Grabbing mechanism of bicycle conveying platform

A conveying table and bicycle technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of low horizontal movement speed of the manipulator, long waiting time for users to take the car, and failure of the gripper of the manipulator, so as to achieve the grasping action. Stable and reliable, appropriate grasping force, smooth action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

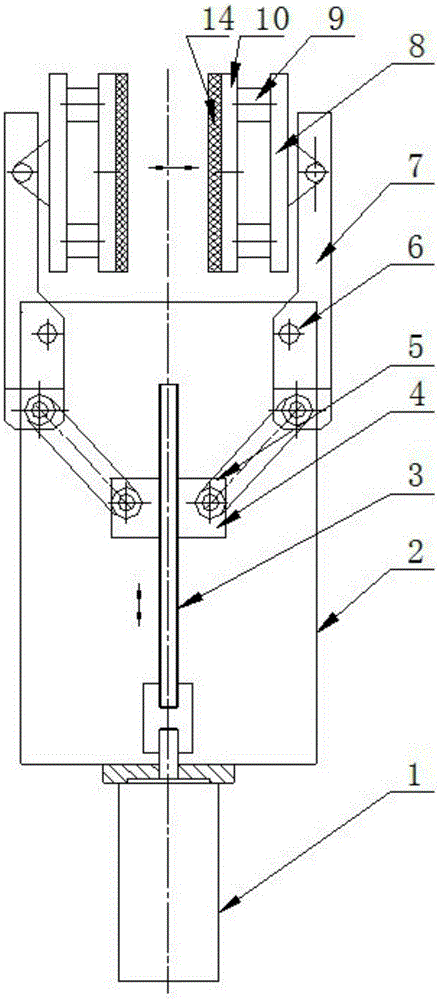

[0022] A gripper mechanism for a bicycle conveyor, which is composed of a gripper slider 2, a gripper motor 1, a screw rod 3, a screw rod sleeve 4, and a symmetrical gripper arm. The gripper motor is fixedly installed on the gripper slider. The motor rod of the gripper motor is connected to the screw rod. The end of the screw rod is connected with the screw rod sleeve. The two sides of the screw rod sleeve are connected to the tail ends of the two grasping arms. The two grasping arms are driven by the gripper motor through the screw rod. closure.

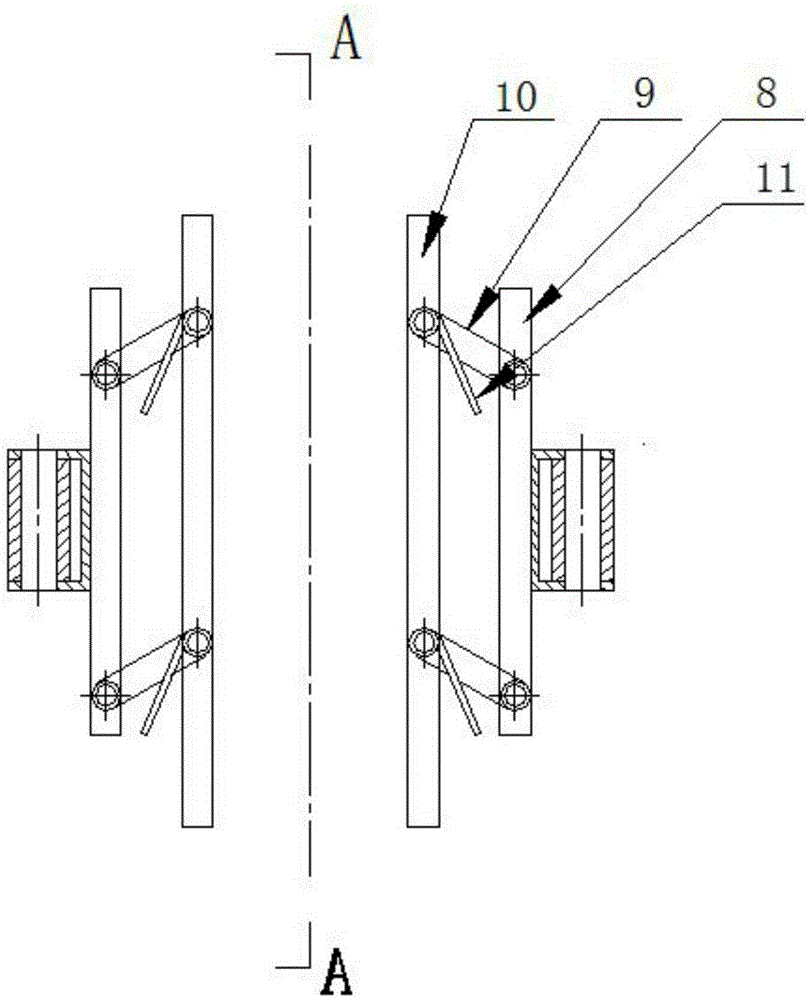

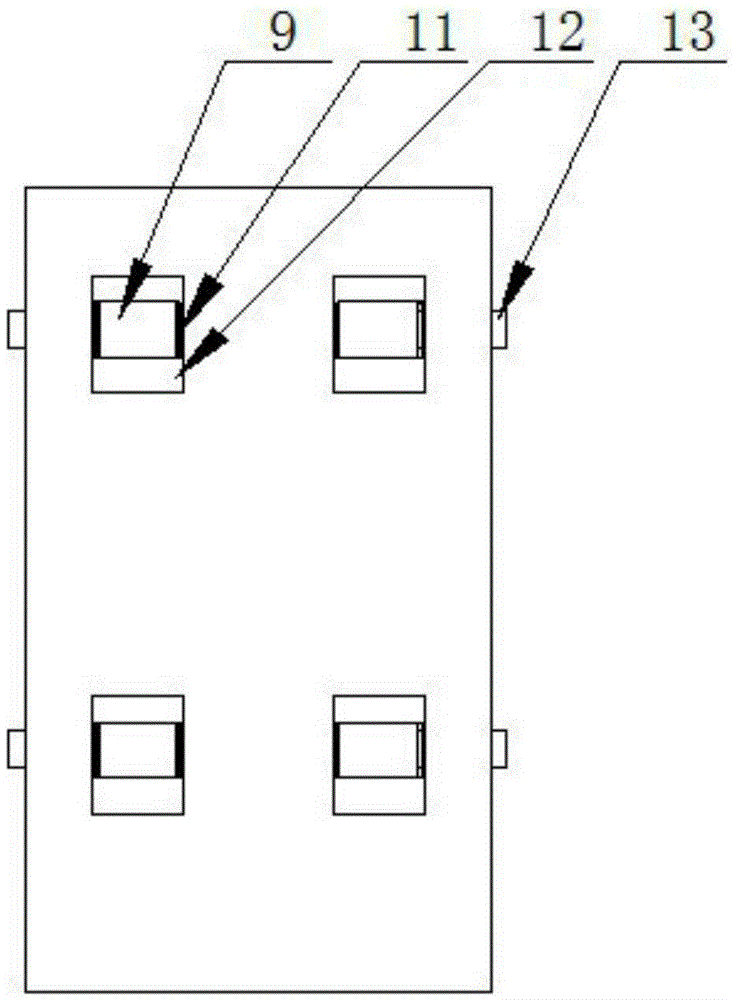

[0023] The symmetrical gripping arms are composed of a driving arm 7, an outer splint 8, an inner splint 10, a parallel link 9 and a torsion spring 11. The middle of the driving arm is hingedly mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com