Detachable multivalve cabin section abutting heat protection structure

A flap-type, heat-proof technology, used in projectiles, self-propelled bombs, offensive equipment, etc., can solve the problems of low efficiency, inconvenient assembly and disassembly, etc., achieve low operation efficiency, meet the requirements of rapid disassembly and assembly, good isolation heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

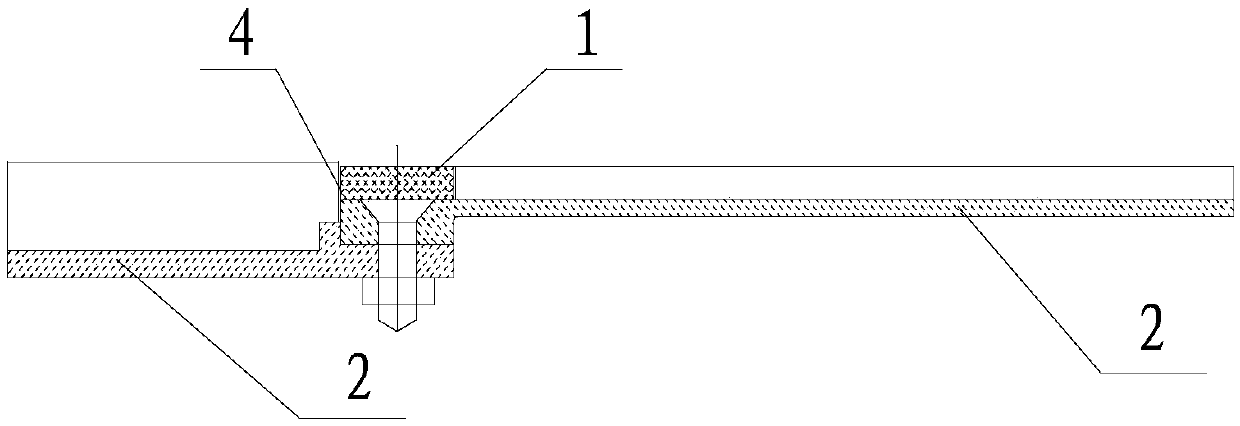

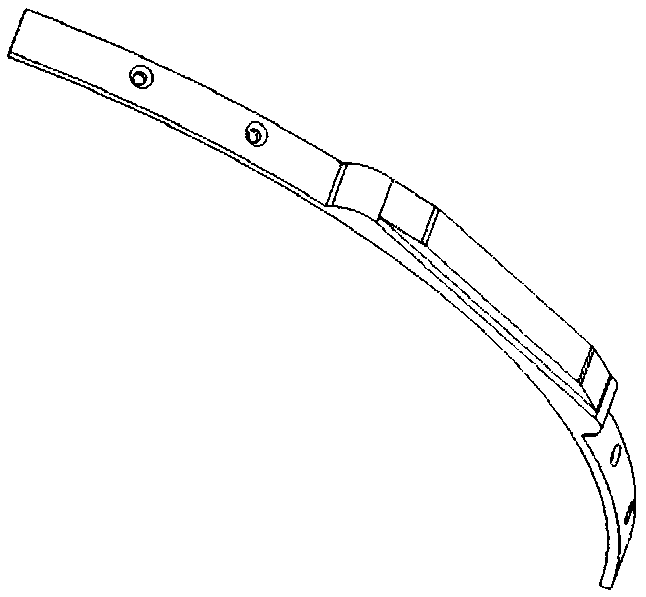

[0027] The multi-lobed heat-proof ring structure at the joint between the hypersonic aircraft cabins is divided into two categories according to the different docking sections, the actuator section and the non-actuator section. The aerodynamic shape of the actuator section is more complicated, so many The shape of the petal-type heat-proof ring structure should also be transitionally designed with its curved surface. However, no matter whether the structure of the multi-lobed heat-proof ring is complex or not, its structure is composed of a multi-lobed heat-proof ring 1, a docking frame 2, a countersunk screw 3, and a silicone rubber 4. The structural composition and installation diagram are as follows figure 1 shown.

[0028] The docking frame 2 between cabin sections is radially connected by countersunk screws, and the connecting thread is processed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com