High-temperature coating material structure for rocket launching pad and application of high-temperature coating material structure

A coating material, rocket launch technology, applied in the direction of layered products, building structures, synthetic resin layered products, etc., can solve the problems of heavy weight, inability to move the launch pad, thick thickness, etc., and achieve the utilization of high temperature resistance The effect of increasing the rate, reducing the back temperature, reducing thermal ablation and thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

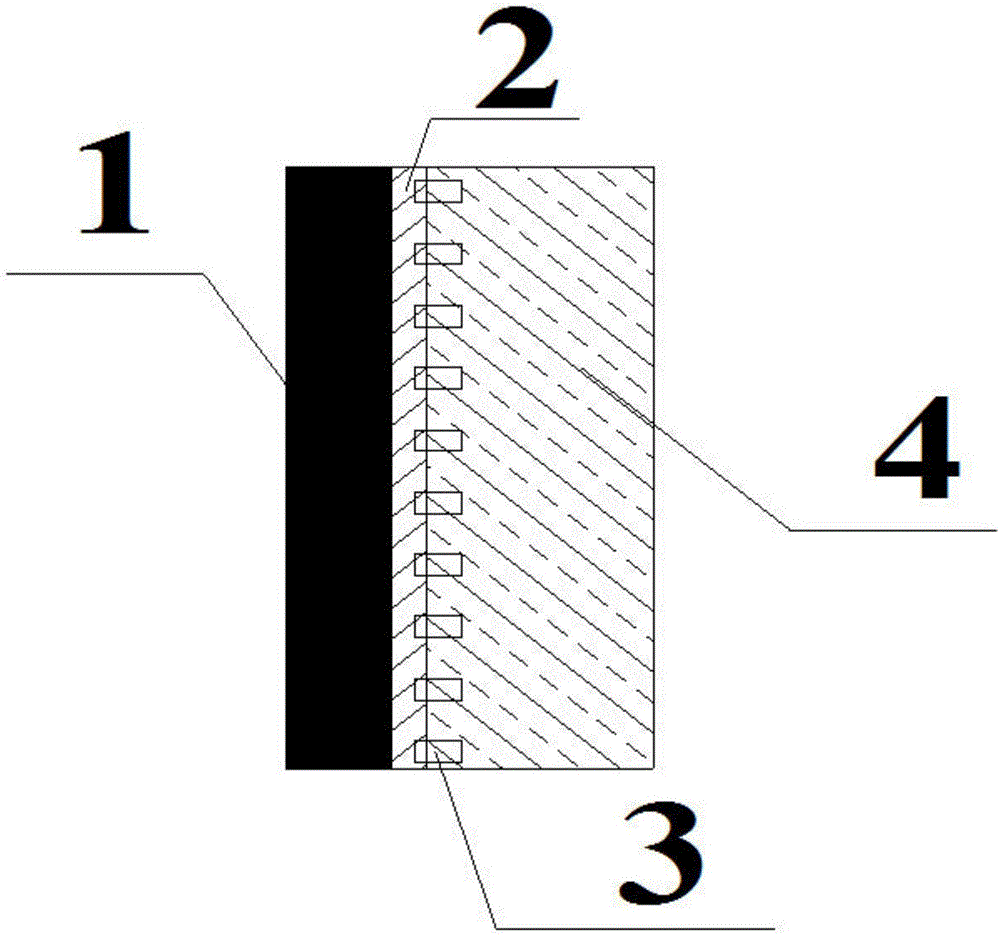

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 high temperature resistant coating material

[0031] 1. Preparation of organic bottom layer: mix epoxy resin, curing agent modified polyamine, and toughening agent liquid rubber according to the ratio of 7:2:1, and coat it on the 190×120×5mm surface after rust removal and paint removal. On the steel plate, the coating thickness is 2mm.

[0032] 2. Preparation of refractory lightweight aggregate: After the organic base layer is coated, evenly spread refractory lightweight aggregate with a particle size of 6-35M on the organic base layer.

[0033] 3. Preparation of organic-inorganic composite surface layer: First, mix the filler sand and cement evenly in a ratio of 2:1, and then add it to the mixed glue of organic adhesive epoxy resin and polyurethane curing agent in a ratio of 3:1, solid and liquid The ratio is 3:1.

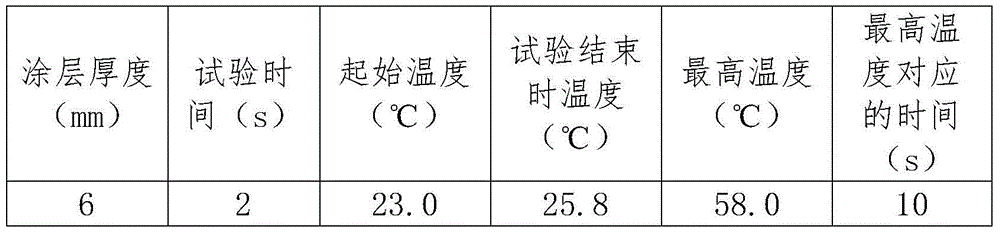

[0034] 4. Evenly coat the organic-inorganic composite surface layer on the refractory lightweight aggregate with a coatin...

Embodiment 2

[0040] The preparation of embodiment 2 high temperature resistant coating material

[0041] 1. Preparation of organic bottom layer: mix epoxy resin, curing agent modified polyamine, and toughening agent liquid rubber according to the ratio of 7:2:1, and coat it on the 190×120×5mm surface after rust removal and paint removal. On the steel plate, the coating thickness is 4mm.

[0042] 2. Preparation of refractory lightweight aggregate: After the organic base layer is coated, evenly spread refractory lightweight aggregate with a particle size of 6-35M on the organic base layer.

[0043] 3. Preparation of organic-inorganic composite surface layer: First, mix the filler sand and cement evenly in a ratio of 2:1, and then add it to the mixed glue of organic adhesive epoxy resin and polyurethane curing agent in a ratio of 3:1, solid and liquid The ratio is 3:1.

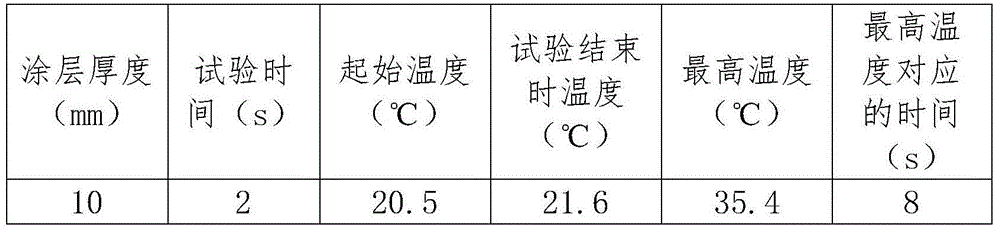

[0044] 4. Evenly coat the organic-inorganic composite surface layer on the refractory lightweight aggregate with a coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com