Anti-coking oil collecting tank for passing vaporized oil

A technology of super-vaporized oil and oil collecting tank, which is applied in fractionation, vacuum distillation, etc., can solve the problems of coking of super-vaporized oil in the vacuum tower, and achieve the effects of solving high-temperature coking, reducing residence time and improving collection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

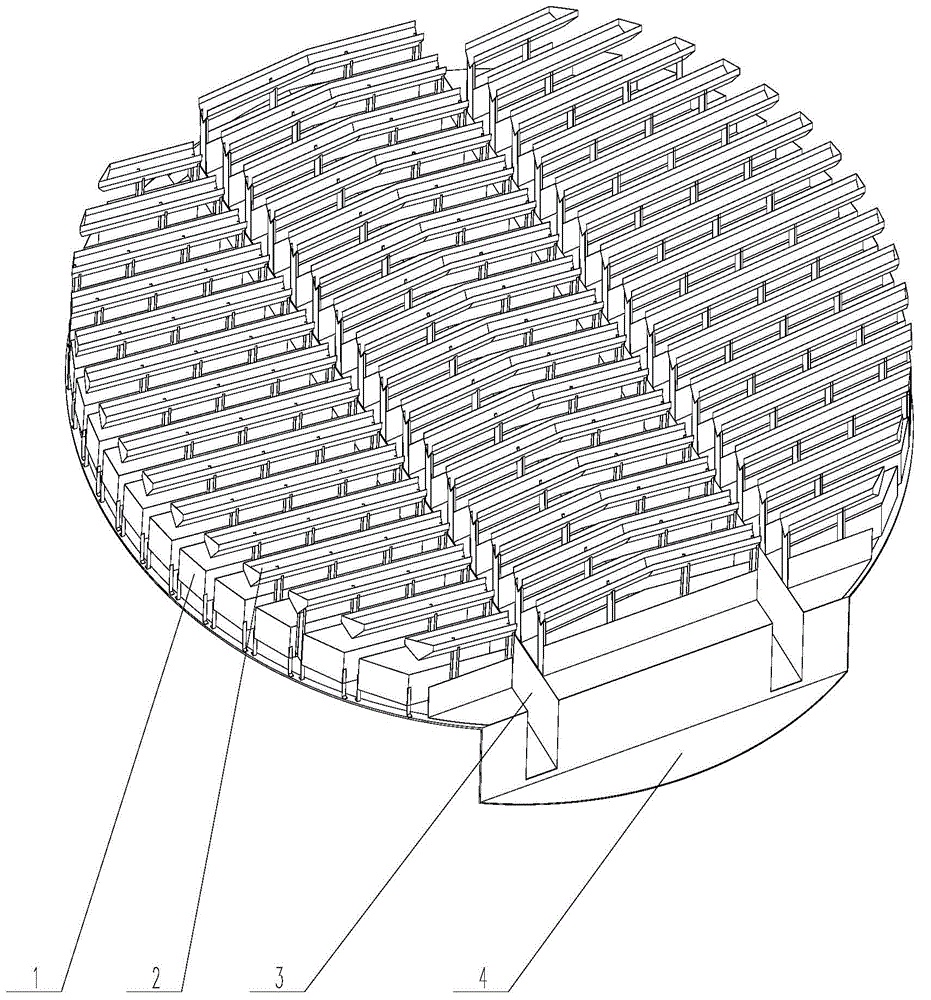

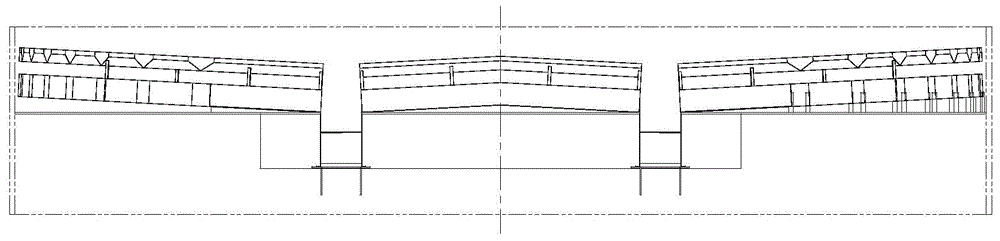

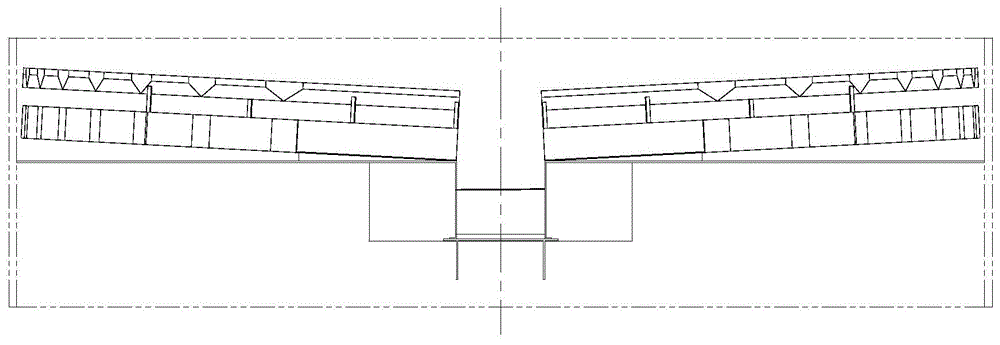

[0015] An anti-coking overvaporized oil collection tank according to the present invention is composed of a liquid collection tank 1, a liquid baffle plate 2, a liquid collection channel 3 and an extraction bucket 4; the liquid collection tank is composed of one or more components of a square groove structure One end of the liquid collecting tank close to the tower wall on both sides is lapped on the support ring, and the other end is lapped on the edge of the liquid collecting channel, forming a high lap at the end of the supporting ring and a low lap at the edge of the liquid collecting channel. The liquid collection channel is inclined; the middle part of the liquid collection channel in the middle is raised upwards, and the two ends are respectively lapped on the two adjacent liquid collection channels and inclined towards the two liquid collection channels; the liquid baffle is square or triangular The trough-shaped structure is fixed above the gap between the collecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com