Thread guide

A technology for yarn guides and guide elements, which is applied in the field of yarn guides, and can solve the problems of easy-to-break guide elements, small elongation at breakage of guide elements, and peeling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

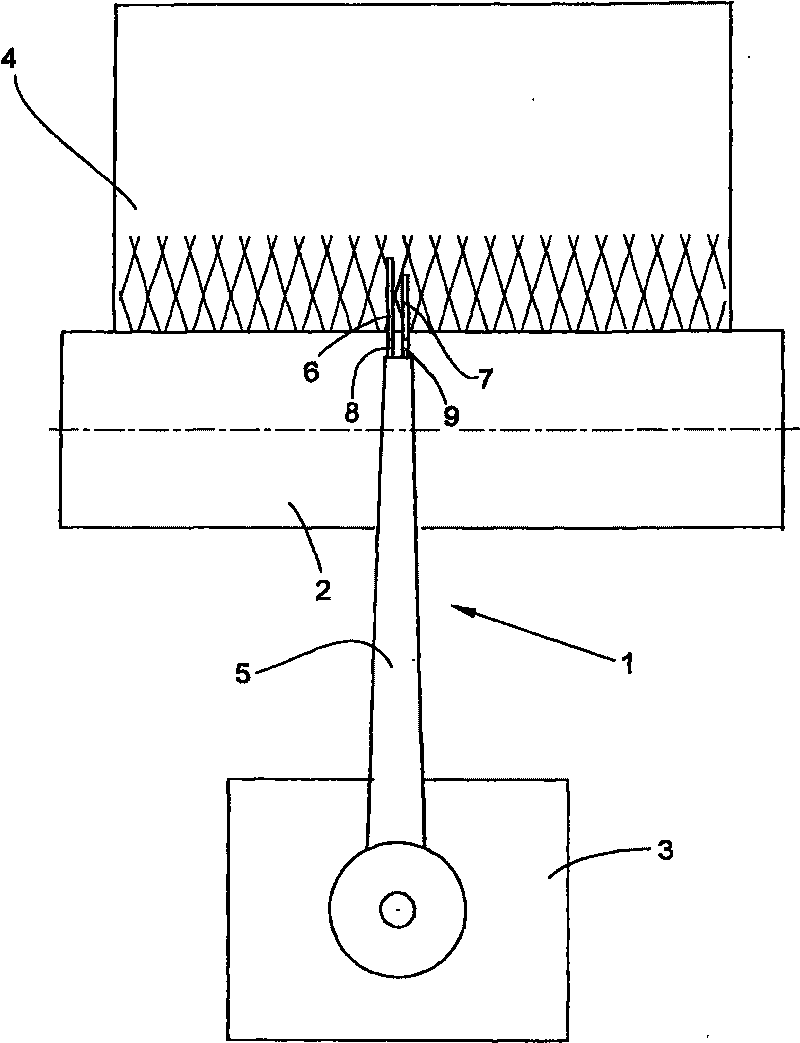

[0020] figure 1 is a schematic diagram of a yarn guide 1 according to the invention. The yarn guide 1 is finger-shaped or pointer-shaped and has a shape that tapers towards its free end. The wider end of the yarn guide 1 is connected to a separate motor drive 3 about the longitudinal axis of which the yarn guide 1 can pivot. In order to lay the yarn on a rotating bobbin 4, which in the shown embodiment is driven by a drive roller 2, the yarn guide 1 is driven along the bobbin by an independent motor drive 3 of the yarn guide 1. Width traverse.

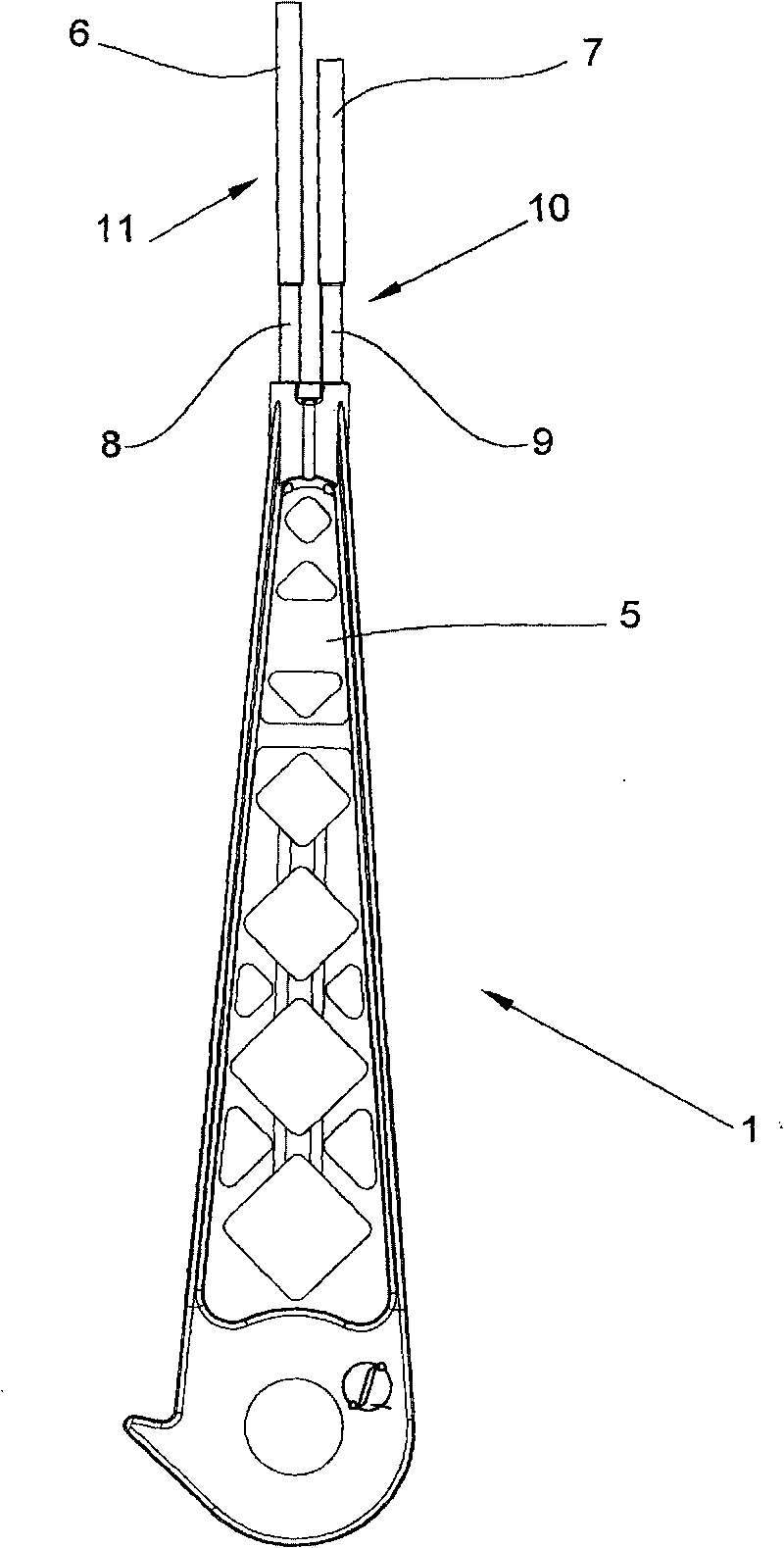

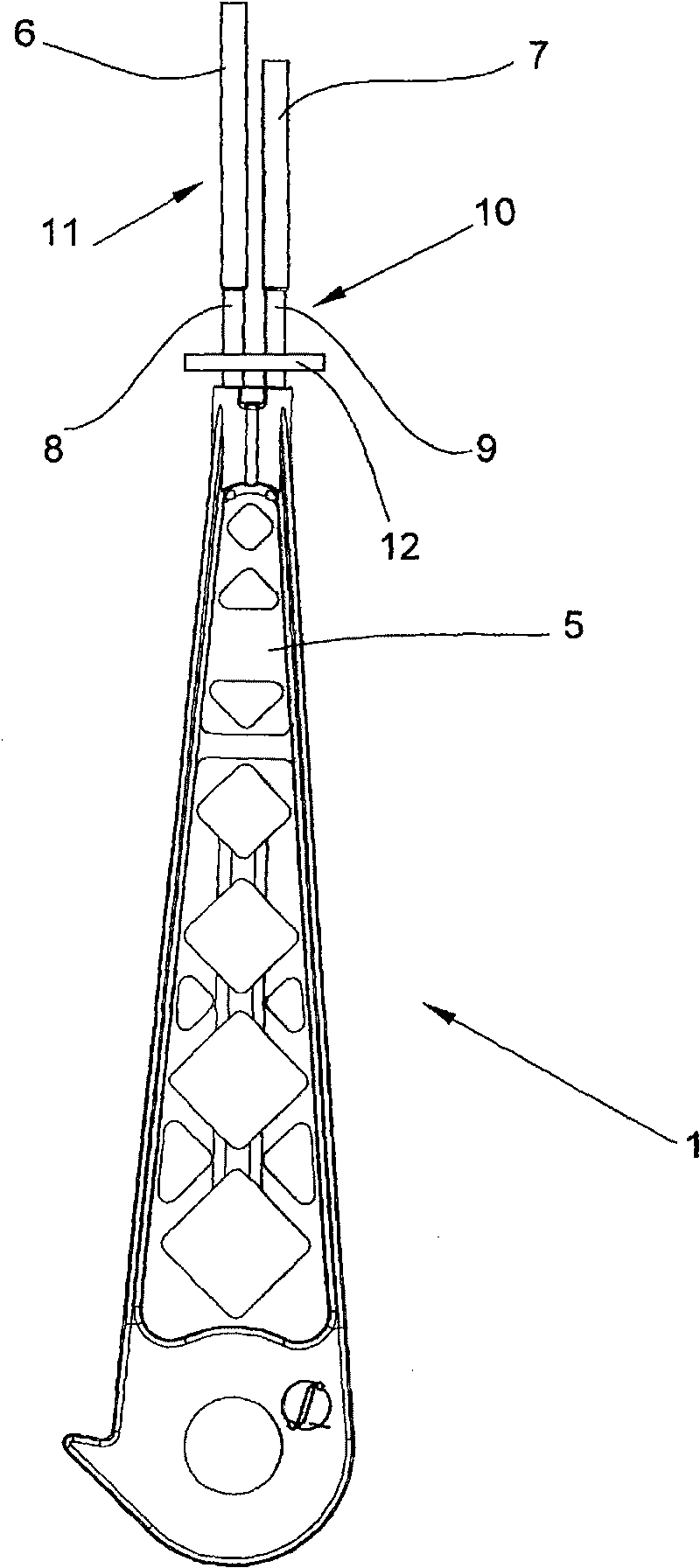

[0021] The arm 5 of the yarn guide 1 has on its narrower free end two guide elements 6, 7 made of ceramics, which are configured as cylindrical hollow bodies, such as figure 2 As shown, both guide elements 6 , 7 are fastened to the arm 5 via elastically bendable rods 8 , 9 in a form-fit and / or force-fit manner. The guide elements 6 , 7 are arranged axially at a distance from the arm 5 via elastically bendable rods 8 , 9 . The ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com