A kind of surface protective conductive composite material and preparation method thereof

A conductive composite material and composite material technology, applied in the field of surface protective conductive composite material and its preparation, can solve the problems of destroying the continuity of the circuit in the metal mesh, easy gaps on the surface, and damage to the composite material, so as to avoid secondary spraying Protective process, avoid thermal shock damage, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

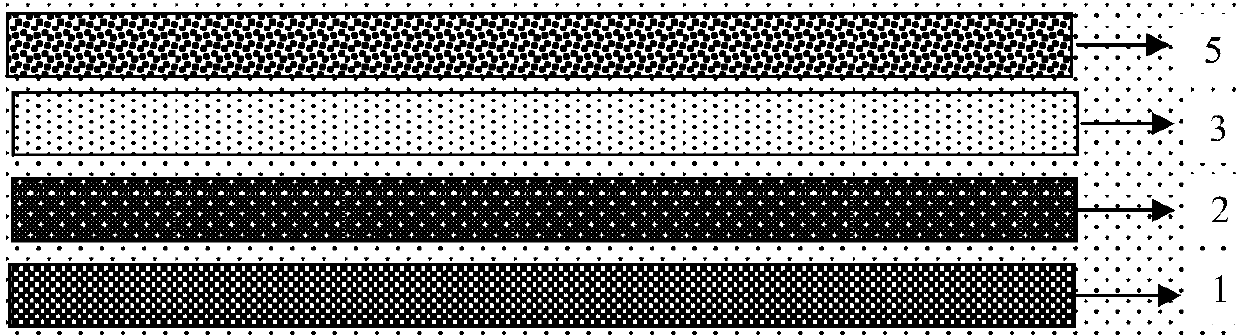

[0040] See attached figure 1 As shown, the production of surface protective conductive composite flat plate: the length is 660mm±5mm, the width is 120mm±5mm, the thickness is 3.5mm±0.2mm, the steps are as follows:

[0041] (1) First lay the T700S / 5228 high-temperature epoxy resin-based composite material prepreg blank with a thickness of 3mm±0.2mm, the size is 670mm in length and 130mm in width, and then use a polymer conductive resin film with a thickness of 0.2mm±0.04mm as The conductive layer 2 is laid on the surface of one side of the prepreg, and then pre-cured at 150°C for 30 minutes to obtain a conductive composite material prefabricated part;

[0042] (2) Cut the size of the prefabricated part 1 to be 660mm in length and 120mm in width, polish the surface of one side of the prefabricated part covered with a conductive layer, clean it with acetone, and then evenly spray the polymer adhesive glue on the surface as the adhesive layer 3 , the adhesive thickness is 0.02mm~...

Embodiment 2

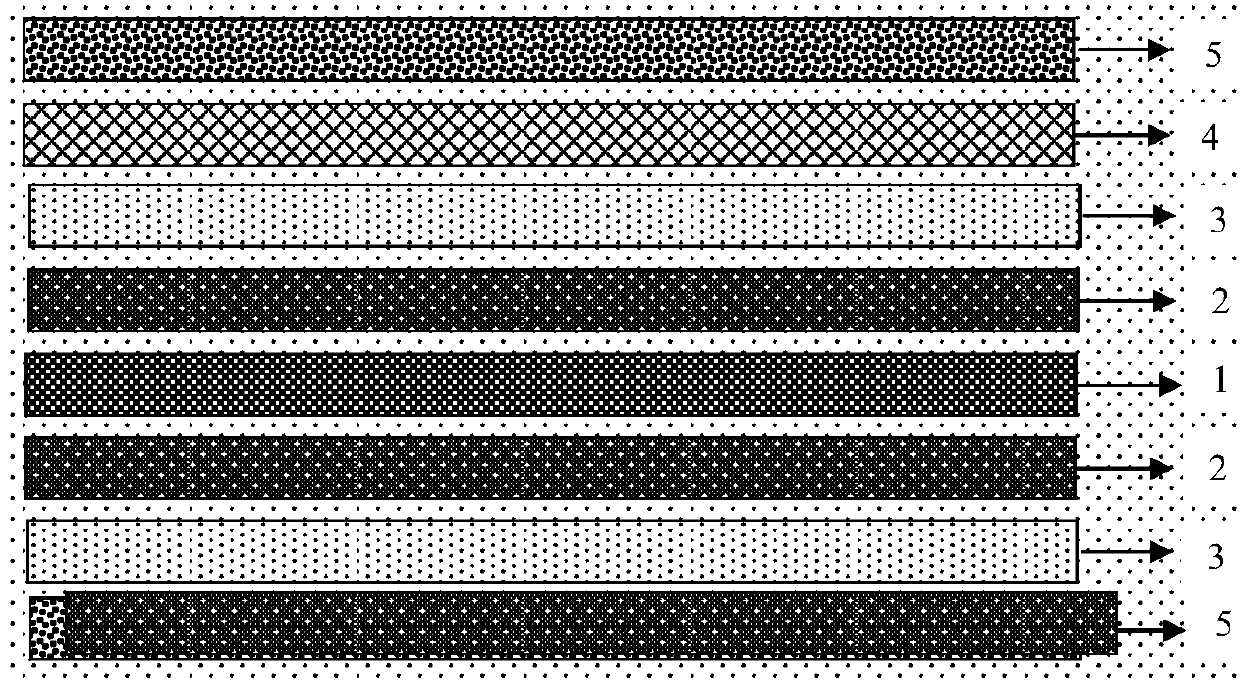

[0046] See attached figure 2 As shown, the production of surface protective conductive composite material curved panels: the length is 660mm±2mm, the width is 120mm±2mm, and the thickness is 4.5mm±0.2mm. The steps are as follows:

[0047](1) First lay the SW280 / benzoxazine resin pre-impregnated fabric blank with a thickness of 3mm±0.2mm, the size is 670mm in length and 130mm in width, and then use a polymer conductive resin film with a thickness of 0.2mm±0.04mm as the conductive layer 2 Lay it on the surface of both sides of the prepreg, and then precure at 150°C for 30 minutes to obtain a conductive composite material prefabricated part;

[0048] (2) Cut the size of the preform 1 to be 660mm in length and 120mm in width, polish the surfaces on both sides of the preform, clean it with acetone, and then evenly spray polymer adhesive glue on the surface as the adhesive layer 3, and the thickness of the adhesive is 0.02 mm~0.04mm;

[0049] (3) On one side of the conductive com...

Embodiment 3

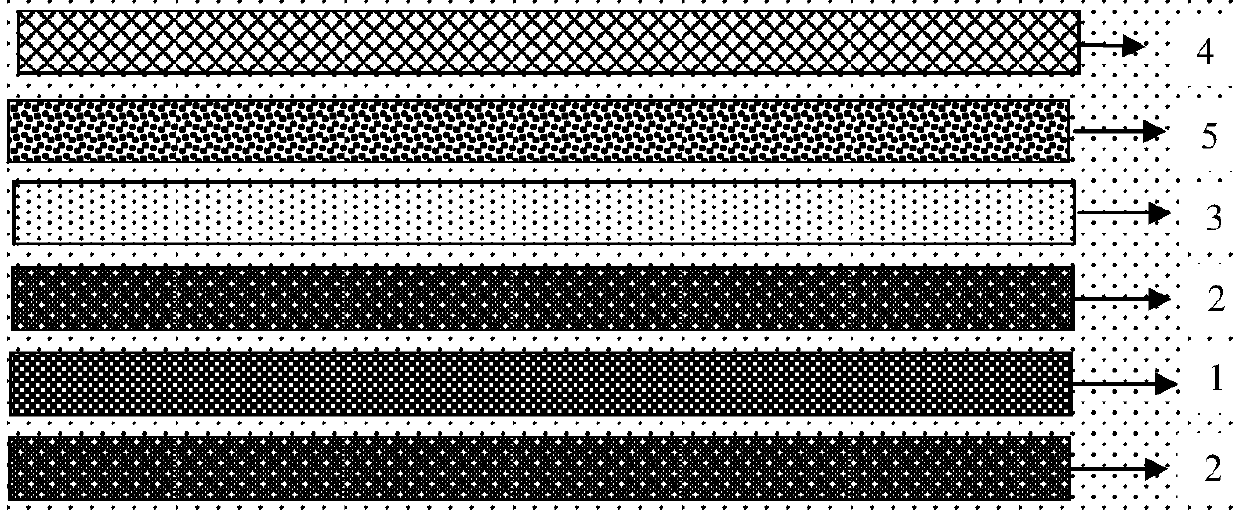

[0053] See attached image 3 As shown, the production of surface protective conductive composite flat plate: the length is 1200mm±2mm, the width is 200mm±2mm, the thickness is 3.3mm±0.2mm, the steps are as follows:

[0054] (1) First lay the DP328 / 3233 aramid fiber prepreg fabric blank with a thickness of 3mm±0.2mm, the size is 1210mm in length and 210mm in width, and then lay the pure metal aluminum foil conductive mesh with a thickness of 0.05mm~0.08mm as the conductive layer 2 Paste on the surface of both sides of the prepreg, and then precure at 125°C for 20 minutes to obtain a conductive composite material prefabricated part;

[0055] (2) Cut the size of the prefabricated part to be 1200mm in length and 200mm in width, polish the surface of one side of the prefabricated part, clean it with acetone, and then evenly spray polymer adhesive glue on the surface as the adhesive layer 3, and the thickness of the adhesive is 0.02mm ~0.04mm;

[0056] (3) Lay high-damping ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com