Metal surface high-temperature-resistant coating structure and applications thereof

A technology of high temperature resistance and coating, applied in coatings, layered products, epoxy coatings, etc., can solve the problems of no relevant reports on the launch pad, inability to move the launch pad, heavy weight, etc., and achieve good heat insulation Performance, back temperature reduction, effect of reducing thermal ablation and thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

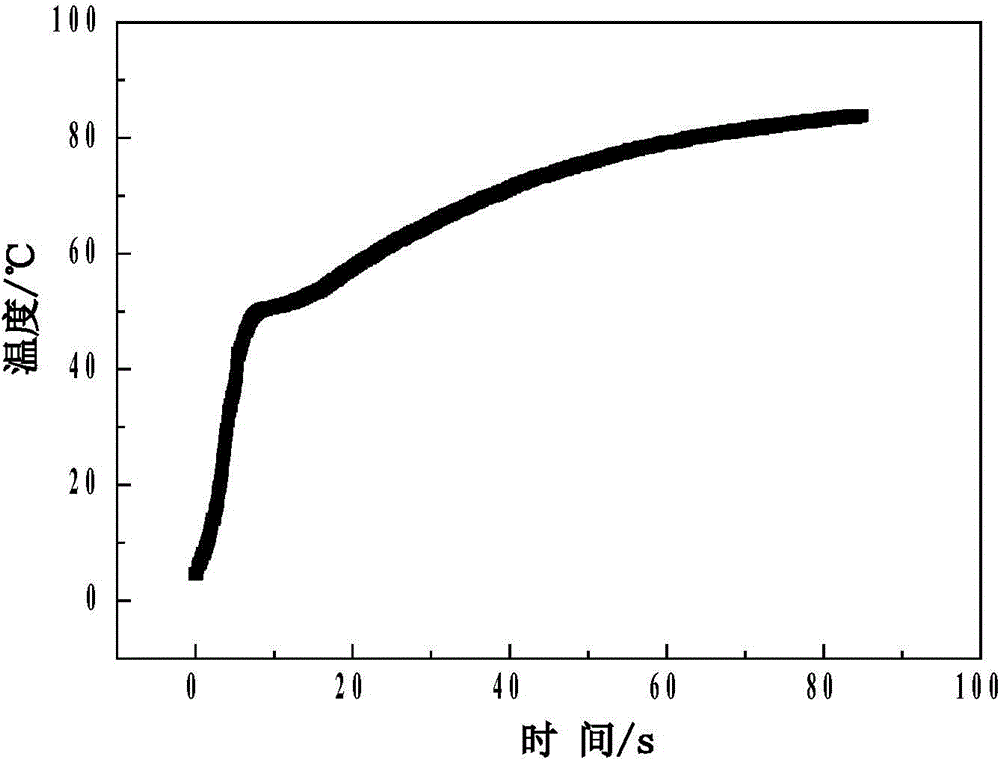

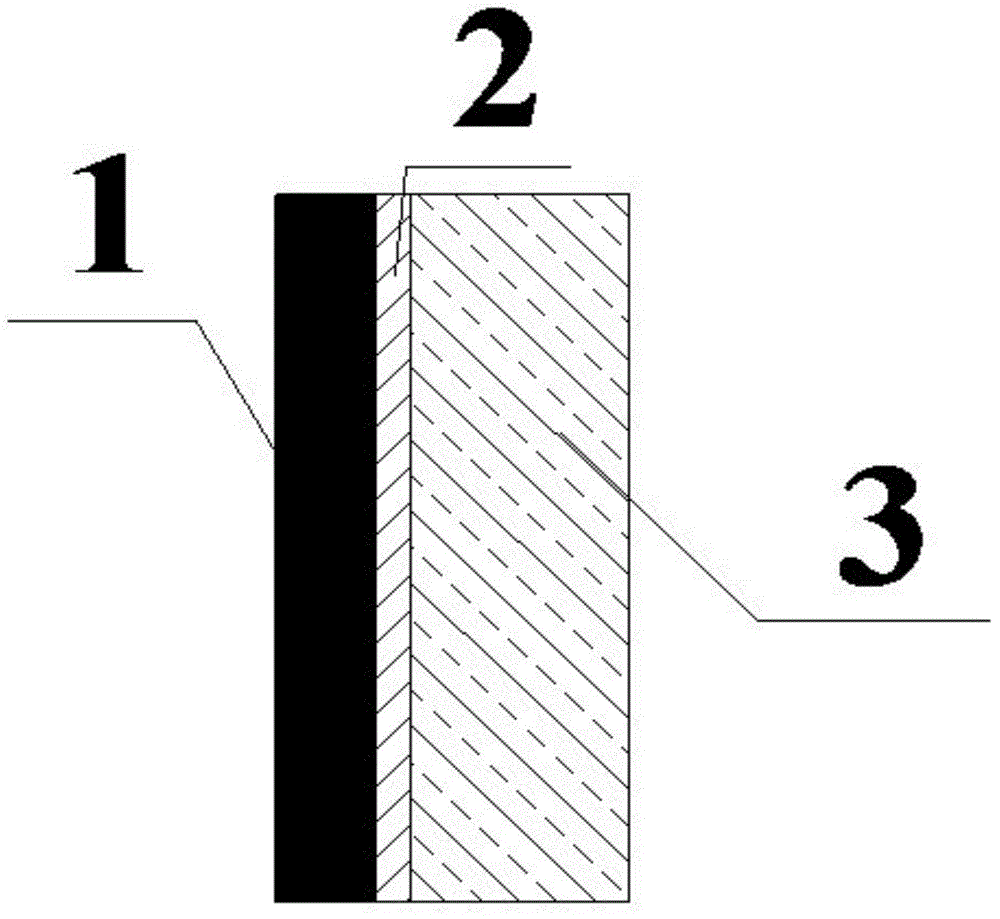

[0018] The preparation of embodiment 1 high temperature resistant coating structure

[0019] 1. Preparation of organic bottom layer: mix epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber according to the mass ratio of 7:2:1, and then coat the rust-removed 190×120×5mm steel plate On the side surfaces, the coating thickness was 2 mm.

[0020] 2. Preparation of inorganic surface layer: firstly, mix 6-35M and 100-325M burnt gemstones evenly according to the mass ratio of 1:1, and then mix the mixed burnt gemstones with cordierite, aluminate cement and silica fume according to the mass ratio Mixed ratio 12:3:4:1. After mixing evenly, add water and stir for 3 minutes. The amount of water added is 16% (mass fraction) of the surface layer ingredients. Before the organic bottom layer is fully cured, the surface layer material is coated on the bottom layer material. A surface layer with a thickness of 8 mm is coated on the bottom layer with a thickness...

Embodiment 2

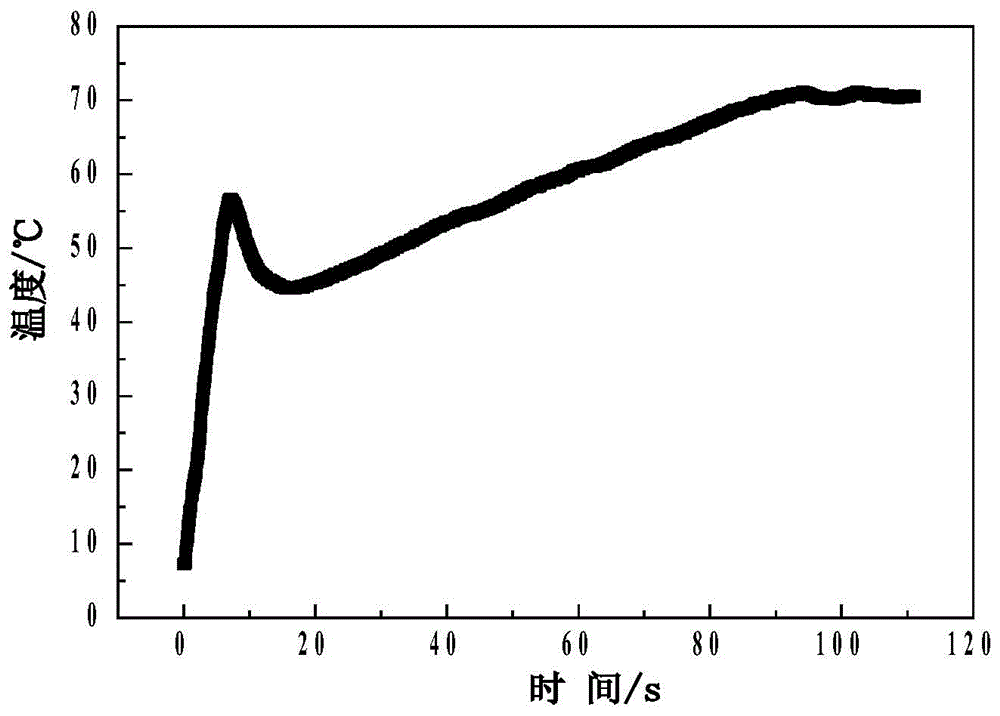

[0024] Preparation of high temperature resistant coating structure

[0025] 1. Preparation of organic bottom layer: mix epoxy resin SM828, curing agent polyamide 650, and toughening agent liquid rubber according to the mass ratio of 7:2:1, and then coat the rust-removed 190×120×5mm steel plate On the side surfaces, the coating thickness was 4 mm.

[0026] 2. Preparation of inorganic surface layer: firstly, mix 6-35M and 100-325M burnt gemstones evenly according to the mass ratio of 1:1, and then mix the mixed burnt gemstones with cordierite, aluminate cement and silica fume according to the mass ratio Mixed ratio 12:3:4:1. After mixing evenly, add water and stir for 3 minutes. The amount of water added is 16% (mass fraction) of the surface layer ingredients. Before the organic bottom layer is fully cured, the surface layer material is coated on the bottom layer material. A surface layer with a thickness of 11 mm is coated on the bottom layer with a thickness of 4 mm to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com