Novel carbide-reinforced cobalt-based superalloy regulator and preparation method thereof

A high-temperature alloy and carbide technology, which is applied to attack equipment, furnace types, manufacturing tools, etc., can solve problems such as low service life, and achieve the effect of prolonging service life and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-28

[0066] Examples 1-28 respectively provide novel carbide-strengthened cobalt-based superalloy regulators with different ratios of raw material components, and the ratio of raw material components of the regulators corresponding to each embodiment is shown in Table 1.

[0067] The raw material component distribution ratio of the regulator of table 1 embodiment 1-28

[0068]

[0069]

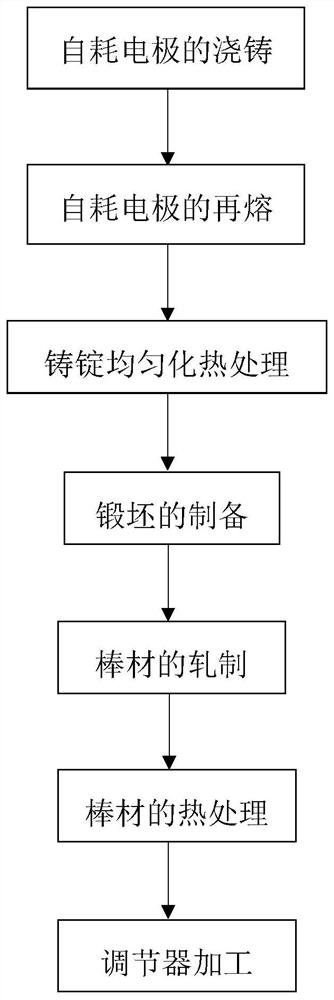

[0070] A method for preparing a novel carbide-reinforced cobalt-based superalloy regulator, specifically comprising the following steps:

[0071] (1) Casting of consumable electrodes: using vacuum induction melting technology, the new carbide-reinforced cobalt-based superalloy prepared from the aforementioned raw materials is cast to form consumable electrodes;

[0072] (2) Smelting of the consumable electrode: using the electroslag remelting continuous directional solidification crystallizer to melt the consumable electrode cast in step (1) to prepare an ingot;

[0073] (3) Ingot homogeniza...

Embodiment 29-48

[0083] Carry out embodiment 29-48 according to the distribution ratio of raw material components in embodiment 20, the difference is that the parameters of each step of embodiment 29-38 are as shown in table 3, and the parameters of each step of embodiment 39-48 are as shown in table 4 .

[0084] Each step parameter in the regulator preparation method of table 3 embodiment 29-38

[0085]

[0086]

[0087] Each step parameter in the regulator preparation method of table 4 embodiment 39-48

[0088]

[0089]

Embodiment 49-60

[0091] Examples 49-60 were carried out according to the ratio of raw material components and the preparation method of Example 46, except that the corresponding slag composition of Examples 49-60 is shown in Table 5.

[0092] The slag system composition in the regulator preparation method of table 5 embodiment 49-60

[0093]

[0094]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com