Bus door structure and sound insulating plate

A technology for sound insulation panels and doors, which is applied in the directions of doors, vehicle parts, and engine sealing, can solve problems such as defective sound insulation effects and difficult installation, and achieve the effects of improving sound insulation effects and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

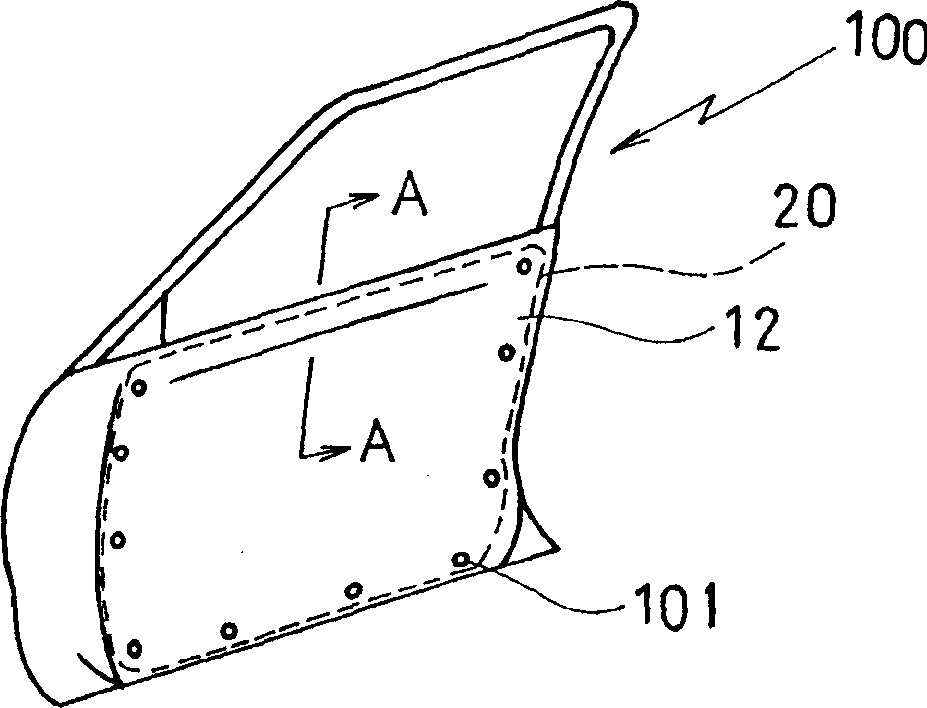

[0110] as attached figure 2 With the first embodiment of the invention shown, there is a problem that both sides of the baffle panel 20 or its lower end protrude from the door liner 12 when the baffle panel 20 is secured by the raised ends and hangs down.

[0111] In this case, the sound insulation panel 20 protrudes from the door lining 12, the overall appearance of the car door will be damaged, and its sound insulation effect will also be damaged.

[0112] Therefore, the purpose of the fourth embodiment of the present invention is to tightly fix the end of the baffle disposed between the door inner panel and the door liner, and to position the baffle so as not to protrude from the door liner.

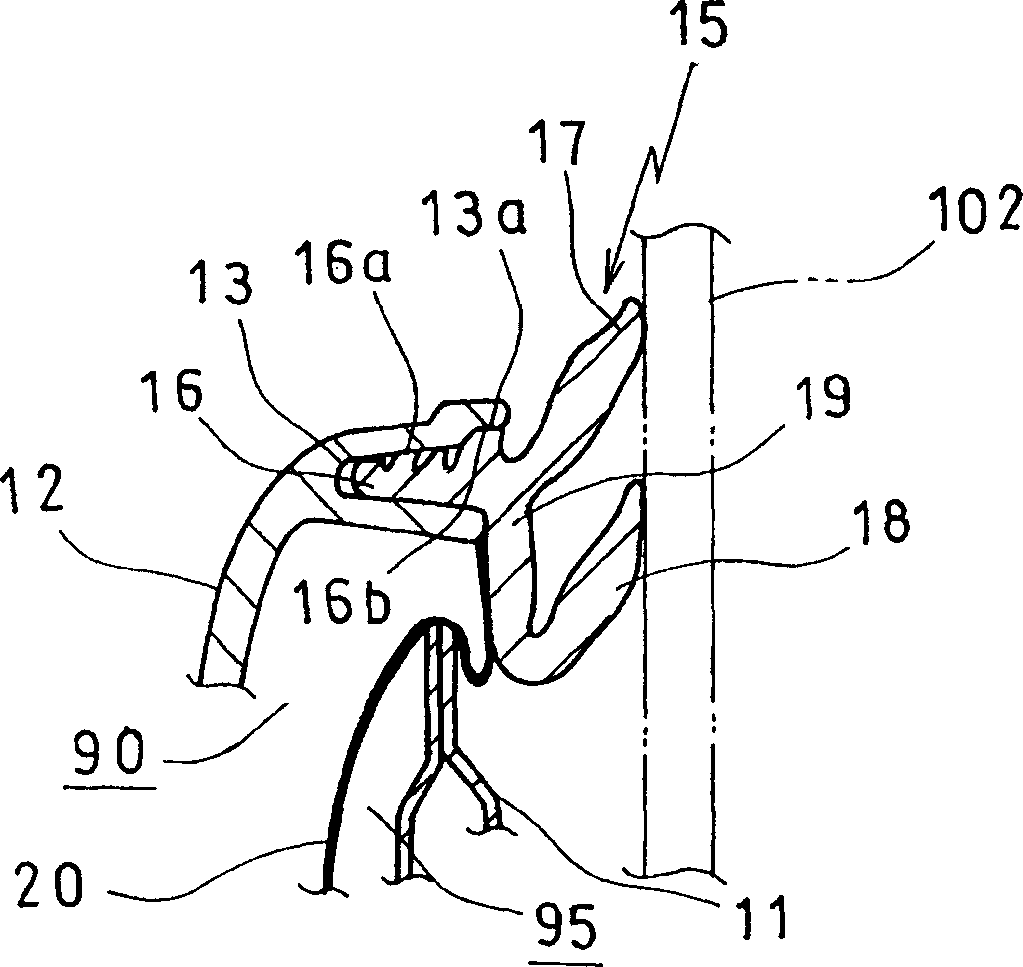

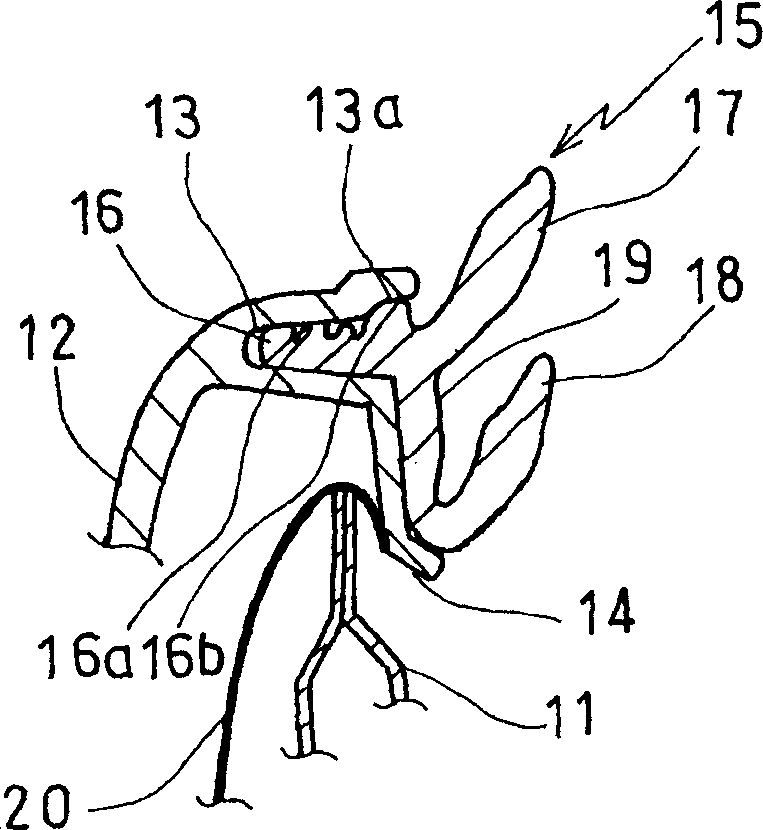

[0113] Refer to attached Figure 12 with 13 , the fourth embodiment of the car door structure of the present invention will be described below. attached Figure 12 is an exploded perspective view showing the door structure of a passenger car according to a fourth embodiment of th...

no. 5 example

[0117] Refer to the attached Figure 14-16 A vehicle door structure in a fifth embodiment of the present invention will be described. attached Figure 14 is a perspective view showing a door structure for a car according to a fifth embodiment of the present invention. attached Figure 15 An enlarged cross-sectional view of the attached Figure 14 Major components in the structure shown. In addition, with Figure 16 The perspective view shows the attached Figure 15 Clamping addition to the clip shown in .

[0118] According to the car door structure in this embodiment, as attached Figure 14 As shown, the acoustic panel 20 is provided with clips 40 on its side as its fixing means, instead of using pins 39 as described in the fourth embodiment.

[0119] Each clip 40 includes a head 42 that protrudes above the neck, an umbrella 43 that protrudes below the neck 41 is larger in size than the head 42, and a leg 44 is formed on the umbrella. 43 below.

[0120] as attached ...

no. 6 example

[0123] The purpose of the sixth embodiment of the present invention is similar to that of the fourth embodiment, in order to securely secure the edge portion of the baffle panel depending from between the door inner panel and the door liner, and to position the panel so that it does not protrude from the door liner. stand out.

[0124] Refer to attached Figure 17 , 18 and 19, the car door structure in the sixth embodiment of the present invention will be described below.

[0125] attached Figure 17 The perspective view of shows the car door structure in the sixth embodiment of the present invention. attached Figure 18 is attached Figure 17 An enlarged cross-sectional view of line F-F in . attached Figure 19 The sectional view of shows the situation when the baffle is pressed into the groove and fixed in it. along with Figure 17 The enlarged sectional view made by the E-E line and the attached in the first operation form figure 2 Corresponding.

[0126] The sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com