Reactor internal-part with high light oil yield, low back-mixing and long-term operation and technological method thereof

A process method and long-term technology, applied in the petroleum industry, cracking, non-catalytic thermal cracking, etc., can solve the problems of back-mixing of reaction materials, affecting conversion rate, and easy formation of dead zones, etc., to reduce back-mixing and increase light oil Yield, effect of improving flow rate radial distribution and residence time distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

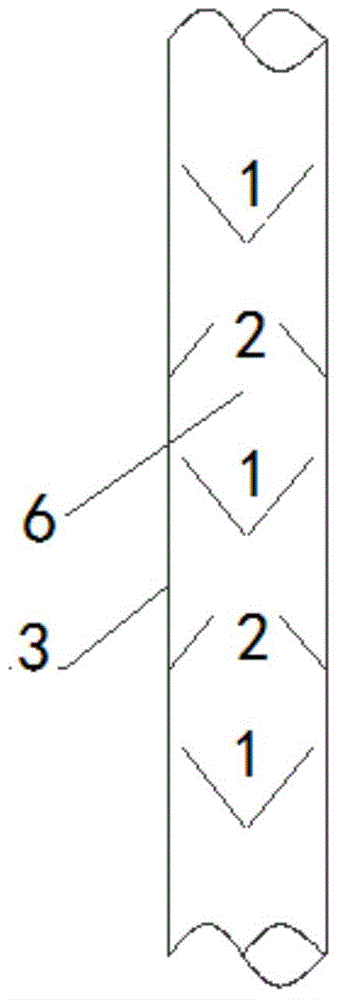

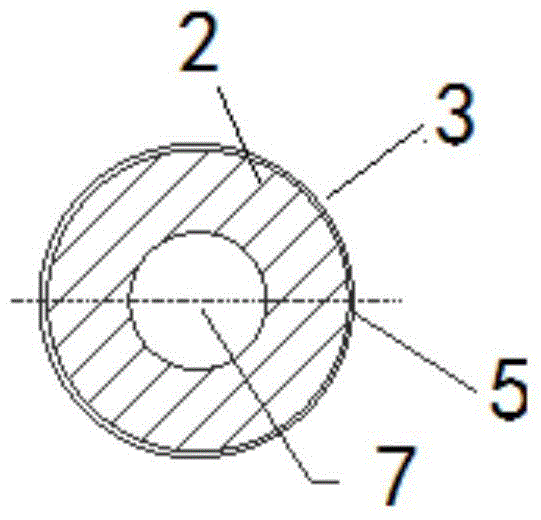

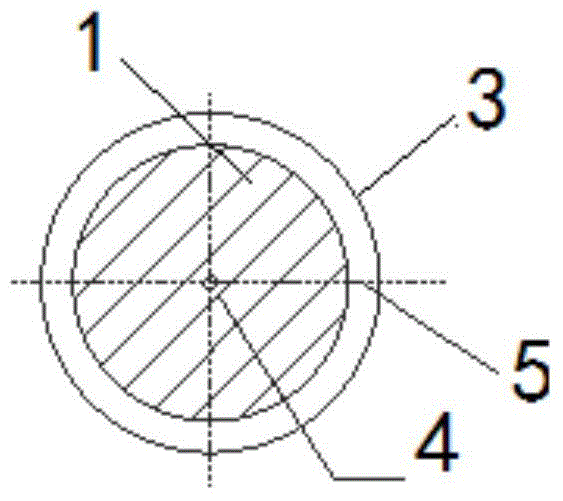

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, a high light oil yield, low back-mixing and long-period operation reactor internals are composed of odd-numbered plates 1 and even-numbered plates 2, and odd-numbered plates 1 and even-numbered plates 2 are arranged in sequence in reactor 3; the cross-section of odd-numbered plates 1 It is in the shape of a "V", and the two vertical section lines of the odd-numbered board 1 form a certain angle; There is a gap 5 between the outer edge and the outer edge of the even-numbered board 2 and the tower body, the first central opening 4 of the odd-numbered board 1 is smaller than the second central opening 7 of the even-numbered board 2, the gap between the odd-numbered board 1 is greater than the gap between the even-numbered board 2, and the reaction The raw oil passes through the odd-numbered plate 1 and the even-numbered plate 2 in sequence, accelerates at the side wall and the center of the reactor in turn, and f...

Embodiment 2

[0028] Example 2, such as figure 1 , figure 2 , image 3 As shown, a high light oil yield, low back-mixing and long-period operation reactor internals, the sequence, number, and spacing of odd-numbered plates 1 and even-numbered plates 2 can be changed.

[0029] A high light oil yield, low back-mixing and long-period operation reactor internals, consisting of figure 1 The odd-numbered plates 1 and even-numbered plates 2 in the long-period visbreaking reactor internals combination diagram are arranged in sequence in the reactor 3 with a certain number of plates. The reaction raw materials enter from the bottom of the reactor 3, pass through the odd-numbered plates 1 and even-numbered plates 2 from bottom to top, and finally exit through the top of the reactor 3. When the reaction material passes through the odd-numbered plates, the flow rate of the liquid is increased under the extrusion of the odd-numbered plates and the tower body, which reduces the back-mixing of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com