Patents

Literature

40results about How to "Industrial Feasibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for in-situ preparing nano-silver compound bactericide

InactiveCN102657228AImprove the bactericidal effectReduce dosageBiocideDisinfectantsRecovery performanceHigh surface

The invention belongs to the technical field of material chemistry, and particularly relates to a method for in-situ preparing a nano-silver compound bactericide. The method is that a hydroxyapatite nano assembled ball chain with the length of micron order is taken as a carrier, the characteristics of the large surface area and high surface activity of the hydroxyapatite nano assembled ball chain are utilized, silver ions are converted into nano-silver on the hydroxyapatite surface through in-situ reduction reaction, so a hydroxyapatite / silver compound bactericide is prepared. The nano-silver compound bactericide has high chemical stability, good recovery performance, and can effectively kill various bacteria, the bactericidal efficiency is greatly improved because of the larger surface area of the nano-silver compound bactericide, under the premise of realizing the same bactericidal effect, the bactericide usage can be saved by about 30-40% compared with pure nano-silver, and the nano-silver compound bactericide has very strong industrial practicability.

Owner:EAST CHINA UNIV OF SCI & TECH

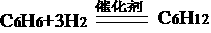

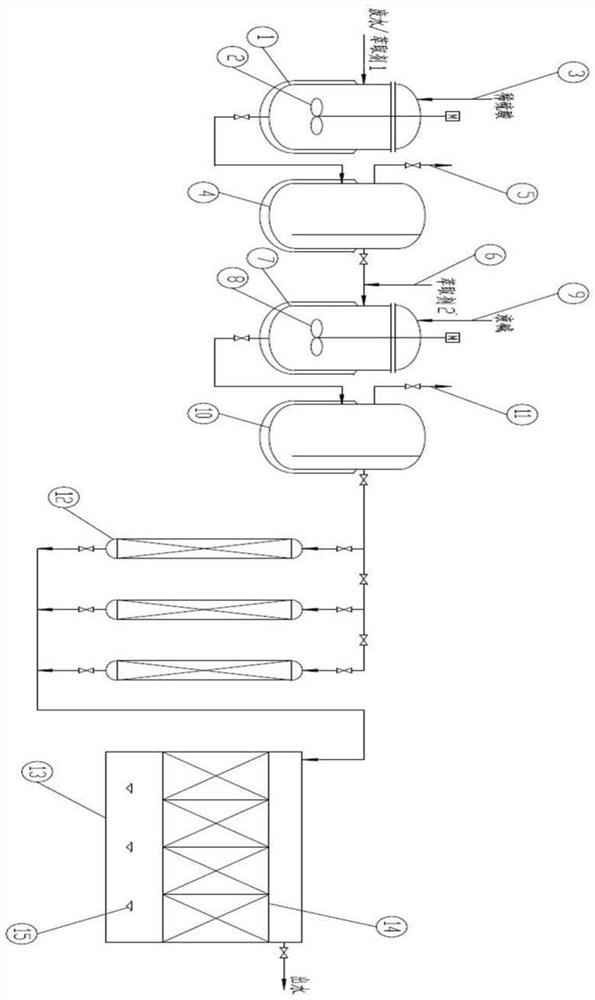

Crude benzene hydrorefining process

ActiveCN103274885AAvoid high temperature polymerization coking to block the systemHigh outputHydrocarbon purification/separationHydrocarbonsCatalytic reformingDistillation

The present invention provides a crude benzene hydrorefining process, which comprises: sequentially carrying out a liquid phase catalysis pre-hydrogenation reaction, a gas phase catalysis pre-hydrogenation reaction and a main catalysis hydrogenation reaction on crude benzene, and then carrying out extraction rectification on the material obtained from the main hydrogenation reaction to obtain distillates of various distillation ranges. Compared with the process in the prior art, the process of the present invention has the following characteristics that: the catalysis hydrogenation process is adjusted into the three stage catalysis hydrogenation technology, heavy benzol pre-separation is not required before catalysis hydrogenation, and unsaturated olefin in the crude benzene is subjected to hydrogenation at a low reaction temperature of 130-140 DEG C to prepare saturated olefin in the liquid phase catalysis reforming pre-hydrogenation step so as to avoid occurrence of system clogging due to high temperature polymerization coking of easy high temperature polymerization unsaturated olefin contained in the crude benzene in the subsequent step. In addition, heavy benzol in the crude benzene can be subjected to hydrogenation to prepare mixed aromatic hydrocarbons, wherein the mixed aromatic hydrocarbons can be used as excellent blending components, and material output values and added values are increased.

Owner:湖北巨邦石油化工有限公司

Method for extracting gold from alkaline cyanide solution

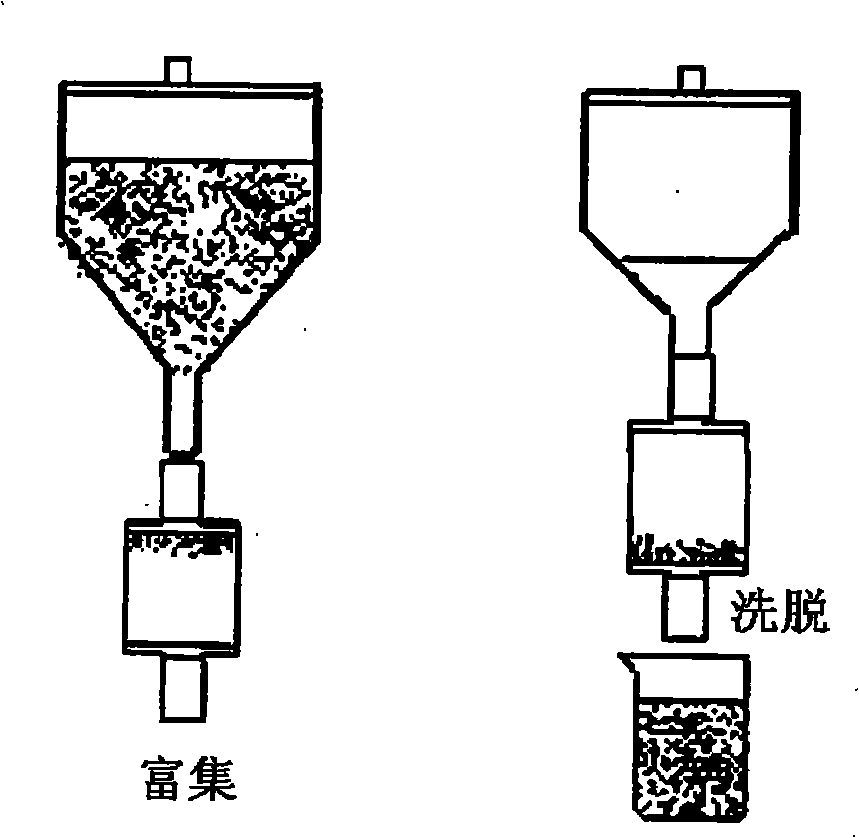

InactiveCN101538656AWide pH rangeHigh column efficiencyPhotography auxillary processesProcess efficiency improvementWater bathsCyanide

The invention discloses a method for extracting gold from alkaline cyanide solution. Porous graphitized carbon black and surfactant acetone solution with the concentration of 10 percent are evaporated in a water bath by stirring, thereby obtaining a graphitized carbon black packing with the attached surfactant. The packing is arranged in a solid-phase extraction column for compaction and washed by dilute sodium hydroxide with pH of 9.4-13 for standby. Gold-containing material liquid passes through the extraction column at the flow rate of 10-100mL / min for extraction and enrichment, then eluate is further used for reverse elution, and the gold in the eluate is finally recovered by the electric deposition method. The method has small environmental pollution, the operable pH range is very wide, the one-time extraction rate of the gold exceeds 96.5 percent, the enrichment times are more than 250 times, and the extraction capacity of the material to the gold is greater than 29mg / g, thereby having a good industrial application prospect.

Owner:YUXI NORMAL UNIV

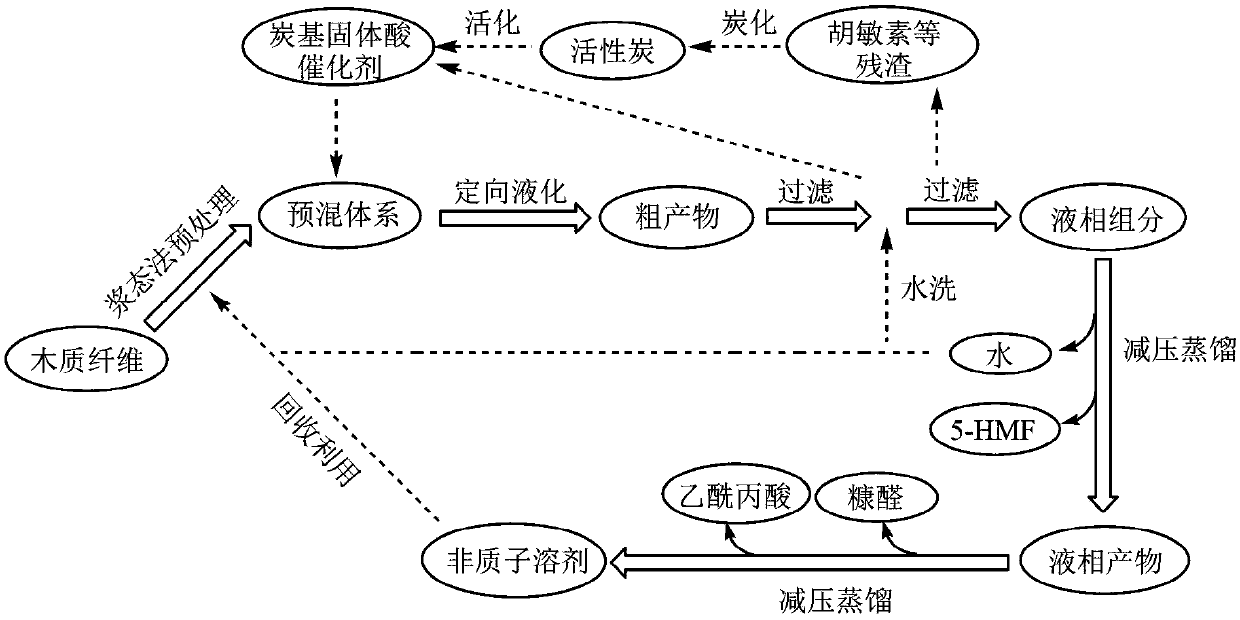

Method for preparing 5-hydroxymethylfurfural through directed liquefaction of wood fiber

PendingCN109535109AIndustrial FeasibilityWide variety of sourcesOrganic chemistryChemical recyclingChemistryDistillation

The invention provides a method for preparing 5-hydroxymethylfurfural through directed liquefaction of wood fiber. The method comprises the steps: adopting wood fiber as a raw material, mixing the wood fiber with a self-made solid acid catalyst and a composite solvent of a polar aprotic solvent and water firstly, pretreating the obtained wood fiber raw material by using a slurry-state method at room temperature, raising the temperature so as to achieve directed catalytic liquefaction and prepare 5-hydroxymethylfurfural; performing filtration, preparing the solid acid catalyst by using the solid residues, and performing fractional reduced pressure distillation on the filtrate so as to isolate water and the target product 5-hydroxymethylfurfural and by-products including furfural and levulinic acid and obtain the remaining aprotic solvent. The renewable wood fiber with a wide source is adopted as the raw material, and thus environmental protection and low cost are achieved; and in the composite solvent system of the polar aprotic solvent and water, a good selectivity to the target product 5-hydroxymethylfurfural, high yield, easy separation, efficient recycling utilization of the solvents, the catalyst and other matter and environmental protection can be achieved, and the method is suitable for industrial production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

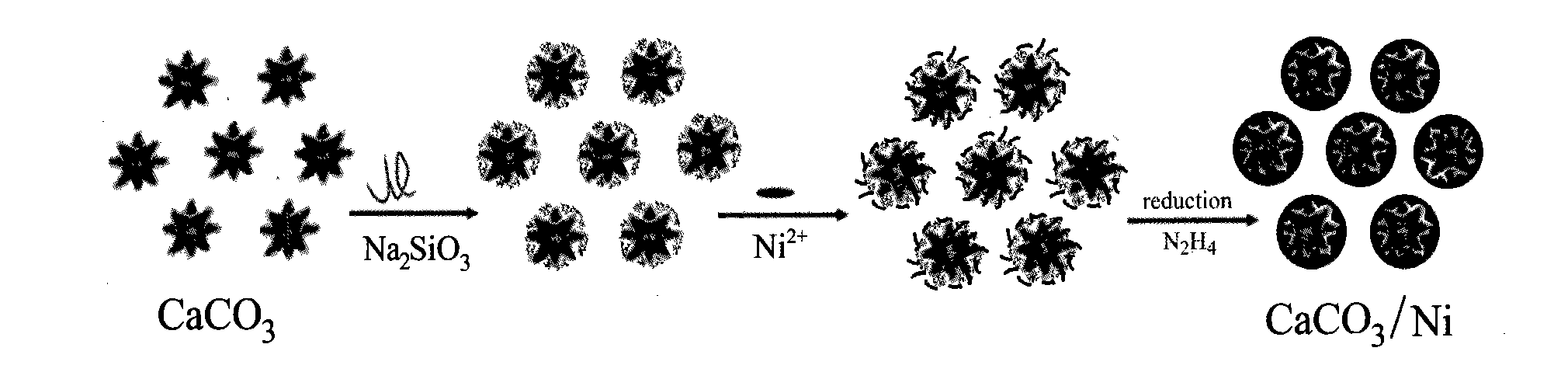

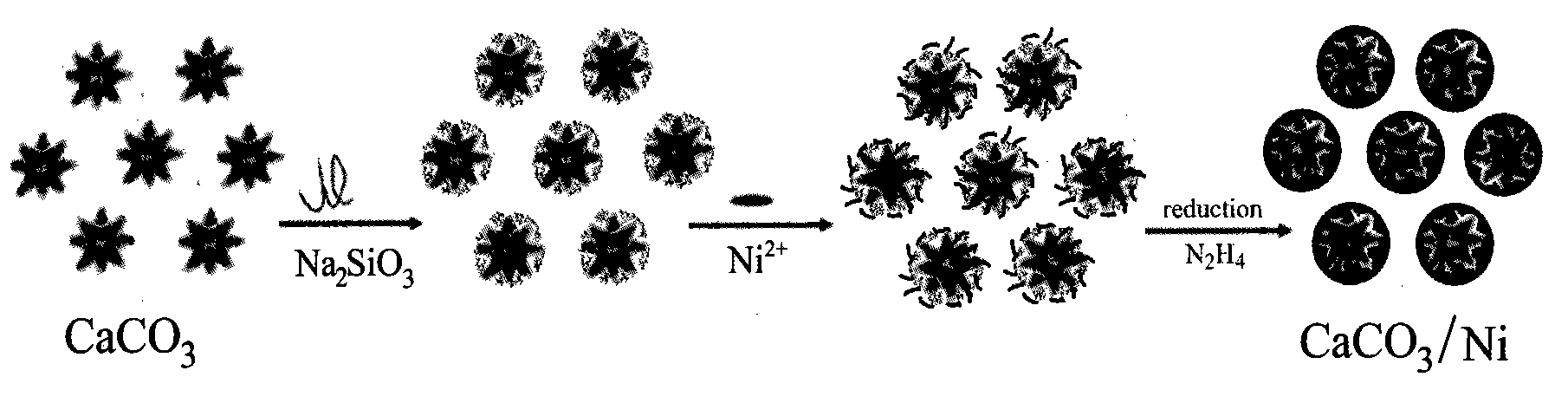

Calcium carbonate/nickel composite conductive powder and preparation method thereof

ActiveCN101923907AFulfil requirementsGood dispersionConductive materialAntistatic MaterialsChemical stability

The invention discloses a calcium carbonate / nickel composite conductive powder and a preparation method thereof. The calcium carbonate / nickel composite conductive powder is prepared by a method of performing in-situ reduction on the surface of a calcium carbonate nano-assembled sphere. The method comprises the following steps of: putting the corresponding calcium carbonate nano-assembled sphere and a nickel source into a reactor, taking water as a medium, adding a proper amount of coupling agent, and adjusting the temperature and a pH value of the system to make the system perform the in-situ reduction; and after full reaction, performing the treatment processes such as filtering, washing, drying and the like on the obtained product to prepare the calcium carbonate / nickel composite conductive powder. The prepared conductive powder has the advantages of high dispersibility, small particle size, uniform size distribution, excellent conductivity, high chemical stability and the like, and can be widely applied to the fields of antistatic materials, anticorona coatings and the like.

Owner:池州市贵兴非矿新材料有限公司

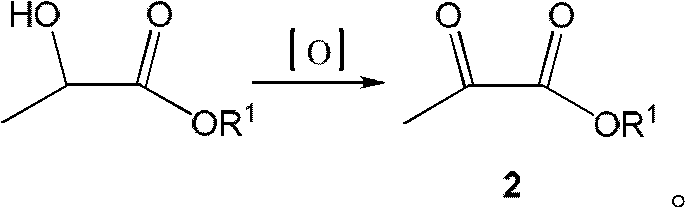

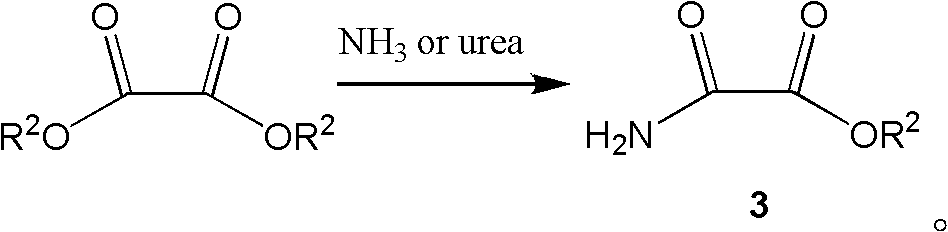

Preparation method of N-alkyloxy oxalyl alanine alkyl ester

ActiveCN102249946AEasy to operateShort preparation cycleOrganic compound preparationCarboxylic acid amides preparationPyruvic acidPhotochemistry

The invention discloses a preparation method of N-alkyloxy oxalyl alanine alkyl ester, comprising the steps of: subjecting pyruvic acid alkyl ester (2) and oxamic acid alkyl ester (3) to a reductive amination reaction so as to obtain a target compound (1) directly in the following reaction route; or, conducting a dehydration reaction to pyruvic acid alkyl ester (2) and oxamic acid alkyl ester (3) first so as to obtain an intermediate Schiff base (4), which then undergoes a reduction reaction, thus obtaining the target compound (1), with a following reaction route; wherein, R1 and R2 respectively represent methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl or t butyl. With the advantages of simple operation, short preparation period, low energy consumption, strong industrial feasibility and the like, the preparation method provided in the invention can satisfy the requirements for large-scale industrial production.

Owner:SHANGHAI HEGNO PHARMA HLDG +2

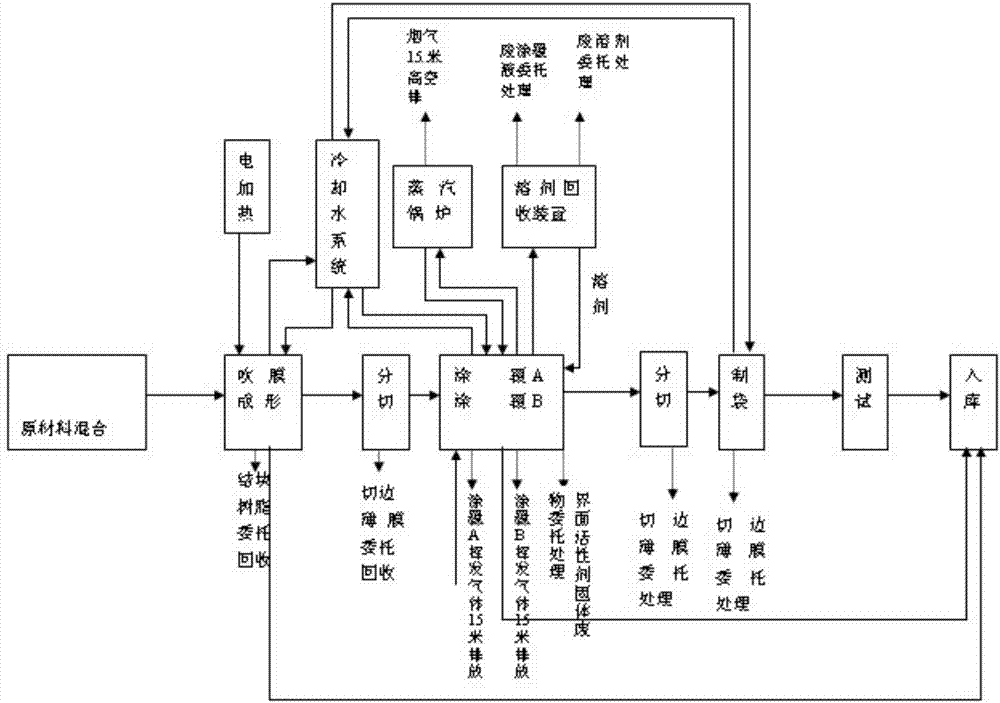

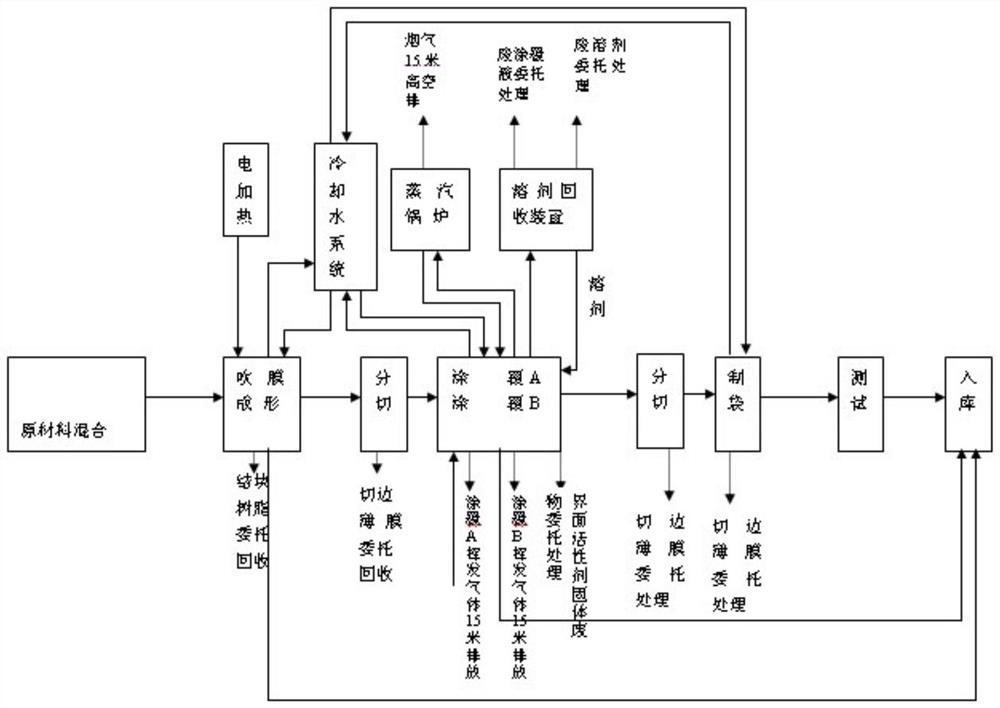

Packaging film with high biomass content and production process therefor

PendingCN107501675AReduce pollutionNo pollution in the processCoatingsLow-density polyethyleneMasterbatch

The invention relates to the technical field of packaging films and particularly relates to a packaging film with high biomass content and a production process therefor. The packaging film is prepared from raw materials, i.e., a biomass raw material, a petroleum raw material and additive color masterbatch, wherein the biomass raw material is prepared from the ingredients in percentage by mass: 30% to 60% of straight-lock very low density polyethylene made from plants, 5% to 30% of low-density polyethylene and 5% to 30% of high-density polyethylene, the petroleum raw material is straight-lock very low density polyethylene extracted from petroleum, the mass percent of the petroleum raw material is 10% to 20%, and the mass percent of the additive color masterbatch is 5% to 10%. Compared with the prior art, the packaging film with high biomass content and the production process therefor have the advantages that the environmental pollution is little, the packaging film is very environmentally friendly, the problem that the traditional packaging films prepared from petroleum raw materials affect environments is solved, the production process is simple, the material performance is stable, the production cost is low, and the industrial feasibility is high.

Owner:SHANGHAI FUKUSUKE IND

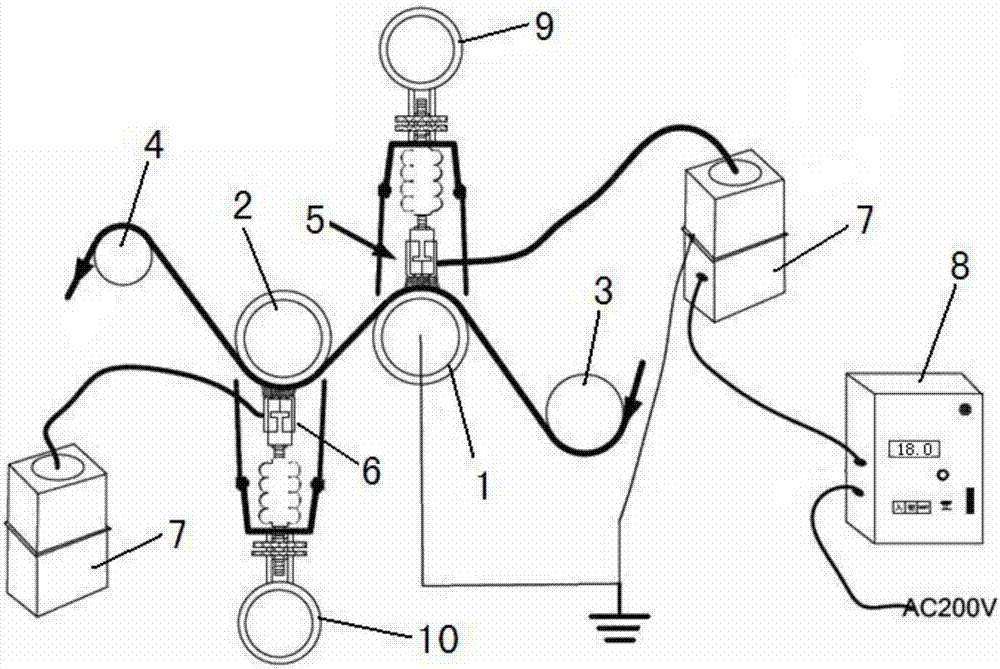

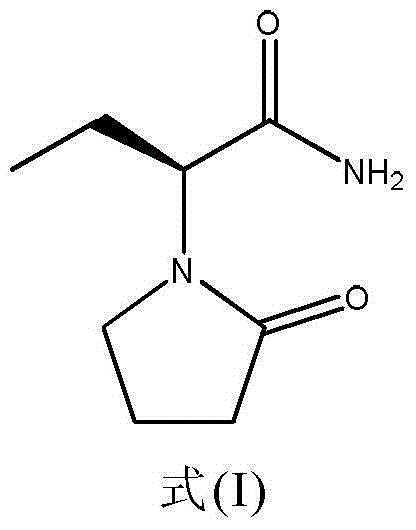

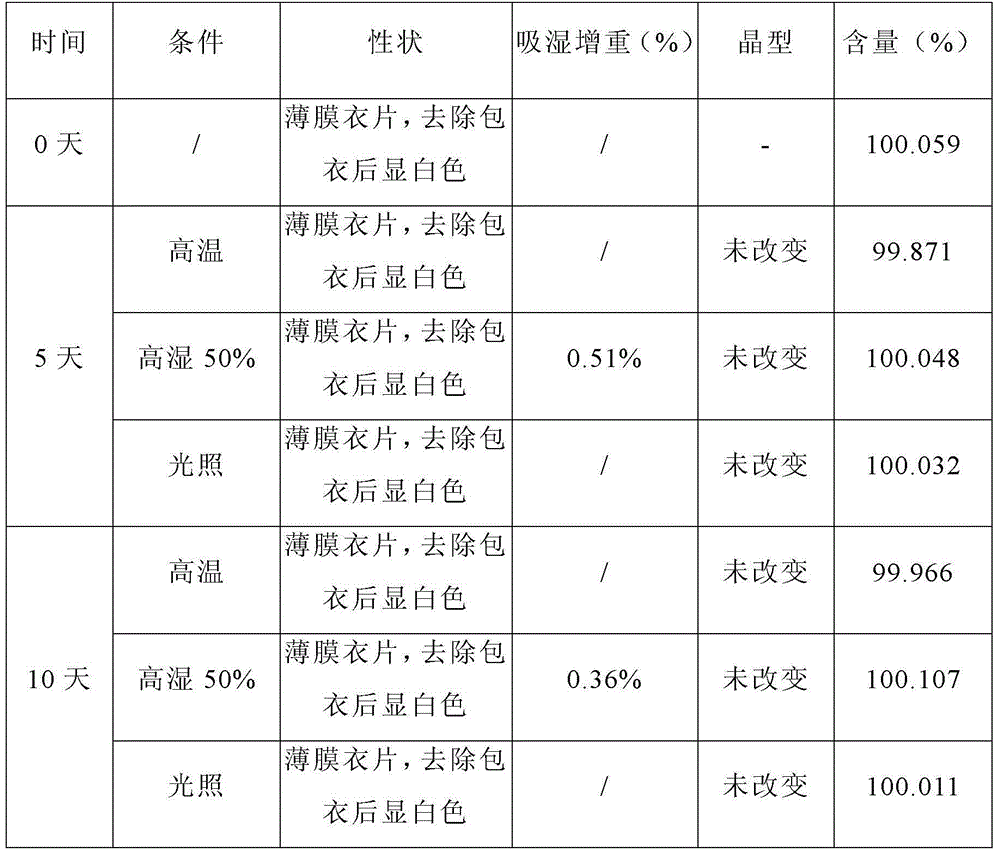

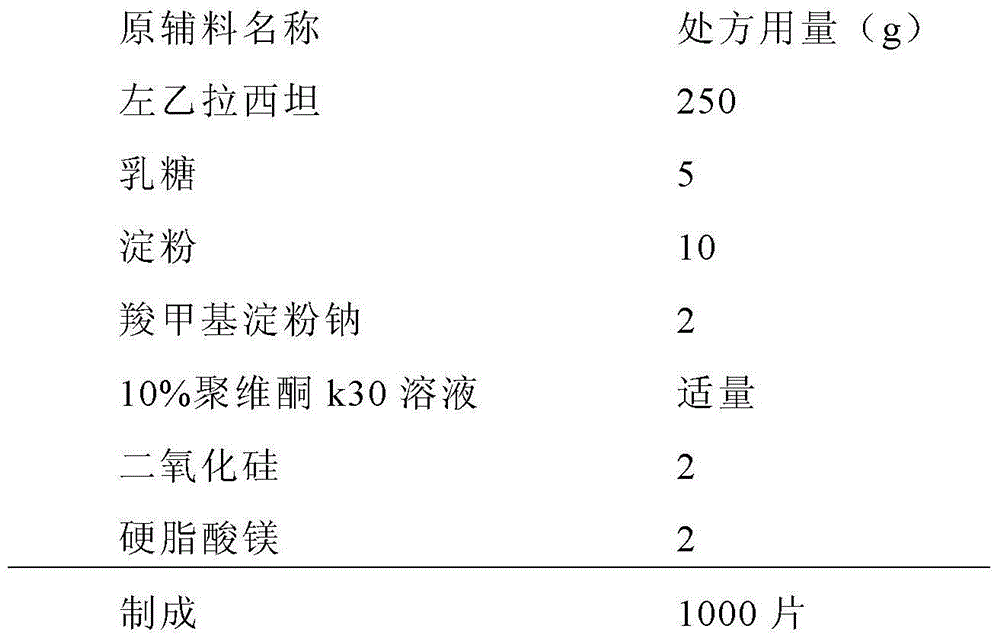

Levetiracetam tablet and preparation method thereof

InactiveCN105434375ASuitable for circulationSuitable for storageOrganic active ingredientsNervous disorderMedicineMedical prescription

The present invention discloses a levetiracetam tablet and a preparation method thereof. The levetiracetam tablet is reasonable in formulation and stable in preparation process, achieves better auxiliary material selection effect, and is low in production cost.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

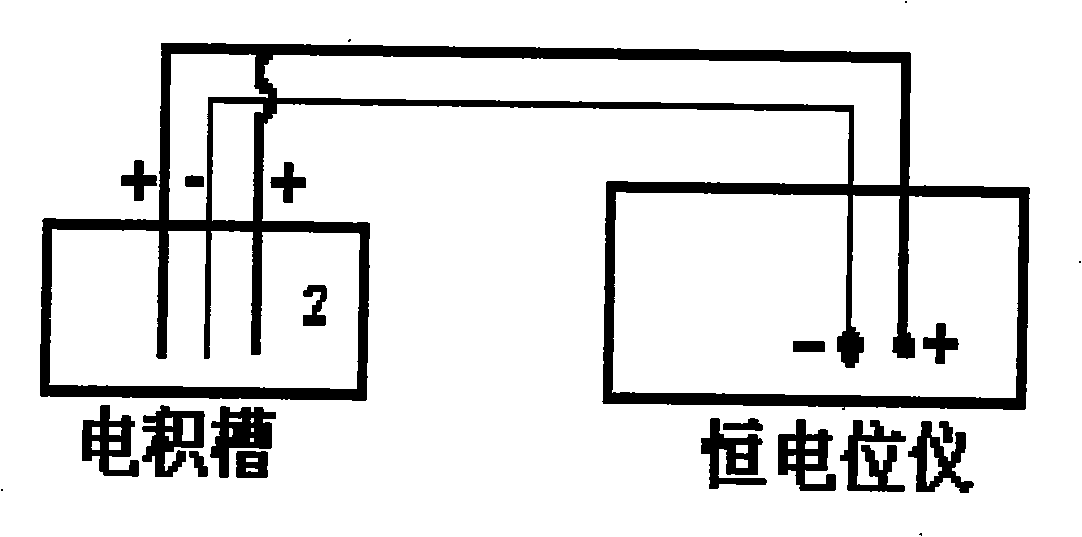

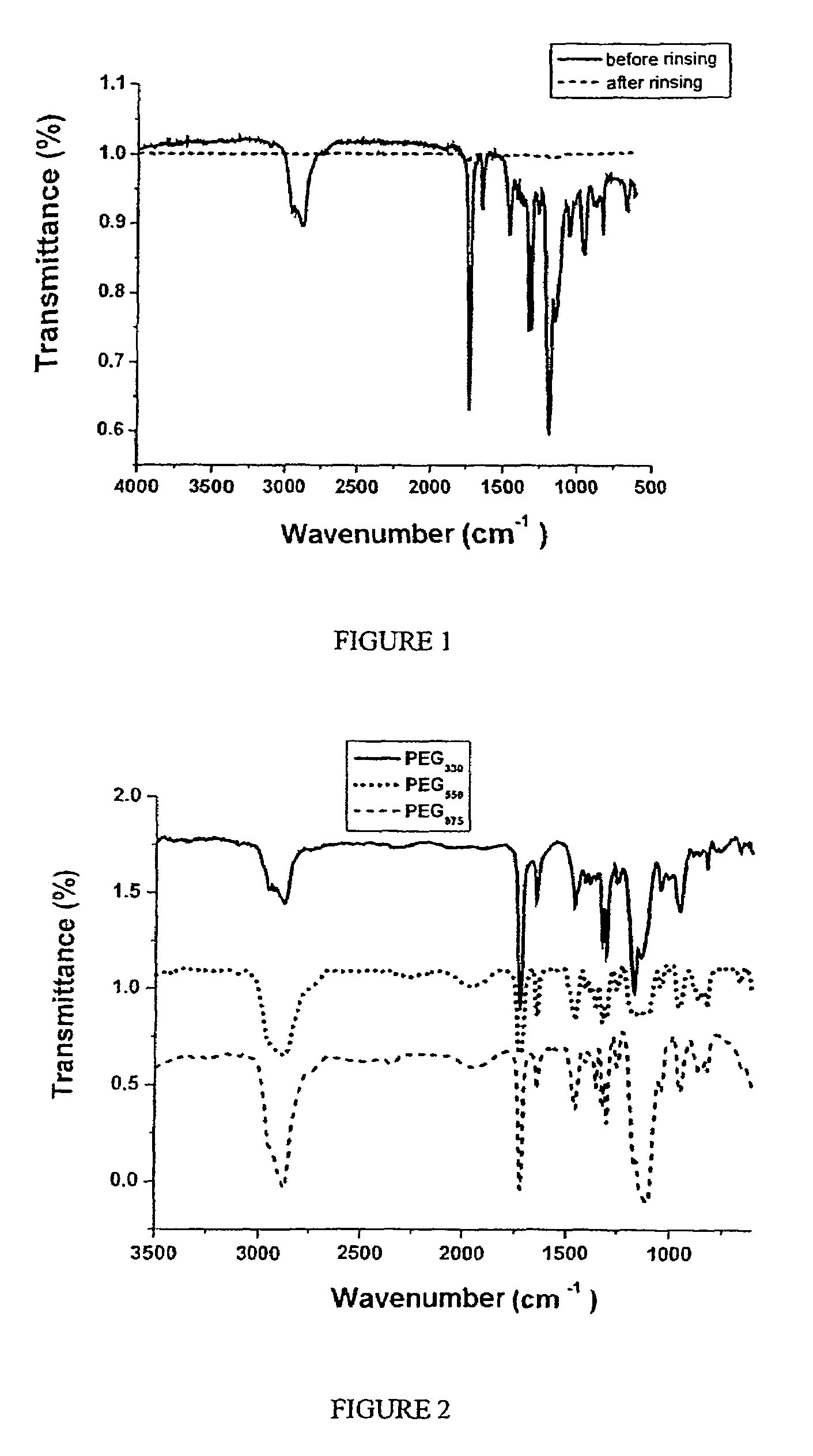

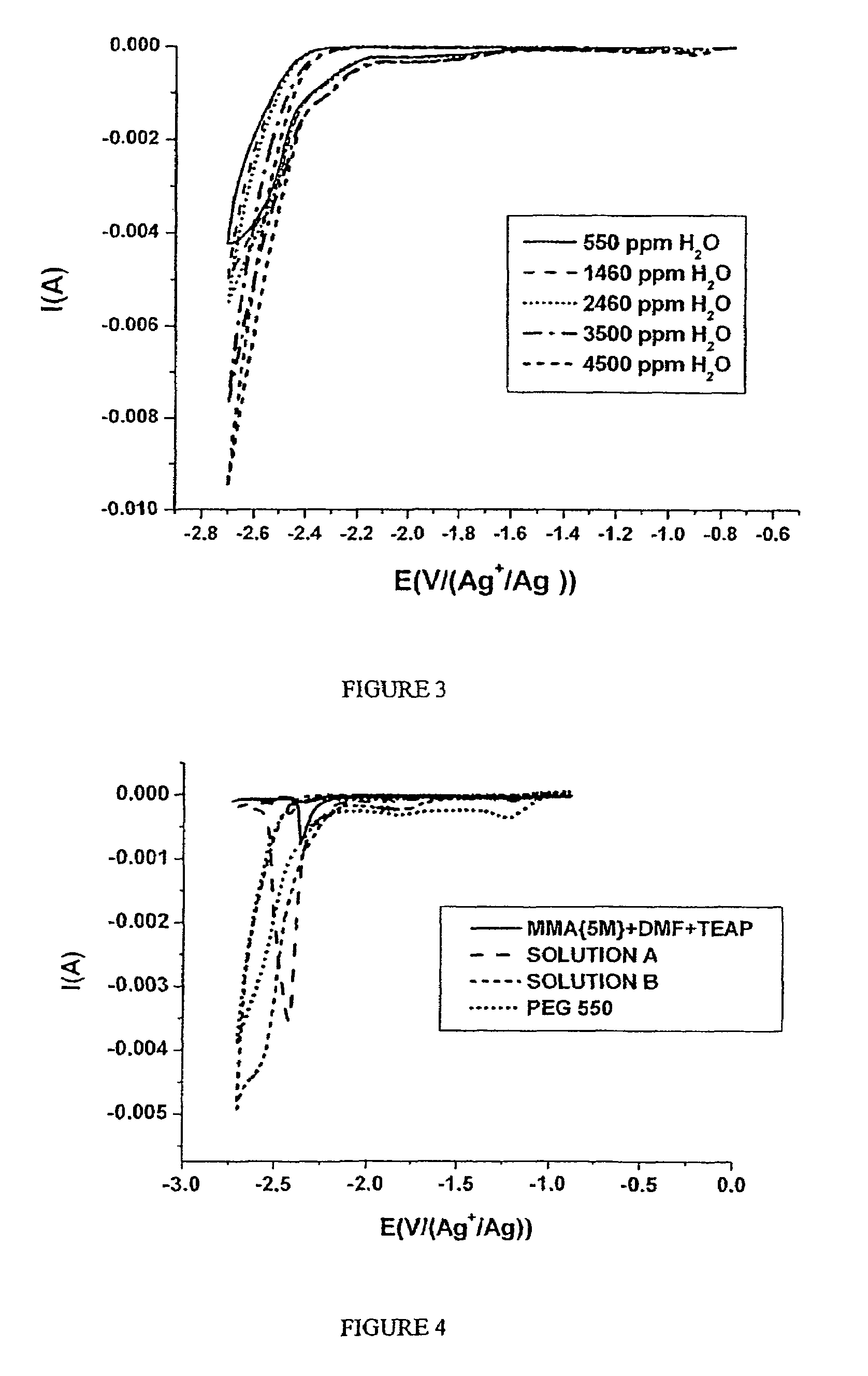

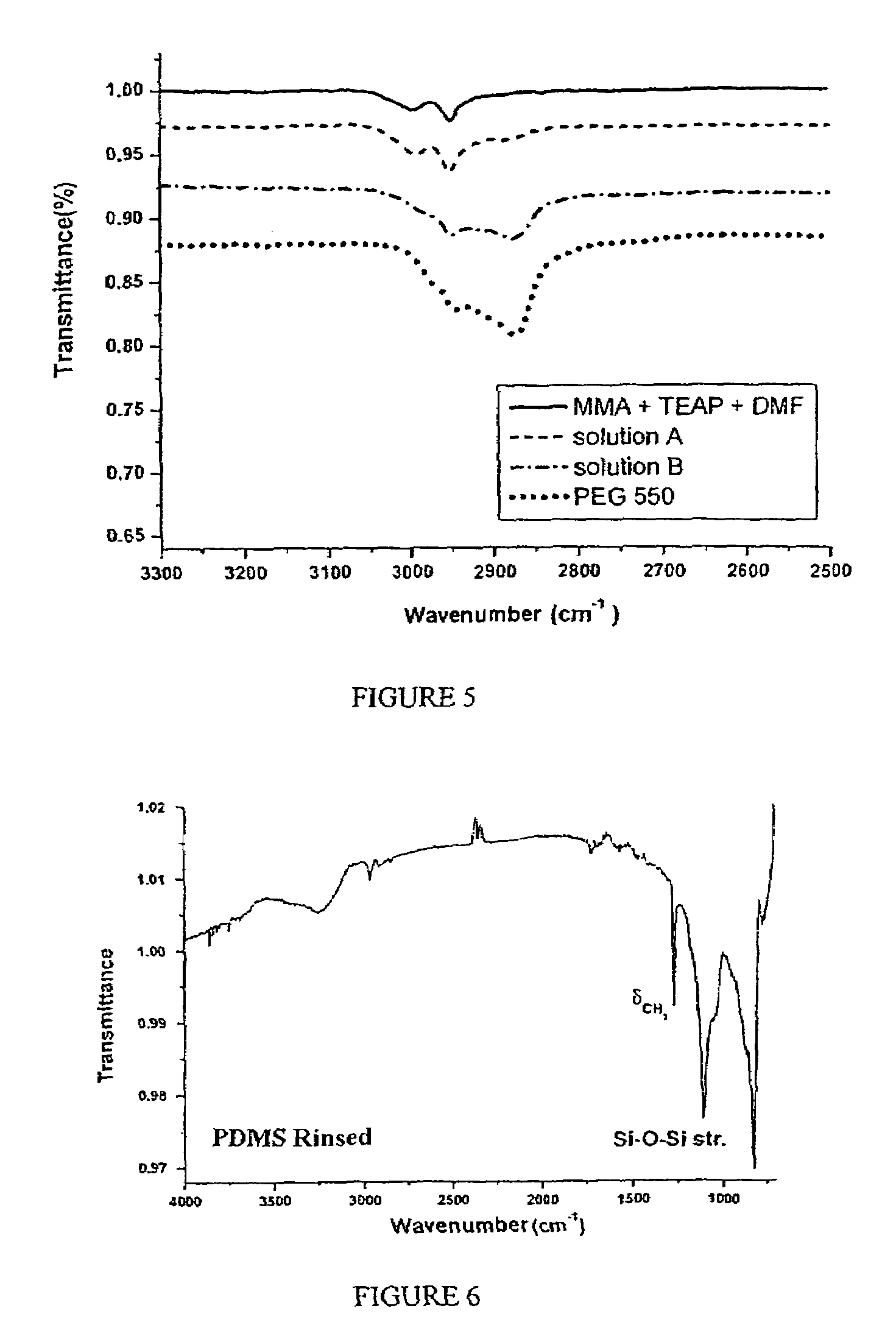

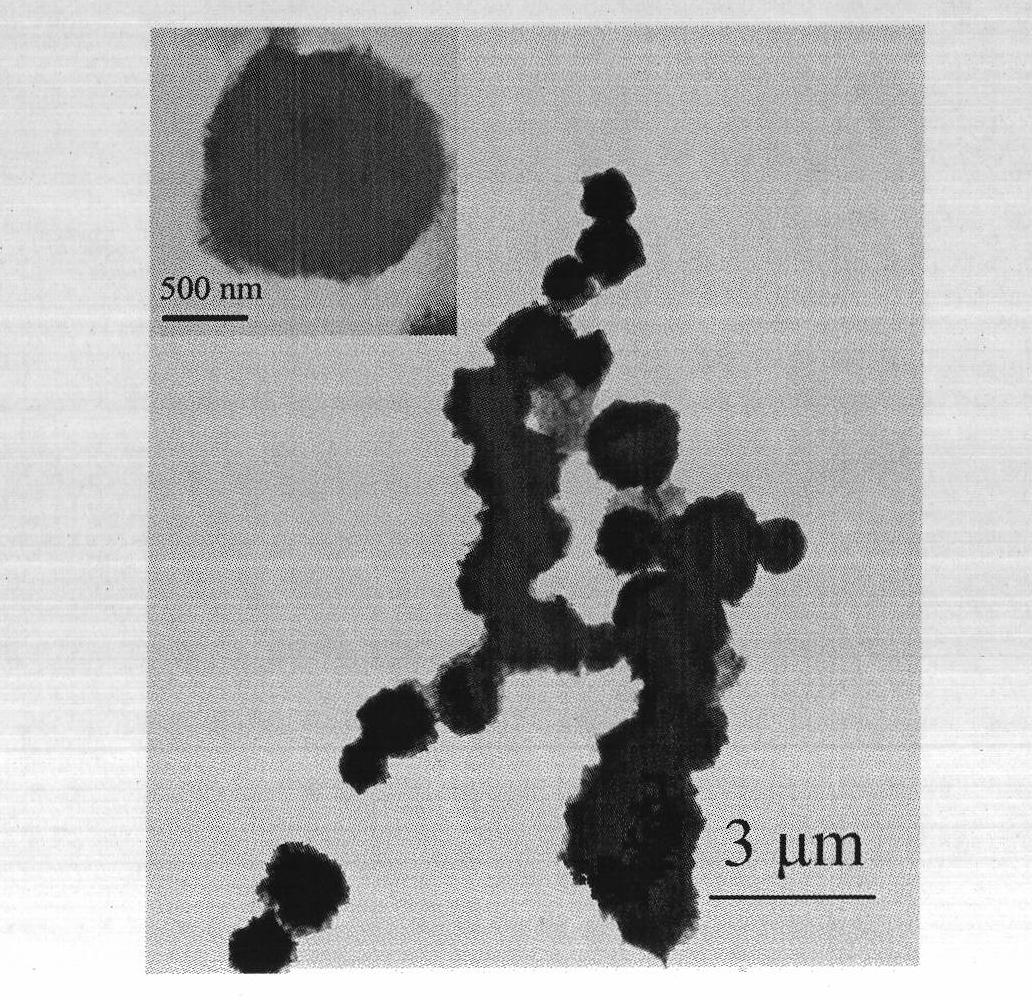

Method of fixing macro-objects to an electricity conducting- or semi-conducting surface by means of electrografting, surfaces thus obtained and applications thereof

ActiveUS7591937B2Promote stabilityImprove stabilityAnodisationElectrolysis componentsElectricityEngineering

The invention relates to a method of fixing macro-objects to an electricity conducting- or semi-conducting surface by means of electrografting. The invention also relates to the electricity conducting- or semi-conducting-surfaces obtained using the aforementioned method and to the applications of same.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Calcium carbonate/nickel composite conductive material matrix antistatic coating and preparation method thereof

ActiveCN101921528AEasy to obtainGuaranteed antistatic effectEpoxy resin coatingsElectrically-conductive paintsMetallic materialsEconomic benefits

The invention discloses a calcium carbonate / nickel composite conductive material matrix antistatic coating and a preparation method thereof. The antistatic coating comprises the following main components in percentage by weight: 10-70 percent of composite conductive material, 0.5-3.0 percent of dispersant, 0.5-3.0 percent of wetting dispersant, 0.1-2.0 percent of deformer, 0.1-2.0 percent of leveling agent, 10.0-50.0 percent of resin and the balance of mixed thinner. In the invention, the antistatic coating is prepared by adding the calcium carbonate / nickel composite conductive material with favorable conductivity so that the antistatic effect of the antistatic coating is equivalent to that of a metal matrix antistatic coating and is stable and unchanged along with the changes of temperature, time, moisture, and the like. Compared with the metal matrix antistatic coating, the prepared antistatic coating greatly decreases the production cost, improves the economic benefits of enterprises, simultaneously solves the problems of excessive metal material consumption, and the like, accords with the sustainable development strategy and can be widely applied to the fields of electronic equipment, container pipelines, indoor decoration, furniture finishing, and the like.

Owner:池州市贵兴非矿新材料有限公司

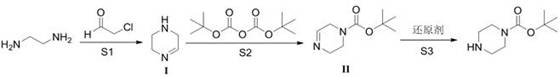

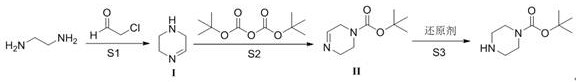

Preparation method of N-t-butyloxycarbonyl piperazine

ActiveCN113185478AAvoid it happening againRaw materials are easy to getOrganic chemistryBulk chemical productionTert-Butyloxycarbonyl protecting groupCombinatorial chemistry

The invention discloses a preparation method of N-t-butyloxycarbonyl piperazine, and belongs to the field of synthesis of drug intermediates. According to the method, ethylenediamine is taken as a raw material, and the N-t-butyloxycarbonyl piperazine is prepared through ring closing, acylation reaction and reduction reaction. The invention provides the preparation method of the N-t-butyloxycarbonyl piperazine. The method is simple and convenient to operate, high in atom utilization rate and good in product purity.

Owner:UNIV OF JINAN

Nanometer composite bactericide used in field of environments

InactiveCN108323529AImprove the bactericidal effectReduce dosageBiocideFungicidesMicrometerHigh surface

The invention belongs to the technical field of environmental chemistry, and particularly relates to a nanometer composite bactericide used in the field of environments. Graphene with the length reaching the micrometer grade is used as a carrier, the characteristics of the large surface area and the high surface activity of the graphene are utilized, silver ions are converted into nanometer silveron the surface of the graphene by means of in-situ reaction, and accordingly the silver phosphate / graphene composite bactericide can be prepared. The nanometer composite bactericide has the advantages that the nanometer silver phosphate composite bactericide which is easy to recycle is high in chemical stability, and diversified bacteria can be effectively killed by the nanometer composite bactericide; the bactericidal performance of the nanometer composite bactericide with the large surface area can be effectively improved.

Owner:上海泽铭环境科技有限公司

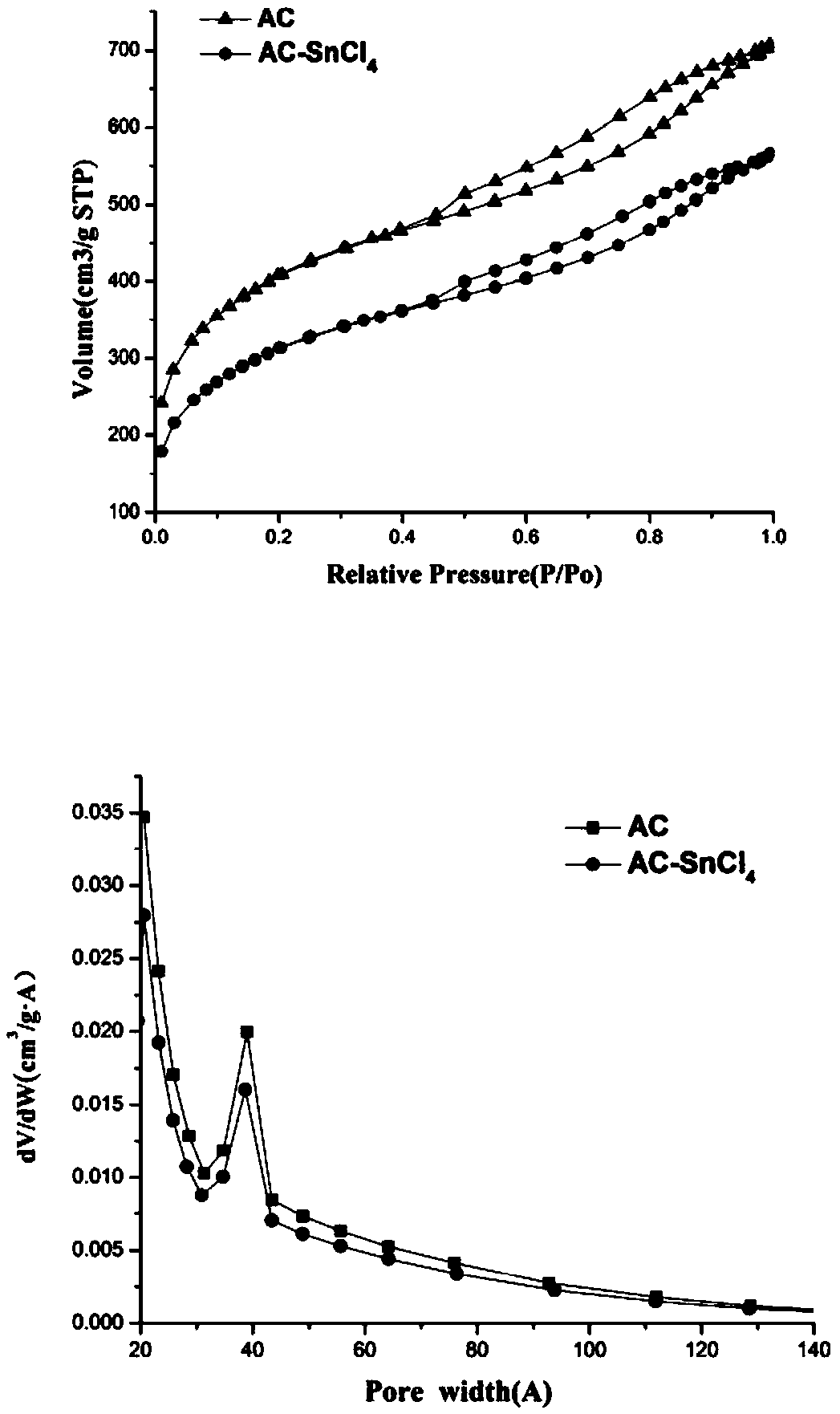

Desulfurization refining method of sulfate turpentine with ultra-low sulfur content

InactiveCN109762470AWell-developed void structureImprove adsorption capacityTurpentine spiritsWater vaporSorbent

The invention provides a desulfurization refining method of sulfate turpentine with the ultra-low sulfur content, and relates to sulfate turpentine. The desulfurization refining method comprises the steps that the sulfate turpentine is rectified and separated through a vacuum rectifying tower to obtain pinene; the pinene is hit into a fixed bed filled with shell activated carbon to be soaked, thenthe pinene is replaced repeatedly and cyclically in the fixed bed through a circulating pump, a pinene material is released from the side line of the circulating pump, ultra-low-sulfur pinene is obtained, the fixed bed is purged through high-temperature water vapor and nitrogen, thus the activated carbon is regenerated, and the desulfurization-refined sulfate turpentine with the ultra-low sulfurcontent is obtained. The small granular shell activated carbon is adopted as an adsorbing agent, the activated carbon has a developed gas structure and is high in absorbing ability, large in strength,stable in chemical property and durable, sulphur residues in the sulfate turpentine are effectively adsorbed, material diffusion is accelerated through the circulating pump, thus materials are distributed evenly, one the one hand, the adsorbing effect of the activated carbon is enhanced, on the other hand, physical damage of stirring on the activated carbon is avoided, operation is easy, energy consumption is small, and industrial feasibility is achieved.

Owner:厦门中坤化学有限公司

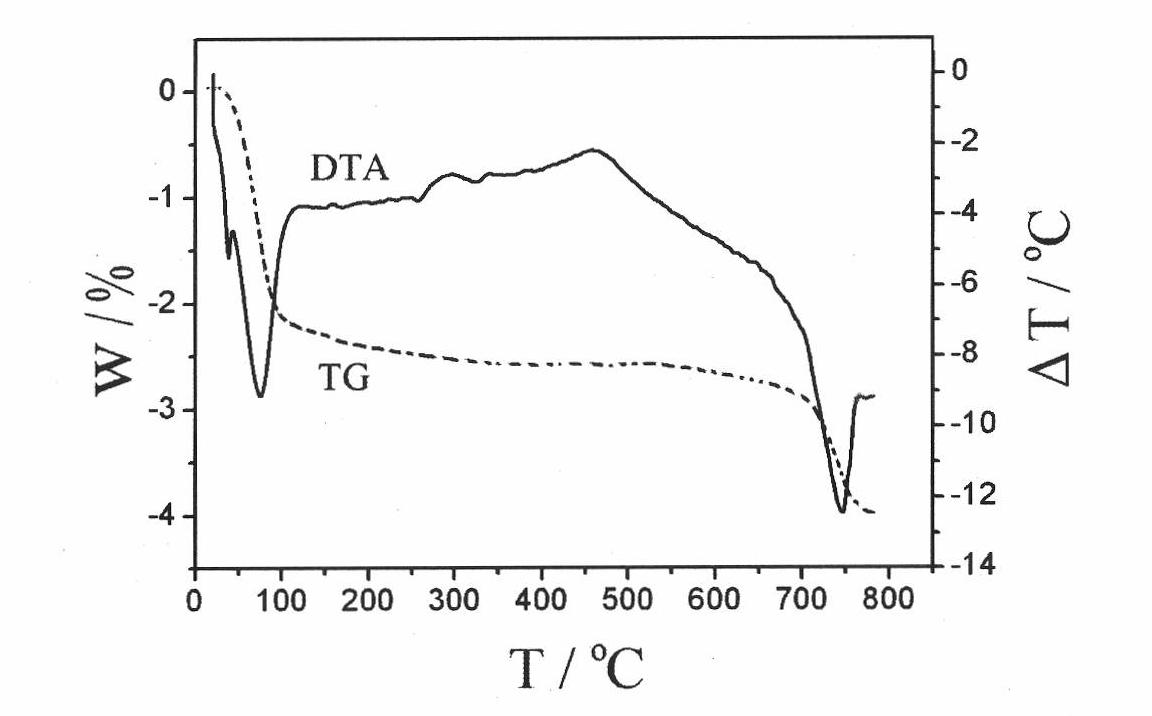

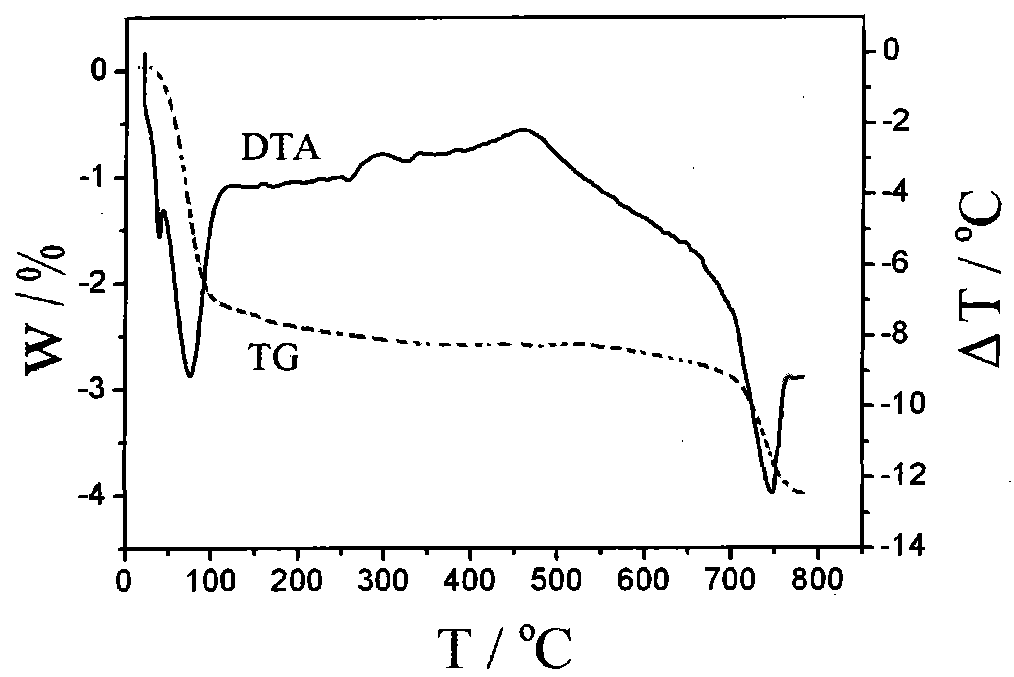

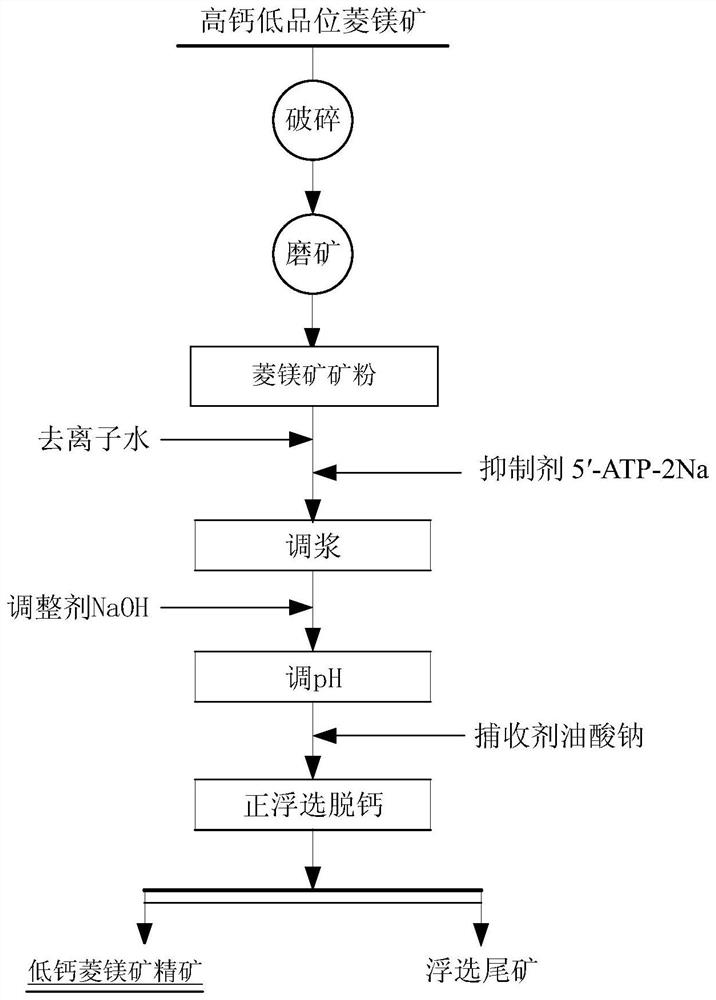

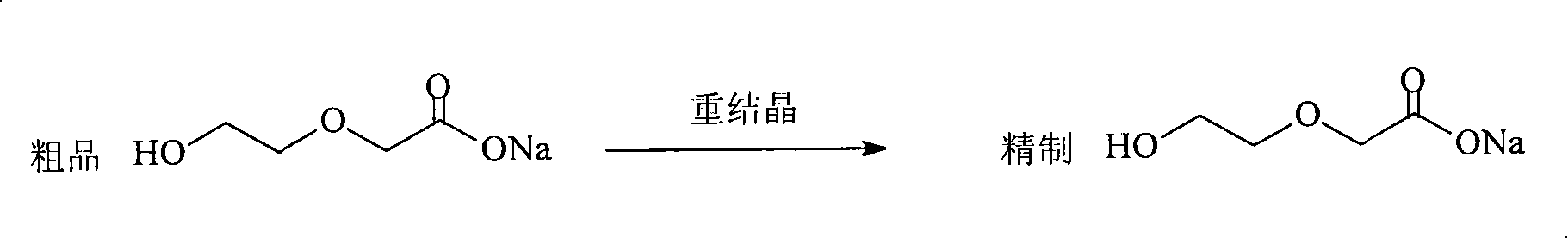

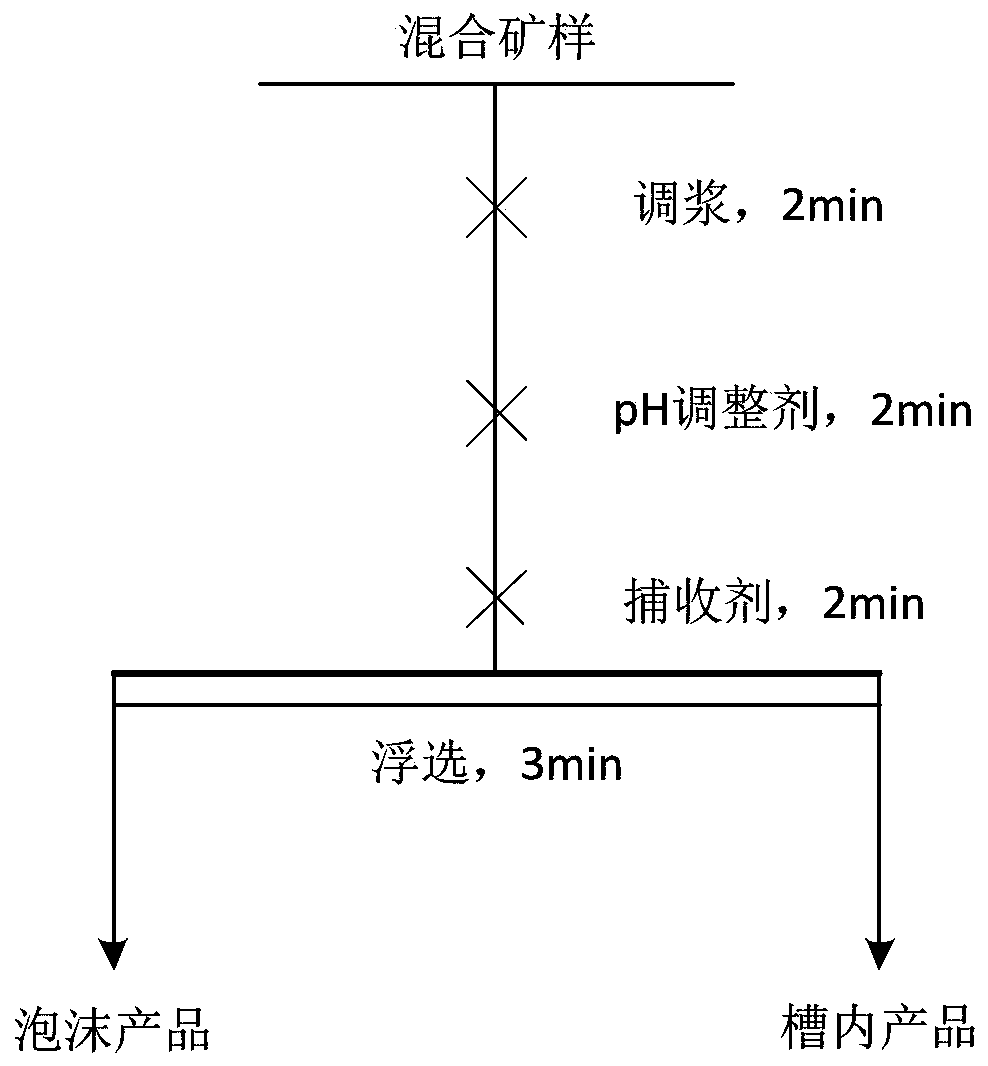

Application of a High Efficiency Inhibitor 5′-atp-2na in Decalcification of Magnesite by Positive Flotation

ActiveCN111036416BLower calcium levelsImprove concentrate flotation indexFlotationPhysical chemistryPhosphoric acid

The application of a high-efficiency inhibitor 5'-ATP-2Na in magnesite positive flotation decalcification belongs to the field of magnesite flotation decalcification inhibitors. This application is to add highly effective inhibitor 5′‑ATP‑2Na (adenosine‑5′‑triphosphate disodium salt hydrate) in the preparation of magnesite slurry during the magnesite positive flotation decalcification process The amount of added efficient inhibitor 5′-ATP-2Na accounts for 0.8mmol / L~1.3mmol / L in molar concentration of magnesite pulp; the mass percentage concentration of magnesite in magnesite pulp is 15~30 %. The high-efficiency inhibitor 5′-ATP-2Na is used for the decalcification of magnesite by positive flotation. Under the sodium oleate or oleic acid flotation system, by adding the high-efficiency inhibitor 5′-ATP-2Na, the simultaneous expansion of magnesite The flotation difference of the calcium gangue mineral dolomite realizes the efficient separation of magnesite and dolomite, thereby reducing the magnesium impurities to improve the quality of magnesite concentrate products, and providing a new method for the flotation separation of high calcium and low grade magnesite flotation inhibitors.

Owner:NORTHEASTERN UNIV LIAONING

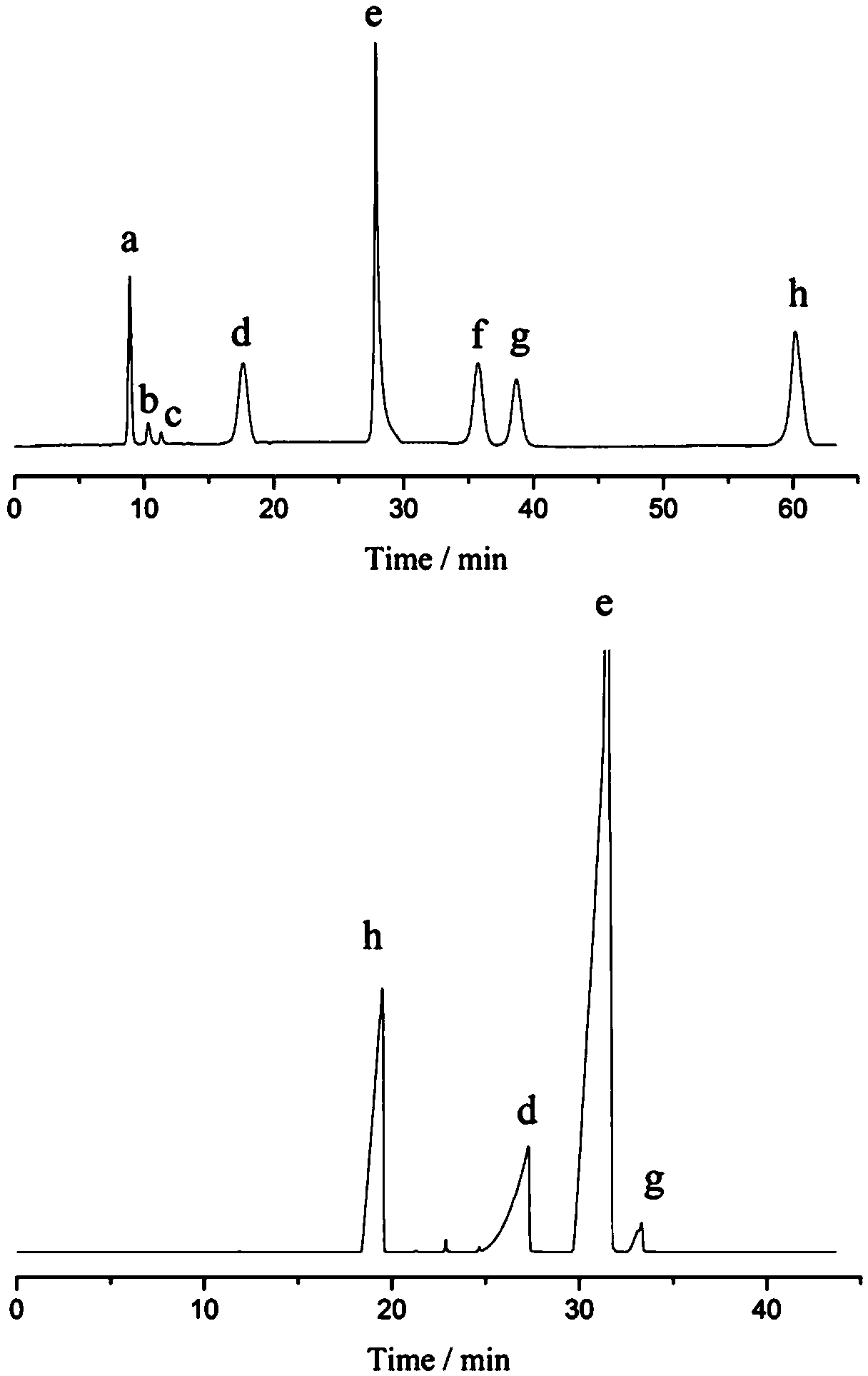

Crude benzene hydrorefining process

ActiveCN103274885BAvoid high temperature polymerization coking to block the systemHigh outputHydrocarbon purification/separationHydrocarbonsCatalytic reformingDistillation

The invention provides a crude benzene hydrogenation refining process, which is obtained by sequentially performing liquid-phase catalytic pre-hydrogenation reaction, gas-phase catalytic pre-hydrogenation reaction and main catalytic hydrogenation reaction on crude benzene, and then extracting, rectifying and main hydrogenation reaction material, obtained distillates of each distillation range; compared with the prior art, the present invention adjusts the catalytic hydrogenation process to a three-stage hydrogenation technology, and does not need to pre-separate heavy benzene before catalytic hydrogenation; In the hydrogenation process, the unsaturated olefins in the crude benzene are hydrogenated into saturated hydrocarbons at a relatively low reaction temperature of 130~140°C, so as to avoid the unsaturated hydrocarbons contained in the crude benzene that are easy to polymerize at high temperatures in the subsequent process. In the case of high-temperature polymerization coking and blockage of the system; the method can hydrogenate heavy benzene in crude benzene to obtain mixed aromatics, which can be used as high-quality blending components of gasoline and diesel, and the output value and added value of materials can be improved.

Owner:湖北巨邦石油化工有限公司

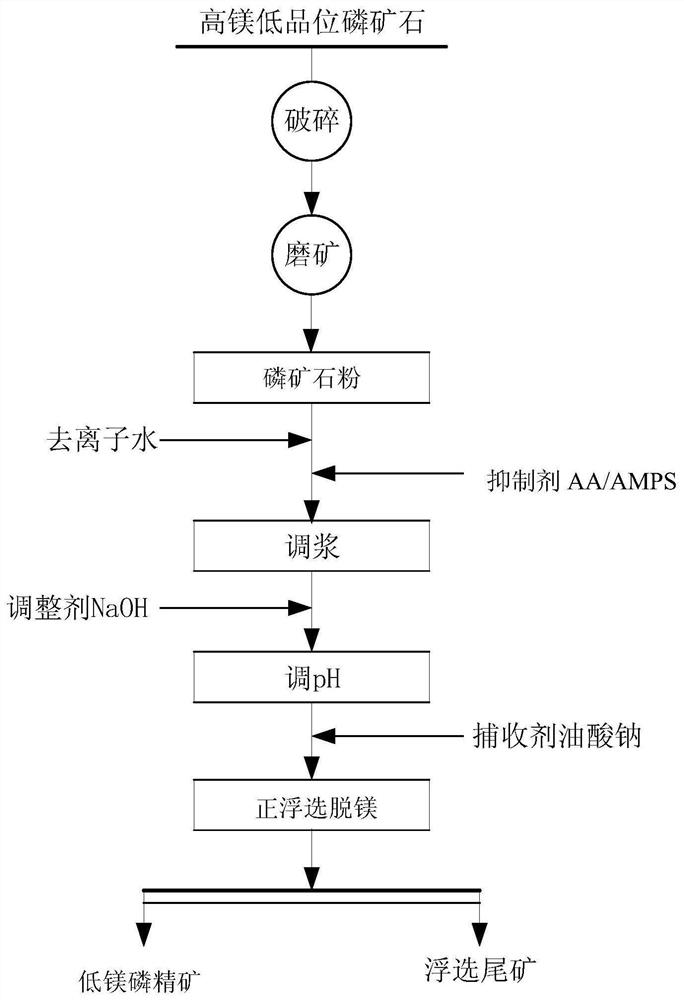

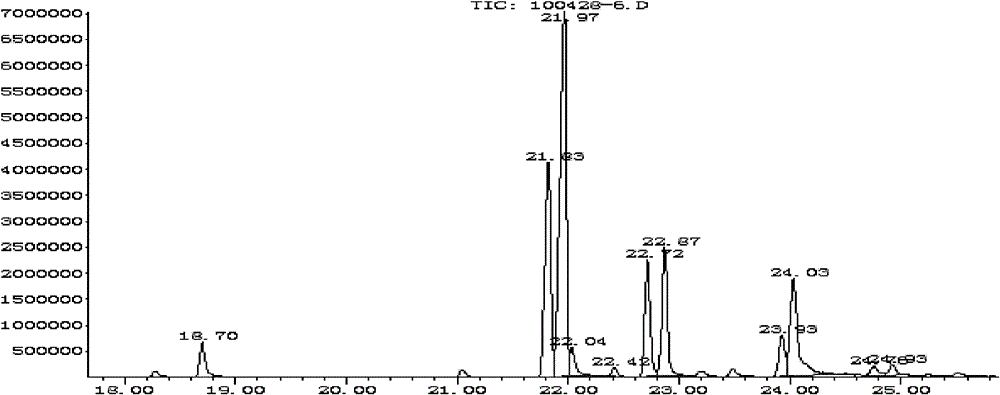

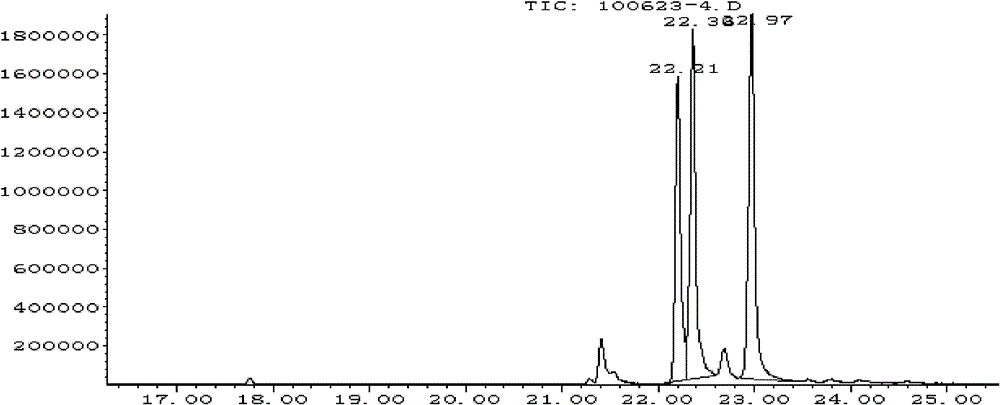

Application of a kind of inhibitor aa/amps in positive flotation demagnesization of phosphate rock

The invention relates to the application of an inhibitor AA / AMPS in positive flotation demagnesization of phosphate rock, which belongs to the field of mineral processing and purification technology of phosphate rock. This application is to add inhibitor AA / AMPS in the process of positive flotation demagnesification of phosphate rock. Specifically, the inhibitor AA / AMPS is used to prepare phosphate rock pulp, wherein the mass concentration of the phosphate rock pulp is 20-25%; the inhibitor AA / AMPS accounts for 100-140 g / t of the phosphate rock pulp. Inhibitor AA / AMPS (acrylic acid-2-acrylamide-2-methylpropane sulfonic acid copolymer), for phosphate rock containing a lot of dolomite, under alkaline conditions, inhibits the flotation of dolomite by positive flotation process It can effectively increase the difference in flotation performance between apatite and dolomite, and facilitate the efficient removal of dolomite. In addition, the inhibitor AA / AMPS has the characteristics of strong selectivity of inhibitory performance, low cost, and simple use, etc. It can effectively reduce the magnesium content of phosphate concentrate, improve the quality of concentrate, and realize the flotation of high-magnesium and low-grade phosphate rock to reduce magnesium. Target.

Owner:NORTHEASTERN UNIV LIAONING

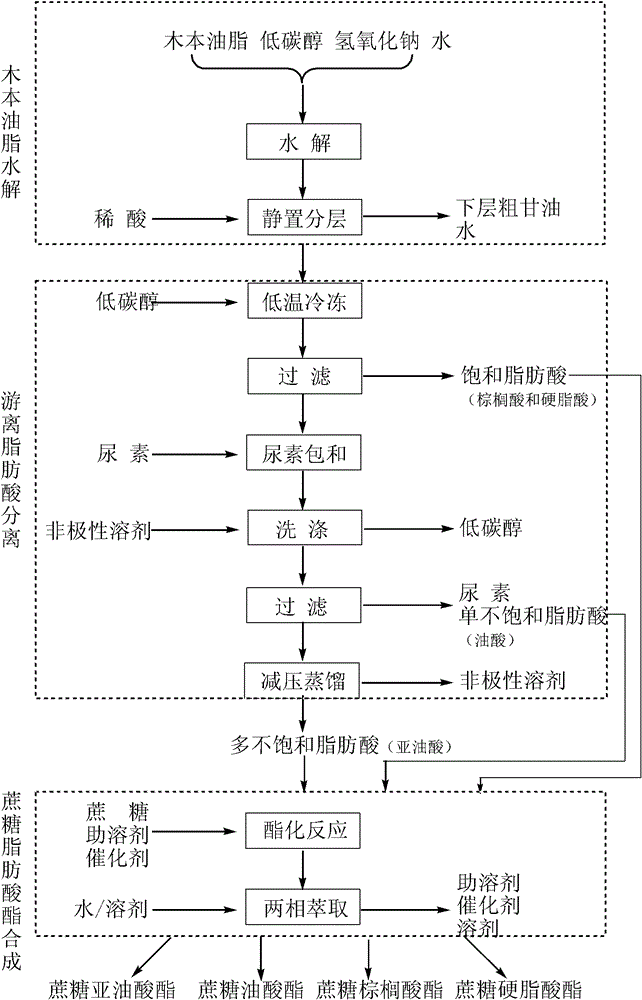

Method for preparing high-grade sucrose fatty acid ester from woody oil

InactiveCN102060881BLow costHigh purityEsterified saccharide compoundsSugar derivativesSucroseAqueous sodium hydroxide

The invention provides a method for preparing high-grade sucrose fatty acid ester from woody oil, comprising the following steps of: mixing woody oil, lower alcohol and an aqueous sodium hydroxide solution for reacting, after the reaction is ended, regulating the pH value to be faintly acid, standing for demixing, separating out a liquid at the upper layer and a hydrous crude glycerol phase at the lower layer; then mixing the liquid at the upper layer with the lower alcohol for sealing, freezing at low temperature, then filtering to obtain a clear filtrate, dissolving filter cakes, and then carrying out reduced pressure distillation to obtain a saturated fatty acid; mixing the clear filtrate with urea, heating until the mixture is dissolved, filtering after freezing at low temperature, rotatably evaporating the filtrate, then dissolving with a non-polar solvent, filtering, rotatably evaporating the filtrate to obtain polyunsaturated fatty acids; and finally, under the protection of N2, mixing the separated fat acids with sucrose, a cosolvent and a catalyst, heating for reacting, and refining the reaction mixture with a two-phase extraction method to obtain the sucrose fatty acid ester. The invention has the characteristics of easy obtaining of rich raw materials, low cost, easy separation of product, stable performance, high purify, and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

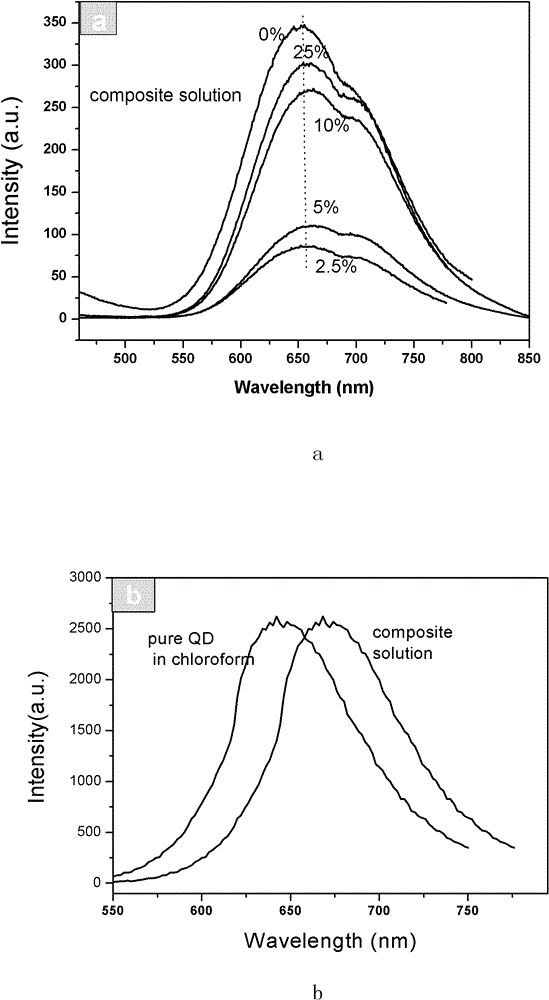

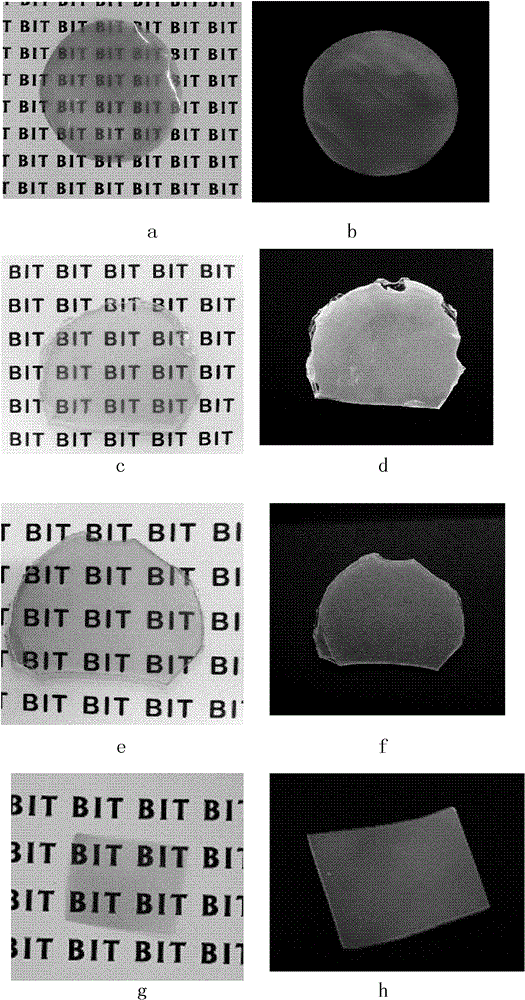

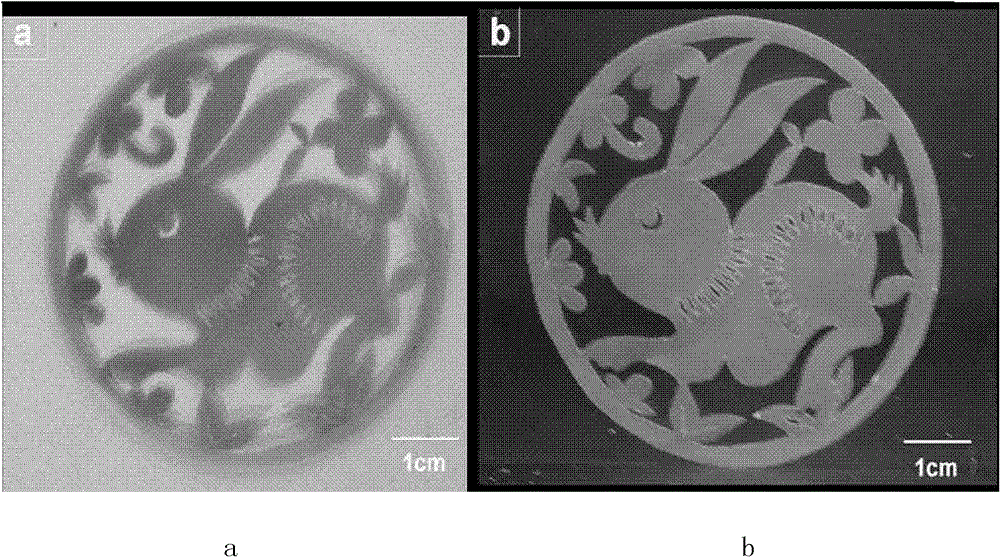

Flexible, environmentally-friendly, transparent and adjustable-illuminant-color film material and preparation method thereof

The invention relates to a flexible, environmentally-friendly, transparent and adjustable-illuminant-color film material and a preparation method thereof, belonging to the field of photoelectric functional high polymer materials. The preparation method comprises the following steps of: diluting mercaptopropionic acid with a DMF (Dimethyl Formamide) solvent, and mixing with a chloroform solution of quantum dots CuInS2 / ZnS to obtain a DMF colloidal solution of the quantum dots; dispersing cyanoethyl cellulose into the DMF solvent, and stirring till the cyanoethyl cellulose is fully dissolved and the concentration of the cyanoethyl cellulose is 10-100 g / L to obtain a DMF solution of cyanoethyl cellulose; mixing the two solutions at room temperature till the quantum dots account for 2.5-25 percent by mass of the cyanoethyl cellulose, and stirring till the quantum dots are uniformly distributed in the DMF solution of the cyanoethyl cellulose to obtain a mixed solution; and pouring the mixed solution to prepare the film material. The obtained film material has the characteristics of nontoxicity, environmental friendliness, transparency, flexibility, adjustable illuminant color and adjustable area. The preparation method is simple and has low cost and high industrial practicability.

Owner:HEBEI YEZHIYUAN CHEM CO LTD

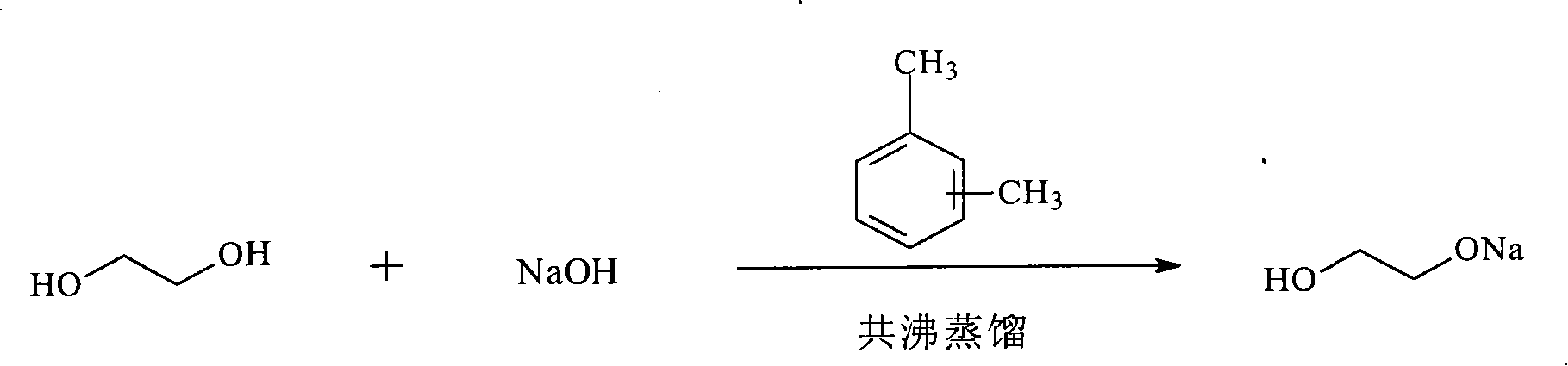

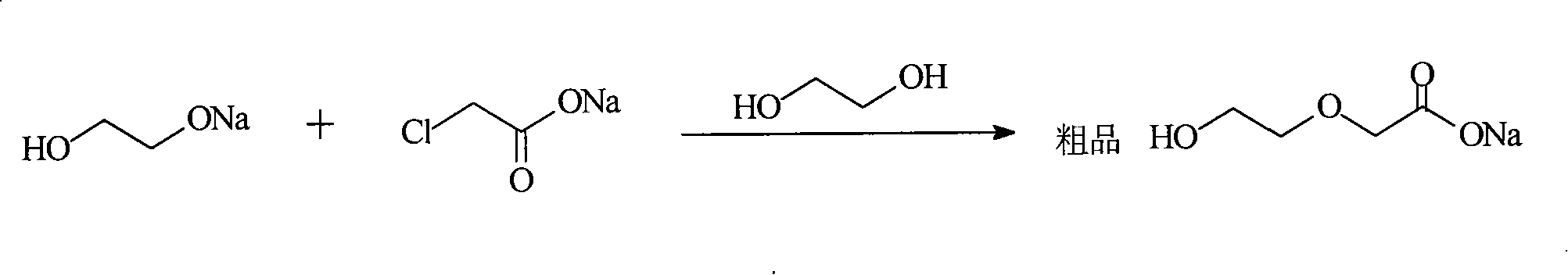

Method for synthesizing 1,4-dioxane-2-ketone by ethylene glycol

Owner:NANTONG FINC PHARMA CHEM +1

Treatment method for ultrahigh-concentration sewage containing phosphorus

InactiveCN102351347BRealize resource utilizationAvoid secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeSewage treatment

A method for treating ultra-high-concentration phosphorus-containing sewage belongs to the field of environmental chemical water pollution control. The method includes the following steps: discharging sewage into a water collection well; Discharge into the adjustment tank, and add sulfuric acid solution into the adjustment tank, when the pH value of the liquid in the adjustment tank reaches 8, stop adding sulfuric acid solution; discharge the adjusted sewage into the underground sedimentation tank, this step is divided into three treatments Stage: In the first stage, calcium chloride is added to the sedimentation tank; in the second stage, hydrogen peroxide is added to the sewage treated in the first stage; in the third stage, compound compound is added to the sewage treated in the second stage flocculant. The TP and COD of the sewage treated by this method can meet the discharge standards, and the precipitated products can be used as coatings and chemical fertilizers, which solves the problem of secondary pollution caused by the chemical sludge produced in the treatment of phosphorus-containing sewage in the past, and the water quality of the treatment Phosphorus resources are recycled while meeting the discharge standards.

Owner:NORTHEAST GASOLINEEUM UNIV

Application of efficient inhibitor 5'-ATP-2Na in magnesite direct flotation decalcification

ActiveCN111036416ALower calcium levelsImprove concentrate flotation indexFlotationPhosphoric acidDolomite

The invention discloses an application of an efficient inhibitor 5'-ATP-2Na in magnesite direct flotation decalcification, and belongs to the field of magnesite flotation decalcification inhibitors. According to the application, in the magnesite direct flotation decalcification technological process, the efficient inhibitor 5'-ATP-2Na (disodium adenosine-5'-triphosphate hydrate) is added in magnesite ore pulp preparation, wherein the molar concentration of the added efficient inhibitor 5'-ATP-2Na in the magnesite ore pulp is 0.8 mmol / L-1.3mmol / L and the mass percentage concentration of magnesite in the magnesite pulp is 15-30%. The efficient inhibitor 5'-ATP-2Na is used for magnesite direct flotation decalcification, under a sodium oleate or oleic acid flotation system, by adding the efficient inhibitor 5'-ATP-2Na, the flotation difference between the magnesite and the calcium-containing gangue mineral dolomite is enlarged, efficient separation of the magnesite and the dolomite is achieved, and therefore magnesium impurities are reduced, the quality of magnesite concentrate products is improved, and a novel flotation inhibitor is provided for flotation separation of high-calcium low-grade magnesite.

Owner:NORTHEASTERN UNIV

A kind of smithsonite type zinc oxide ore flotation desiliconization method

ActiveCN107570326BRealize the goal of silicon reduction in flotationSimple systemFlotationSodium propionateQuartz

Owner:NORTHEASTERN UNIV LIAONING

Biopolyethylene-containing packaging film and production process thereof

The invention relates to the technical field of packaging films, particularly to a packaging film containing biopolyethylene, and a production process thereof. The packaging film is prepared from, bymass, 5%-70% of biopolyethylene, 25%-85% of petroleum raw material polyethylene and 5%-10% of additive color masterbatch. Compared with the prior art, the packaging film of the invention has the advantages of less environmental pollution, environmental friendliness, simple production process, stable material performance, low production cost and high industrial feasibility, and solves the influenceof the traditional packaging film taking petroleum as a raw material on the environment.

Owner:SHANGHAI FUKUSUKE IND

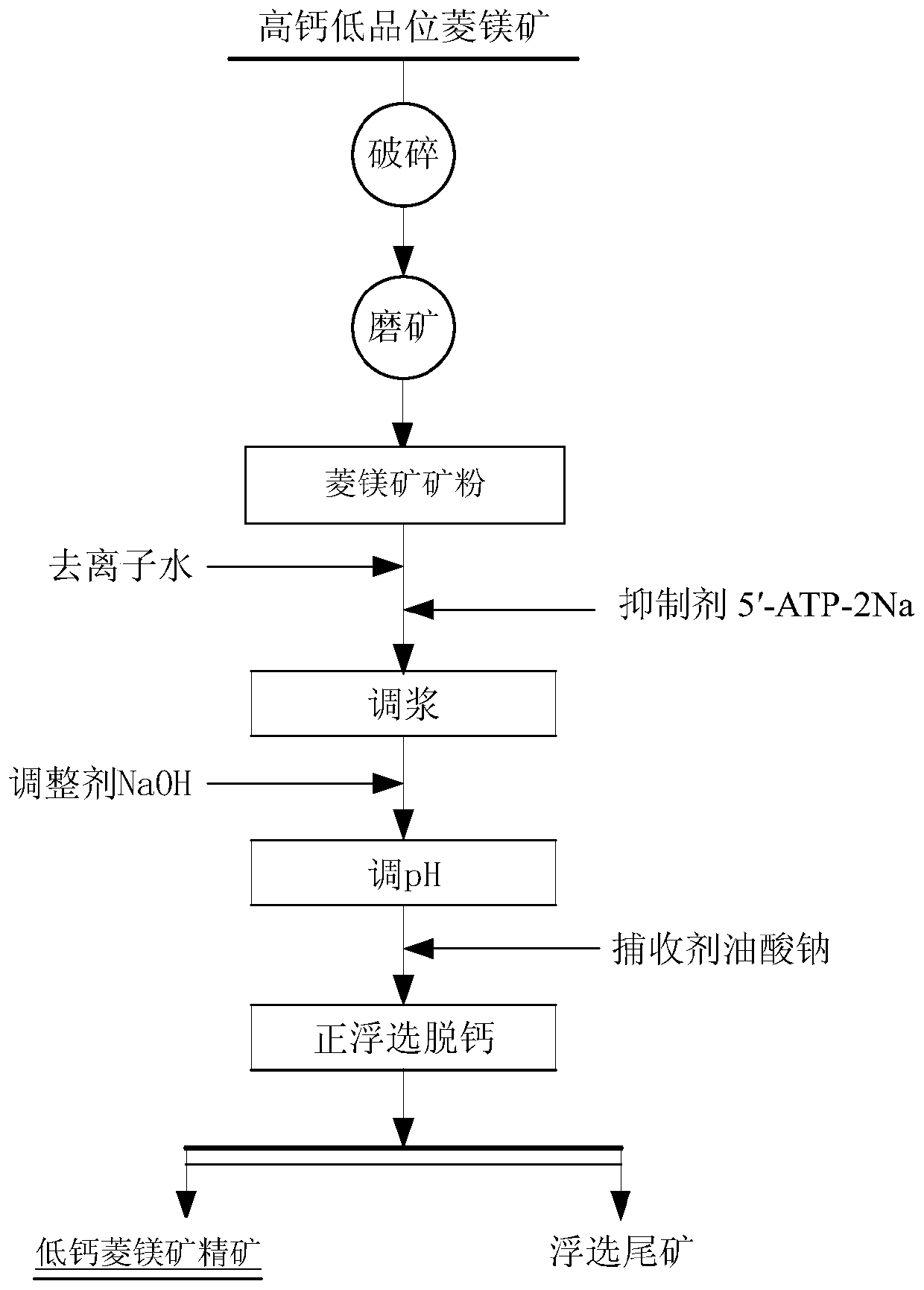

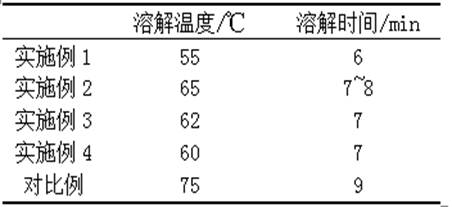

A method for flotation purification of hemimorphite from quartz

The invention relates to a method for flotation and purification of hemimorphite from quartz, specifically to a flotation separation method for hemimorphite and quartz, and belongs to the technical field of mineral flotation separation in the field of mineral processing engineering. A method for flotation and purification of hemimorphite from quartz. Mix the mixed mineral sample of hemimorphite and quartz to be processed with deionized water, and add a collector to the evenly stirred slurry. The amount of collector is 750 ~900g / t; stir the slurry added with the collector evenly and then perform flotation, wherein the collector is sodium N,N'-bis-fatty acyl ethylenediamine dipropionate. The process proposed by the present invention for flotation and purification of hemimorphite from quartz has a simple process flow, simple chemical system, convenient operation, and good industrial feasibility prospects.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of N-alkyloxy oxalyl alanine alkyl ester

ActiveCN102249946BEasy to operateShort preparation cycleOrganic compound preparationCarboxylic acid amides preparationPyruvic acidPhotochemistry

The invention discloses a preparation method of N-alkyloxy oxalyl alanine alkyl ester, comprising the steps of: subjecting pyruvic acid alkyl ester (2) and oxamic acid alkyl ester (3) to a reductive amination reaction so as to obtain a target compound (1) directly in the following reaction route; or, conducting a dehydration reaction to pyruvic acid alkyl ester (2) and oxamic acid alkyl ester (3) first so as to obtain an intermediate Schiff base (4), which then undergoes a reduction reaction, thus obtaining the target compound (1), with a following reaction route; wherein, R1 and R2 respectively represent methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl or t butyl. With the advantages of simple operation, short preparation period, low energy consumption, strong industrial feasibility and the like, the preparation method provided in the invention can satisfy the requirements for large-scale industrial production.

Owner:SHANGHAI HEGNO PHARMA HLDG +2

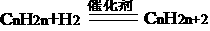

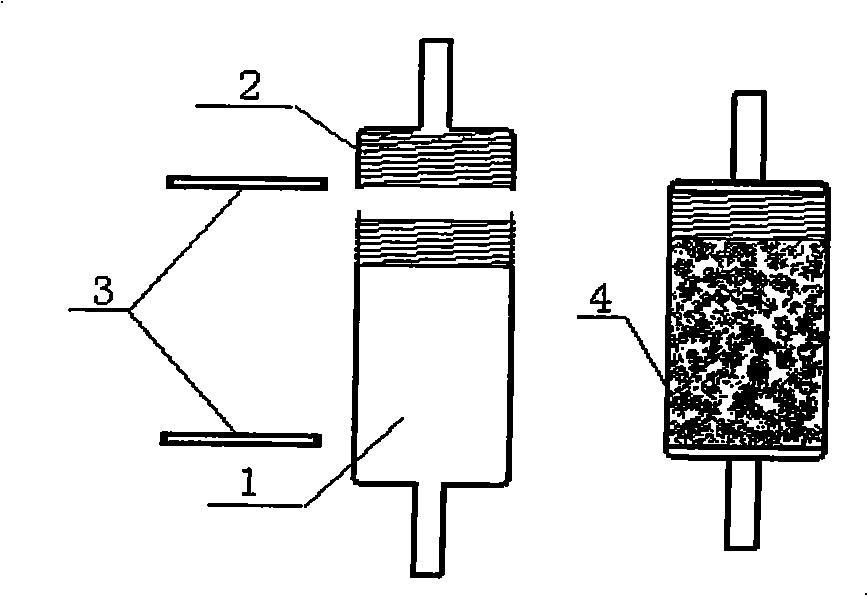

A device and method for treating high-salt wastewater containing phenol and aniline

ActiveCN110857233BReduce subsequent biochemical loadReduce biochemical loadWater treatment parameter controlSpecific water treatment objectivesAnilinePolymeric adsorbent

The invention belongs to the technical field of fine chemical wastewater treatment, and in particular relates to a device for treating high-salt wastewater containing phenol and aniline (fine chemical wastewater such as high-salt phenol and aniline produced in the production process of 2,6-dichlorotoluene products) and processing methods. The device is used to separate the pollutants phenol and aniline in the wastewater by means of continuous extraction. After the extraction, the wastewater is then adsorbed by resin, so that the treated wastewater TOC is less than 350mg / L and then undergoes high-salt biochemical treatment, which realizes the purification of wastewater. For the treatment, the phenol and aniline in the wastewater are separated by two-stage continuous extraction, and the characteristic pollutants phenol and aniline are separated at the same time, and made into resources. The invention has the characteristics of industrial feasibility, continuous operation, reasonable design of device structure, and remarkable treatment effect. , Aniline resources.

Owner:DESIGN ENG OF SYRICI

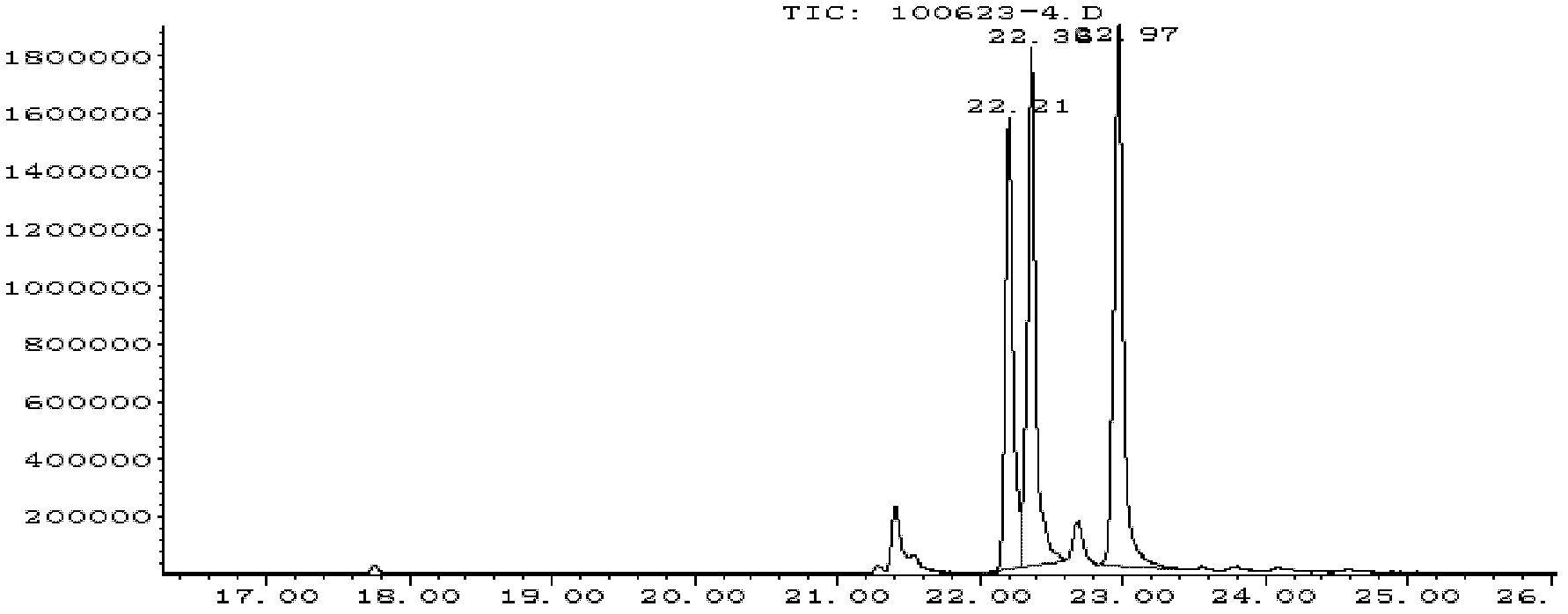

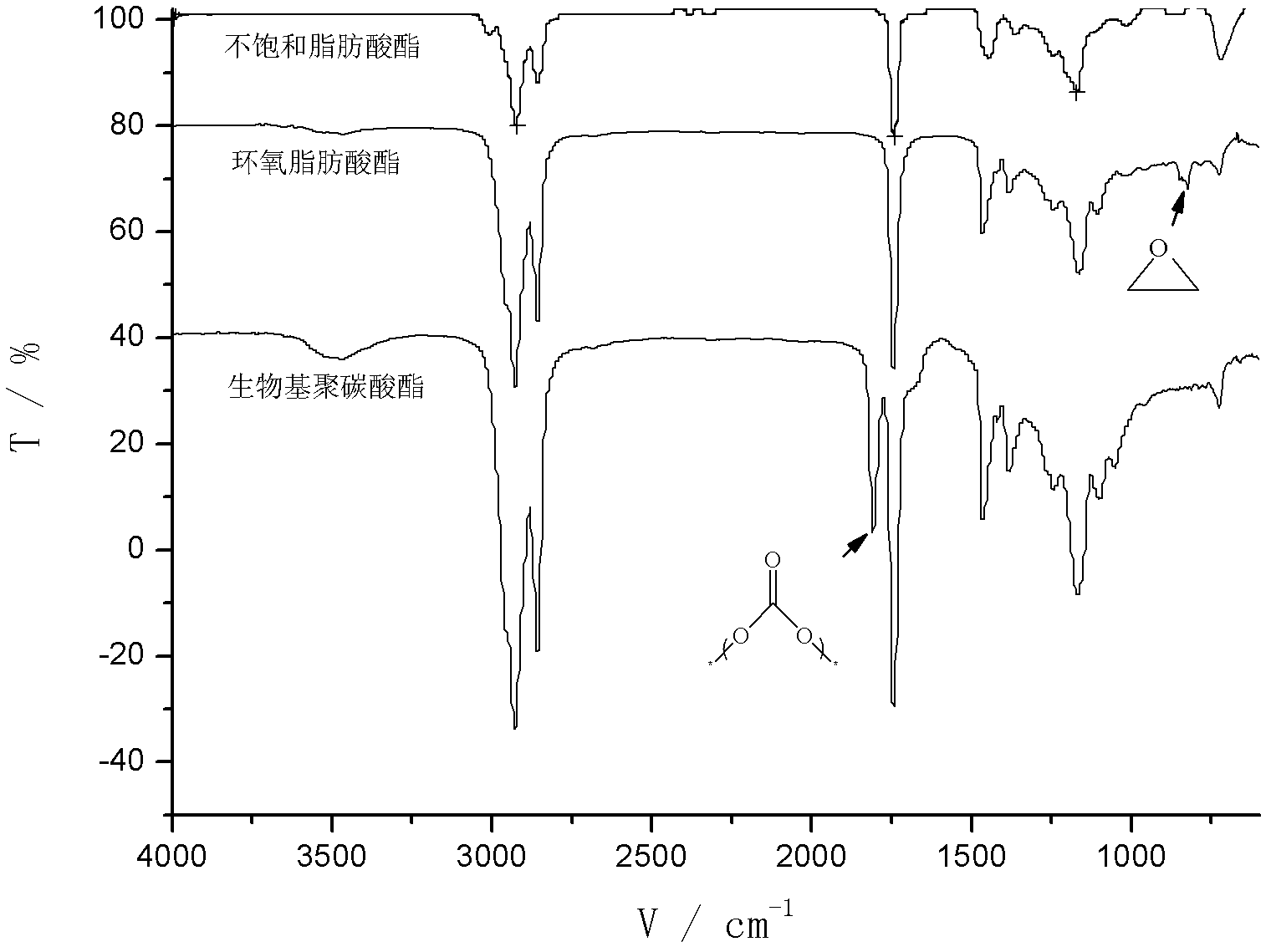

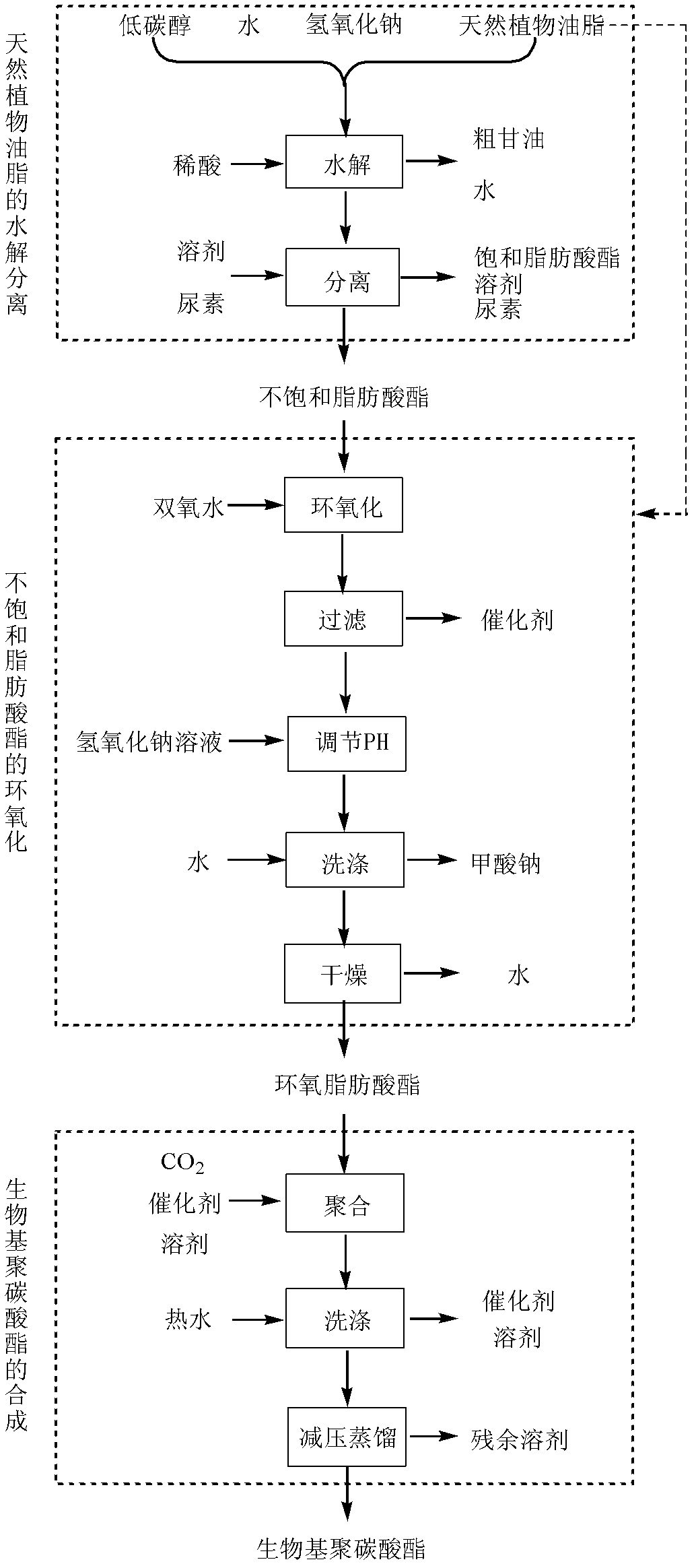

Biologic polycarbonate and preparation method thereof

InactiveCN102585192BLow costImprove performanceFatty acid esterificationFatty acids production/refiningEpoxyVegetable oil

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

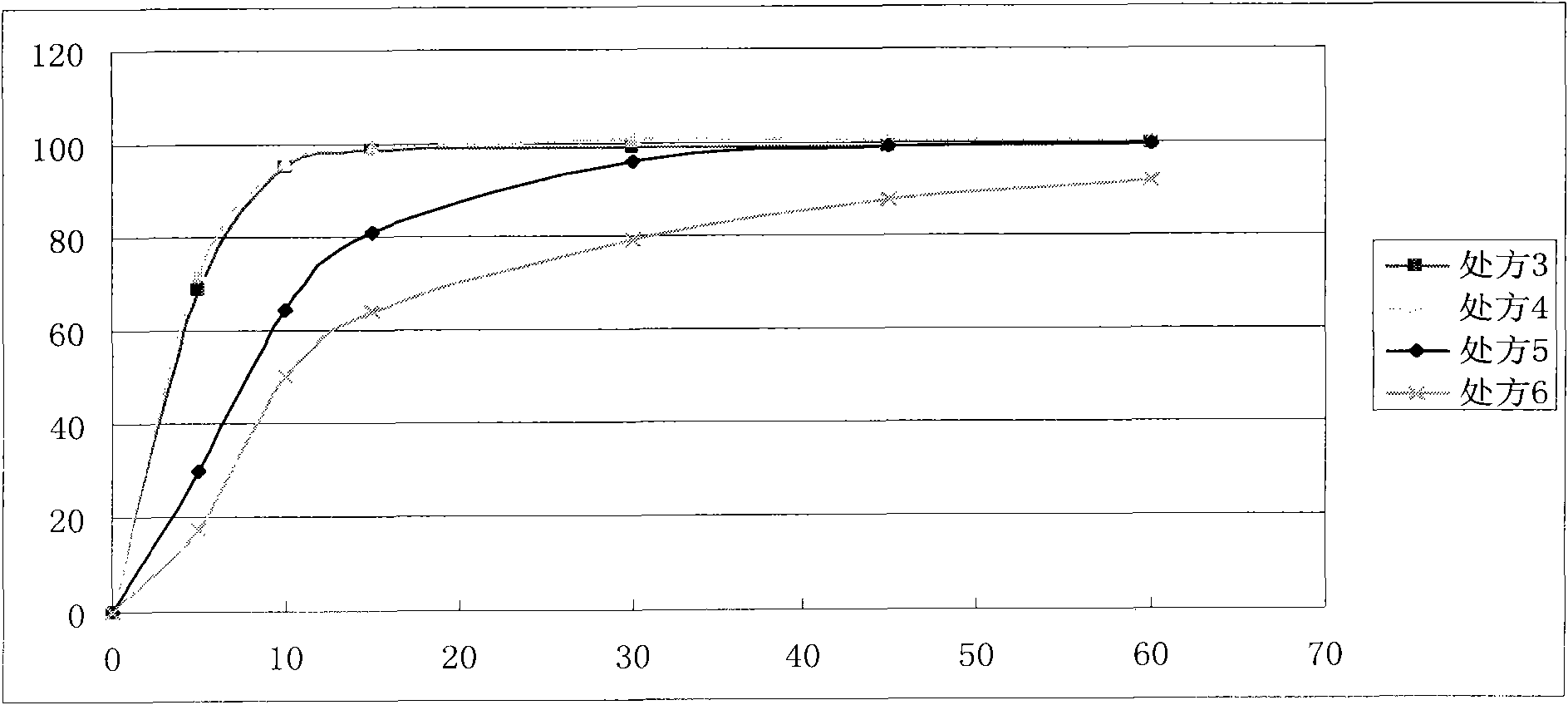

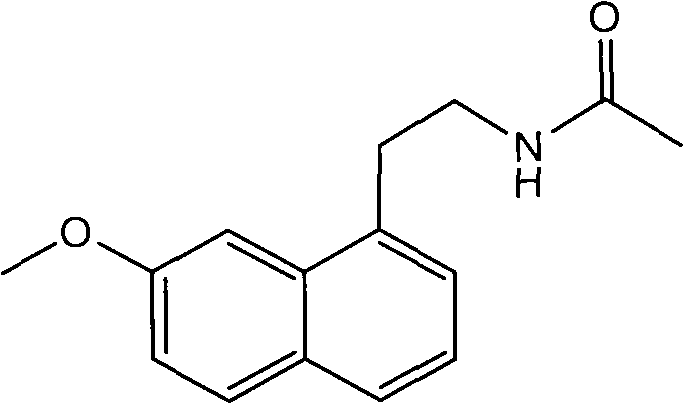

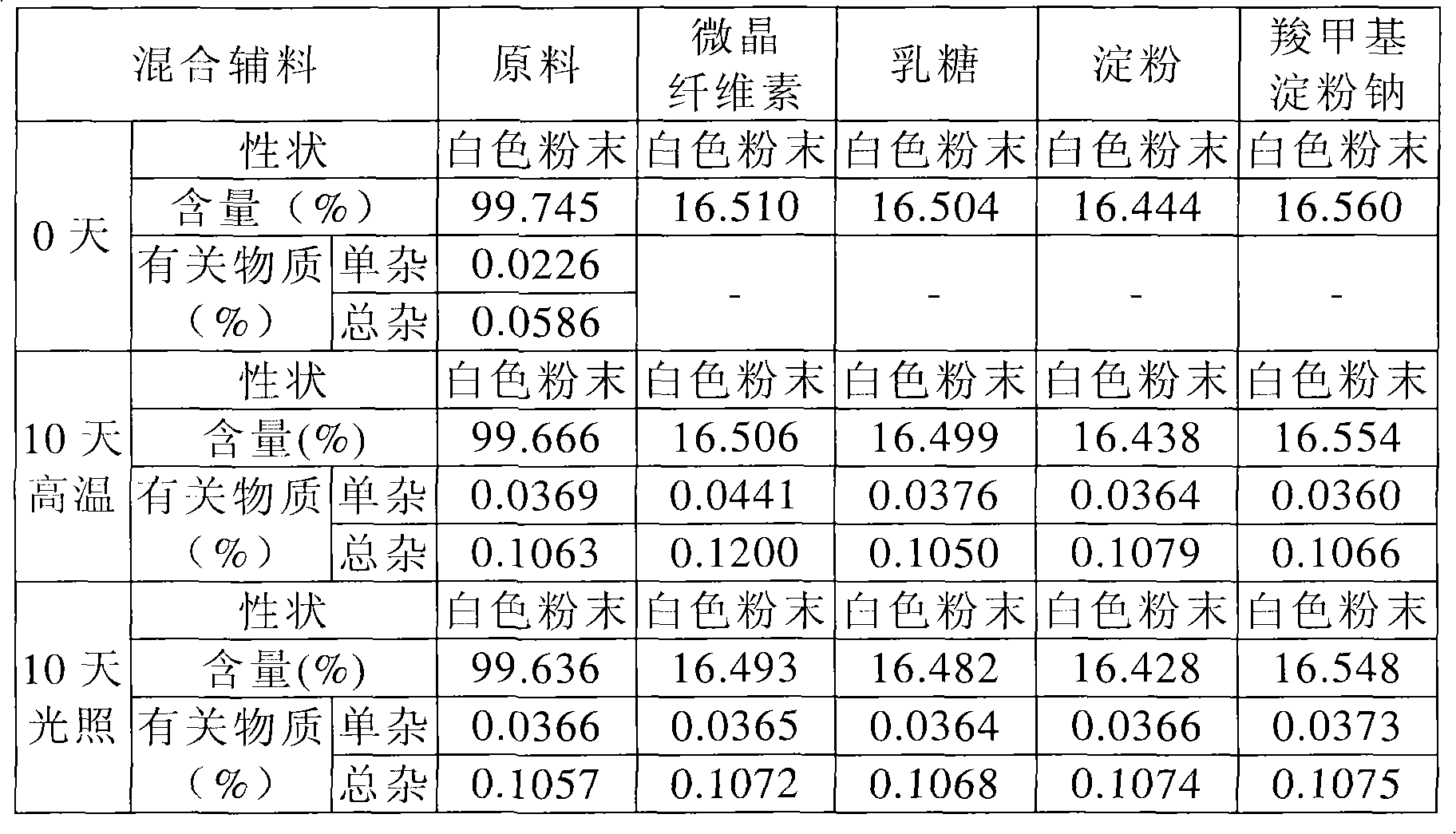

Agomelatine tablet and preparation method thereof, as well as coated tablet of agomelatine tablet and preparation method thereof

ActiveCN102552188BSuitable for storageReasonable prescriptionOrganic active ingredientsNervous disorderCoated tabletsAdhesive

The invention relates to an agomelatine tablet and a preparation method thereof, as well as a coated tablet of the agomelatine tablet and a preparation method thereof. The agomelatine tablet comprises the following components in percentage by weight: 10 to 15 percent of agomelatine, 80 to 89 percent of filler, 0.1 to 2 percent of sodium carboxymethyl starch serving as a disintegrating agent, 0.5 to 4 percent of lubricant, and 0.5 to 2 percent of adhesive. The agomelatine tablet has reasonable prescription and stable preparation process, good effects to auxiliary material selection and content selection of main drug and auxiliary materials, and low production cost.

Owner:NEW FOUNDER HLDG DEV LLC +2

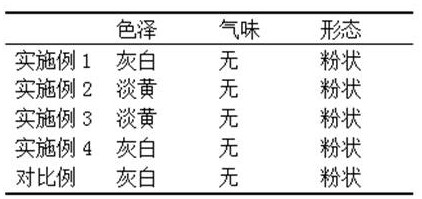

A kind of preparation method of low temperature instant agar

ActiveCN108783404BDissolve fastImprove solubilityFood ingredient functionsCentrifugationPhysical chemistry

The invention relates to low-temperature instant agar, in particular to a preparation method of low-temperature instant agar, which comprises the following steps: 1) mixing agar powder and microcrystalline cellulose, and wet grinding by a ball mill to obtain agar fine powder; 2) putting the agar fine powder in into water, heated to dissolve above the solubility of the agar fine powder, to obtain an agar polymer solution mixed with microcrystalline cellulose 3) processing the agar polymer solution through high-pressure equipment 4) centrifuging the discharge obtained from the high-pressure equipment to obtain Agar polymer clarified solution 5) The agar polymer clarified solution is spray-dried and stored in ice-cooling to obtain low-temperature instant agar. The agar obtained by the invention has good solubility, the dissolution temperature is less than or equal to 60 DEG C, and the dissolution is rapid. Simultaneously, the invention has simple process, high reutilization rate of agar mixture obtained by centrifugation, less waste and strong industrial feasibility.

Owner:FUJIAN TIANYUAN XINGDA BIOTECHNOLOGY CO LTD

Method for flotation and silica removing of bonamite zinc oxide ore

ActiveCN107570326ARealize the goal of silicon reduction in flotationSimple systemFlotationMineral flotationSodium propionate

The invention relates to a method for flotation and silica removing of bonamite zinc oxide ore, in particular to a bonamite and quartz flotation separation method, and belongs to the technical field of mineral flotation separation in the field of mineral process engineering. According to the method for flotation and silica removing of bonamite zinc oxide ore, a to-be-treated mixed ore sample of bonamite and quartz and deionized water are mixed, and the mass ratio of the deionized water to the ore sample is 3-5:1; sodium carbonate is adopted as a pH value adjusting agent firstly, a collecting agent is added in evenly-stirred pulp, and the usage amount of the collecting agent is 300-360 g / t; and the pulp in which the collecting agent is subjected to flotation after being evenly stirred. Thecollecting agent is N,N'-bi-fatty acyl group quadrol bi-sodium propionate. According to the provided method for flotation and silica removing of bonamite, the regime of agent is simple, the technologyprocess is simple, operation is convenient, and good industrial feasible prospects are achieved.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com