Crude benzene hydrorefining process

A technology for hydrofining and crude benzene, which is applied in the fields of hydrocarbons, chemical instruments and methods, organic chemistry, etc. It can solve the problems of excessive waste of raw materials, easy coking and blockage of the reaction system, high requirements for reaction temperature, etc., and achieve a stable reaction process , reduce the risk of coking in the system, and reduce equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

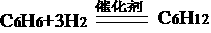

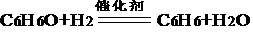

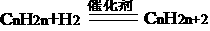

Method used

Image

Examples

Embodiment 1

[0047] First, the raw material is coordinating thick benzene, the component and mass score it contains as follows:

[0048] Benzene: 75%, toluene: 13.9%, two toluene: 2.24%, light group points: 0.86%, reorganization points: 8%, total sulfur content 6546.57ppm, total nitrogen content 899.3ppm.

[0049] 2. In this embodiment, the response temperature of the hydrogen hydrogenation reaction of hydrogenation is 140 ° C, the catalyst is CO-MO, and the volume ratio of hydrogen oil is 500: 1. -1 , Pressure 2.8MPa;

[0050] The reaction temperature of the gas catalytic pre-hydrogenation reaction is 190 ° C, the catalyst is NI-MO catalyst, the volume ratio of hydrogen oil is 400: 1. -1 , Pressure 2.0MPa;

[0051] The reaction temperature of the main catalytic hydrogenation reaction is 270 ° C, the catalyst is CR-MO catalyst, the volume ratio of hydrogen oil is 400: 1. -1 , Pressure 2.0MPa.

[0052] After hydrogenation reaction:

[0053] The total sulfur content of the product is 0.2PPM tota...

Embodiment 2

[0055] Examples of this embodiment are operated according to Example 1, the difference is:

[0056] In this embodiment, the reaction temperature of the hydrogen hydrogenation reaction of the hydrogenation is 130 ° C, the catalyst is CO-MO, and the volume ratio of hydrogen oil is 300: 1, the volume airspace 0.1H -1 , Pressure 2.4MPa;

[0057] The reaction temperature of the gas catalytic pre-hydrogenation reaction is 210 ° C, the catalyst is NI-MO catalyst, the volume ratio of hydrogen oil is 500: 1. -1 , Pressure 2.8MPa;

[0058] The reaction temperature of the main catalytic hydrogenation reaction is 290 ° C, the catalyst is CR-MO catalyst, the volume ratio of hydrogen oil is 500: 1. -1 , Pressure 2.8MPa.

[0059] After hydrogenation reaction:

[0060] The total sulfur content of the product is 0.2PPM total nitrogen content is less than 0.3PPM liquid -phase catalytic aromatics reactor 99.662%gas phase catalytic pre -hydrogen hydrocarbon rectification feed rate is 99.668%of the pr...

Embodiment 3

[0062] Examples of this embodiment are operated according to Example 1, the difference is:

[0063] In this embodiment, the reaction temperature of the hydrogen hydrogenation reaction of the liquid phase is 135 ° C, the catalyst is CO-MO, the volume ratio of hydrogen oil is 400: 1. -1 , Pressure 2.6MPa;

[0064] The reaction temperature of the gas catalytic pre-hydrogenation reaction is 200 ° C, the catalyst is NI-MO catalyst, the volume ratio of hydrogen oil is 450: 1. -1 , Pressure 2.6MPa;

[0065] The reaction temperature of the main catalytic hydrogenation reaction is 280 ° C, the catalyst is CR-MO catalyst, the volume ratio of hydrogen oil is 450: 1. -1 , Pressure 2.6MPa.

[0066] After hydrogenation reaction:

[0067] The total sulfur content of the product is 0.2PPM total nitrogen content is less than 0.3PPM liquid -phase catalytic aromatics reaction reaction rate of 99.67%gas phase catalytic pre -hydrogen hydrogen reaction aromatics.99.678%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com