Overheating protection circuit based on p-n junction forward voltage drop temperature characteristic

An overheat protection circuit, forward voltage drop technology, applied in emergency protection circuit devices, emergency protection devices with automatic disconnection, circuit devices, etc., can solve the nonlinear relationship between resistance and temperature, and the consistency and exchange of components Poor performance, easy aging of components, etc., to achieve the effects of good stability, sensitive protection, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

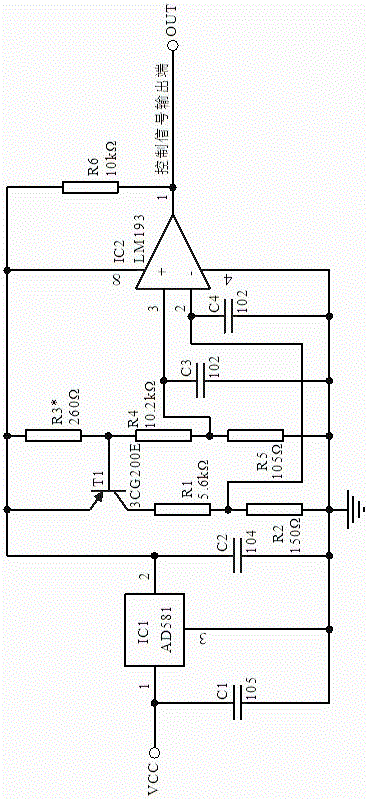

[0012] The technical scheme of the patent of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] like figure 1 As shown, an overheating protection circuit based on the temperature characteristic of PN junction forward voltage drop is composed of a voltage conversion circuit and an over-temperature control signal conversion circuit. The voltage conversion circuit is composed of a first integrated circuit IC1, a first capacitor C1, and a second capacitor C2: one end of the first capacitor C1 is connected to pin 1 of the first integrated circuit IC1 to the power supply voltage input end, and the first integrated circuit IC1 Pin 2 of the first capacitor C2 is connected to one end of the second capacitor C2, the first capacitor C1, the other end of the second capacitor C2 and pin 3 of the first integrated circuit IC1 are grounded. The over-temperature control signal conversion circuit is composed of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com