Piston upper part with enlarged cooling chamber for assembled or welded pistons

A technology for pistons and piston tops, applied in pistons, manufacturing tools, casting and molding equipment, etc., can solve the problems of loss of strength and shape stability of piston materials, thermal aging, etc., to reduce the risk of lubricant coking, improve cooling, The effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

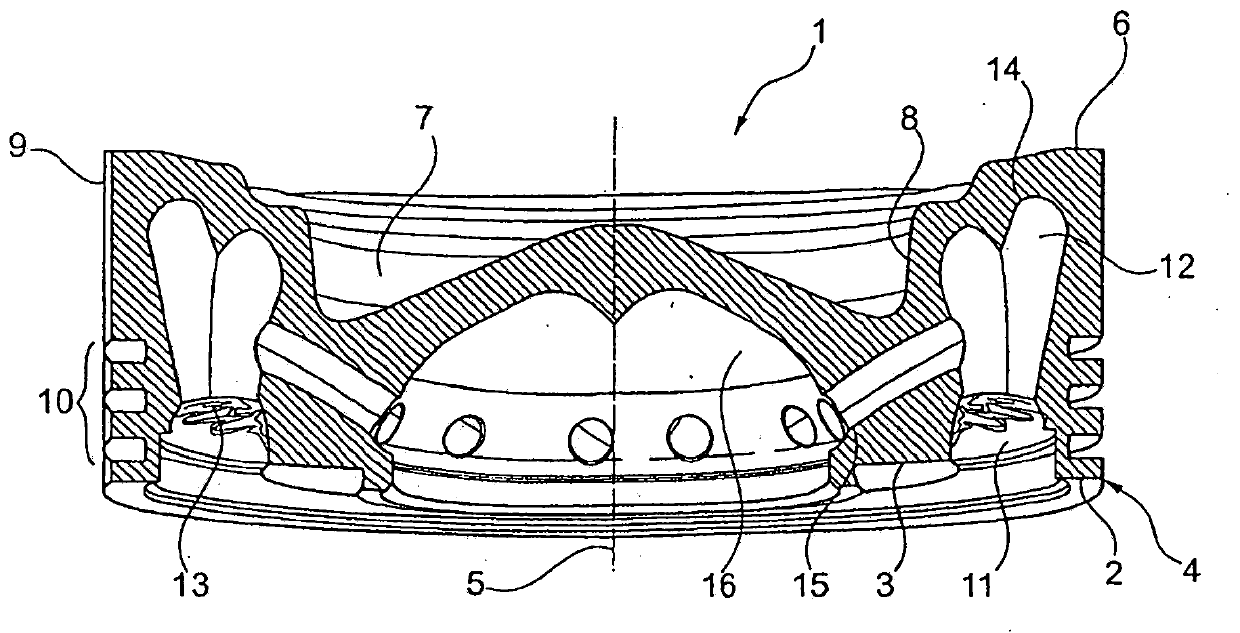

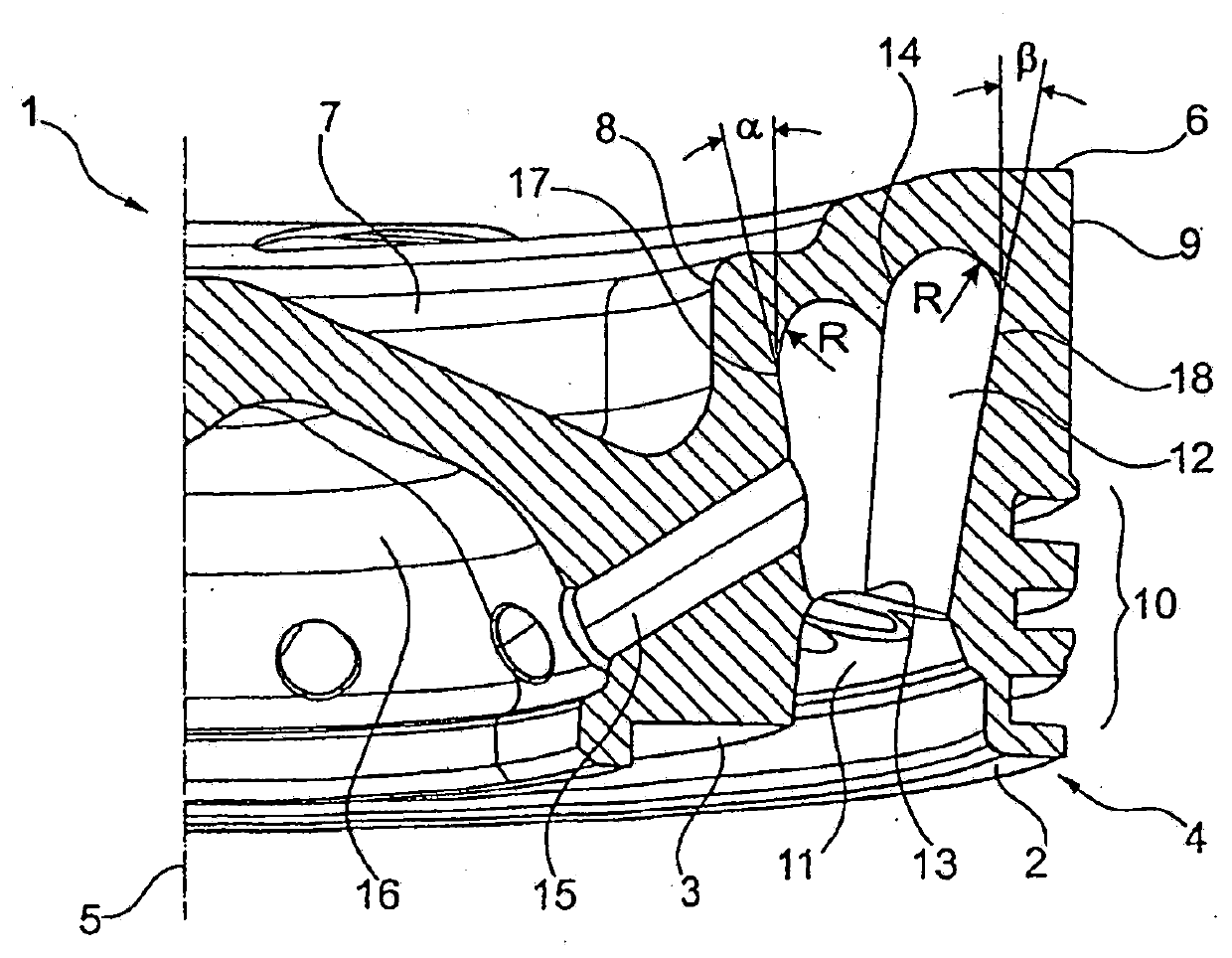

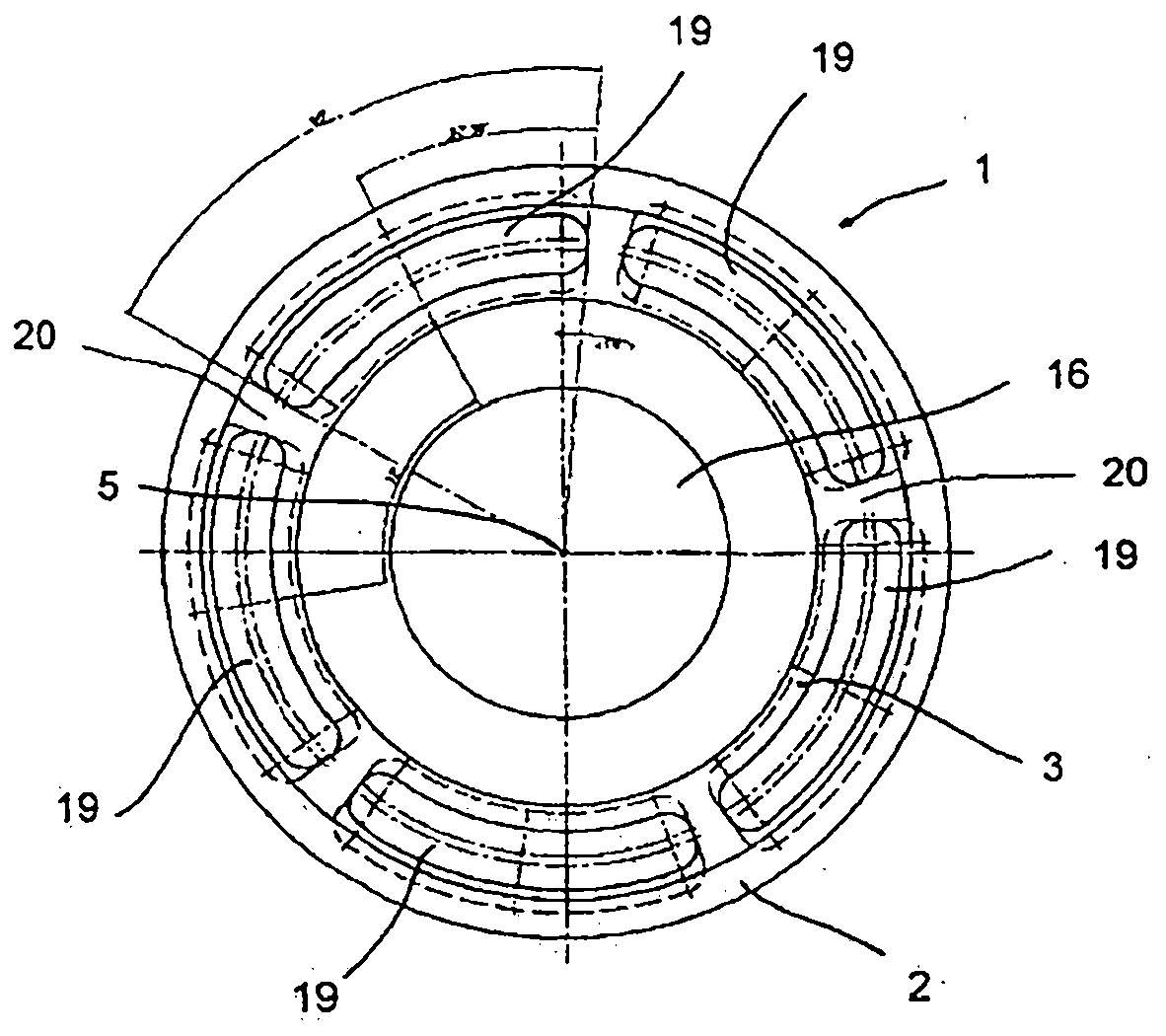

[0033] figure 1 A longitudinal section through a piston upper part 1 is shown, which is, for example, a steel alloy component produced by means of a forging process. As an alternative, the piston upper part 1 can also be made of aluminium, an aluminum alloy or an iron alloy. Alternatively, the piston upper part 1 can also be produced by any other forming or forming process. piston upper 1 and figure 1 The lower part of the piston, not shown in , together forms a two-part piston that is assembled in a friction fit or welded in a material fit, which is cooled by a liquid. Via two circumferential joint webs 2 , 3 offset radially from one another, the piston upper part 1 is supported on corresponding joint webs of the piston lower part. All joining webs together form a separating plane 4 via which the lower piston part and the upper piston part 1 are permanently connected to each other by means of a frictional fit, preferably a screw connection or a material fit, preferably a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com