Method for Improving Performance of Capacitive Ni-MH Battery

A nickel-metal hydride battery, capacitive technology, applied in the field of square nickel-hydrogen power batteries, can solve the problems of affecting the discharge capacity and operating temperature of the battery, unable to effectively isolate the positive and negative plates, and reducing the electrochemical performance of the battery, etc. Effects of thermal stability, preservation of electrochemical performance, reduction of probability of hot spot failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

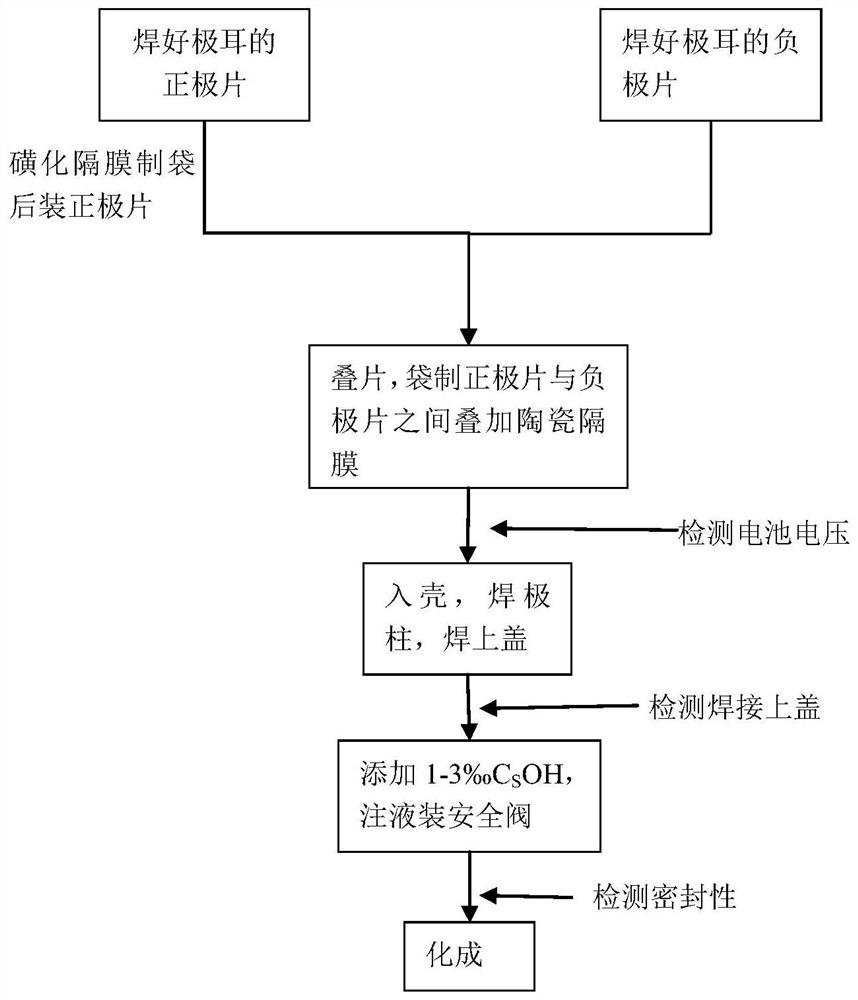

[0026] The preparation method of the capacitive nickel-hydrogen battery described in Example 1 is specifically: after the positive and negative electrode materials are respectively configured into slurry and then pressed into sheets, they are cut into correspondingly sized pole pieces, and the tabs are laser welded; The positive and negative plates are stacked according to the required stacking method, and the poles are laser welded into the battery case. After the cap is filled with liquid, it is melted and finally plastic-sealed to detect the finished product.

[0027] The method for improving the performance of the capacitive nickel-hydrogen battery described in Example 1, specifically, the positive pole piece of the capacitive nickel-hydrogen battery is made of a sulfonated diaphragm, and a ceramic diaphragm is stacked between the positive pole piece and the negative pole piece of the bag. ; Electrolyte is made up of alkaline solution and additive, and additive is cesium hy...

Embodiment 2

[0035] The preparation method of the capacitive nickel-hydrogen battery described in embodiment 2 and the method for improving the performance of the capacitive nickel-hydrogen battery are the same as in embodiment 1, the difference is that the amount of additive cesium hydroxide is different, and the amount of hydrogen added in this embodiment is The mass of cesium oxide accounts for 2‰ of the electrolyte mass.

Embodiment 3

[0037] The preparation method of the capacitive nickel-hydrogen battery described in embodiment 3 and the method for improving the performance of the capacitive nickel-hydrogen battery are the same as in embodiment 1, the difference is that the amount of additive cesium hydroxide is different, and the amount of hydrogen added in this embodiment is The mass of cesium oxide accounts for 3‰ of the electrolyte mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com