Dehumidification, pyrolysis and gasification device for household garbage, and use method thereof

A domestic waste, pyrolysis and gasification technology, applied in the field of solid waste resource treatment, can solve the problems of low calorific value of combustible gas, the temperature of the secondary combustion chamber cannot be raised, and increase the cost of waste treatment, so as to improve the treatment efficiency , reduce the carbon content, reduce the effect of the risk of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

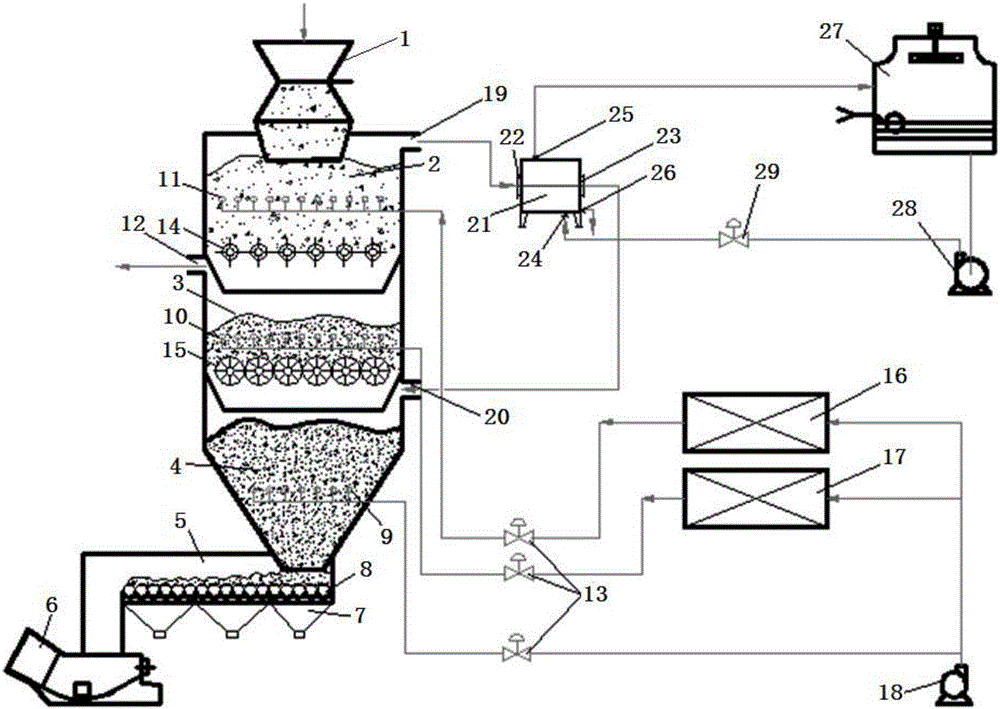

[0026] Such as figure 1 As shown, a kind of household garbage dehumidification pyrolysis gasification device described in the present invention includes a garbage treatment tower, a condensation dehumidifier 21, a high-temperature air preheater 16, a low-temperature air preheater 17 and a blower 18. The garbage treatment The tower is provided with a drying pyrolysis chamber 2, a pyrolysis gasification chamber 3 and a roasting chamber 4 in sequence downwards in the vertical direction, and the drying pyrolysis chamber 2 is provided with a drying pyrolysis air inlet pipe 11 and a drying pyrolysis chamber in sequence vertically downwards. The furnace bar 14 is rotated, the dry pyrolysis air inlet pipe 11 is connected to the blower 18 through the high-temperature air preheater 16, and the pyrolysis gasificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com