Polycrystalline diamond composites

一种多晶金刚石、化合物的技术,应用在多晶材料生长、晶体生长、单晶生长等方向,能够解决不足金属间化合物等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

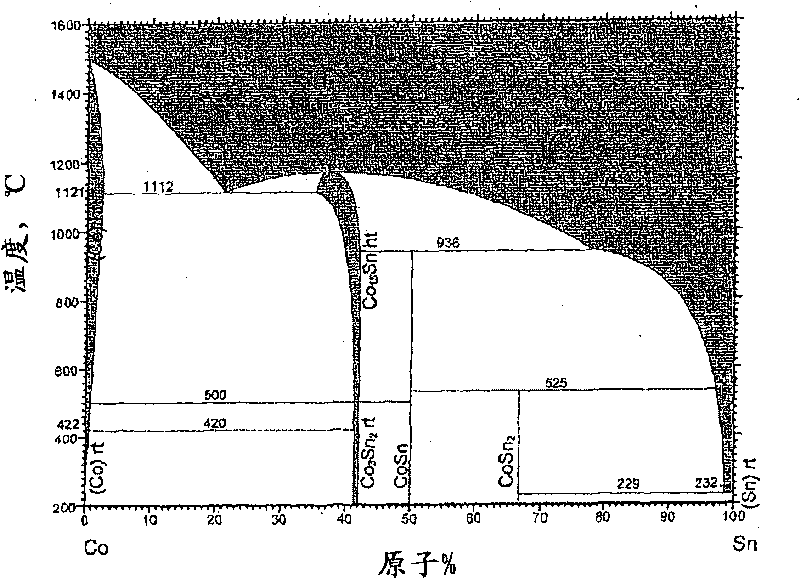

[0074] Example 1: Using the unbacked PCD sample produced by the Co-Sn system.

[0075] Various PCD samples sintered in the presence of Co-Sn-based binders were prepared. Produce a mixture of several Co and Sn metal powders with a certain range of Co:Sn ratio. For each sample, a bed of multimodal diamond powder with an average diamond grain size of about 20 μm was then placed in a niobium metal can, and a metal powder mixture layer sufficient to provide a binder accounting for 10% by volume of diamond was placed on the powder Bed. The tank was then evacuated to remove air, sealed, and processed under standard HpHT conditions of about 55 kbar and 1400°C to sinter the PCD.

[0076] Then take the sintered PCD composite sheet out of the can and use the following for inspection:

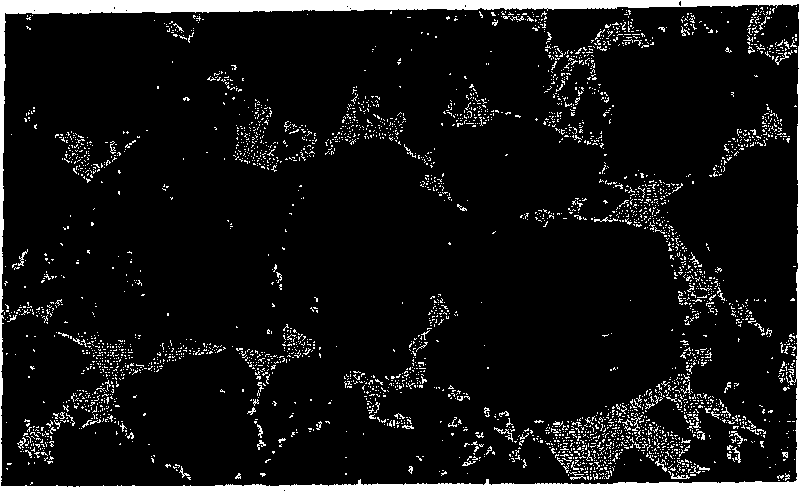

[0077] · Scanning Electron Microscopy (SEM) is used to demonstrate cross-growth; and

[0078] • XRD analysis to determine the phases present in the adhesive.

[0079] The characterization results are summarized ...

Embodiment 2

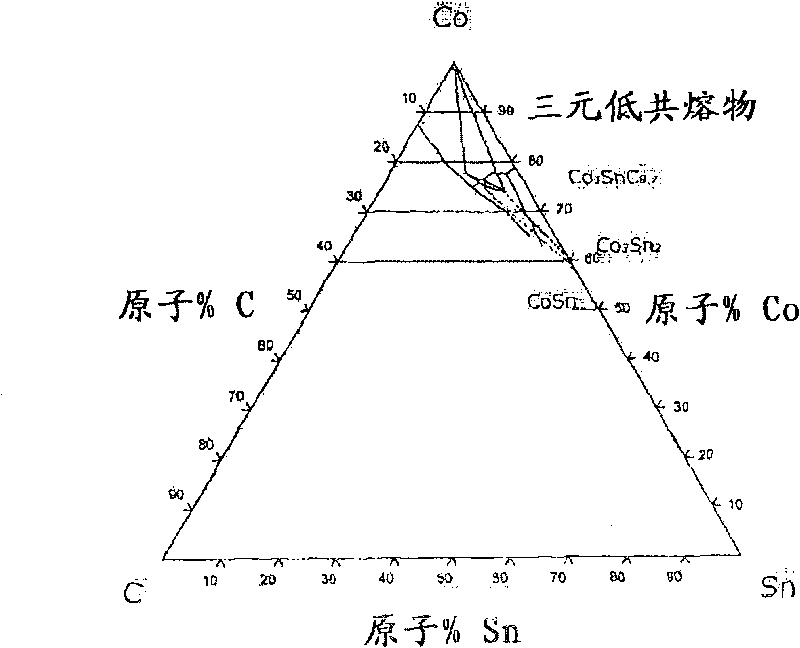

[0088] Example 2: Using Co-Sn system to produce PCD samples with carbide substrate backing

[0089] Several Co-Sn-based PCD samples sintered onto cemented carbide substrates were prepared. In various cases, tin powder and cobalt metal powder are pre-reacted to produce a CoSn alloy / intermetallic compound with a specific atomic ratio of 1:1. This pre-reaction source is then introduced into the unsintered diamond powder material by pre-synthesis mixing or in-situ infiltration.

[0090] A 1:1 CoSn pre-reacted powder mixture was prepared by grinding the Co and Sn powders together in a planetary ball mill. The powder mixture is then heat treated in a vacuum furnace (600°C-800°C) to produce a reacted CoSn material. This pre-reacted material is then further crushed / milled to break up agglomerates and reduce particle size.

[0091] The characteristics of the diamond powder used are multimodal and have an average grain size of about 22 μm. Then a selected amount of this CoSn material (expr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com