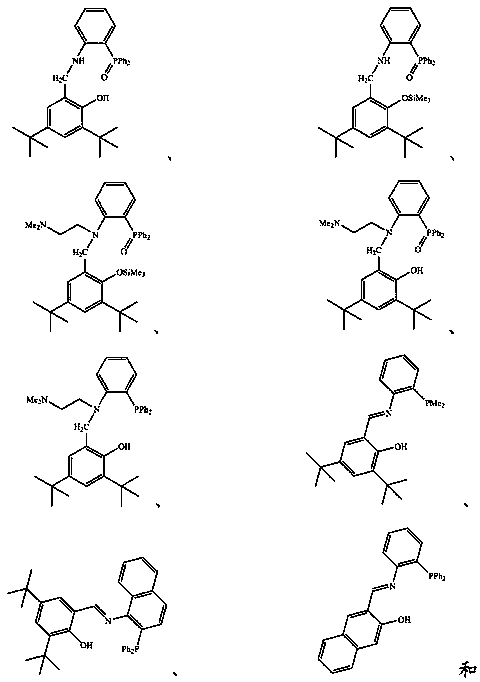

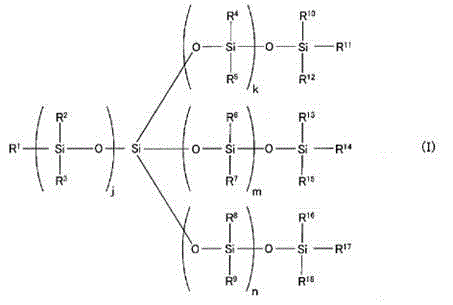

Method for producing modified conjugated diene rubber

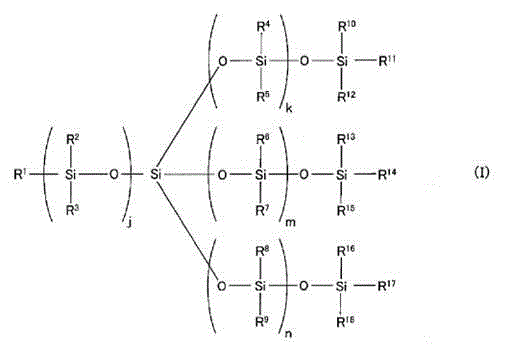

Provided is a method for producing a modified conjugated diene rubber, which is provided with a step wherein monomers including at least a conjugated diene compound are polymerized using, as a polymerization initiator, an alkali metallized aromatic compound that has three or more carbon atoms directly bonded to an alkali metal atom and an aromatic ring in each molecule, and then an active terminal of the thus-obtained polymer is reacted with a compound represented by general formula (I). (In general formula (I), one of R1 and R10-R18 represents an atom or a reactive group that is reactive with an active terminal of the polymer or a hydrocarbon group that contains the atom or a reactive group; each of the rest of R1 and R10-R18 and R2-R9 independently represents a hydrogen atom, an alkyl group or an aryl group; and each of j, k, m and n represents an integer of 0-100.)

Owner:ZEON CORP

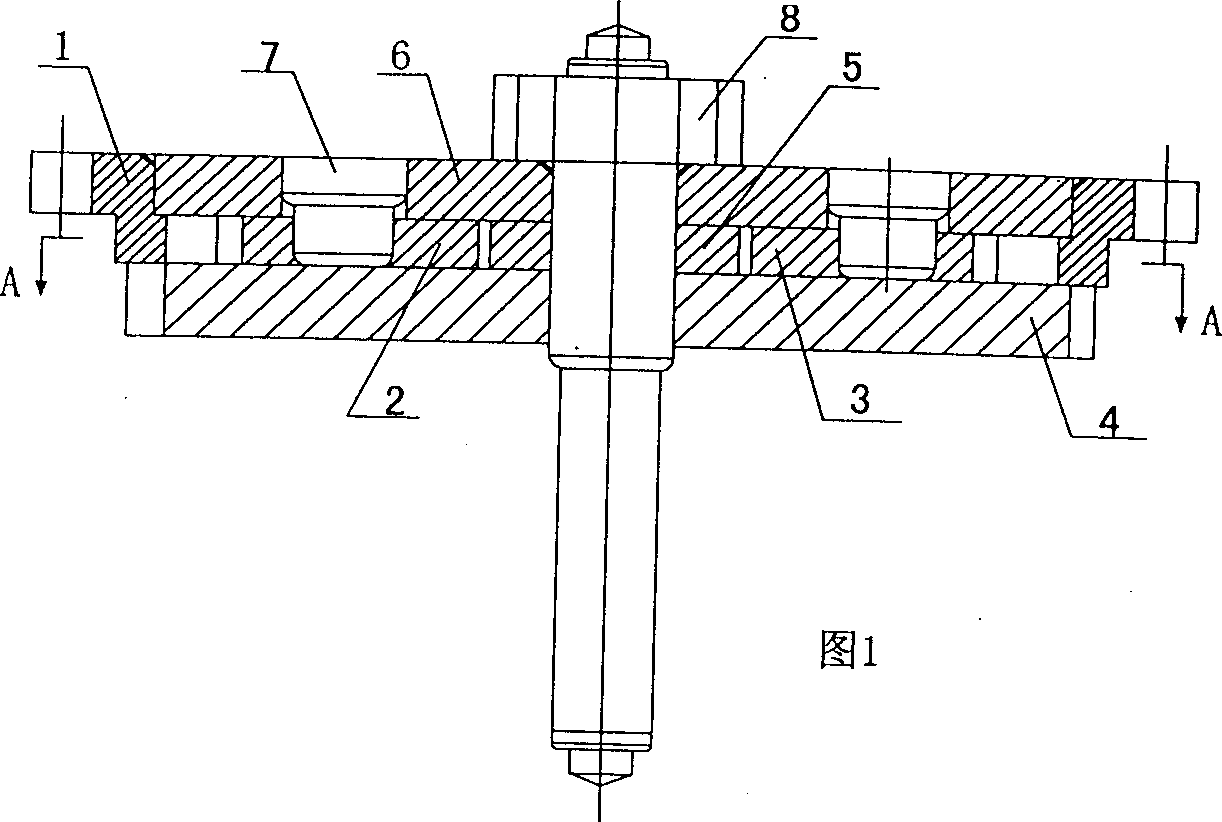

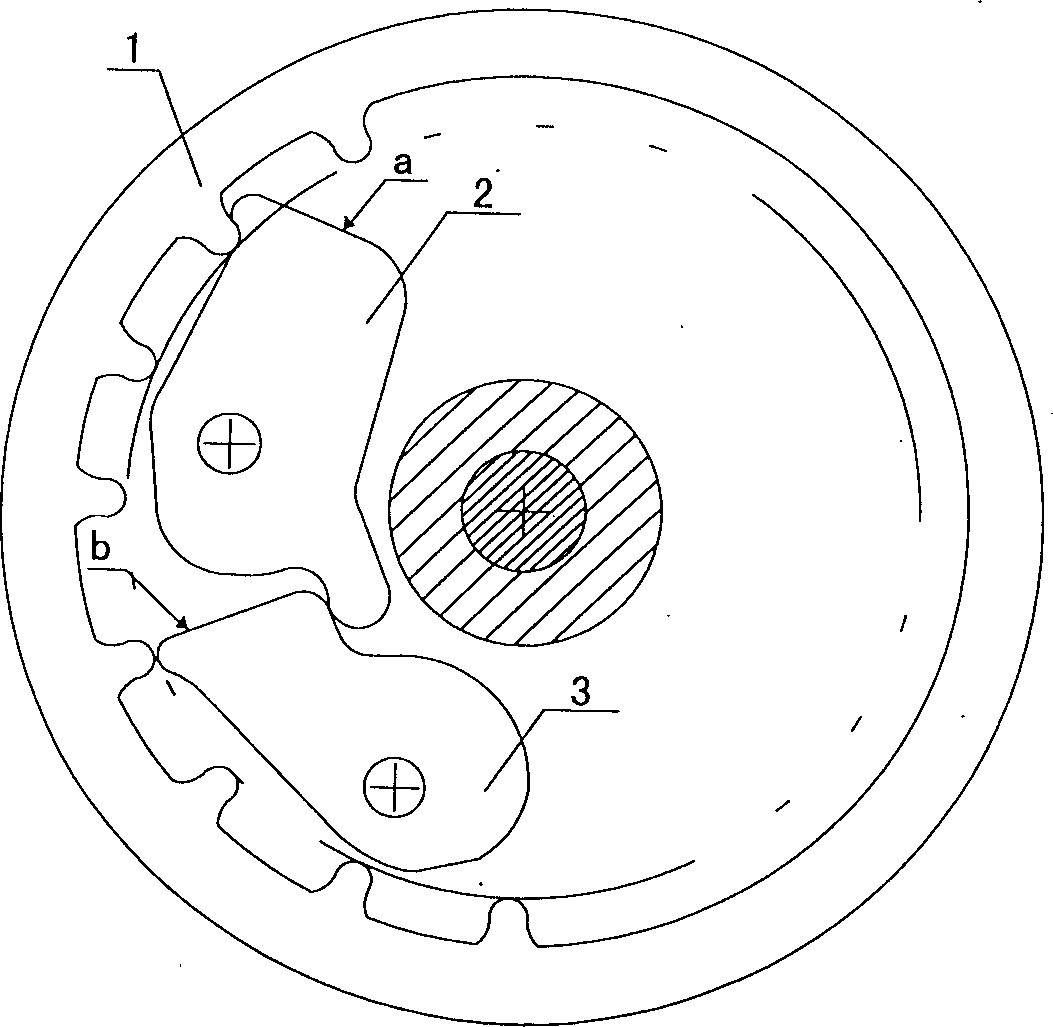

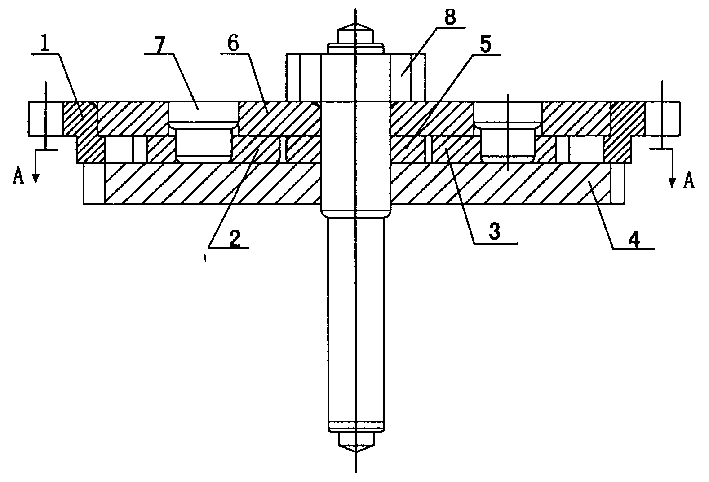

Double-lever interlocking change-over mechanism and method for automatic watch

InactiveCN1374570AImprove wear resistanceReduced wear resistanceAutomatic windingManufacturing technologyGear wheel

The present invention relates to the manufacture of watch. The double-lever interlocking change-over mechanism consists of gear, double swing links, ratchet wheel, isolating ring, wheel sleeve, nail and toothed shaft assembled together. The key point of the mechanism is that the gear with both inner and outer teeth and the double swing links constitute one enclosed transmission chain for transferring motion and force in single way. The mechanism has mesh between gear and automatic hammer and mesh between toothed shaft and automatic spring winding wheel. The mechanism is high in reliability, long in service life, low in cost and high in efficiency.

Owner:刘越雄

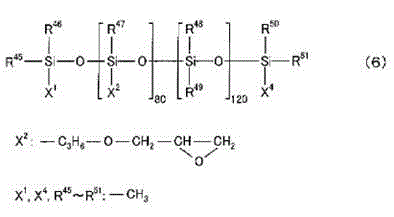

Active energy ray-curable resin composition and cured article thereof

The present invention provides an active energy ray-curable resin composition that exhibits high close-adhesiveness and excellent wear resistance even under high temperature and high humidity without virtually any warping when cured by ultraviolet rays, electron beam, or other active energy ray, and that has secondary processability such as excellent molding after curing. This active energy ray-curable composition is characterized by containing: a urethane resin having a plurality of acrylate groups or methacrylate groups; at least one amide or amide derivative selected from those having an ethylenic double bond; at least one bifunctional acrylate or bifunctional methacrylate selected from those having a cyclic skeleton containing no carbon-carbon double bond; a photopolymerization initiator; and a polymer containing no ethylenic double bond. This active energy ray-curable composition is characterized if furthermore characterized in that the polymer containing no ethylenic double bond dissolves in at least one amide or amide derivative selected from those having an ethylenic double bond.

Owner:TAIYO INK MFG

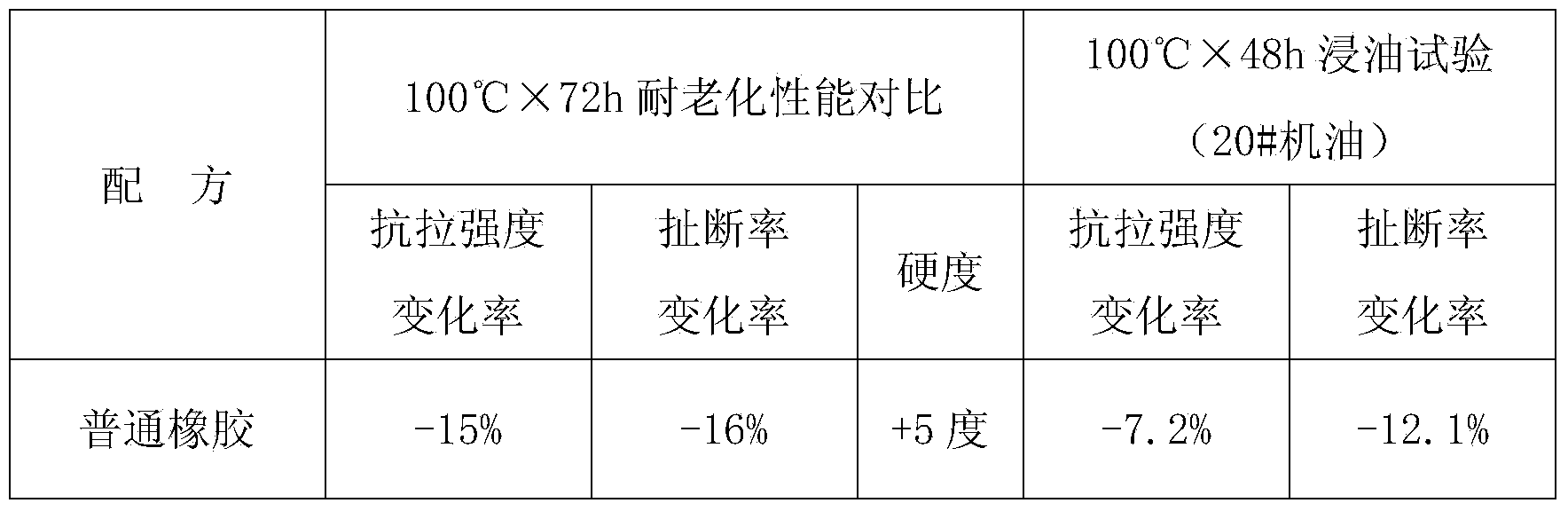

Modified ethylene propylene diene monomer composite gasket material, and preparation method thereof

The invention discloses a modified ethylene propylene diene monomer composite gasket material, and a preparation method thereof. The modified ethylene propylene diene monomer composite gasket material comprises following raw materials, by weight, 30 to 35 parts of ethylene propylene diene monomer, 52 to 57 parts of unitary epichlorohydrin rubber, 12 to 18 parts of copolyepichlorohydrin rubber, 4 to 5 parts of zinc stearate, 1 to 3 parts of antioxidant RD, 10 to 15 parts of electric furnace fly ash, 2 to 3 parts of silica powder, 1.5 to 3 parts of sulphur, 2 to 4 parts of promoter DM, 35 to 40 parts of N351 carbon black, 14 to 18 parts of N660 carbon black, 10 to 12 parts of dioctyl maleate, and 10 to 12 parts of modified attapulgite. According to the modified ethylene propylene diene monomer composite gasket material, modified attapulgite is added, so that processing properties of the modified ethylene propylene diene monomer composite gasket material are improved; and environmental friendly accessory ingredients are used, so that toxic and side effects are reduced, and pollution on the environment is reduced. The modified ethylene propylene diene monomer composite gasket material possesses excellent mechanical properties and elasticity, is low in compressive deformation, is high in abrasion resistance and leak tightness, is reasonable in formula, is simple in technology, is low in cost, and is suitable for industrialized production.

Owner:蚌埠赛英电子科技发展有限公司

Quasi cobalt carbon diaphragm

InactiveCN1958835AHigh strengthImprove bindingVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

This invention provides a diamond-like carbon film, which is composed of n layers (n is 6-30). The component of each layer is diamond-like carbon containing C, H and X, where, X is Cr, Ti, Cr-Ti alloy or chromium nitride. The component of layer m is a-C: H :( n-m+1) X, where, m is 1-n. The atomic percentage of X is decreasing from the layer of 1 (nearest to the matrix) to n. The diamond-like carbon film can be used as a protection film for molds, cutters or magnetic storage media.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

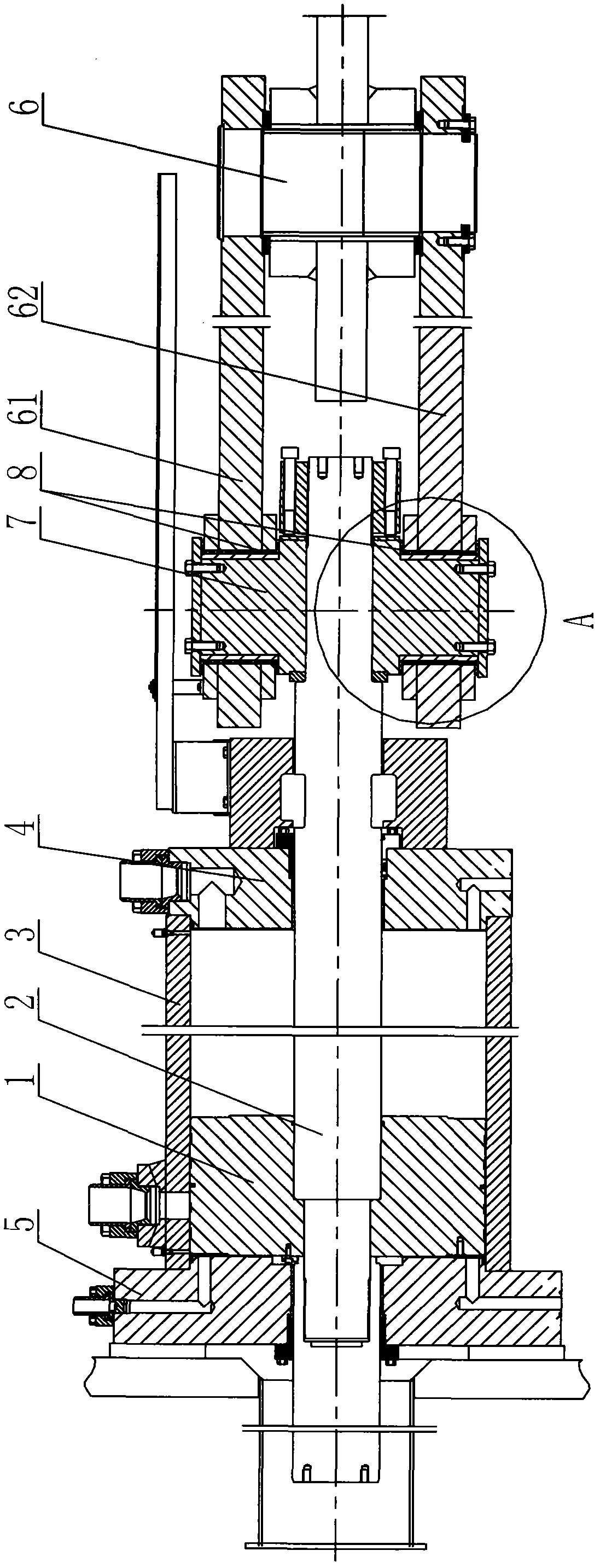

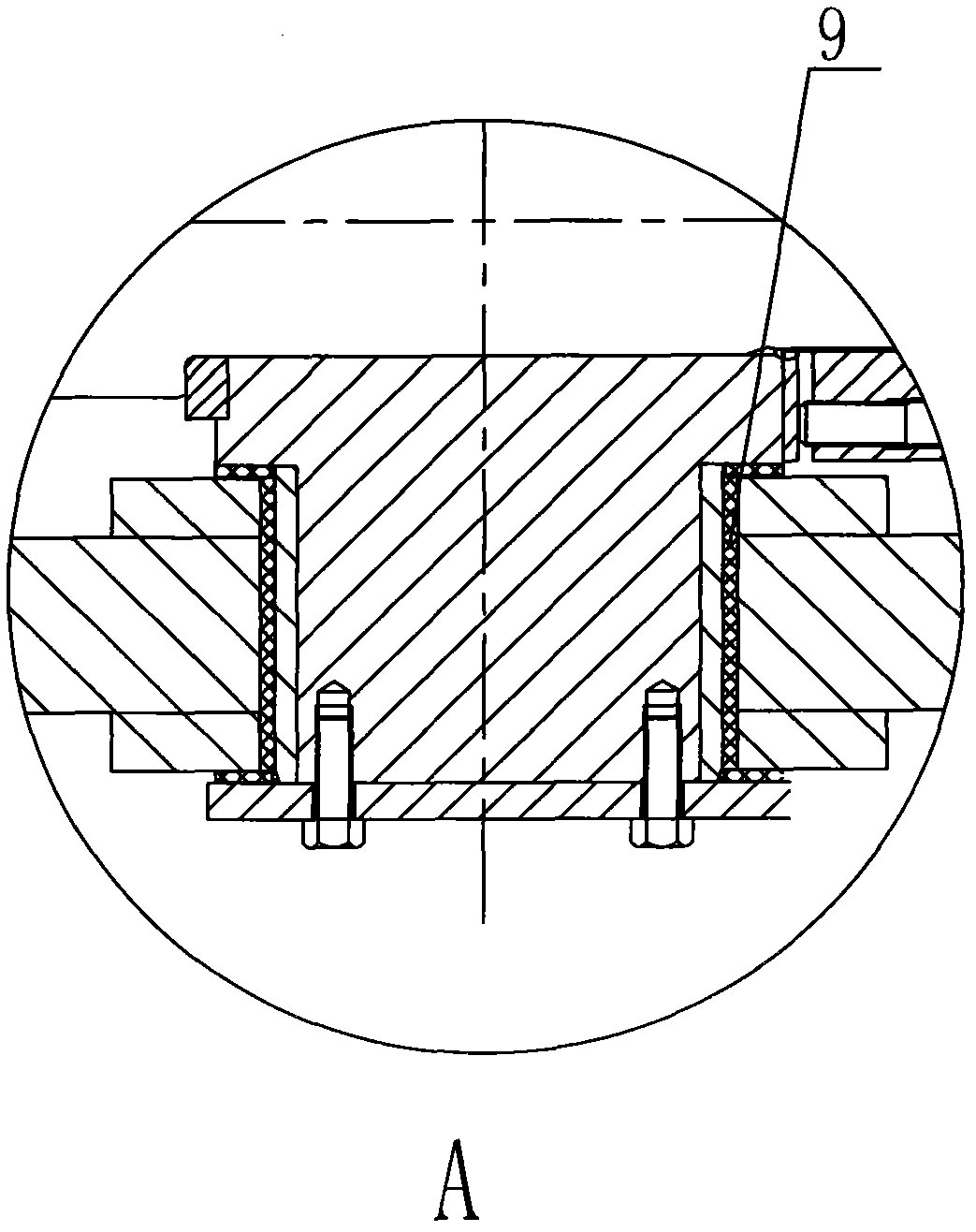

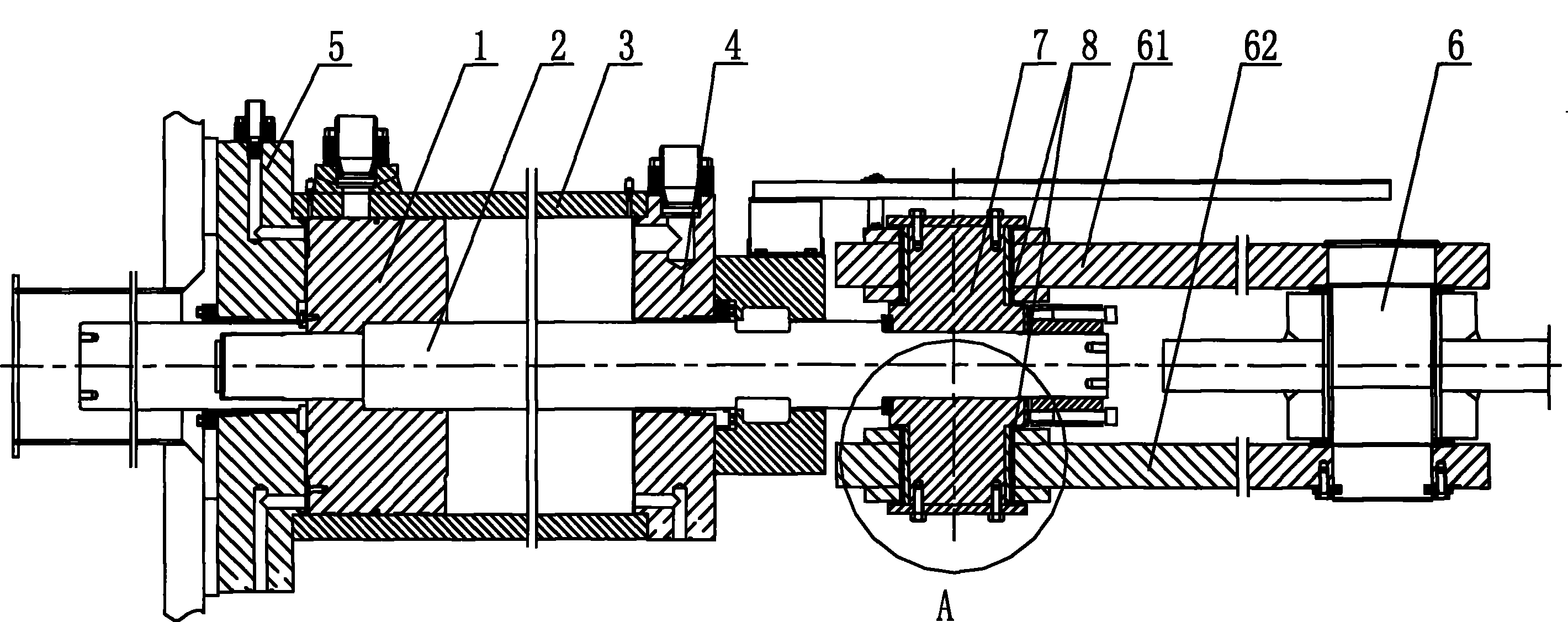

Hydraulic servomotor for hydroelectric generating set

ActiveCN101985914AImprove carrying capacityReduce frictionHydro energy generationMachines/enginesMoisture absorptionEngineering

The invention relates to a hydraulic servomotor for a hydroelectric generating set, which comprises a piston, a piston rod and a cylinder barrel, wherein the front and rear ends of the cylinder barrel are respectively provided with a front cylinder cover and a rear cylinder cover, the piston is in hydraulically sealing fit and arranged in the cylinder barrel, and the piston is fixedly connected with the piston rod; one end of the piston rod protrudes out of the cylinder barrel, and the piston rod is rotatably connected with a connecting mechanism by a connecting pin; and the connecting mechanism comprises an upper connecting plate and a lower connecting plate, and a connecting part between the connecting pin and the upper connecting plate and a connecting part between the connecting pin and the lower connecting plate are respectively provided with a fiber-wound bearing. Because of adopting the fiber-wound bearings, the hydraulic servomotor of the invention is convenient for processing and installation, and has high load capacity, good impact resistance, high boundary bearing capacity, low friction, abrasion resistance, corrosion resistance, good dimensional stability, low moisture absorption and no expansion.

Owner:CHANGZHOU HYDRAULIC COMPLETE EQUIP

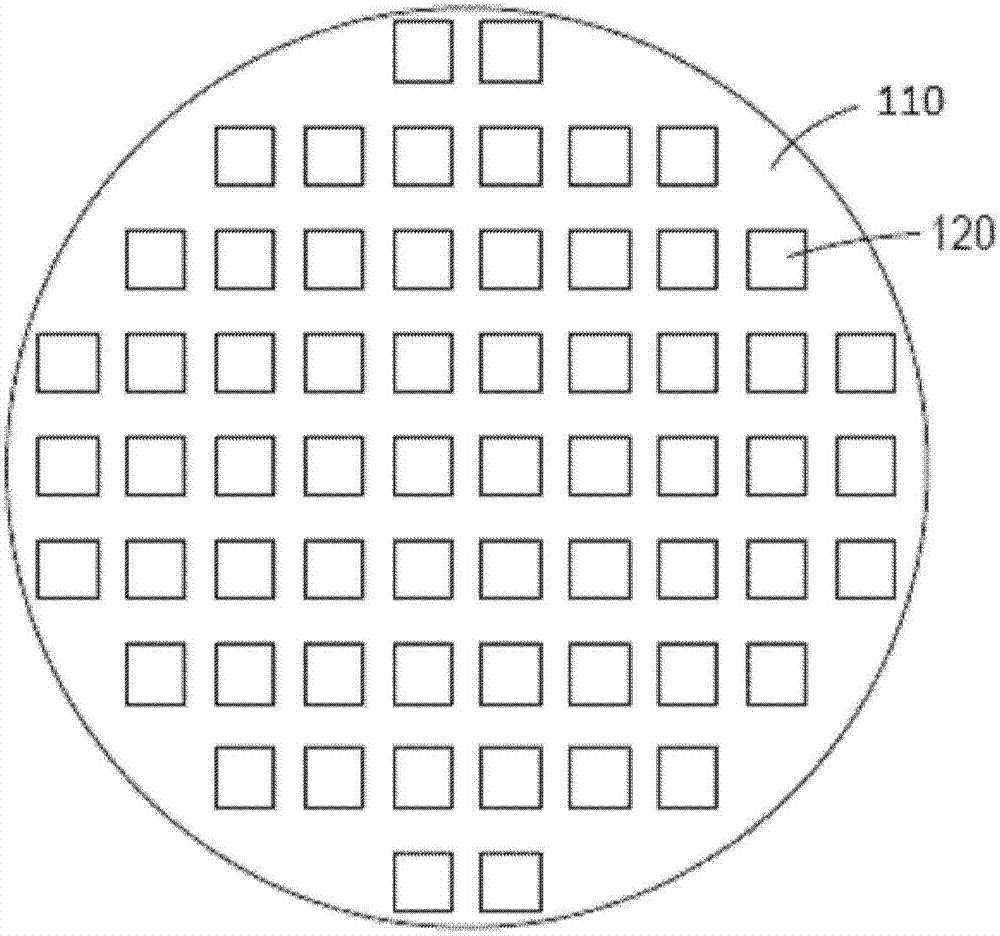

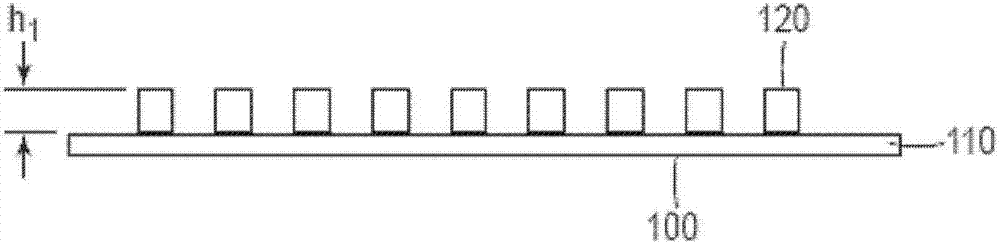

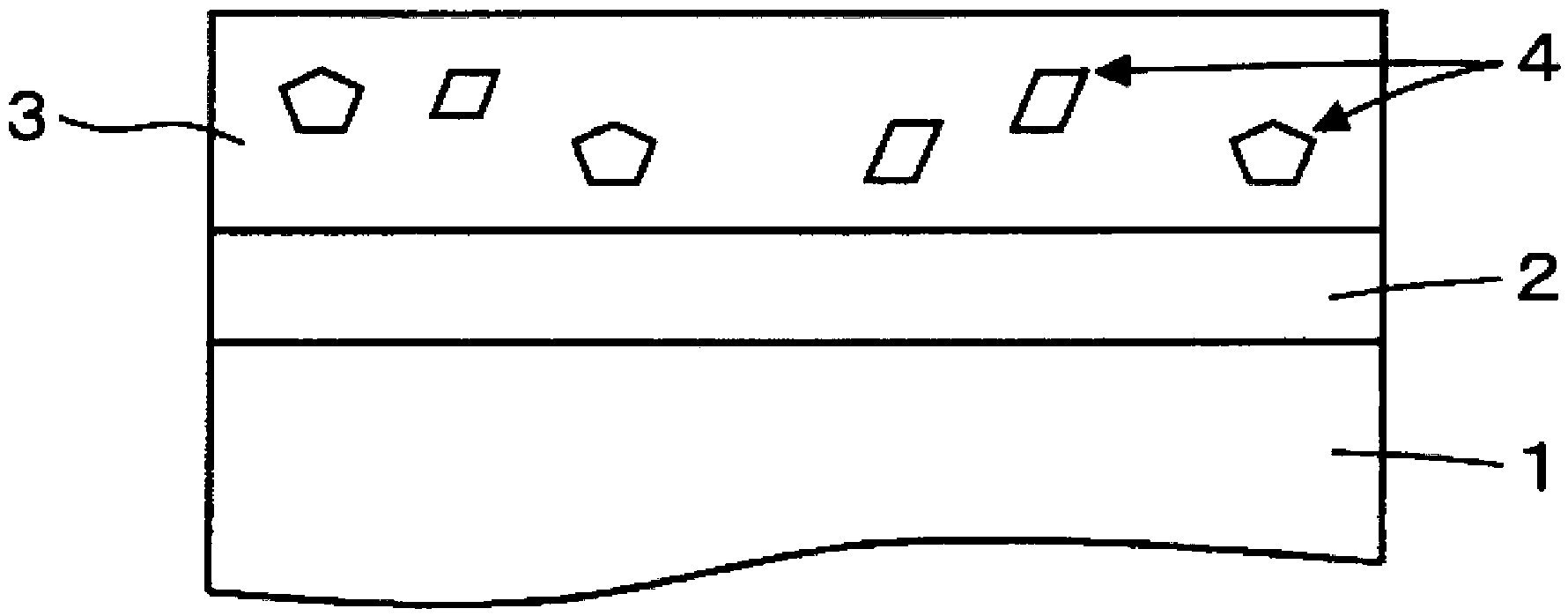

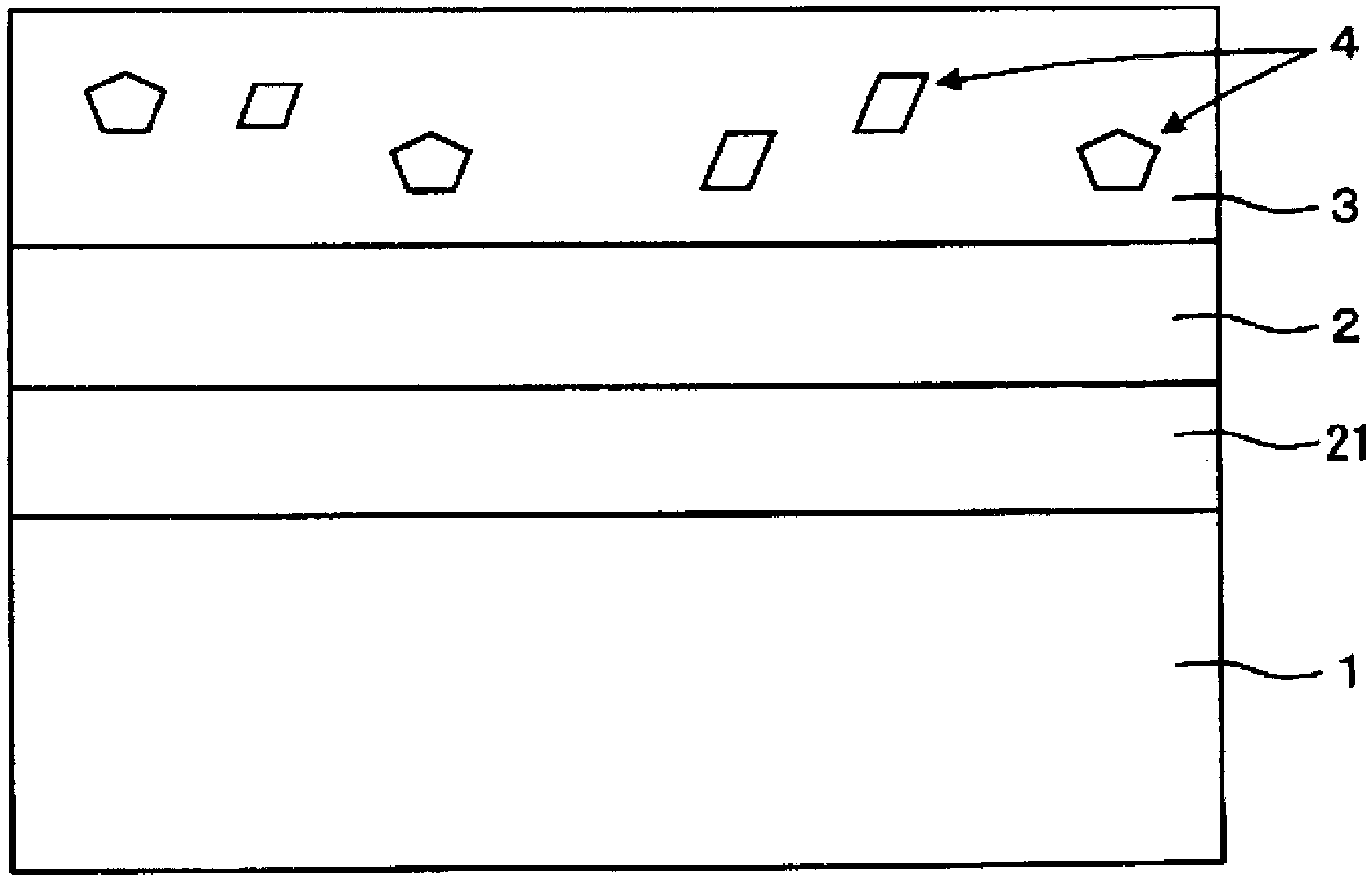

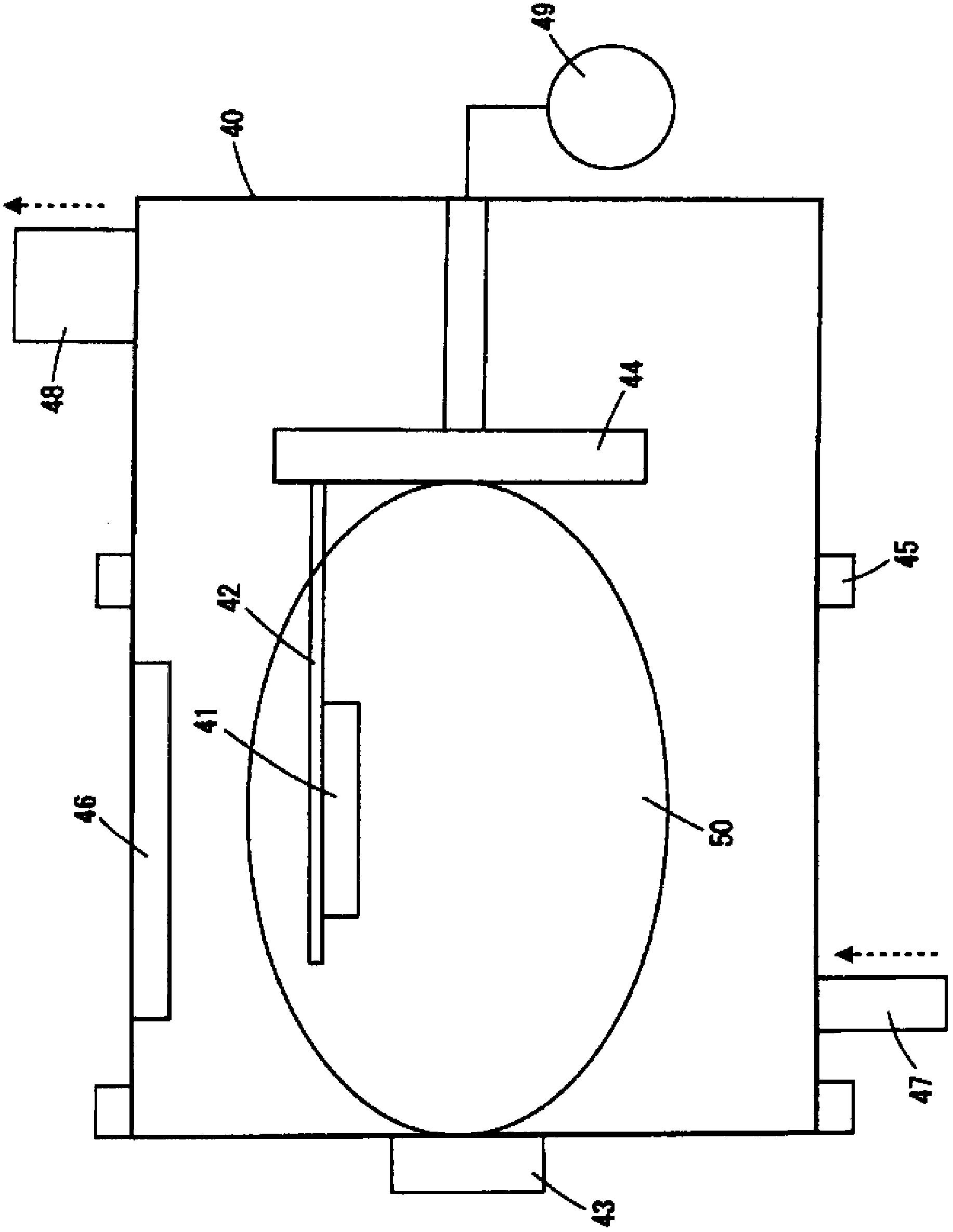

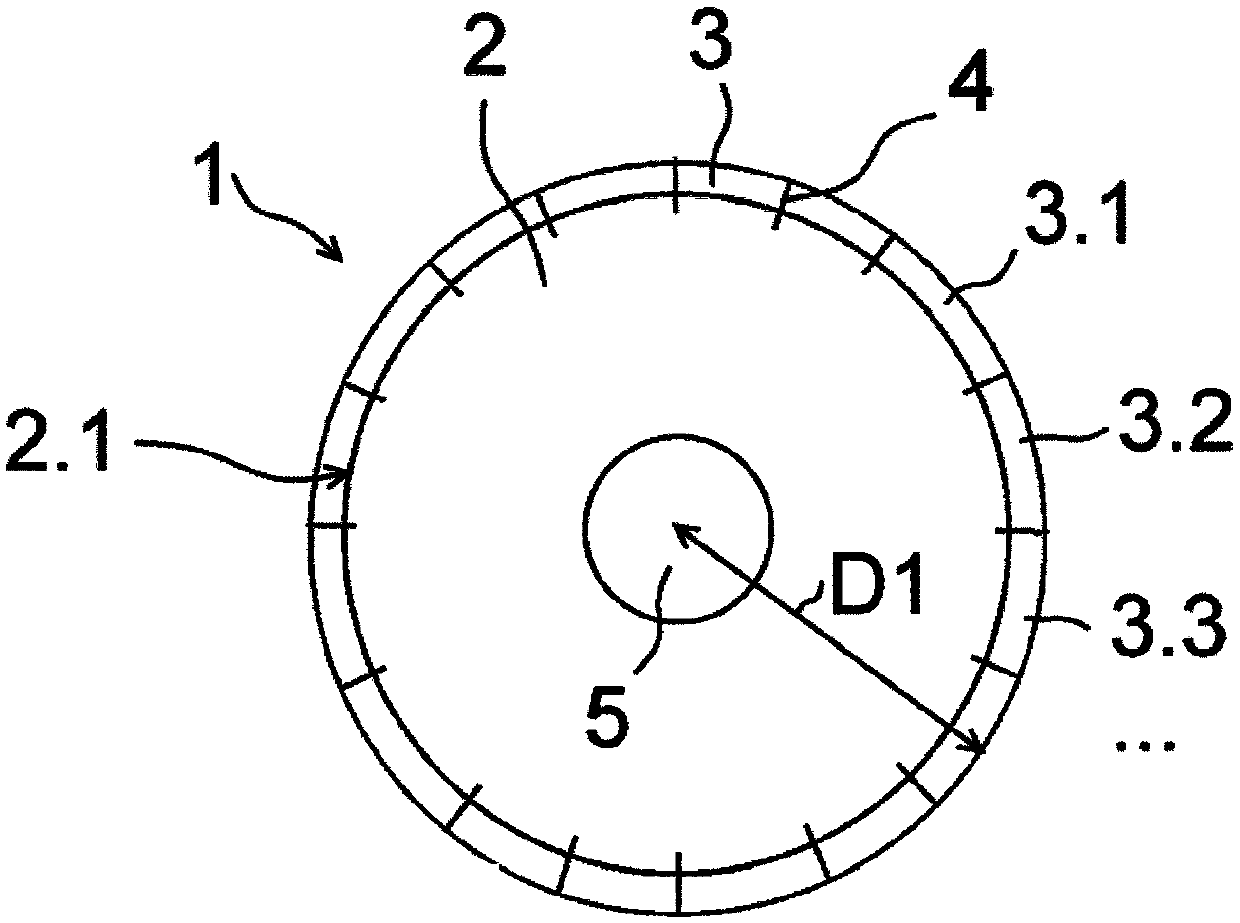

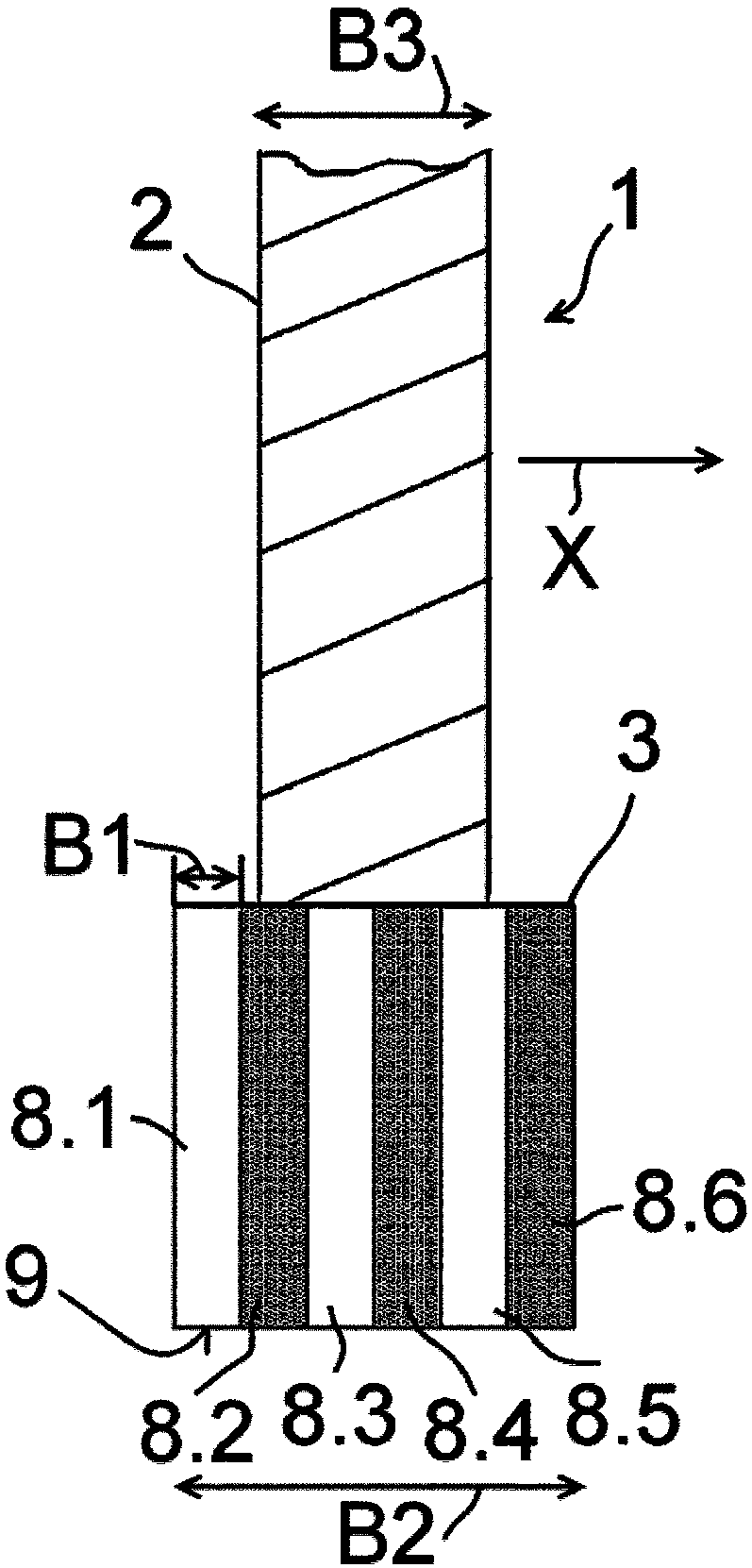

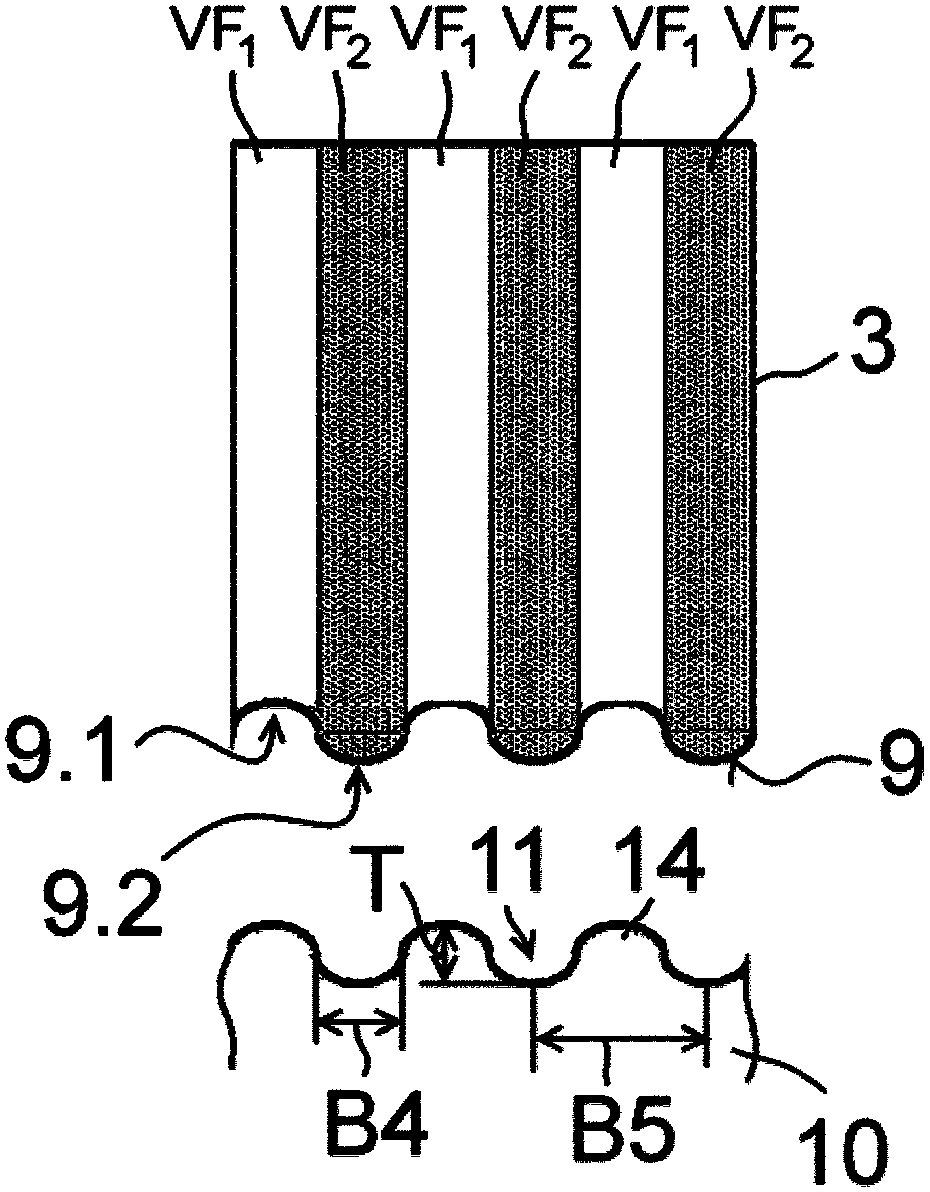

Sawing Tool Having A Plurality Of Diamond Saw Blades For Forming A Surface Structure On A Road Surface

ActiveCN107660175AImprove wear resistanceReduced wear resistanceMetal sawing toolsRoads maintainenceRoad surfaceEngineering

The invention relates to a sawing tool (7) for forming a surface structure on a road surface, at least having: a shaft (6) and a plurality of diamond saw blades (1), wherein each diamond saw blade (1)has a disc-shaped core with a hole for placing on the shaft (6), and a segment (3) which is arranged on an outer circumference of the core, wherein the diamond saw blades (1) are arranged on the shaft (6) by way of the disc-shaped core. The invention provides for the segments (3) of adjacent diamond saw blades (1) to be in surface contact on a longitudinal side (13), wherein each segment (3) is formed from at least two layers (8.i; i=1...6) that adjoin one another in the axial direction and each extend in the radial and axial direction, wherein layers (8.i; i=1...6) of the segment that axially adjoin one another each have different wear resistances (VF, VF1, VF2) and the wear resistance (VF, VF1, VF2) of the layers (8.i; i=1...6) in the axial direction alternates over the entire segment (3), wherein a furrow is able to be formed in each case by two layers (8.i; i=1...6) that axially adjoin one another, in order to set a grip and a level of noise of the road surface, and layers (8.i; i=1..6) that axially adjoin one another of adjacent segments (3) have different wear resistances (VF, VF1, VF2) in order to form an alternating layer structure over the entire sawing tool (7).

Owner:赛迪玛金刚石制品及建筑机械有限公司

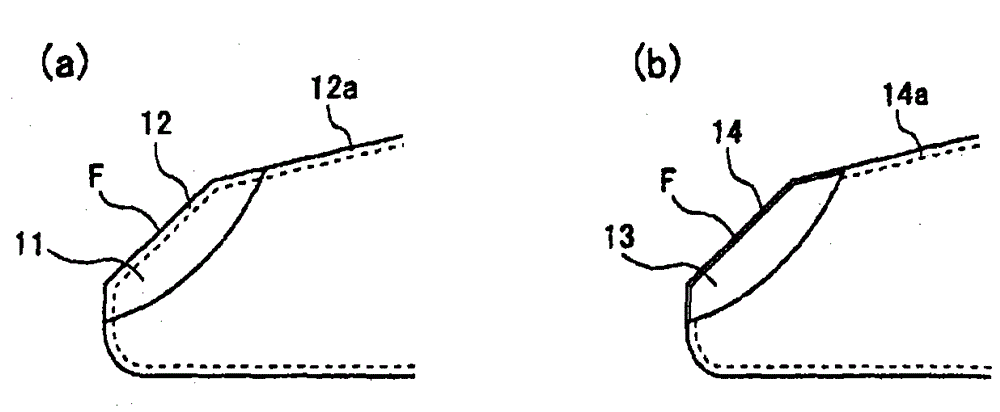

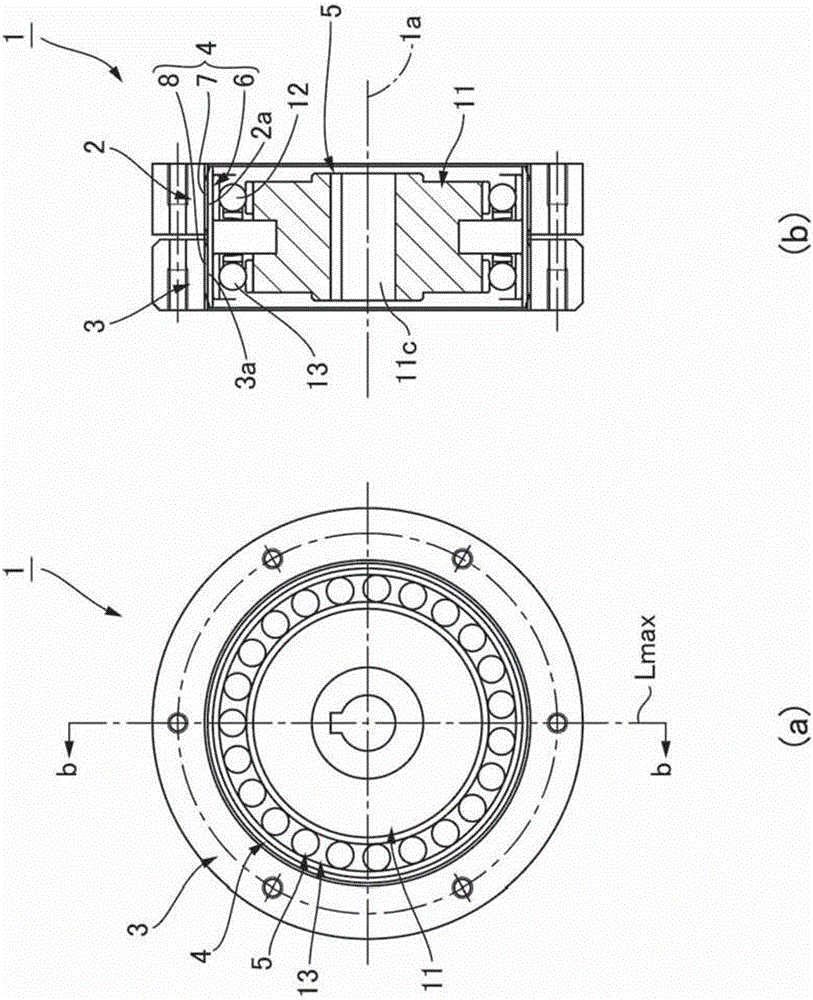

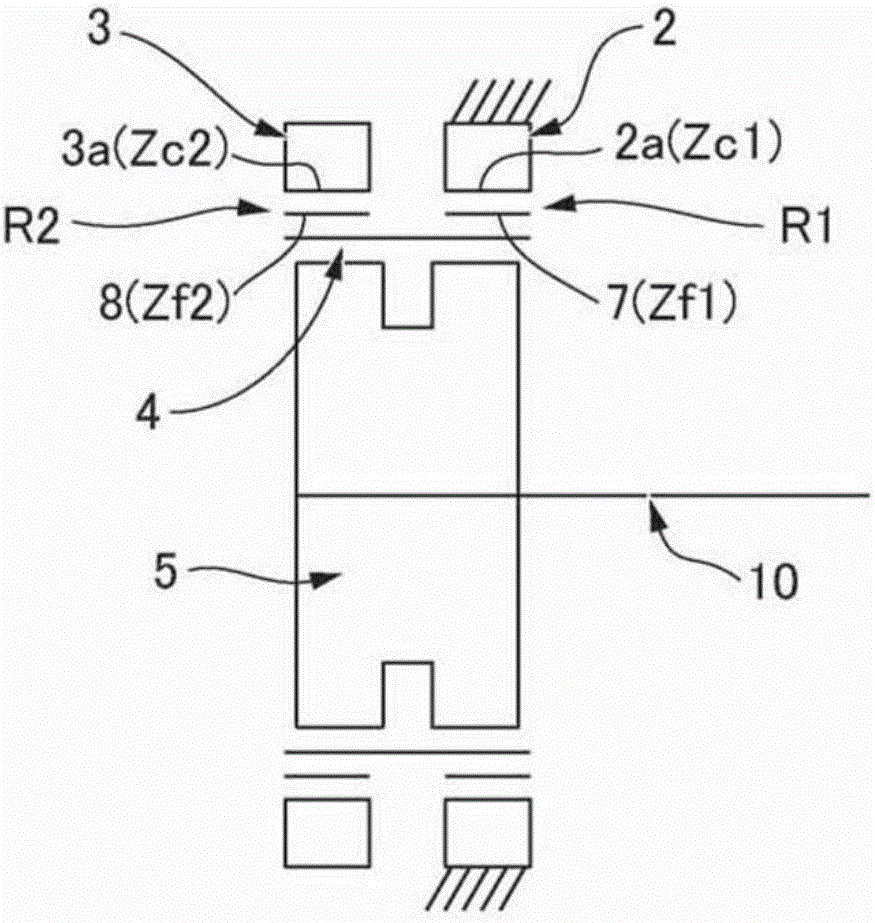

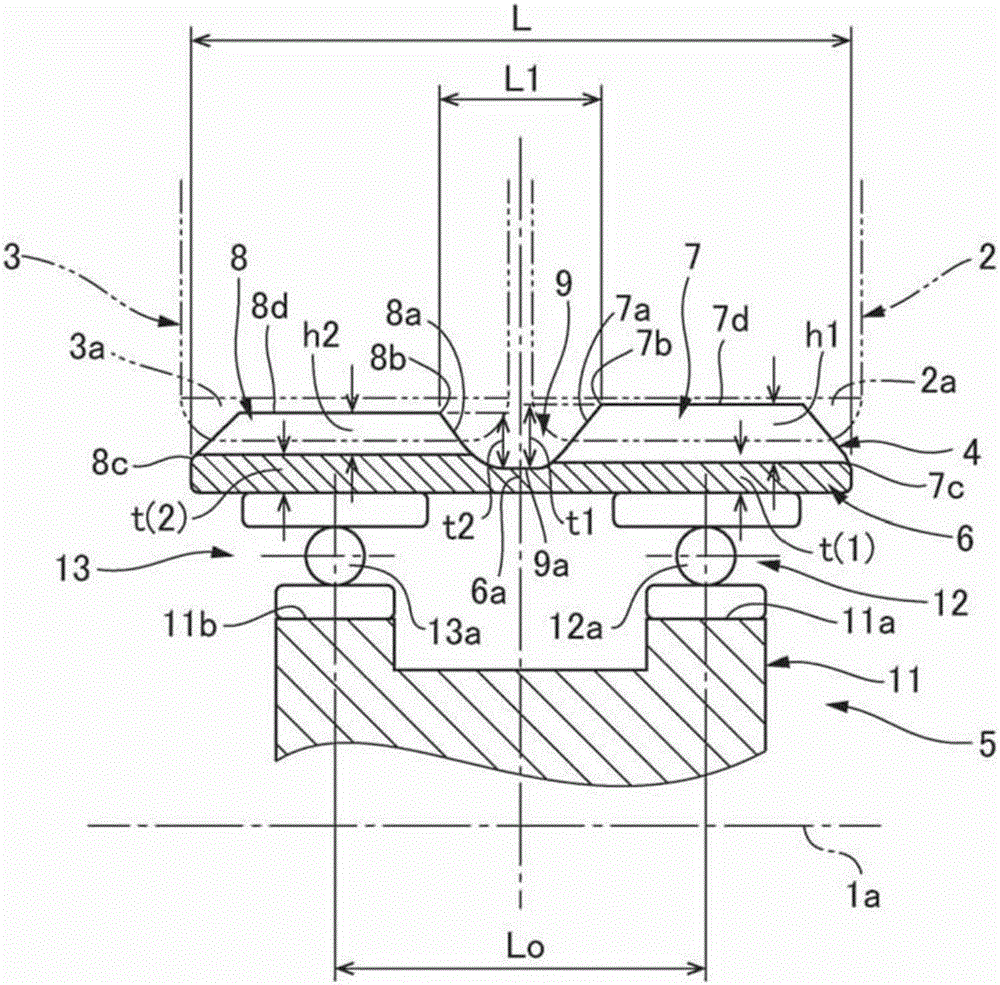

Dual-type wave gear device

ActiveCN106536979AReduce load capacityReduced wear resistanceToothed gearingsGearing elementsLower toothEngineering

An externally toothed gear of a dual-type wave gear device is provided with first and second external teeth (7, 8) having different teeth numbers. The first and second external teeth (7, 8) are bent by a wave generator by the same bending amount, into an elliptical shape. The tooth depth (h1) of tooth profiles (70) of the first external teeth (7) having a low teeth number is smaller than the tooth depth (h2) of tooth profiles (80) of the second external teeth (8) having a high teeth number. Accordingly, a dual-type wave gear device can be achieved with which the first and second external teeth having different teeth numbers can be suitably bent to form excellent mating states with respective internally toothed gears.

Owner:HARMONIC DRIVE SYST IND CO LTD

A preparation method for reducing the sintering temperature of a dense ultrafine-grained boron carbide ceramic material

ActiveCN106854080BLower sintering densification temperatureReduce energy consumptionHigh entropy alloysCeramic

The invention discloses a method for preparing a compact ultrafine-grain boron carbide ceramic material with a reduced sintering temperature. The method comprises the following steps: selecting coarse boron carbide powder with an average particle size of less than 20 [mu]m and carrying out ball milling and settlement so as to obtain ultrafine boron carbide powder with a particle size of less than 1 [mu]m; mixing the ultrafine boron carbide powder with MnNiCoCrFeX high-entropy alloy powder and carrying out ball milling so as to obtain B4C-MnNiCoCrFeX mixed powder; and subjecting the mixed powder to pressure sintering so as to obtain the compact ultrafine-grain boron carbide ceramic material with a reduced sintering temperature. According to the invention, the MnNiCoCrFeX high-entropy alloy powder is added into a boron carbide matrix, so a liquid phase is formed during high-temperature sintering and can fill in pores, and thus, the sintering densification temperature of the boron carbide ceramic material is effectively reduced, and energy consumption is decreased; and a boron carbide product with a density of greater than 99% is obtained after a temperature of 1900 DEG C is maintained for 5 min, and compared with the prior art, sintering temperature is reduced by 200 DEG C and heat preservation time is substantially shortened.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com