Quasi cobalt carbon diaphragm

A carbon film, a kind of technology, applied in the field of diamond-like carbon film, can solve the problems of high internal stress of diamond-like carbon film, weak bonding, and restrictions on the development and application of diamond-like carbon film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

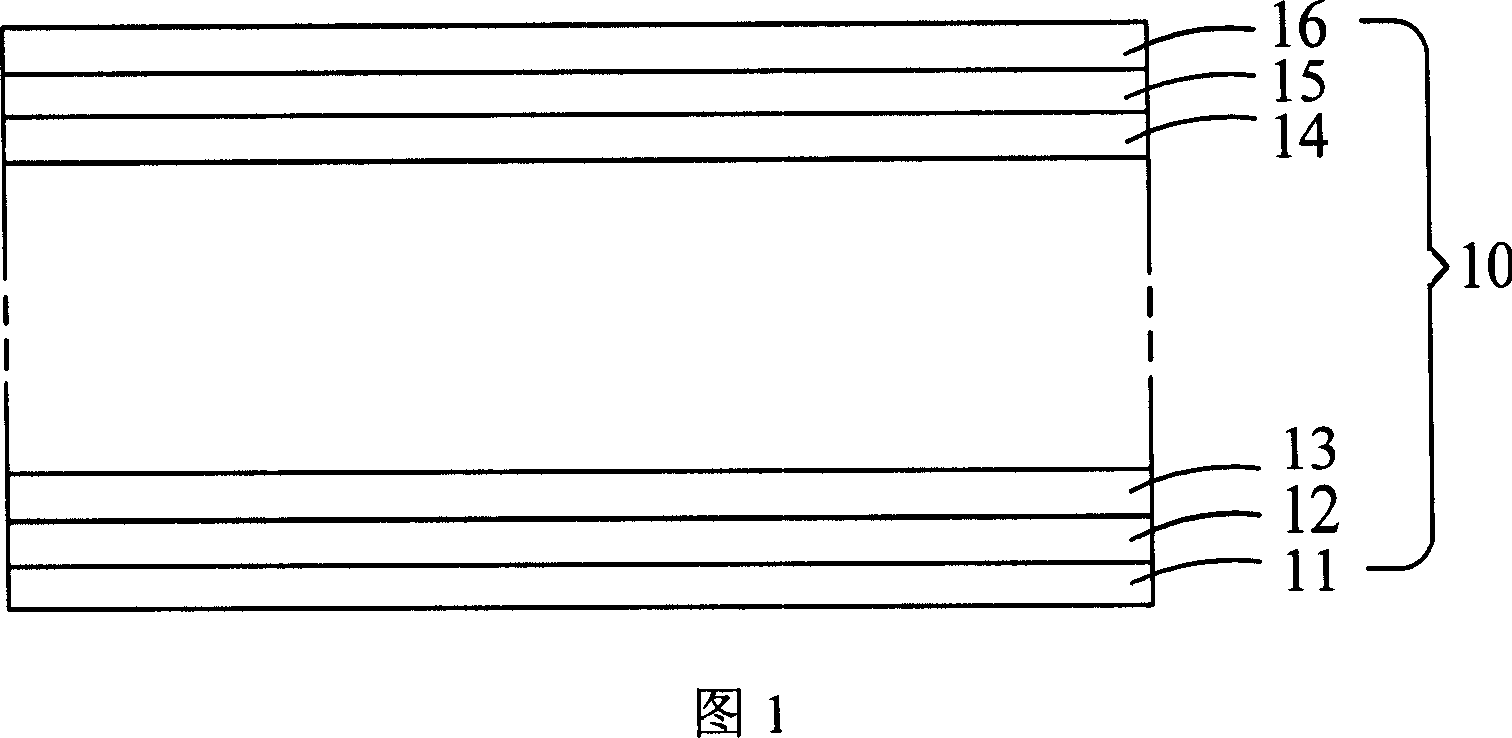

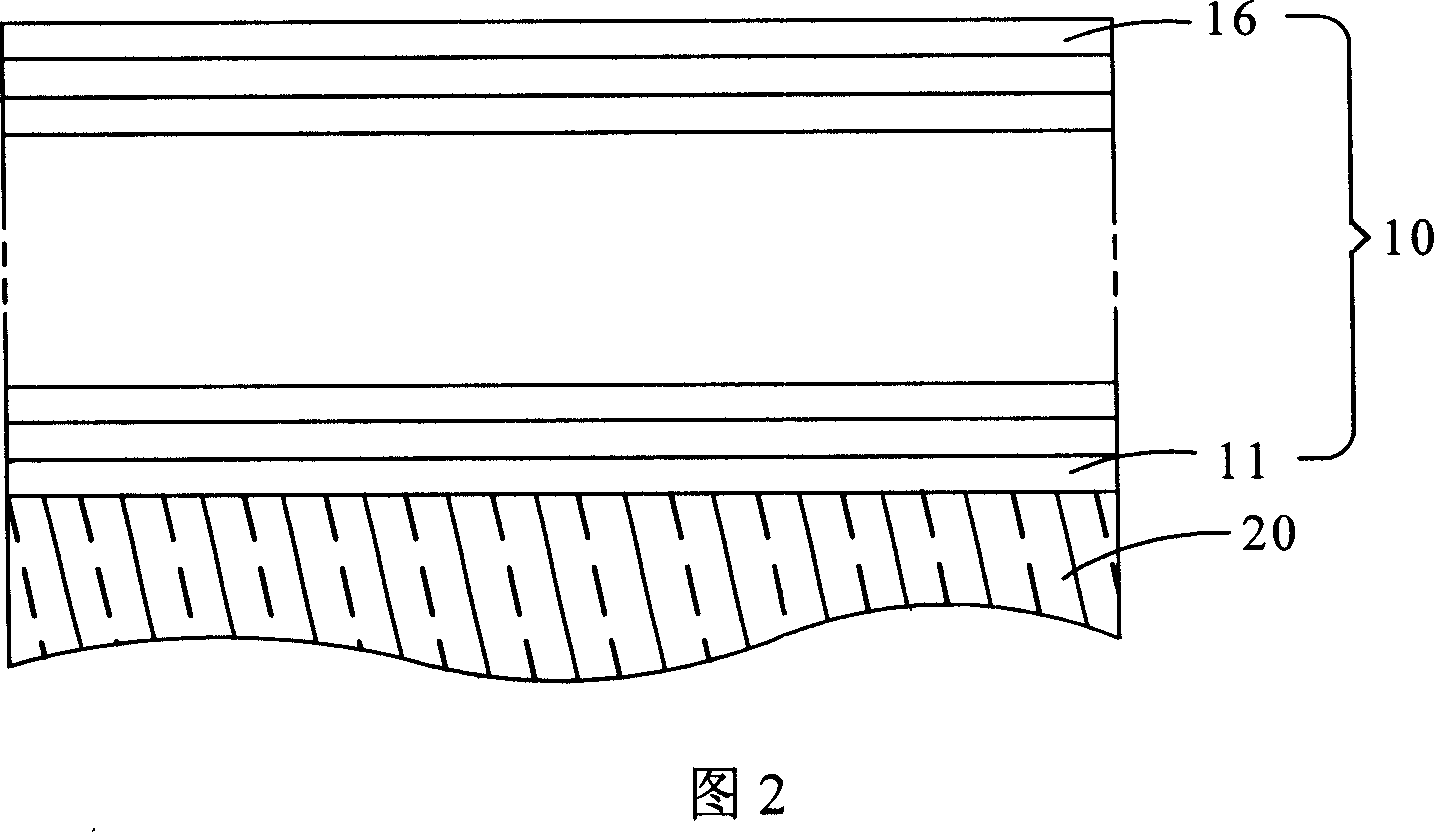

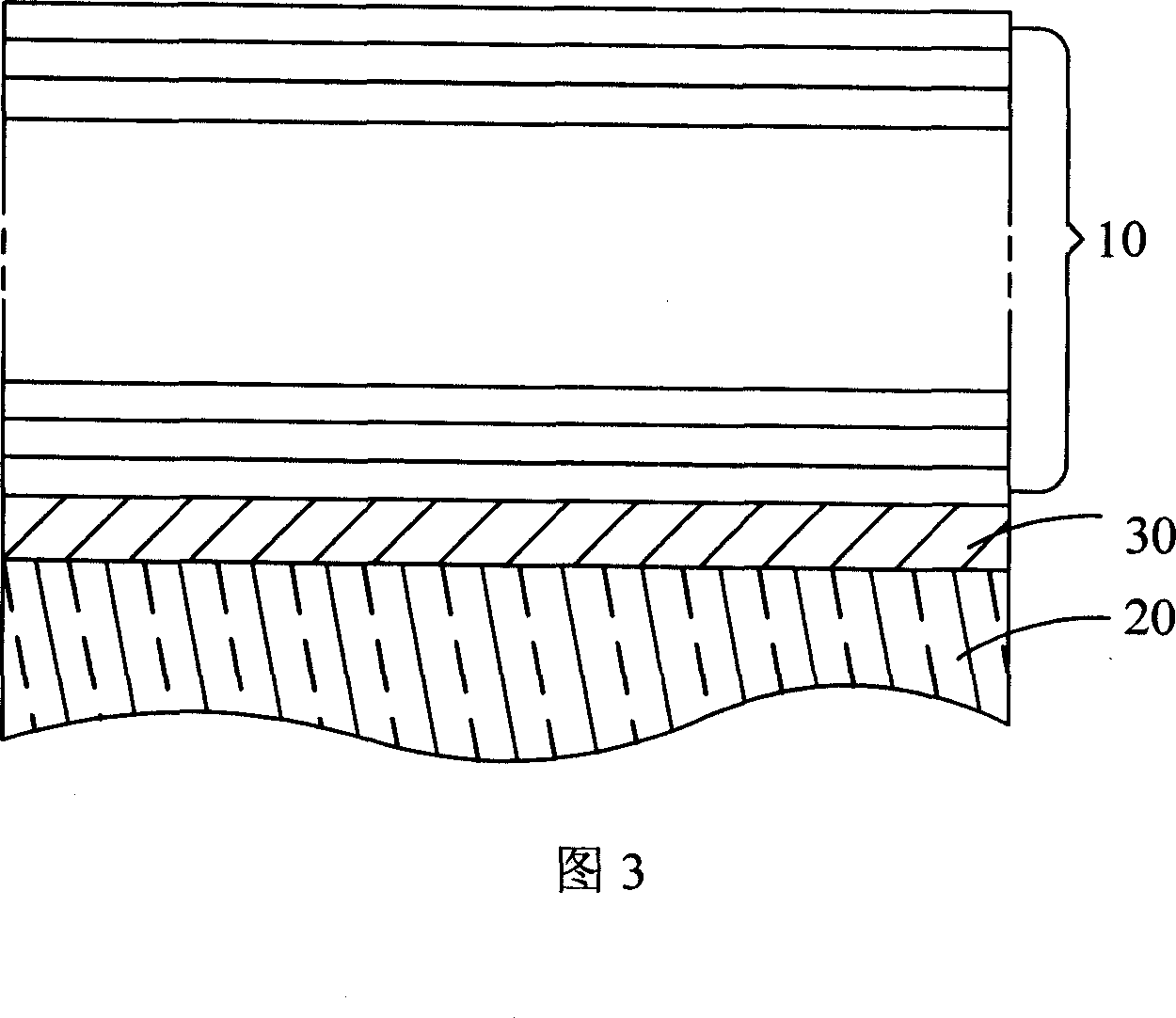

[0015] In order to reduce the internal stress of the diamond-like carbon film and improve its adhesion to the substrate, the embodiment provides a diamond-like carbon film with a multi-layer structure, and the diamond-like carbon film is amorphous hydrogen-containing diamond-like carbon. Please refer to FIG. 1 , which is a schematic diagram of the structure of the diamond-like carbon film 10 . The number of layers contained in the diamond-like carbon film 10 is represented by n, and the value of n is an integer ranging from 6 to 30, and the composition of each layer is different from other layers. It is assumed that one end combined with the substrate is the first layer 11 , and the other end opposite to it is the nth layer 16 . Assuming that a certain layer is the mth layer, and m is an integer from 1 to n, the composition of the mth layer is a-C:H:(n-m+1)X. That is to say, the composition of the first layer 11 is: a-C:H:nX, the composition of the second layer 12 is: a-C:H:(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com