Environmentally friendly and degradable aromatic polyurethane foam material and preparation method thereof

A foaming material, polyurethane technology, applied in the field of foaming materials, can solve the problems of lavender powder's aroma volatilization faster, lasting effect, affecting comfort, etc., to achieve improved biodegradable rate, long-lasting aroma effect, foaming good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

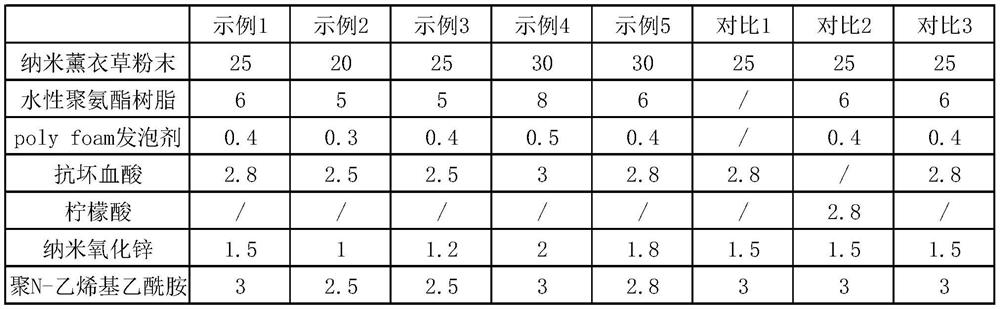

Image

Examples

Embodiment Construction

[0024] The invention provides an environmentally friendly and degradable aromatic polyurethane foam material. The environmentally friendly and degradable aromatic polyurethane foam material is formed by mixing and foaming group material A and group material B, wherein: group material B is aliphatic isocyanate , Group A includes the following components in parts by weight: 80 to 100 parts of complex polyol, 4 to 8 parts of blowing agent, 0.5 to 0.8 part of catalyst, 0 to 1 part of crosslinking agent, 0.5 to 100 parts of 1 part of foam stabilizer and 15 to 25 parts of modified lavender particles, wherein the complex polyol is composed of 50% to 65% of vegetable oil-based polyether polyol, 20% to 30% of polypropylene oxide Ether and 15% to 25% alcoholysis products of polyurethane insoles.

[0025] Wherein: the vegetable oil-based polyether polyol is castor oil polyol; the polypropylene oxide ether uses sorbitol as an initiator, has a hydroxyl value of 430-470 mgKOH / g, and a funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com