Environment-friendly degradable aromatic polyurethane foaming material and preparation method thereof

A foaming material and polyurethane technology, applied in the field of foaming materials, can solve the problems of lavender powder's aroma volatilization quickly, long-lasting effect, and affecting comfort, so as to improve biodegradable rate, long-lasting aroma effect, and reduce density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

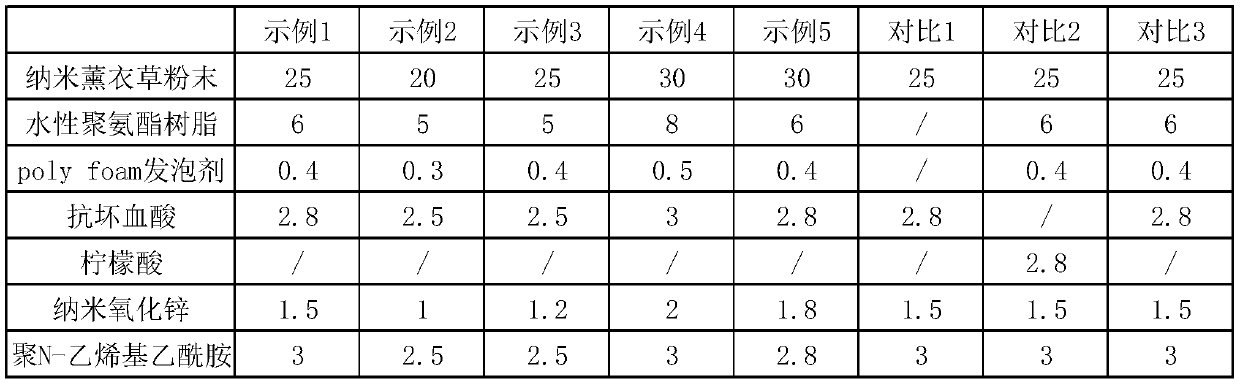

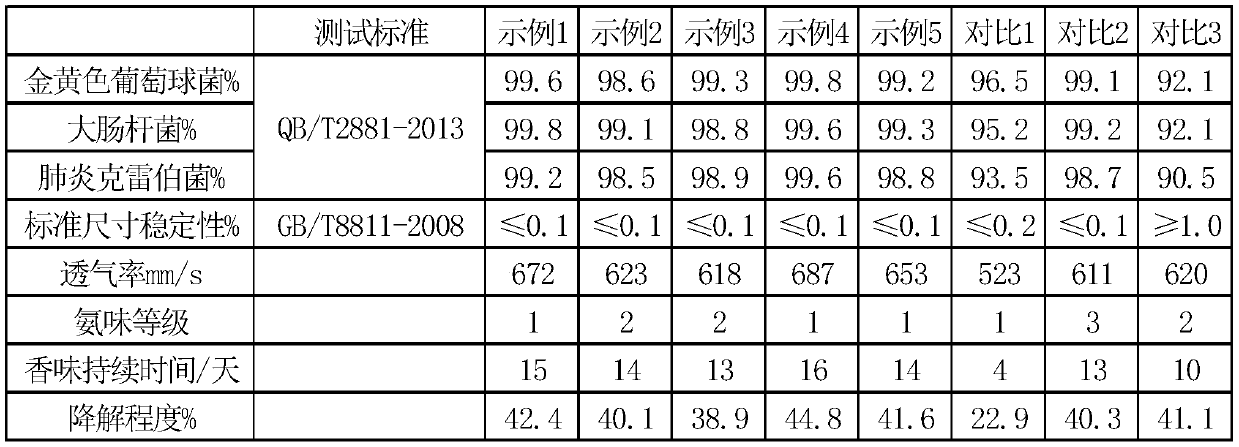

[0024] The present invention provides an environmentally friendly and degradable aromatic polyurethane foam material. The environmentally friendly and degradable aromatic polyurethane foam material is formed by mixing and foaming a component A and a component B, wherein: the component B is an aliphatic isocyanate , Component A includes the following components in parts by weight: 80-100 parts of composite polyol, 4-8 parts of foaming agent, 0.5-0.8 parts of catalyst, 0-1 part of cross-linking agent, 0.5-1 part of 1 part of foam stabilizer and 15 to 25 parts of modified lavender particles, wherein the composite polyol is composed of 50% to 65% by mass of vegetable oil-based polyether polyol, 20% to 30% of polypropylene oxide It is composed of ether and 15% to 25% alcoholysis product of polyurethane insole.

[0025] Wherein: the vegetable oil-based polyether polyol is castor oil polyol; the polypropylene oxide ether uses sorbitol as the starting agent, the hydroxyl value is 430-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com