Testing device and testing method for spark voltage of electrolyte under non-critical state

A technology of flashing voltage and testing equipment, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve problems such as flicker, fluctuation of the measured area, and asynchrony

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

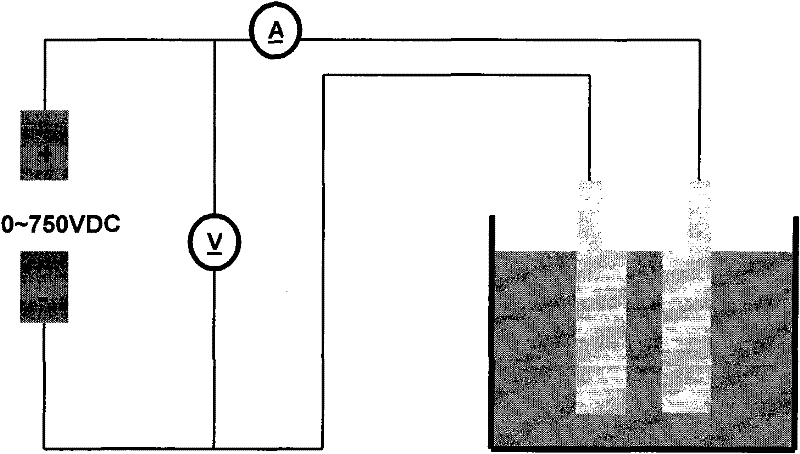

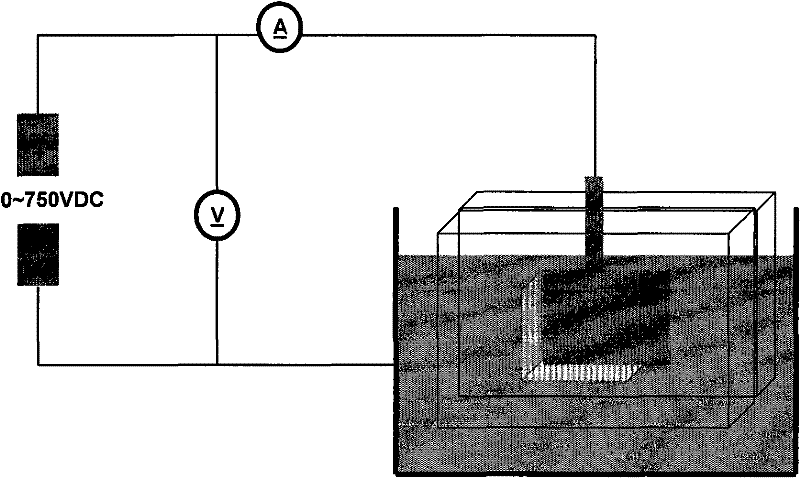

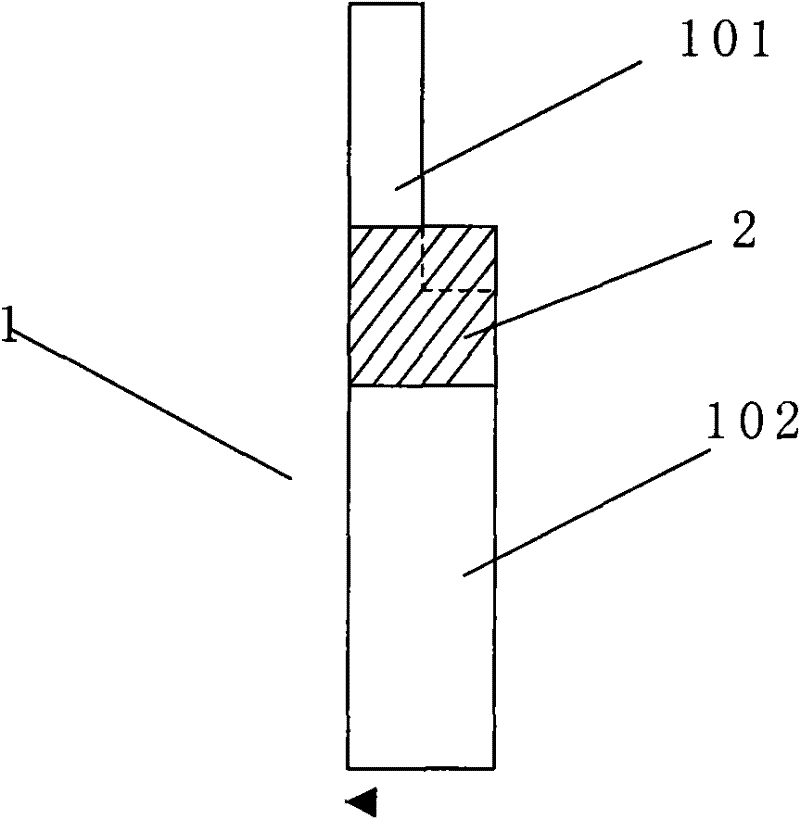

[0022] Such as Figures 3 to 4 Shown: a testing device for the flash voltage of the electrolyte in a non-critical state, including a 1000V-T-V tester, a beaker, a high-voltage electrolyte 3 and an electrode foil 1, the middle of the electrode foil 1 is wrapped more A layer of insulating tape 2, the insulating tape 2 separates the electrode foil 1 into a floating area 101 and a sinking area 102.

[0023] The electrode foil 1 is a pure aluminum product with a specification of 50*10mm, and the liquid sink area 102 of the electrode foil 1 is 40*10mm.

[0024] The most readily available test electrode materials are as follows:

[0025] Electrolyte theoretical flash voltage value Electrode foil selection Electrode foil type

[0026] >480V 600WV chaff 10mm wide chaff

[0027] >530V 600WV chaff 10mm wide chaff

[0028] >550V 620VF plain foil 110UM

[0029] >580V 640VF plain foil 110um

[0030] >600V 660VF plain foil 110um

[0031] >630V 720VF plain foil 110um

[0032] >750V 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com