High-temperature-resistant composite color steel tile and production equipment thereof

A technology for production equipment and color steel tiles, which is applied in mechanical equipment, metal processing equipment, roofs using tiles/slate tiles, etc. The effect of high temperature resistance, improved high temperature resistance and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] High temperature resistant coatings are prepared by the following steps:

[0038] Step 1. Add 15.6 mL of siloxane monomer to a four-necked flask equipped with a condenser, thermometer, dropping funnel and stirrer, stir to raise the temperature, add 8.5 mL of deionized water and 0.65 mL of catalyst to the dropping funnel, When the temperature in the four-neck flask rose to 65°C, deionized water and catalyst were added dropwise, and the temperature was continued to rise to 85°C, and the reaction was carried out at a constant temperature for 3 hours, and finally, vacuum distillation was carried out for 2 hours, and the pressure was set at 0.06MPa to obtain a silicone prepolymer;

[0039]Step 2: Weigh 9.5mL of epoxy resin, 13.5mL of acetone and 6.8mL of ethyl acetate into the reaction kettle, heat in a water bath until the epoxy resin is completely melted, then add 5.8mL of silicone prepolymer, stir and heat up to 80 At ℃, add 0.3mL catalyst dropwise to raise the temperatur...

Embodiment 2

[0042] High temperature resistant coatings are prepared by the following steps:

[0043] Step 1. Add 13.6mL siloxane monomer into a four-necked flask equipped with a condenser, thermometer, dropping funnel and stirrer, stir to raise the temperature, add 6.5mL deionized water and 0.55mL catalyst into the dropping funnel, When the temperature in the four-necked flask rose to 65°C, deionized water and catalyst were added dropwise, and the temperature was continued to rise to 85°C, and the reaction was carried out at a constant temperature for 3 hours. Finally, vacuum distillation was carried out for 2 hours, and the pressure was set at 0.07 MPa to obtain a silicone prepolymer;

[0044] Step 2. Weigh 6.5mL of epoxy resin, 10.2mL of acetone and 4.1mL of ethyl acetate into the reaction kettle, heat in a water bath until the epoxy resin is completely melted, then add 3.5mL of silicone prepolymer, stir and heat up to 80 At ℃, add 0.1mL catalyst dropwise to raise the temperature to 95℃...

Embodiment 3

[0047] The high temperature resistant composite color steel tile is prepared by the following steps:

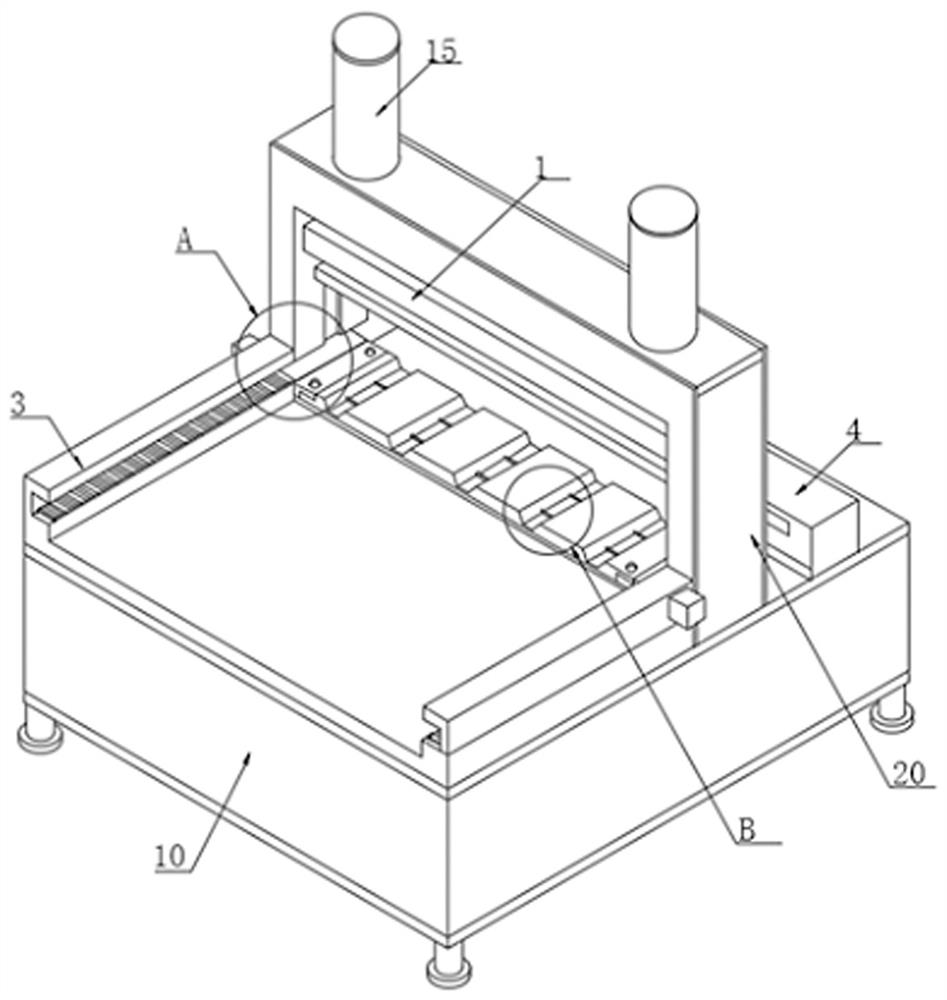

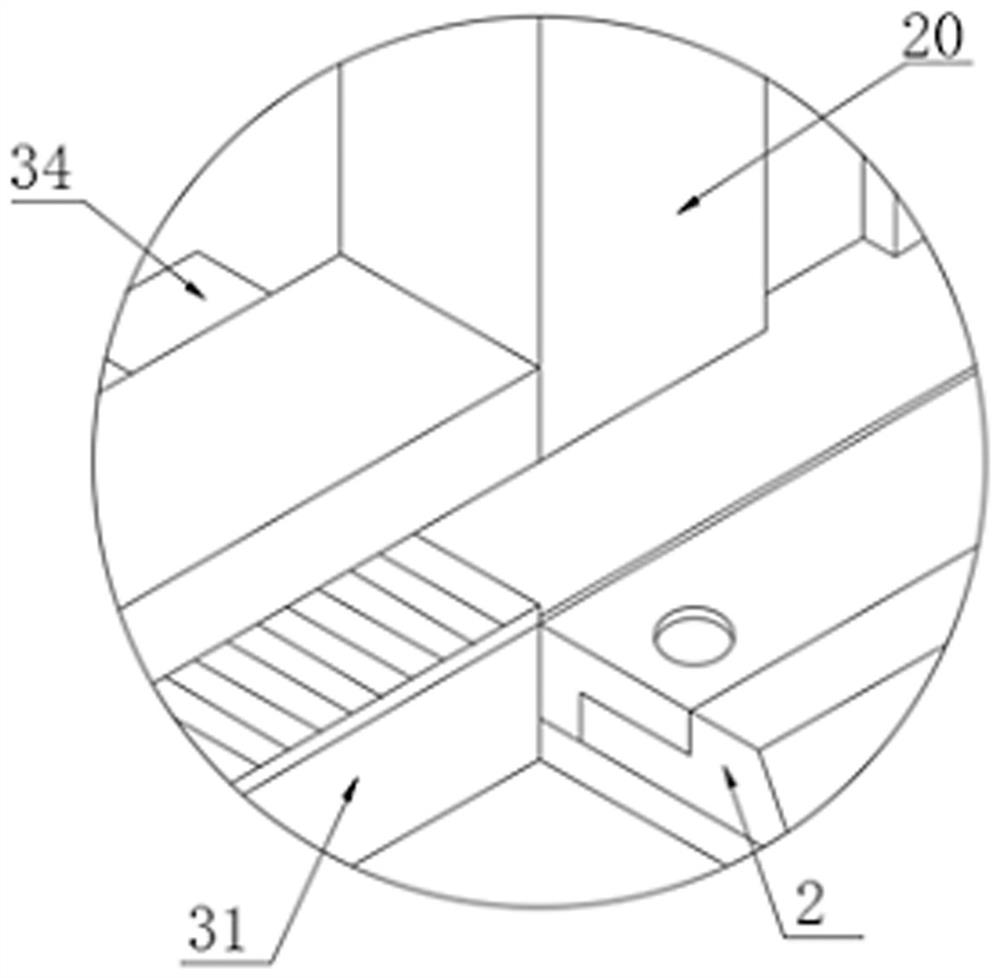

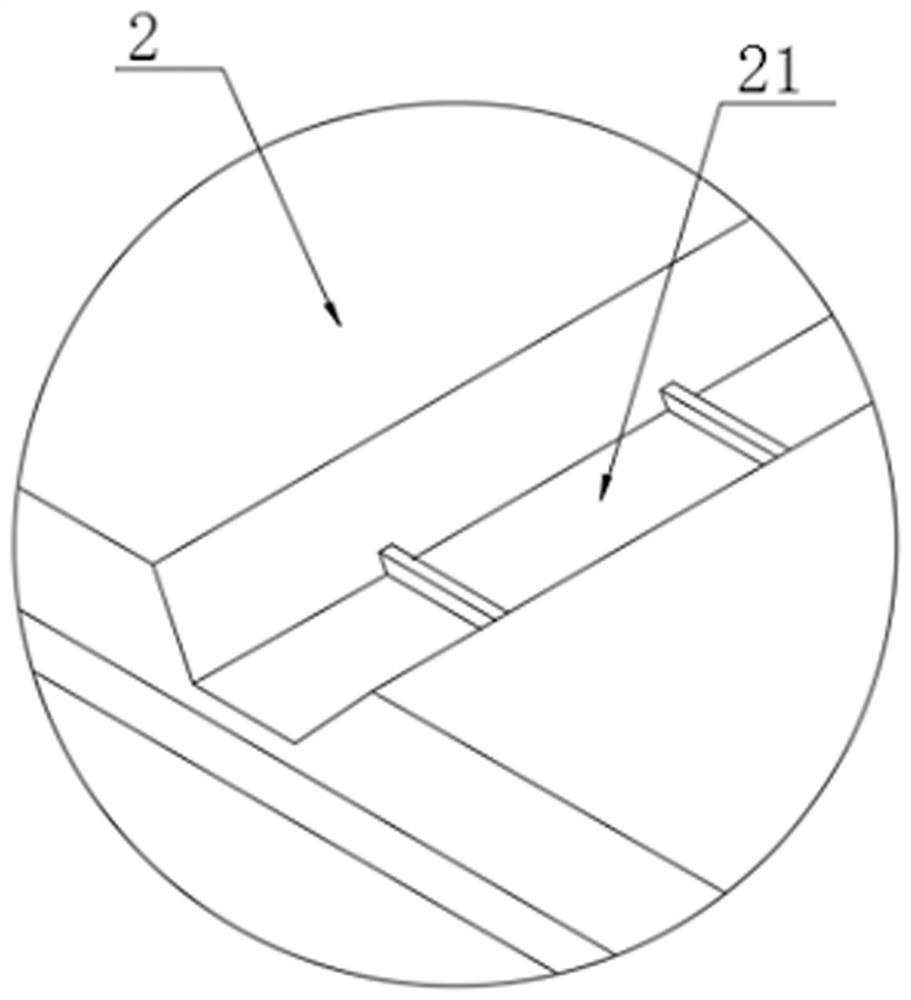

[0048] The first step is to use production equipment to cold-press the composite steel plate to obtain composite color steel tiles;

[0049] In the second step, the high-temperature-resistant paint prepared in Example 1 is evenly coated on the surface of the composite color steel tile, and dried at room temperature to obtain a high-temperature-resistant composite color steel tile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com