Lubricant composition for low-friction sliding material and sliding mechanism using same

A technology of lubricating oil composition and sliding material, applied in the direction of lubricating composition, metal material coating process, base material, etc., to achieve the effect of excellent low friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

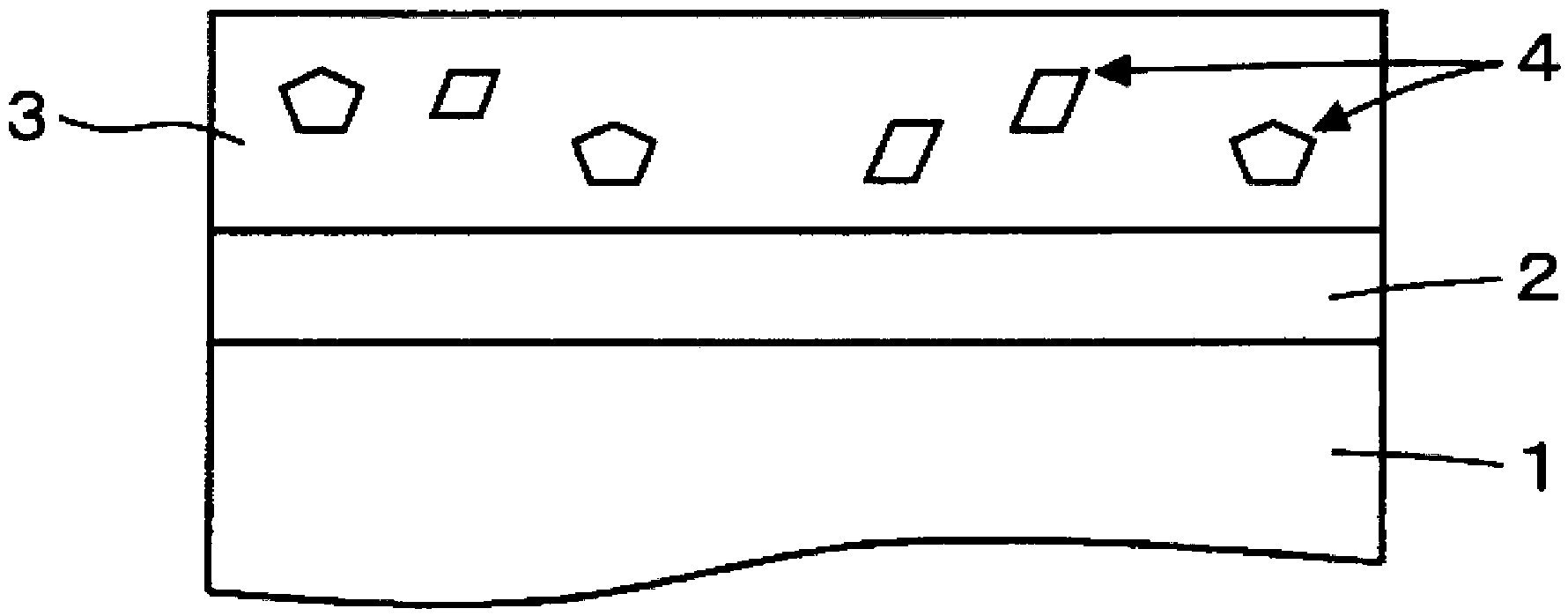

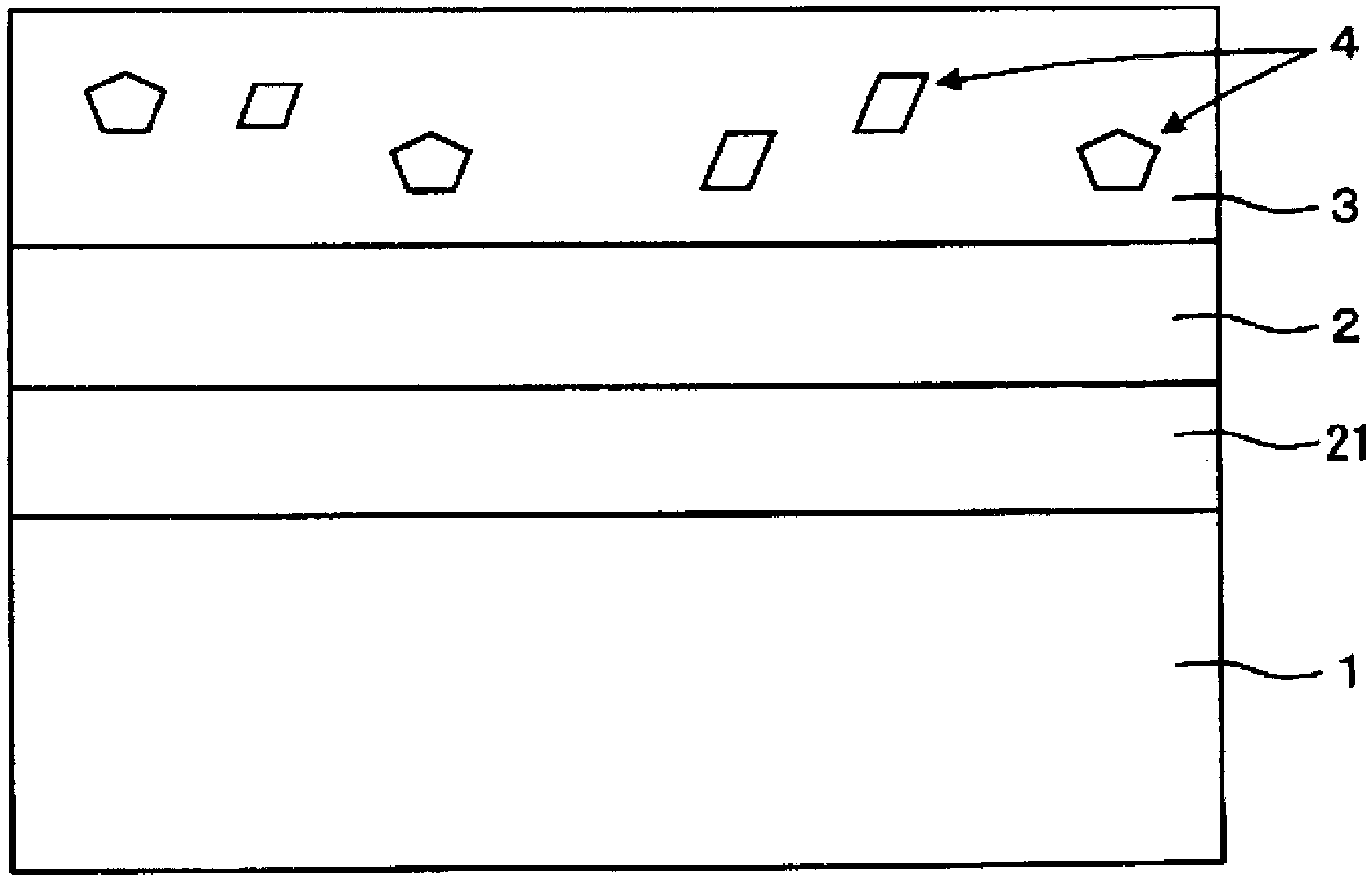

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~4

[0186] A lubricating oil composition having the composition shown in Table 1 was prepared, and the friction characteristic test shown below was carried out to obtain the friction coefficient and wear depth. The results are shown in Table 1.

[0187] In addition, DLC containing 20% hydrogen was used for the coating of the DLC-coated disk.

[0188]

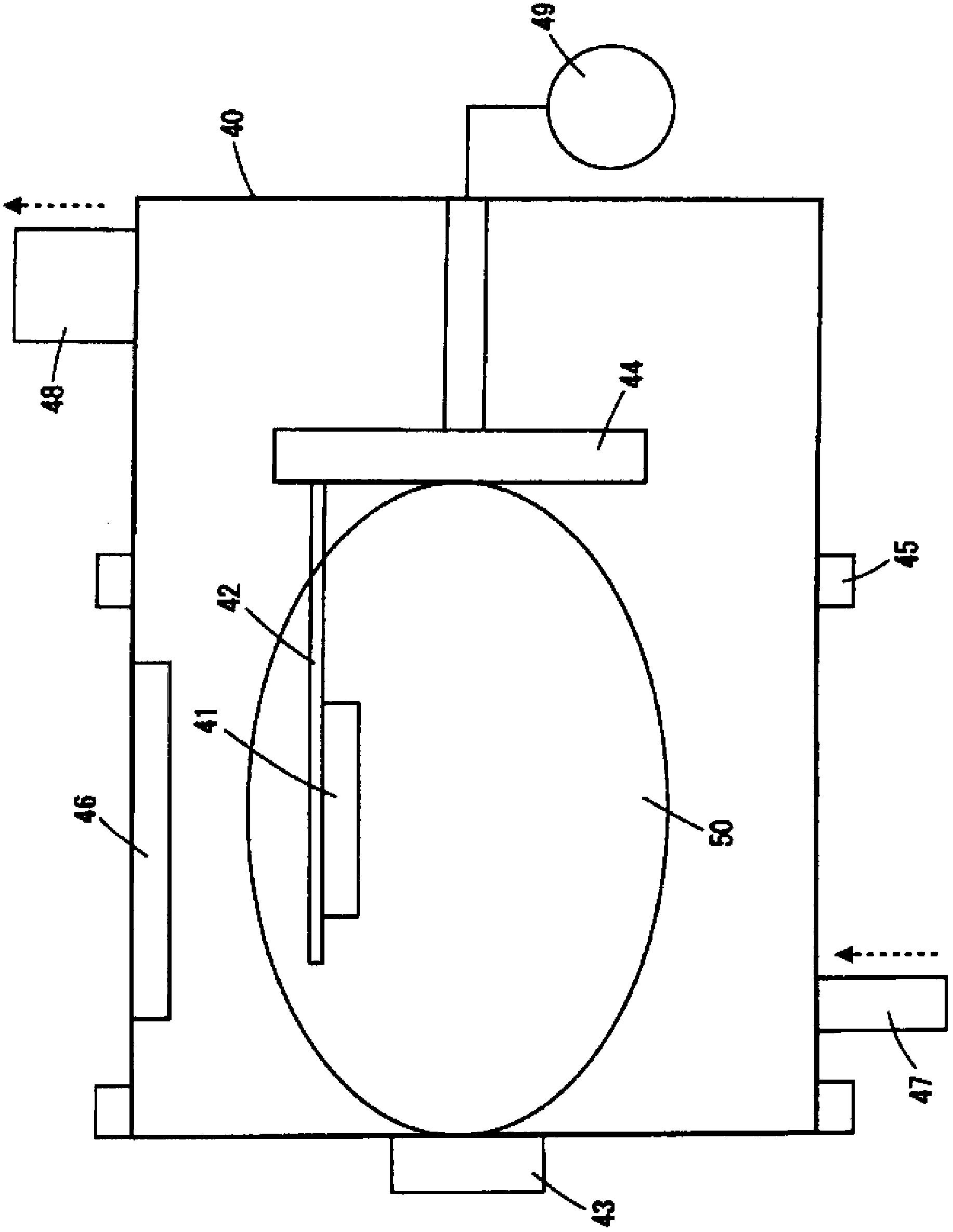

[0189] The coefficient of friction was measured by the following method using a reciprocating friction tester (SRV reciprocating friction tester manufactured by Optimar Corporation).

[0190] As a test piece, a DLC-coated disc (24 mm in diameter, 7.9 mm in thickness) was used, and several drops of sample oil (lubricating oil composition) were dropped thereon. The coefficient of friction was obtained under the conditions of a load of 400N, an amplitude of 1.5mm, a frequency of 50Hz, and a temperature of 100°C with a cylinder made of SCM420 (diameter 15mm, thickness 22mm) mounted on the top of the disc.

[0191]

[0192] The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com