Sawing Tool Having A Plurality Of Diamond Saw Blades For Forming A Surface Structure On A Road Surface

A diamond saw blade and surface structure technology, applied in stone processing tools, manufacturing tools, metal sawing equipment, etc., can solve problems such as uneven road surfaces, and achieve the effect of reducing noise level, small groove spacing, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

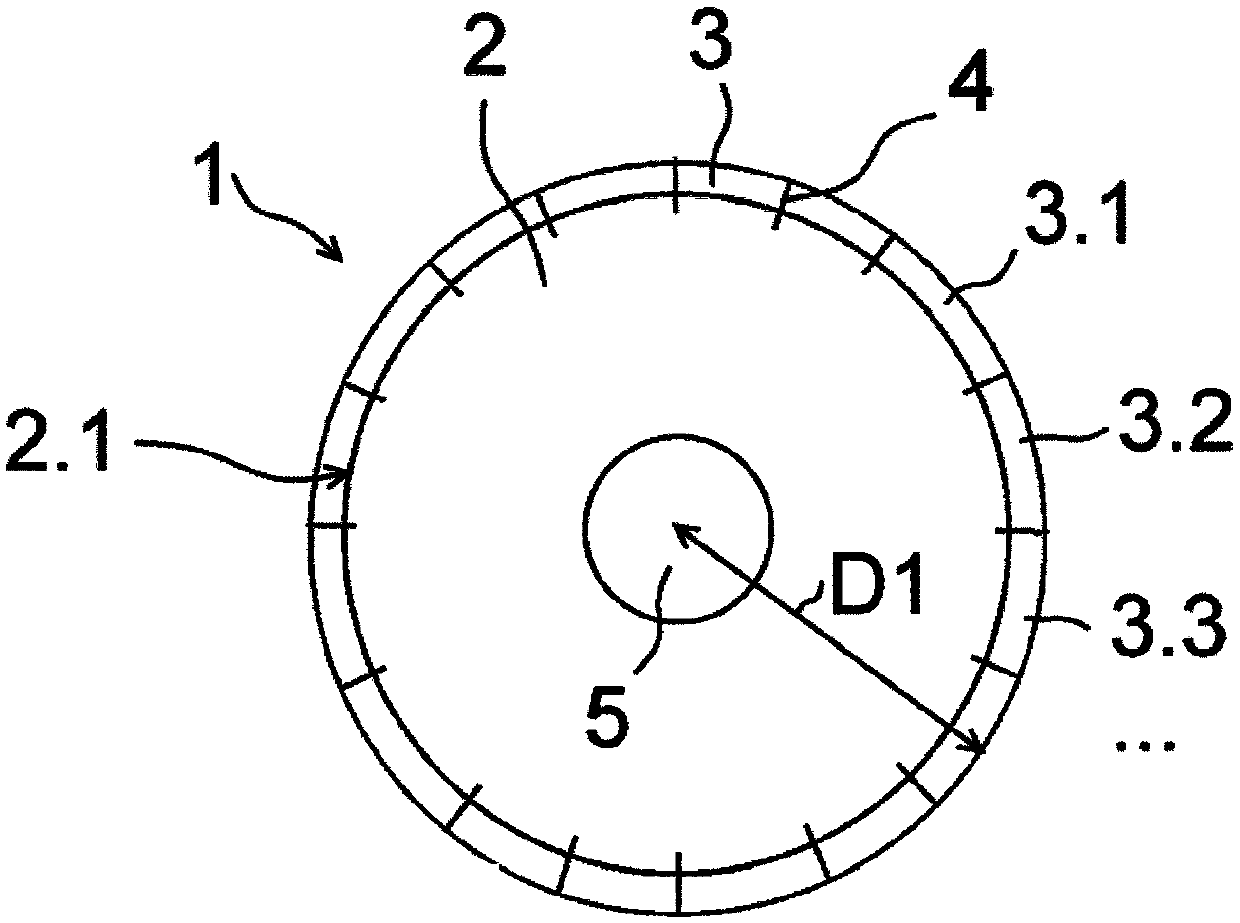

[0049] according to figure 1 A diamond saw blade 1 is shown, which has a disk-shaped core 2 and has a surrounding section 3 on its outer circumference 2.1. The segment 3 is subdivided into a plurality of segment regions 3.1, 3.2, 3.3 etc. by means of radially extending cutouts 4. FIG. The segments 3 or the segment regions 3.1, 3.2, 3.3 are preferably fastened to the core 2 by sintering, soldering, adhesive bonding or welding. Centrally provided in the core 2 is a concentric hole 5, by means of which the diamond saw blade 1 can be inserted onto the shaft 6 of a sawing tool 7 (see image 3 ).

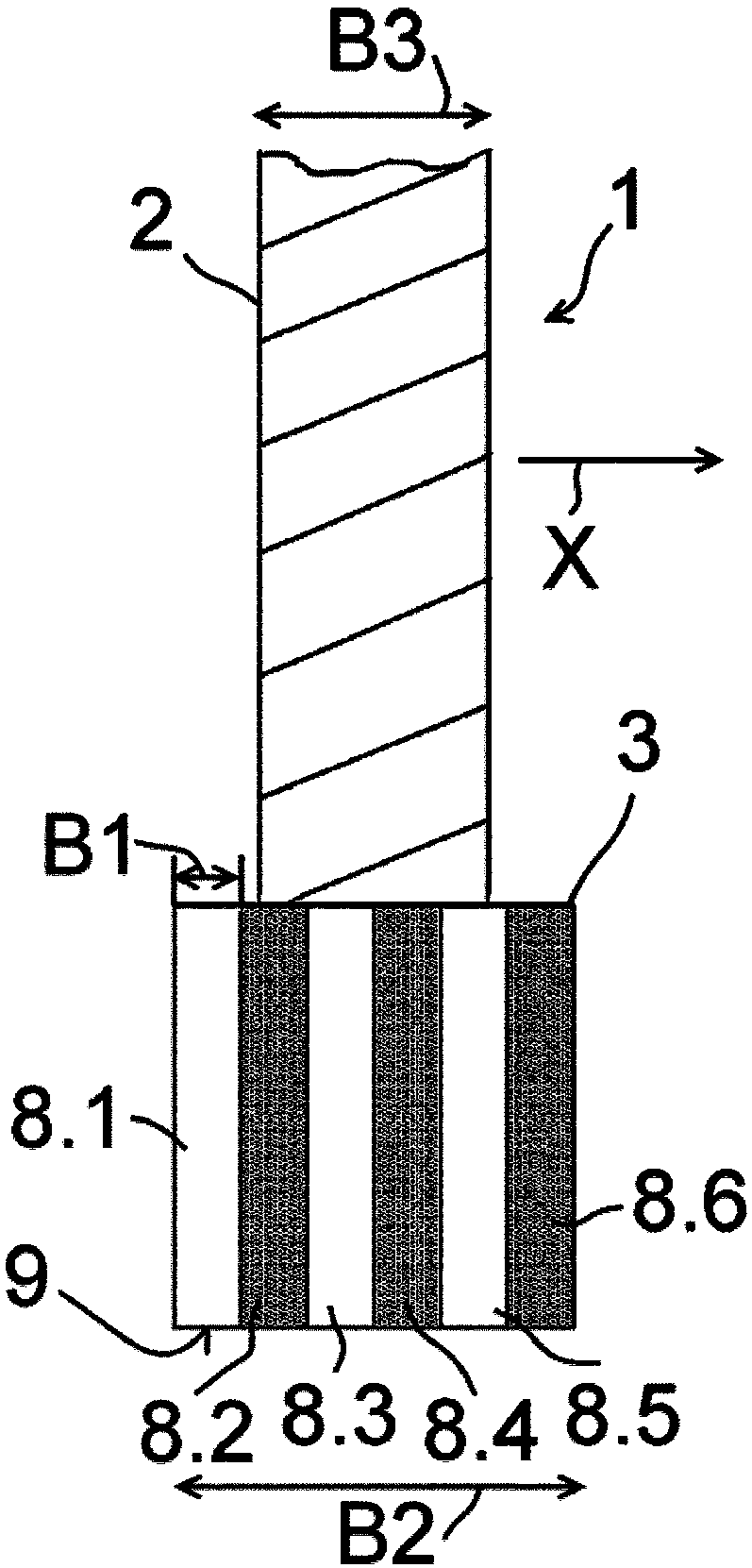

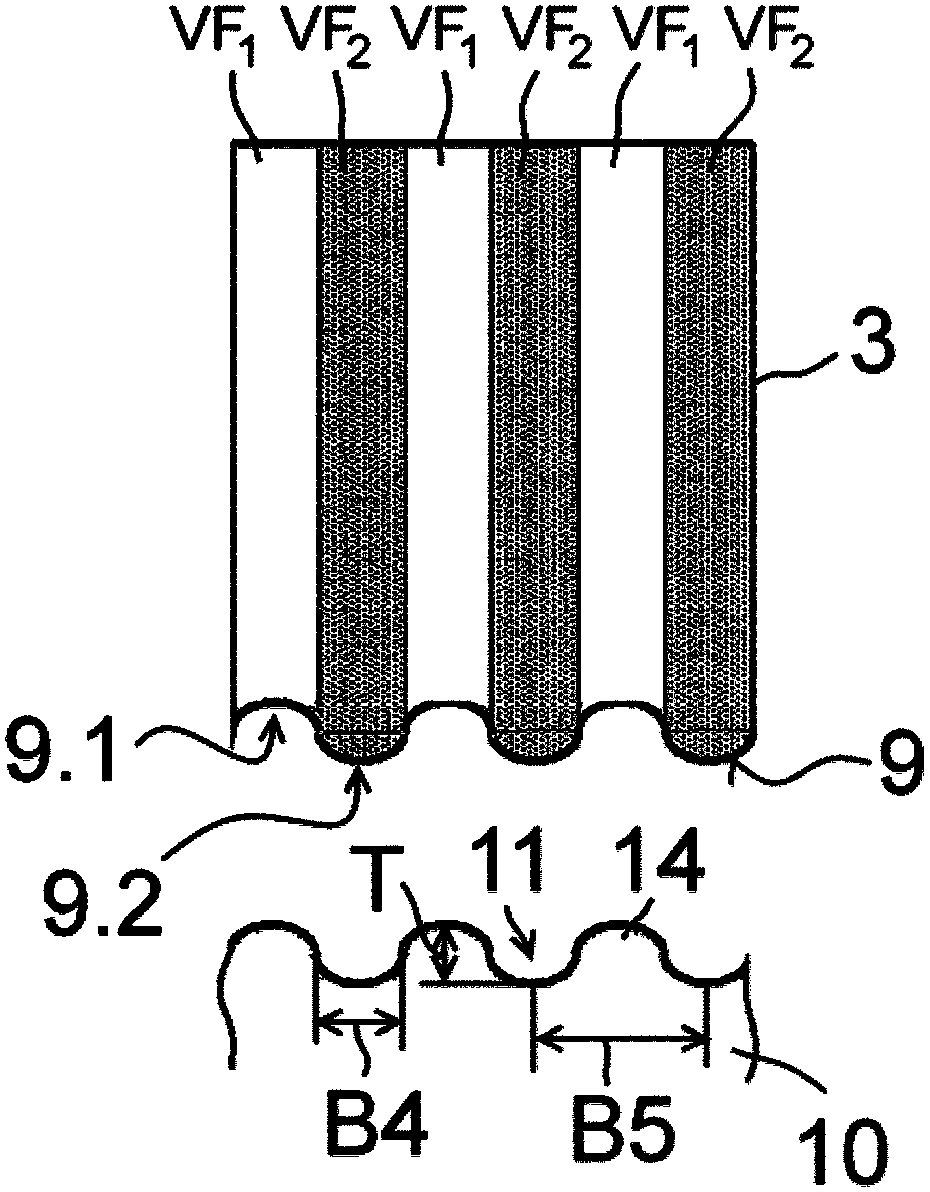

[0050] According to this embodiment, the segment 3 is formed by six layers 8.i (i=1 to 6), the layers adjoining each other planarly in the axial direction X, as in figure 2 as shown in. In the axial direction X, each layer 8.i has a layer width B1 of approximately 1 mm, so that the segments 3 have in total a segment width B2 of 6 mm. The core width B3 is approximately 3 mm, ie the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com