Dual-type wave gear device

A technology of wave gears and gears, applied in gear transmissions, transmissions, belts/chains/gears, etc., to achieve the effects of eliminating insufficient meshing, good meshing state, and increasing average pressure angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, embodiments of a duplex wave gear device to which the present invention is applied will be described with reference to the drawings.

[0067] [Overall configuration of the wave gear unit]

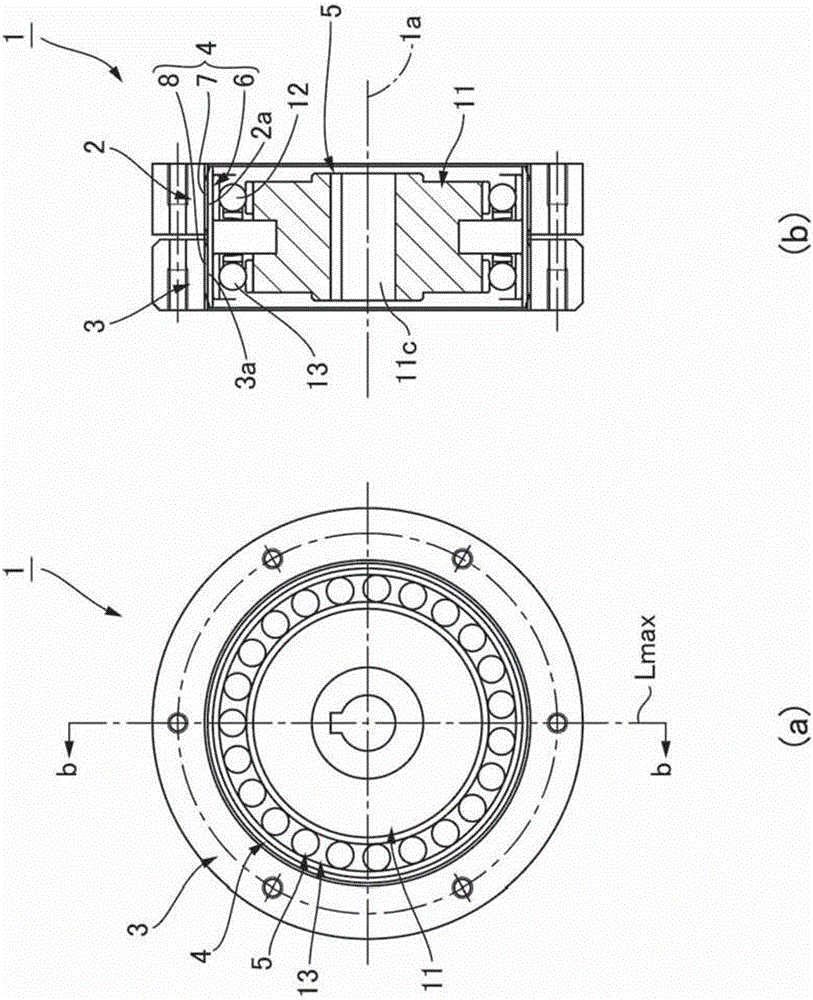

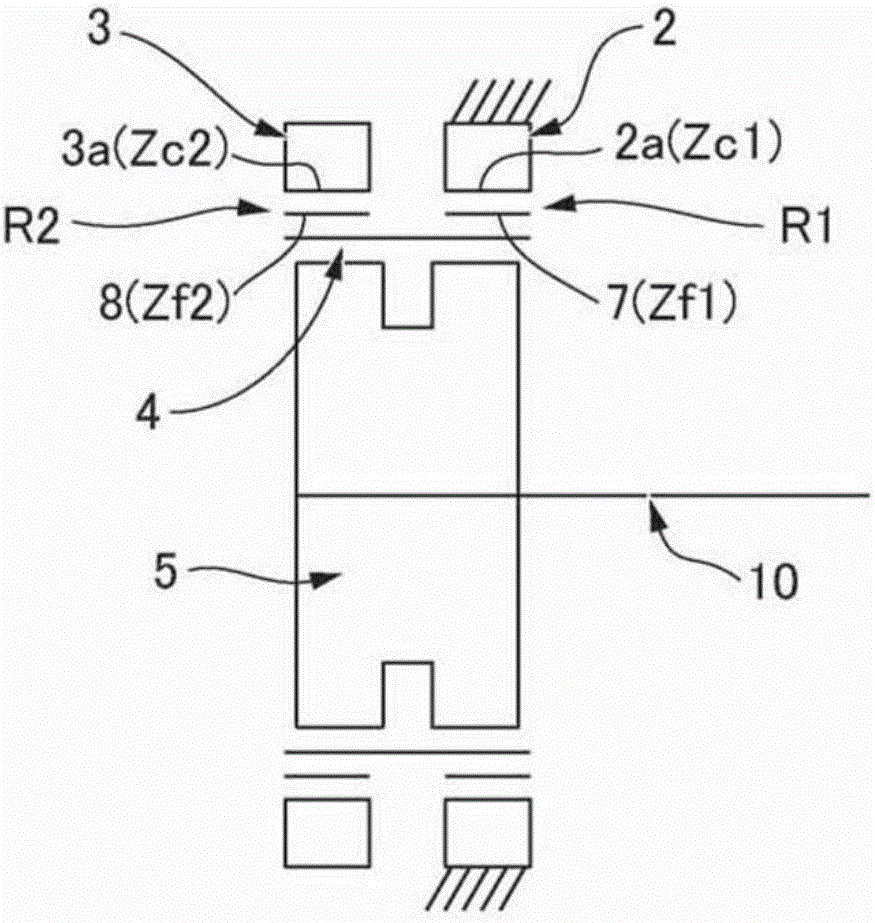

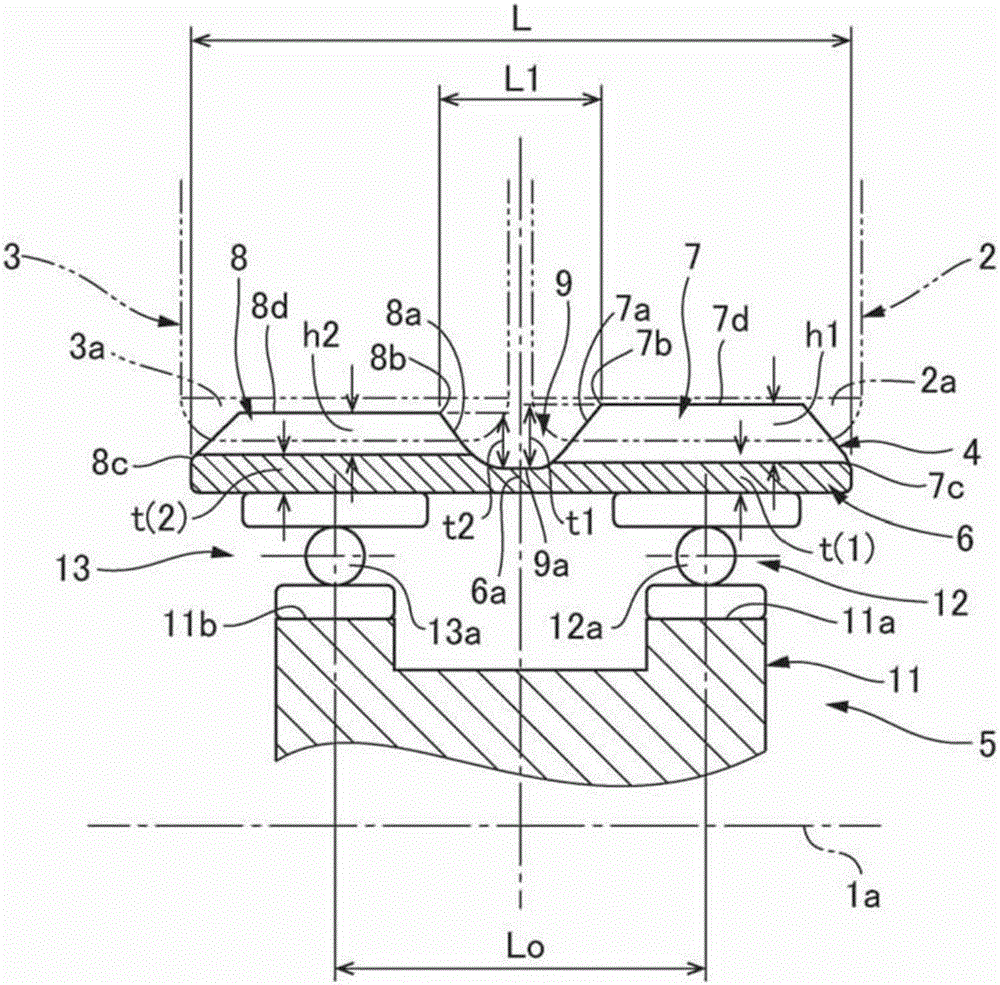

[0068] figure 1 It is an end view and a longitudinal sectional view showing a dual type wave gear device (hereinafter, simply referred to as a "wave gear device") according to an embodiment of the present invention, figure 2 is its schematic diagram. The wave gear device 1 is used as, for example, a speed reducer, and includes: an annular rigid first internal gear 2, an annular rigid second internal gear 3, and a thin elastic body capable of bending deformation in the radial direction. A flexible external tooth gear 4 in a cylindrical shape and a wave generator 5 with an elliptical profile are formed.

[0069] The first and second internally toothed gears 2 and 3 are coaxially arranged in parallel with a predetermined gap in the direction of the center axis 1a. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com