A kind of ink sludge harmless resource treatment process and system

A technology of sludge treatment and ink, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problems that ink sludge cannot meet the environmental protection requirements, and achieve the realization of no pollution detrimental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

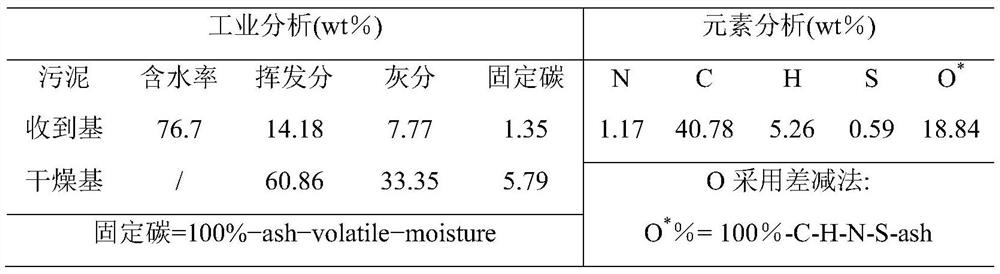

[0063] In this example, the ink sludge obtained from Shanghai Jielong Color Printing Factory was treated by using the ink sludge harmless and resourceful treatment process and system of the present invention. The composition analysis of the ink sludge is shown in Table 1.

[0064] Table 1 Industrial Analysis and Elemental Analysis Table of Example 1 Ink Sludge

[0065]

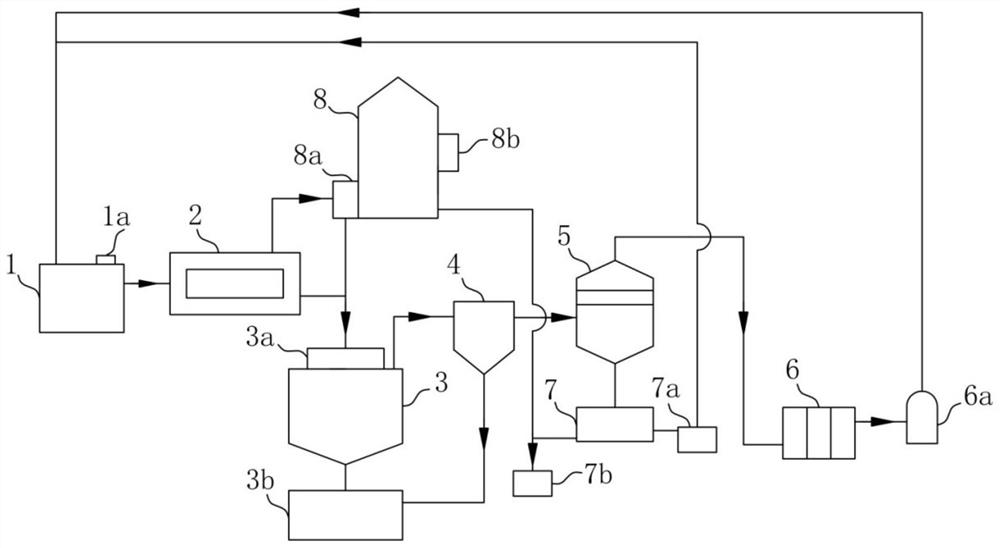

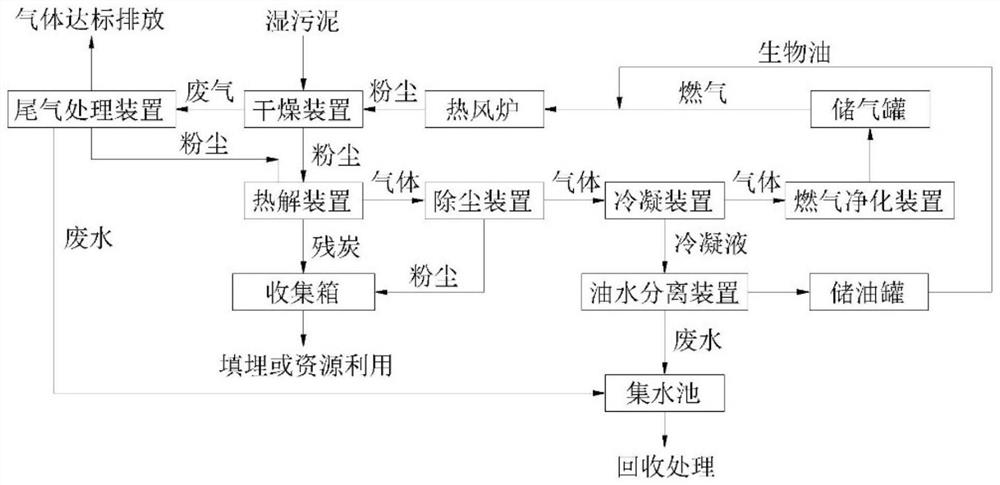

[0066] Such as figure 1 As shown, the treatment process and system for the harmless recycling of ink sludge include a hot blast stove 1, a drying device 2, a feeding device, a pyrolysis device 3, a dust removal device 4, a condensation device 5, a gas purification device 6, Oil-water separation device 7 and tail gas treatment device 8.

[0067]The hot blast stove is equipped with a fuel inlet, an air inlet, and a hot flue gas outlet; the drying device is equipped with a wet sludge inlet, a hot flue gas inlet, a sludge outlet, and a waste gas outlet, and the hot flue gas inlet is connected to the hot flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com