Active energy ray-curable resin composition and cured article thereof

A curable composition, active energy ray technology, applied in the direction of coating, can solve the problems of low curing shrinkage, poor abrasion resistance/impact resistance, large curing shrinkage, etc., to achieve low warpage, high adhesion performance, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

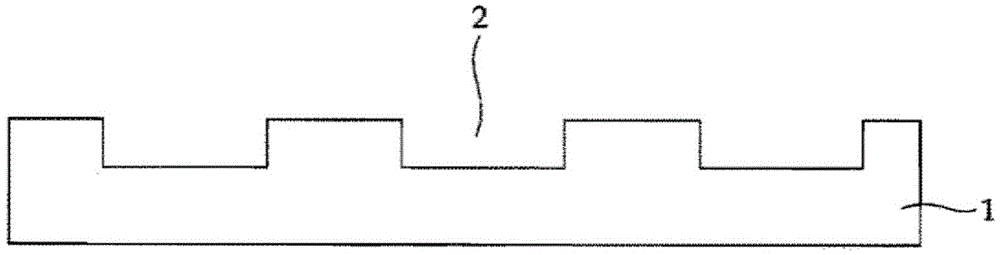

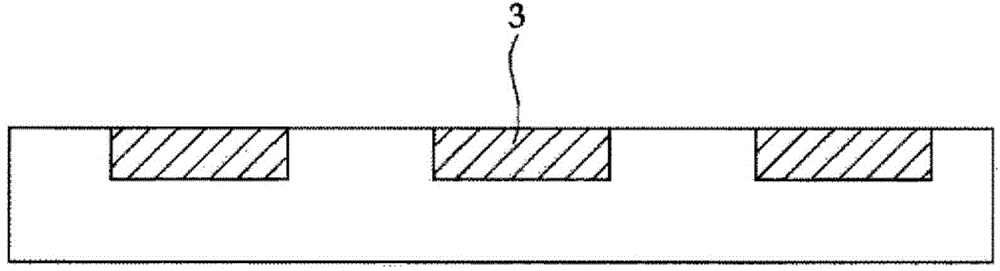

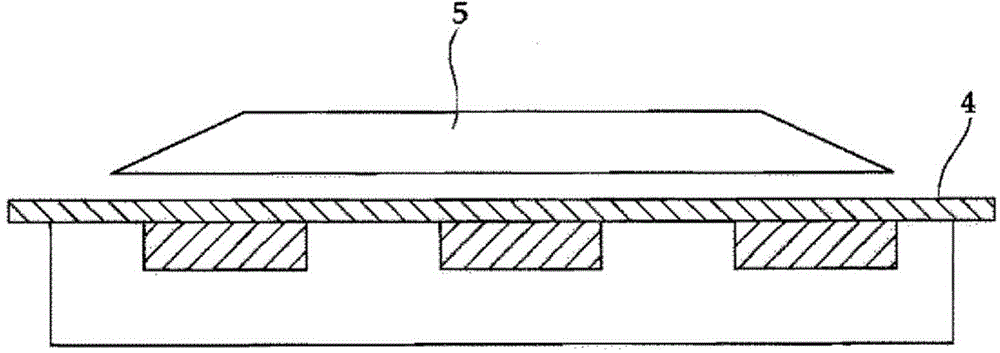

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~6

[0091] (Preparation of Active Energy Ray Curable Resin Composition)

[0092] The components shown in Table 1 and Table 2 were mixed with the resin produced as described above, stirred and dissolved at 80° C., and an active energy ray-curable resin composition was prepared.

[0093] Table 1

[0094]

[0095] In addition, the components of Table 1 are as follows.

[0096] EBECRYL 8807: Aliphatic bifunctional urethane acrylate (manufactured by Daicel-Cytec Company Ltd.)

[0097] KAYARAD RM-1001: N-acryloylmorpholine (manufactured by Nippon Kayaku Co., Ltd.)

[0098] LIGHTACRYLATE IB-XA: Isobornyl acrylate (manufactured by KYOEISHA CHEMICAL Co., LTD.)

[0099] ARONIX M-5700: 2-Hydroxy-3-phenoxypropyl acrylate (manufactured by TOAGOSEI CO., LTD.)

[0100] NK Ester A-DCP: tricyclodecane dimethanol diacrylate (manufactured by Shin-Nakamura Chemical Co., Ltd.)

[0101] CD406: Cyclohexanedimethanol diacrylate (manufactured by Sartomer Corporation)

[0102] Neoma BA-641: Ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warping | aaaaa | aaaaa |

| Warping | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com