Closed planetary gear reducer

A gear reducer, planetary gear technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of small output torque, bearing capacity, impact resistance, vibration resistance, etc. Long service life, compact structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

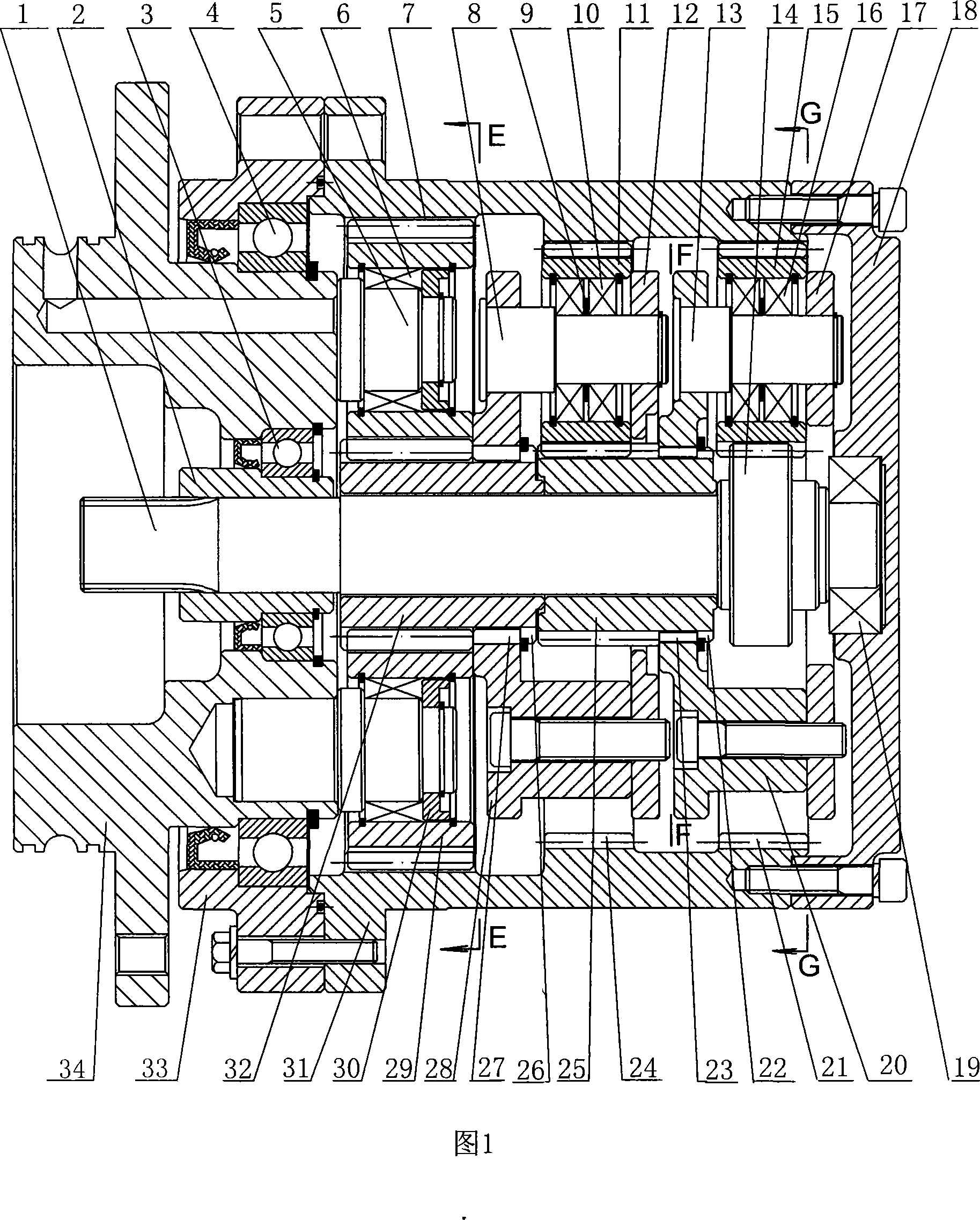

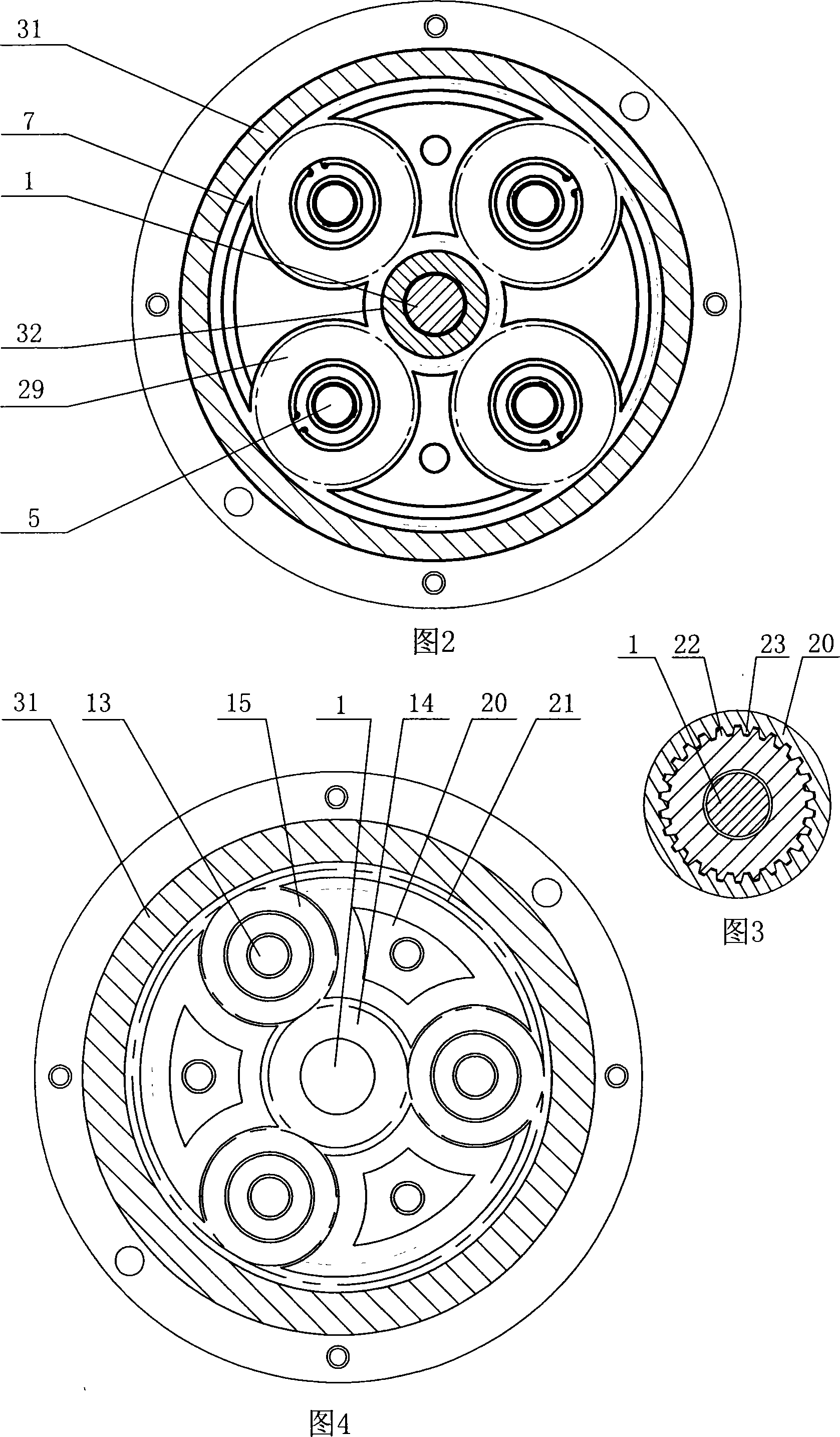

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] The first and second-level planetary carriers 20 and 28 have the same structure. There are one and second-level center wheels 23 and 27 at the middle through hole, and three arc-shaped bosses uniformly distributed on the surface and arranged at intervals between the first and second-level planet shaft holes. There are screw holes in the middle of the boss, as shown in Figure 1, Figure 2, and Figure 4.

[0013] The outer ring at one end of the three-stage planet carrier 34 and the middle through hole are respectively tightly fitted with the bushing 2 with the bearing 3 and the bearing seat 33 with the bearing 4, and there are four three-stage planetary shafts evenly distributed on one end surface hole, as shown in Figure 1.

[0014] There are through holes in the middle of two and three-stage sun gears 25,32, and one end is a gear, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com